-

Posts

2,032 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tlevine

-

whats an easier build for a first kit

tlevine replied to rdestefano01's topic in Wood ship model kits

I am torn by which advise to give you. Logically, it makes sense to build something small and relatively easy to hone your skills. But whatever you build, you must have a passion for. Otherwise it is simply a woodshop exercise. As an adult, my first ship model was also a Connie, the plastic Revell version. I was very proud of it and kept it on display as my first "real" ship model for several years. Unfortunately it was crushed during a cross-country move. My next model was Mantua's Peregrine Galley. And yes, I was way over my head. I even bought an Italian dictionary to translate the instructions. To this day, I display her to oohs and aahs from friends and foe alike (it is my only ship with a full complement of sails). I, on the other hand, shudder whenever I look at her, realizing all the mistakes and rediculous design features. But I had a passion to build her and she was completed within a year. You need to decide what you want more...a logical "training wheel" model or something that passion will force you to complete no matter how frustrated you may become. Chuck, I like the Hawaii idea. Our field trip could be in outrigger canoes and our banquet could be a luau. You can suggest it to Kurt! And, yes, you can never have too many clamps. -

Tools and Supplies for My "Shipyard"

tlevine replied to daveward's topic in Modeling tools and Workshop Equipment

I use Elmer's wood putty. I would recommend a color a few shades darker than your first planking layer. This helps the high and low spots stand out more prior to sanding. Drywall joint compound or Spackle will not accept wood glue very well. I have never tried Bondo. -

Questions regarding old kit(Mantua 776, HMS Victory)

tlevine replied to Smoke's topic in Wood ship model kits

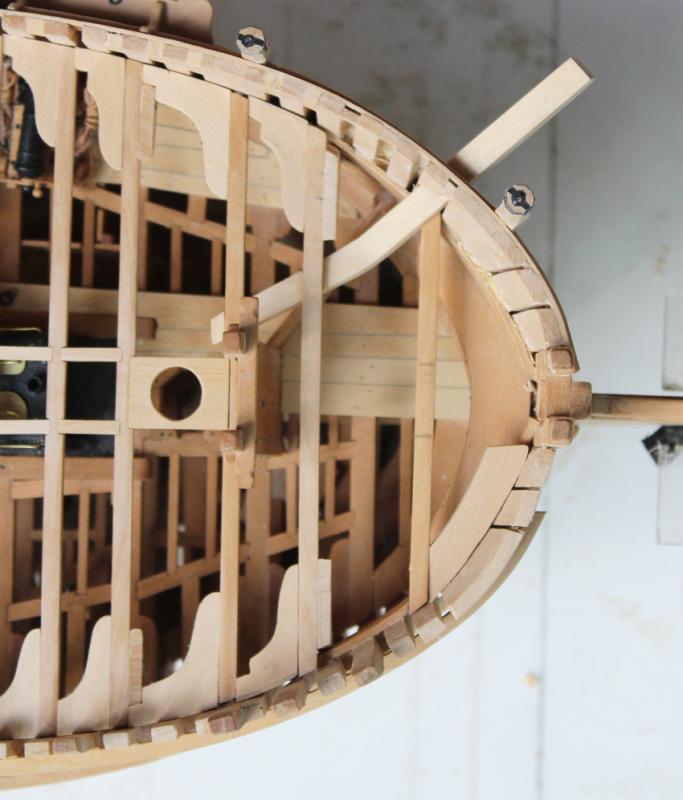

I found a couple of old pictures from early in the rigging process. The pics are low quality as they were taken with a 1st generation digital camera. Hope this helps your decision making process. -

Questions regarding old kit(Mantua 776, HMS Victory)

tlevine replied to Smoke's topic in Wood ship model kits

I built this kit several years ago. It makes up into a nice build out of the box. I kit-bashed it rather severely using Longridge's book and the series of articles from SIS. My suggestion...go for it! First, decide whether you want to build it as-is or kit-bashed. Either way, get the articles by Gene McClure in SIS. Kurt posted links to the articles here http://modelshipworld.com/index.php/topic/12994-ships-in-scale-magazine-articles/. The biggest problem is that the pieces are printed on fairly low quality plywood which is prone to splintering. I replaced several of these with pieces cut from basswood. The walnut vernier meant nothing to me because I painted her. As far as resale value, next to none. -

Yes, sir, it has. It won't stay that way long. I have a question about the foremost swivel gun mount. Should it be perpendicular to the water line or in line with the hull configuration?

