-

Posts

3,663 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Baker

-

-

-

If you stop your galleon now.Then there is a chance that you will not start again.

I would finish this first.- Ferrus Manus, GrandpaPhil, Isaiah and 1 other

-

3

3

-

1

1

-

-

-

-

Here you can find a pdf of the 1977 plans

https://www.hismodel.com/soleil-royal-12

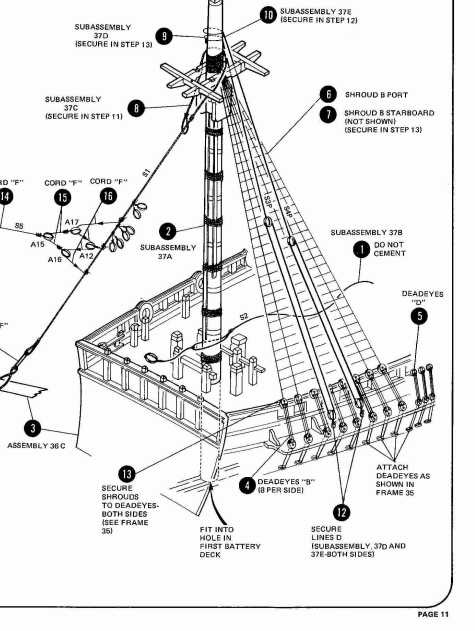

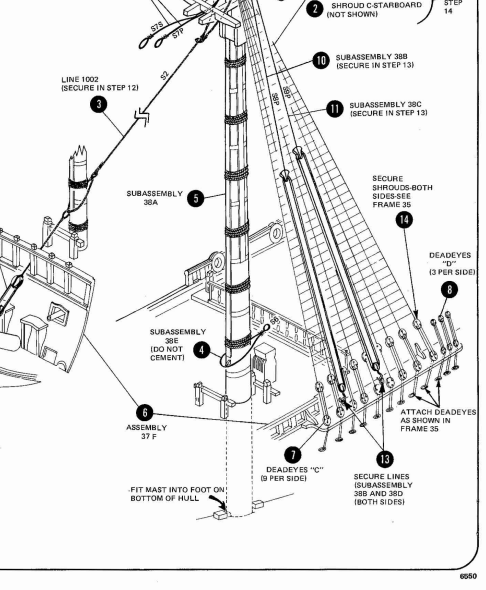

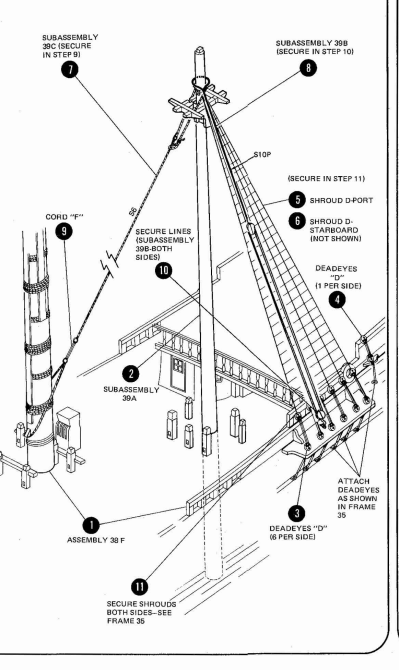

fore mast

main mast

mizzen mast

-

-

That's why this build is going so fast.

Each morning an early wake up call by supervisor Roland 🤣- mtaylor, Glen McGuire, GrandpaPhil and 3 others

-

1

1

-

5

5

-

-

Good idea Druxey

But, I can't work with copper and brass.I have new artificial lenses in both my eyes (cataract surgery). One of the side effects are halos and after 9 years I still suffer from them.

Small shiny objects shine so hard under a lamp that I can't see what I'm doing.

Small blackened iron nails are just about to succeed. All other "metal" objects will be made in painted plastic.It is what it is.

There was no turning back after the surgery

And, me, a military modeller. A little rust here and there...😉

- Louie da fly, BANYAN and mtaylor

-

1

1

-

2

2

-

4 hours ago, Dan DSilva said:

What I'm a bit concerned about in the immediate future is how I'm going to drill or chisel holes for the anchor cables to go into under the windlass.

Drill 2 holes and use 2 pieces of cable.

nobody will notice this once the model is ready.

a hole in the bow where the anchor cable enters the hull.

a hole under the windlass where the cable comes "out".I used this trick in my Bounty project (see link in signature)

- Dan DSilva and mtaylor

-

2

2

-

-

Tanks for the comments. This is much appreciated 👍

The idea is to apply the iron nails and the treenails.And not to paint the hull white below the waterline.

The original MR may have had white stuff below the waterline.But this has never really been investigated.

