-

Posts

4,286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Baker

-

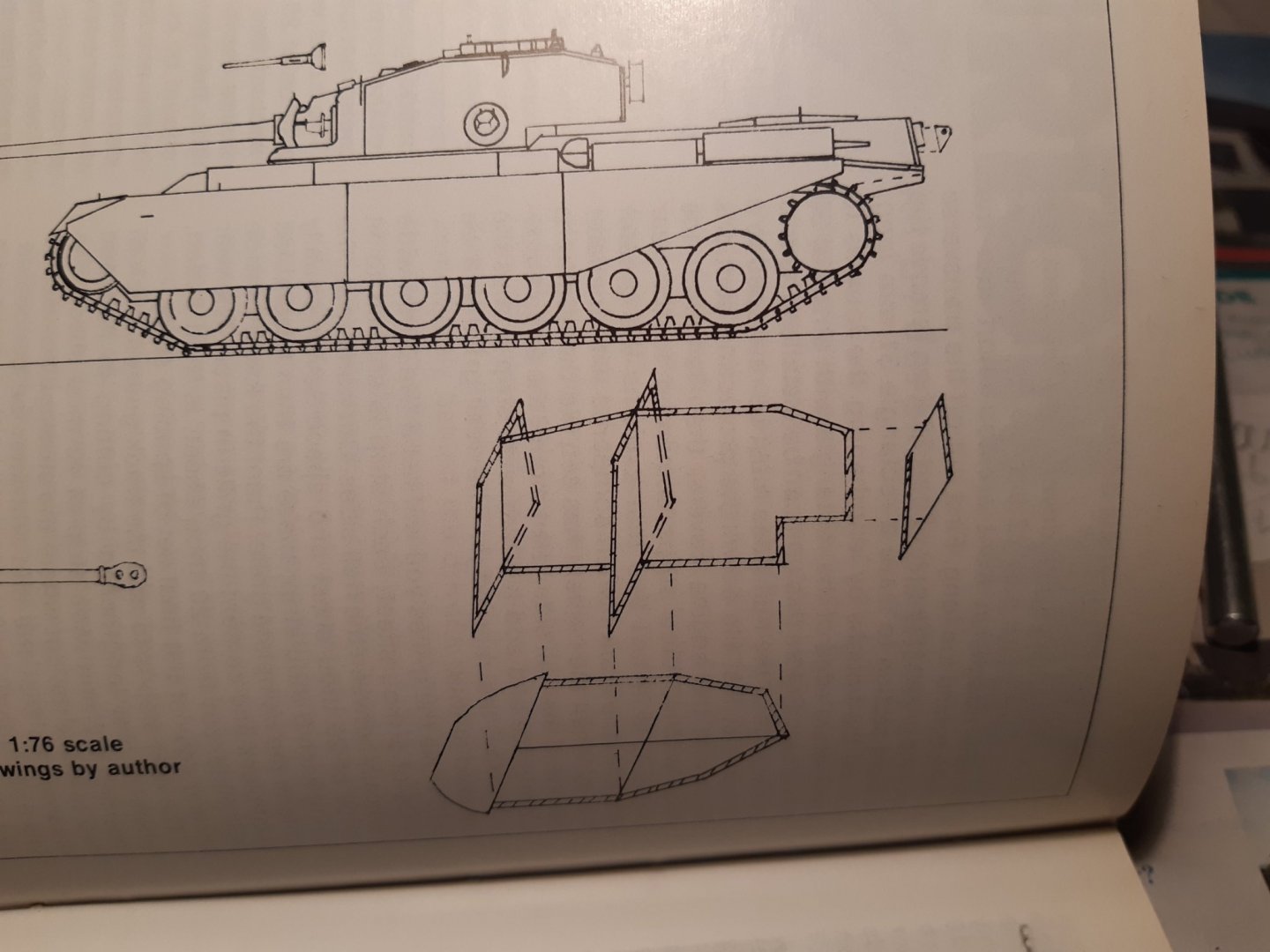

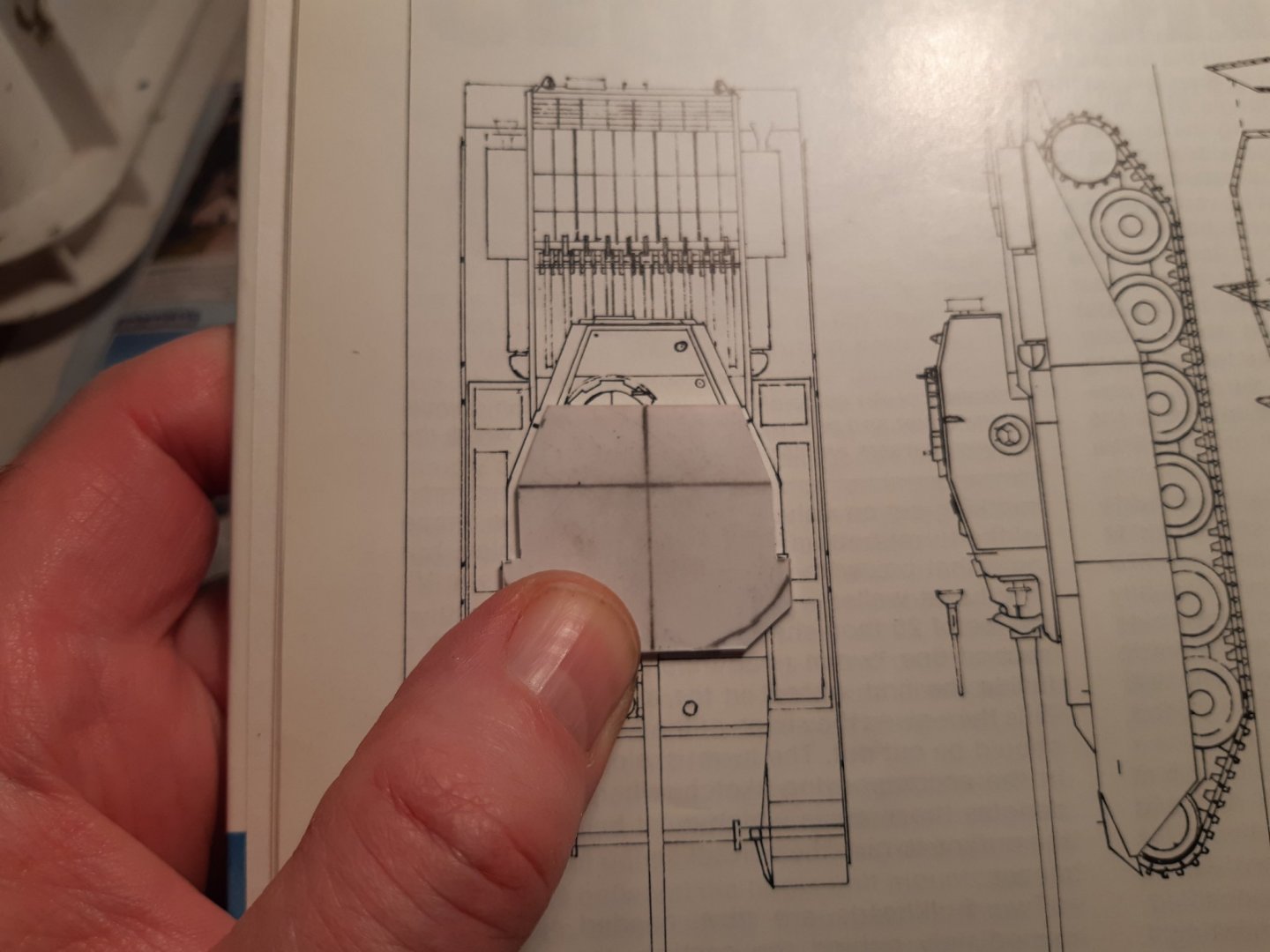

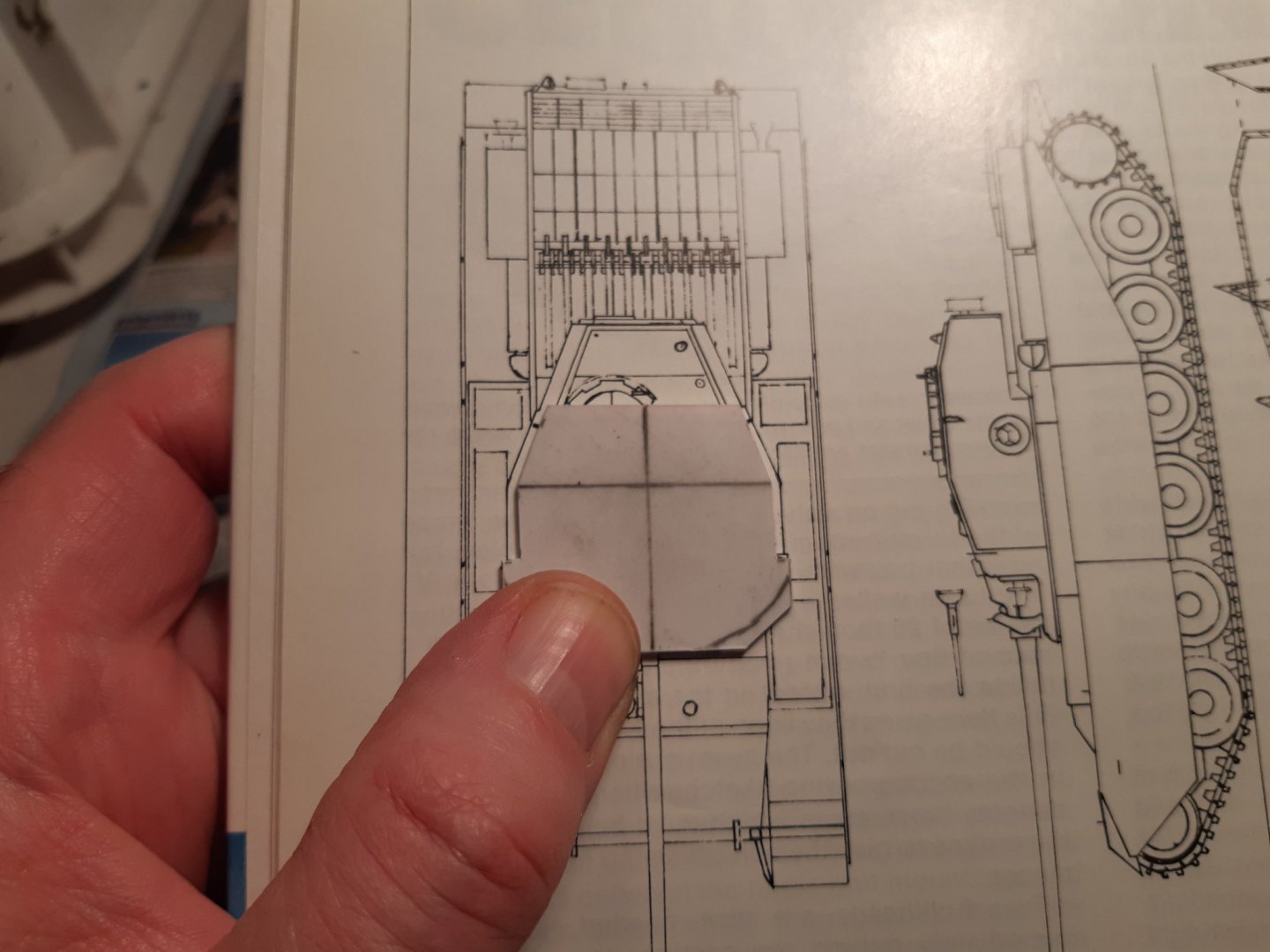

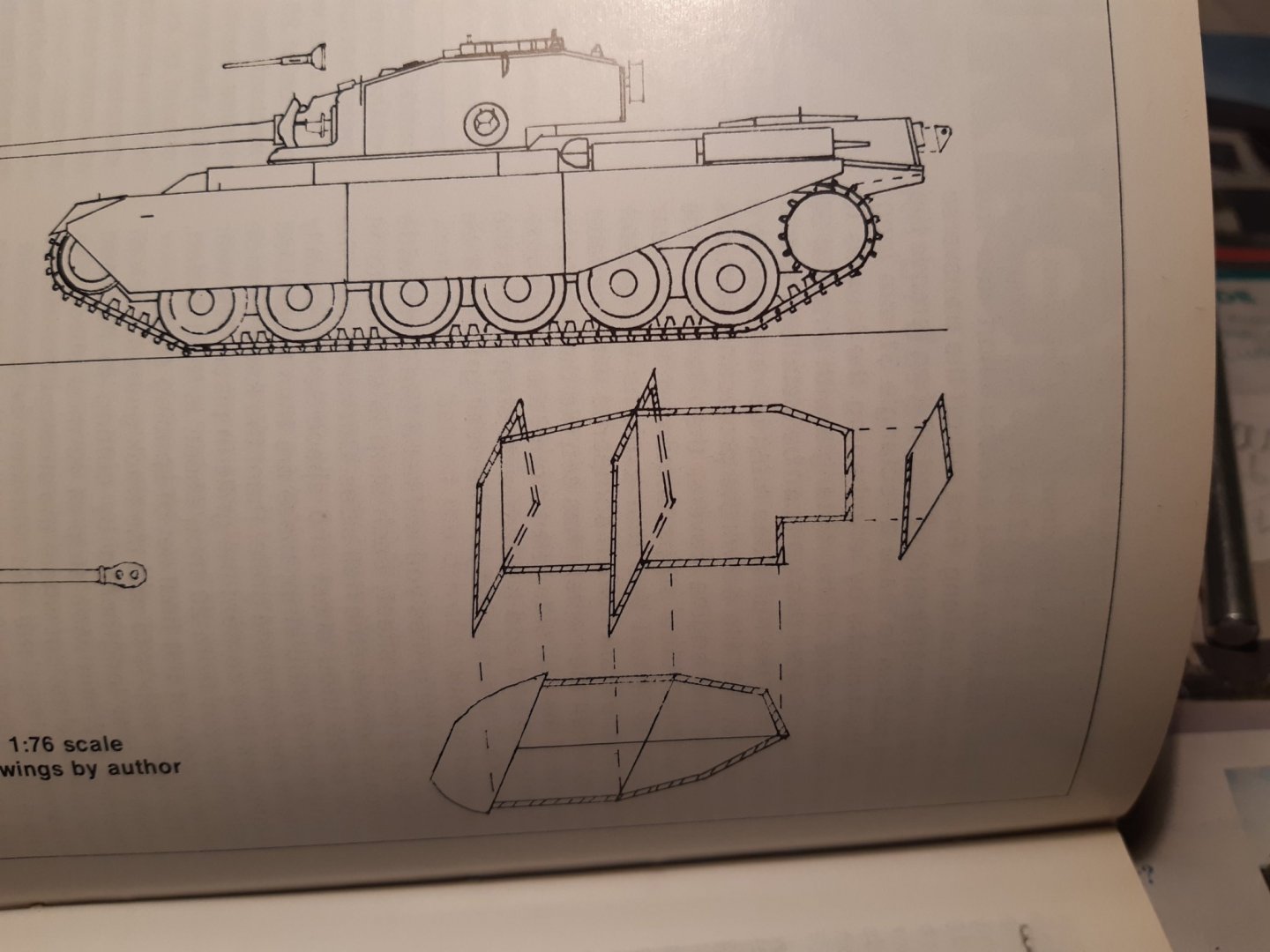

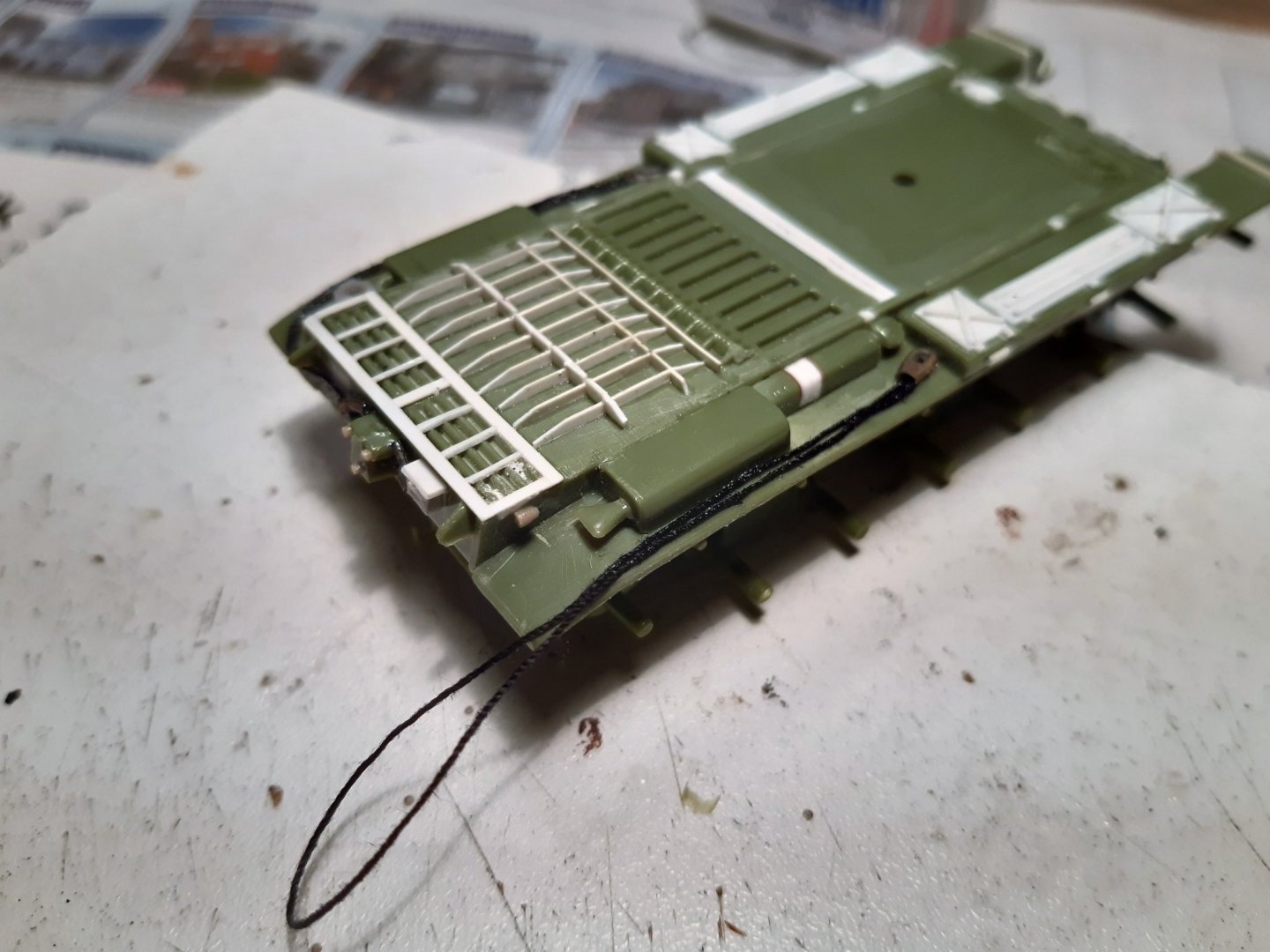

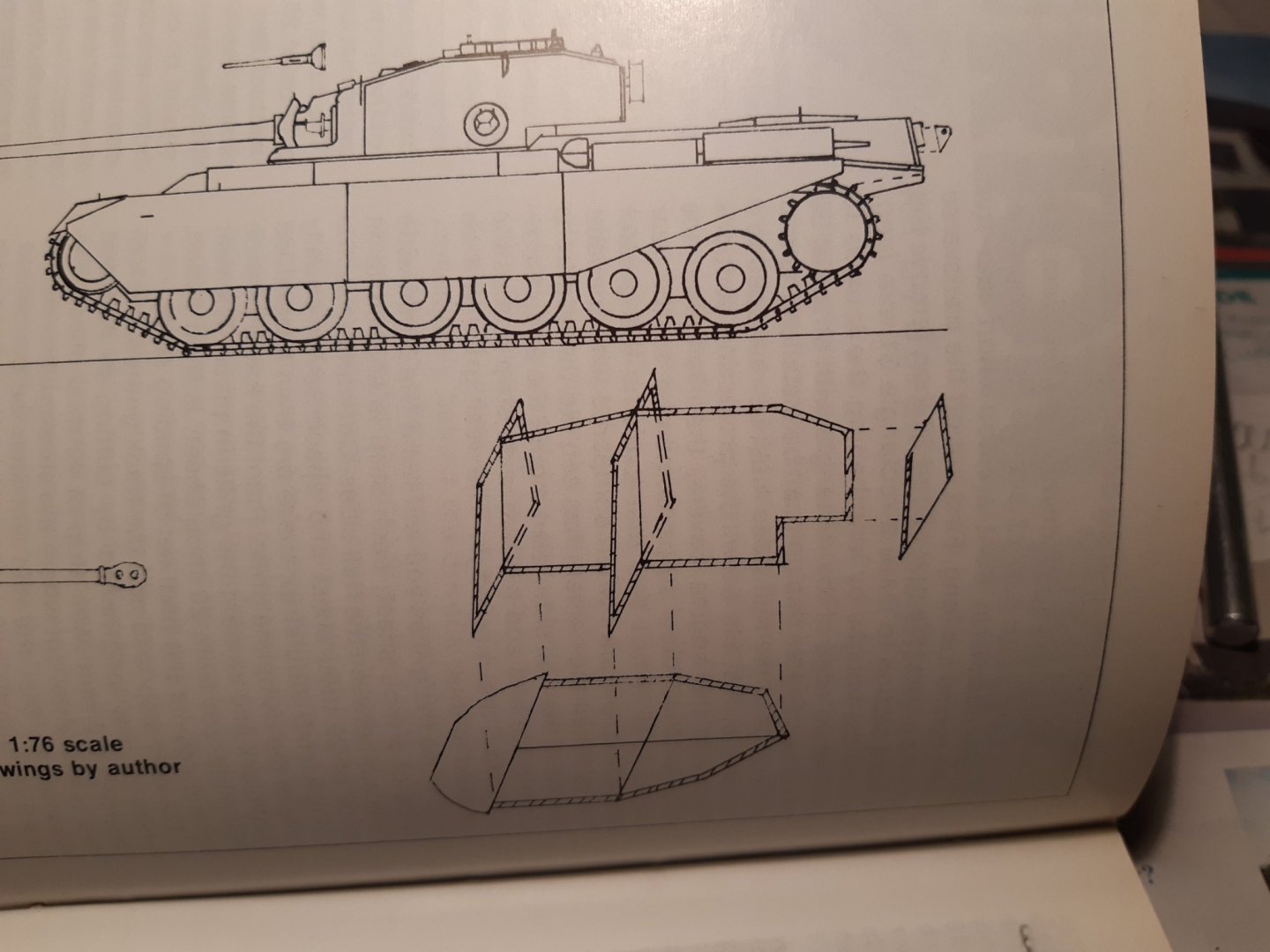

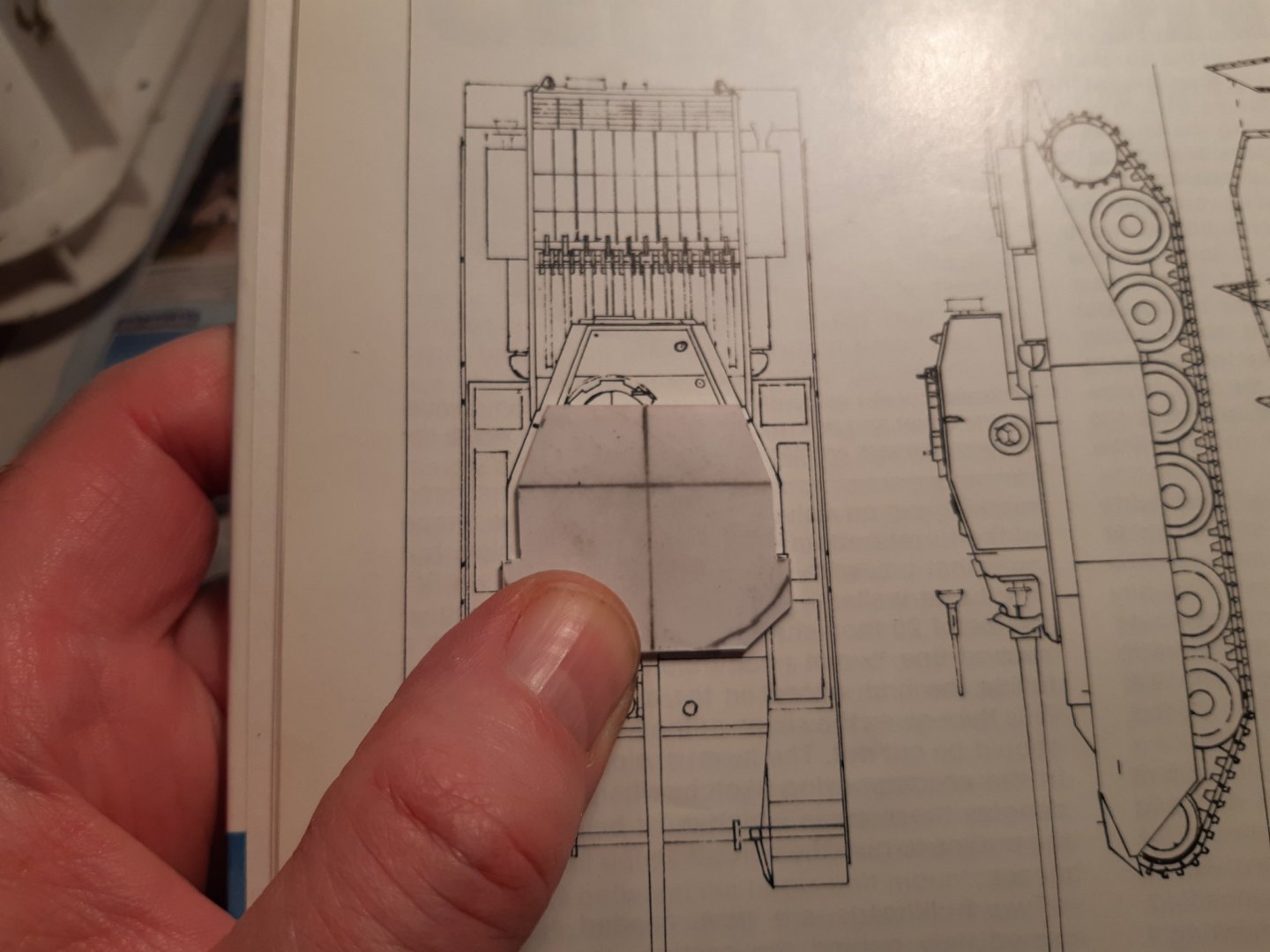

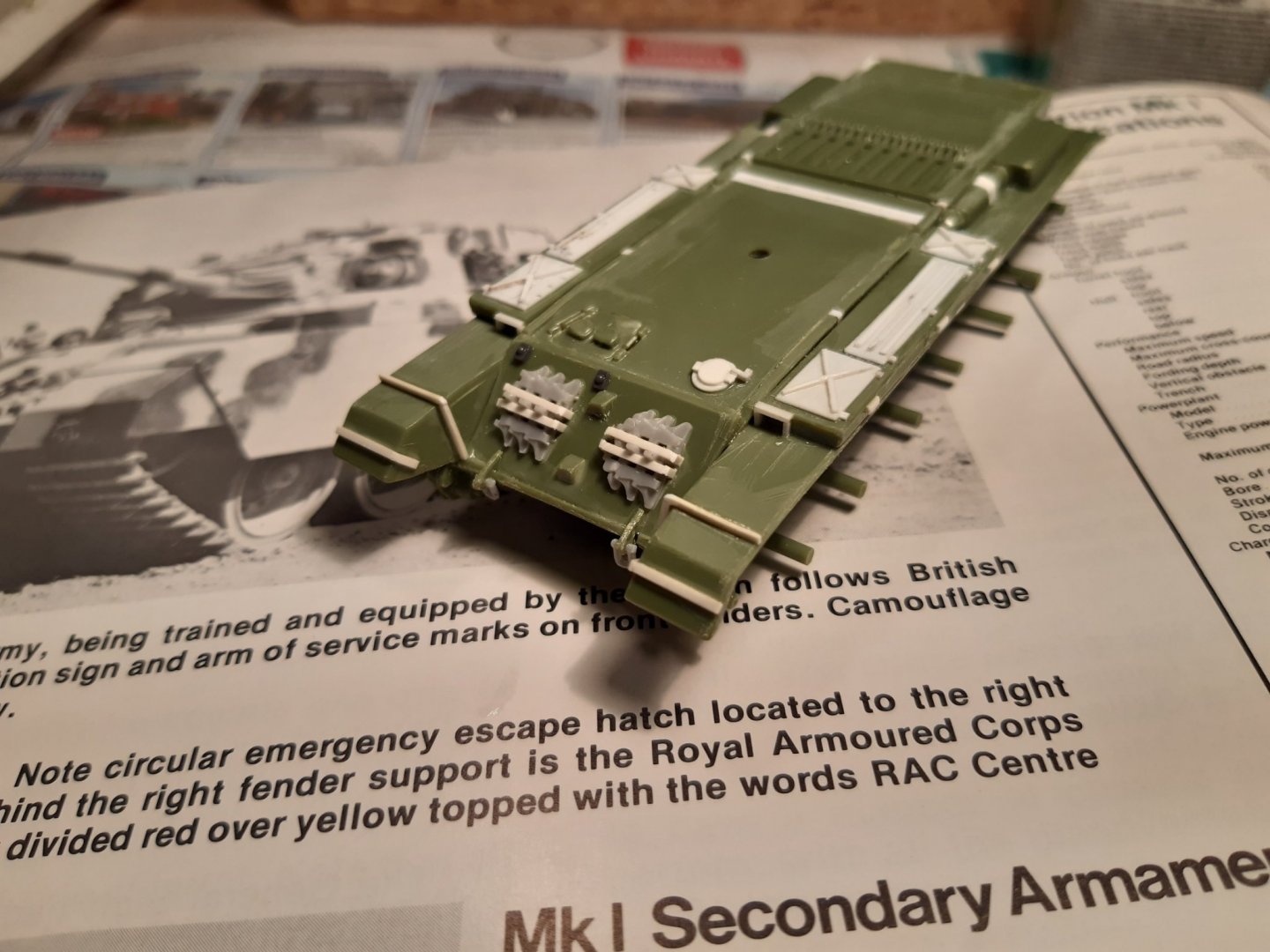

Continue with the hull. The modifications for a Mk.1 on the engine compartment with plastic strip Extra details and cabels at the rear. the Turret .. The author of the article explains the construction method very well. Unfortunately, it does not provide any dimensions or clear construction drawings. That is why we start with the bottom plate and some "frames" as supports for the sides and tops of the turret. To be continued, thanks for following.

-

You will not see such costumised cars in Belgium very often. Too much paperwork and extra inspections before you can drive it on public roads. And then park somewhere with the windows open 😲 It will be empty when you return from shopping ... It is possible to order a personalized number plate for your car in Belgium (costs 1000 euros extra). Will be a nice model

-

The nice thing about German camouflage between 1943-45 is that there is plenty of room for free interpretation. If you don't want to use a brown color, that's fine too. The only "general rule" for most German vehicles (Panthers also) is : Sand color as a basis. Green and or brown as additional colors. No green and no brown, but only sandcolor is also allowed. And when it snows and you have white paint and a brush. Then... a whitewash Have fun

-

Greetings from Belgium. Here it is now 14h. 19 minutes in the afternoon (we dont do AM and PM over here). Good luck with the Bounty model.

-

Because the foremast is so far forward. I think this info is somewhere in my Pelican build.

-

Thanks The numbering does indeed have a logic GB = Groot Britanie (Great Britain) A = Amerika (USA) F = Frankrijk (France) etc... The number under the letter is the number per country. The small number at the bottom right is the number in the total collection The name of the manufacturer is printed on the back So GB Great Britain 179 the 179th "Englishman" 1426 N° 1426 build All this is in an Excel file, otherwise I have no idea what I have already built.

-

Finishing the models applying rust Glued on the base plate (afther this a wash with thinned black) ready and tagged The 2 vehicles are given an English number, so all vehicles of this chassis are together. The trailer has a French number, then I remember what the origin was Belgium 1941 on the training ground Belgium 2021 in the cabinet Ps Good advice from the manufacturer It has been a long time since I built such difficult models. If anyone ever buys a kit from Ace, don't start with these 2. Finished ! Thanks for the following, the likes and of course the comments on these builds .