There will be no whipstaff on the tiller in this era.- Hubac's Historian, Ondras71, Jeff T and 2 others

-

5

5

-

-

To everyone who missed the start, welcome.

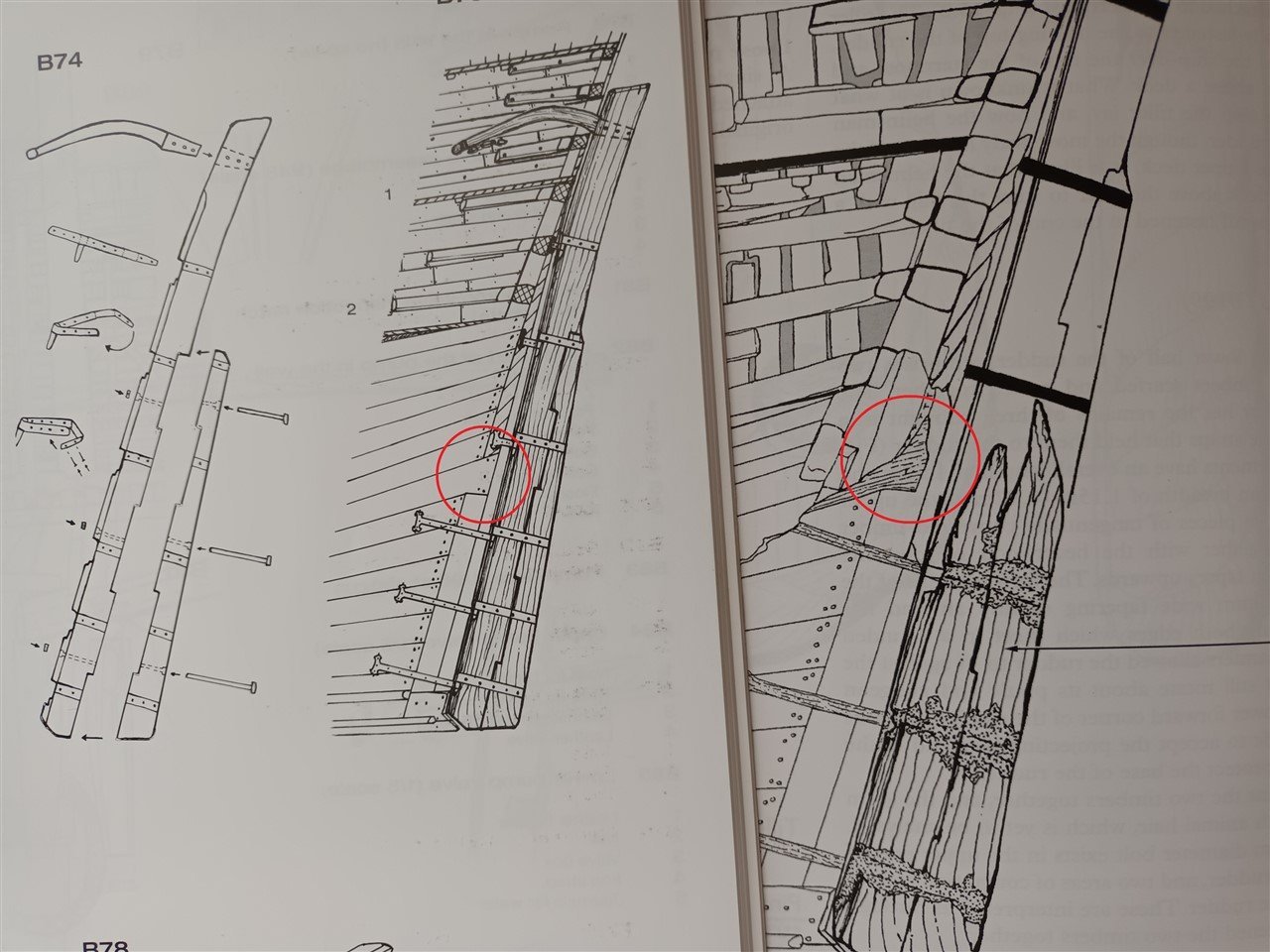

Finishing the planking on this side.

One strake has a weird shape to the stern.

W.i.p.

The last streak

One side is done, and received a sanding with 60 grit sandpaper.

And not upside down

Thanks for following, comments and likes

-

-

The model is starting to look nice.