-

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

Verry good planking Steven. If anyone comments on this. Just say. This way of planking is historically much more correct and it was very difficult to do

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Another beautiful update, always a pleasure to look forward to. Great work

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Welkom Pieter

-

Hi, I'm Neil. Gonna scratch build Orca from Jaws.

Baker replied to neilm's topic in New member Introductions

-

Firstly..Happy New year everyone 😃😃

Baker replied to Capt. Jack Sparrow's topic in New member Introductions

-

Great first model.

-

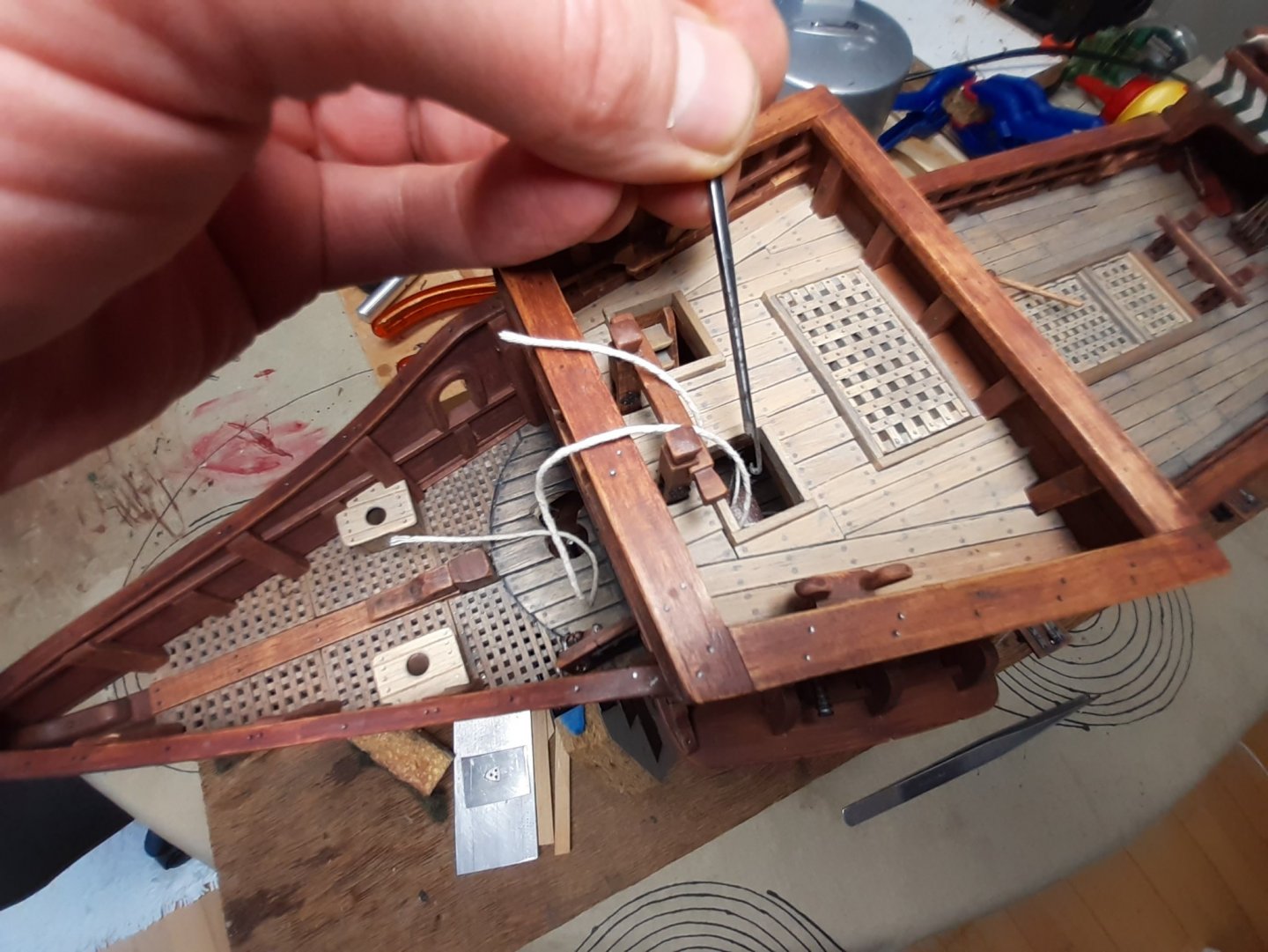

Hello, First, i wish everyone a happy and above all healthy 2021. All masts and bowsprit are now mounted (work in progress) Made some useful tools from large needles They came in handy for this job. Next time I rig these blocks before installing the deck. The bowsprit mounting is extra reinforced with a nail Then "camouflaging" this nail so that it is no longer visible Ready Thanks for following,comments and likes.

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.a9fc55d4f0837daca547fbf8dc80ff8c.jpg)