The deadeyes with chains are great.Congrats

- AON, mtaylor and Rock_From_Korea

-

3

3

-

8 hours ago, Ferrus Manus said:

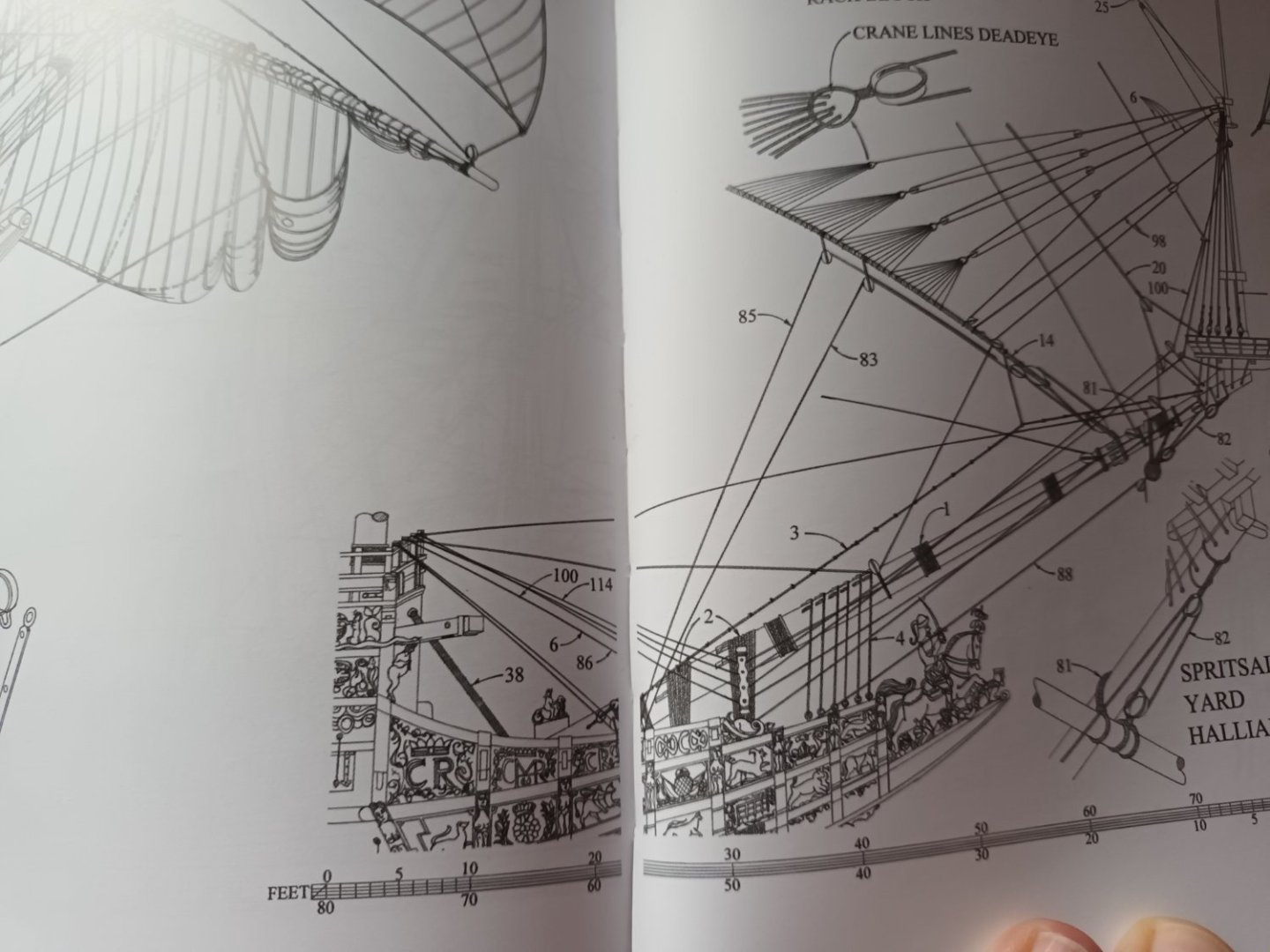

The one frustrating thing is that most artists, even Vroom, omitted many small/light lines in the interest of simplicity.

Of the current artists, Ferrus has skipped little or nothing

- Ferrus Manus and Jeff T

-

2

2

-

-

Wow,

problem solved 👍 thanks

-

If I open MSW on a PC I can see the signature at the bottom of each post.

When I open MSW on my smartphone, I don't see any signature at the bottom of each post.

This applies to my own posts and those of others.

Am I doing something wrong or do I need to adjust settings.I've always had this problem, but always forgot to ask if there is a solution

-

-

-

11 minutes ago, Roger Pellett said:

Thanks Roger.

I knew roughly what it meant.

but did not get it worded correctly in the English text .

- mtaylor and Roger Pellett

-

2

2

Spanish Galleon 1607 by Ferrus Manus - FINISHED - Imai - 1/100 - with modified rigging

in - Kit build logs for subjects built from 1501 - 1750

Posted

you are going in the right direction.

patience 😉