- 1,449 replies

-

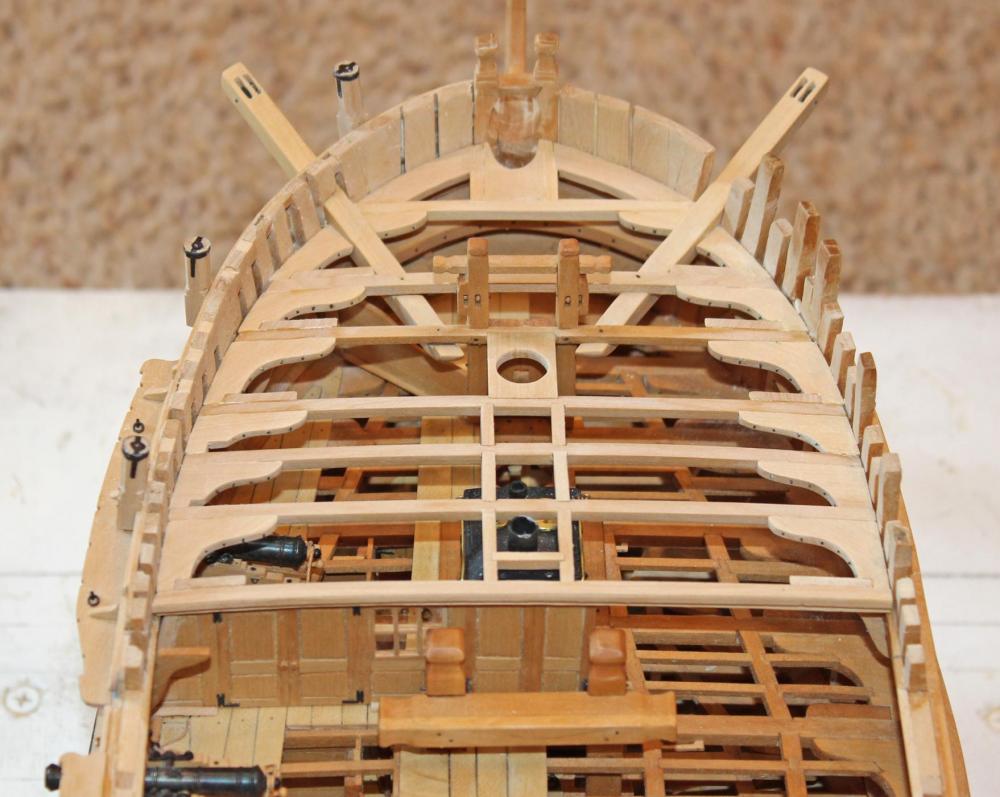

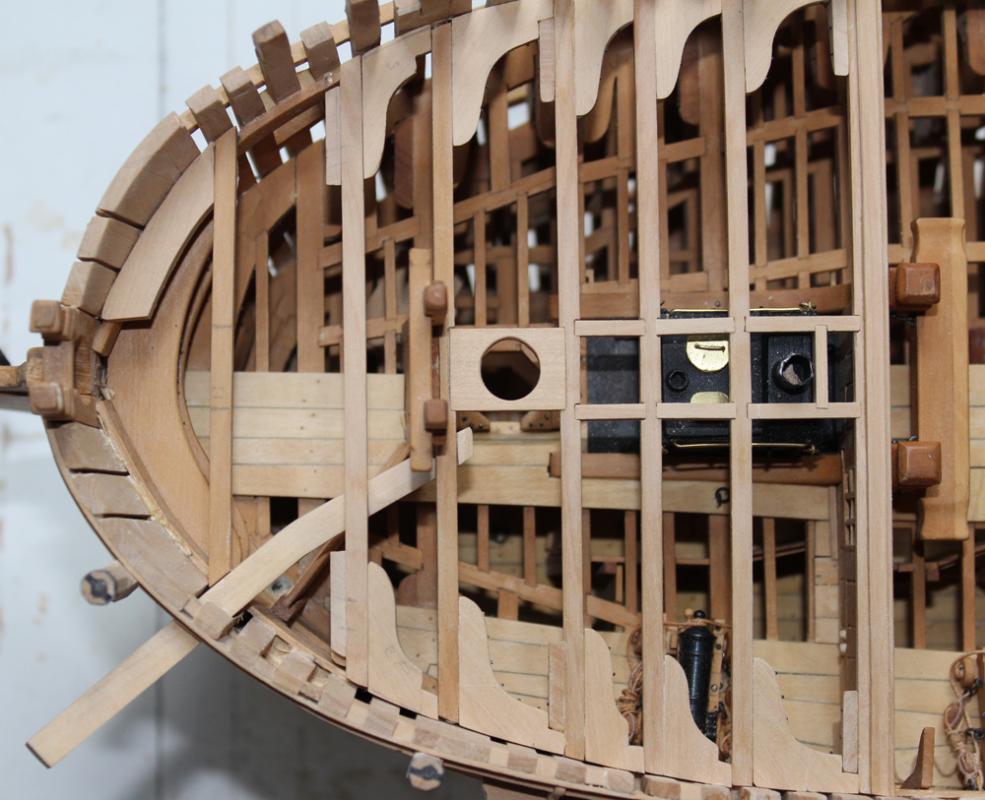

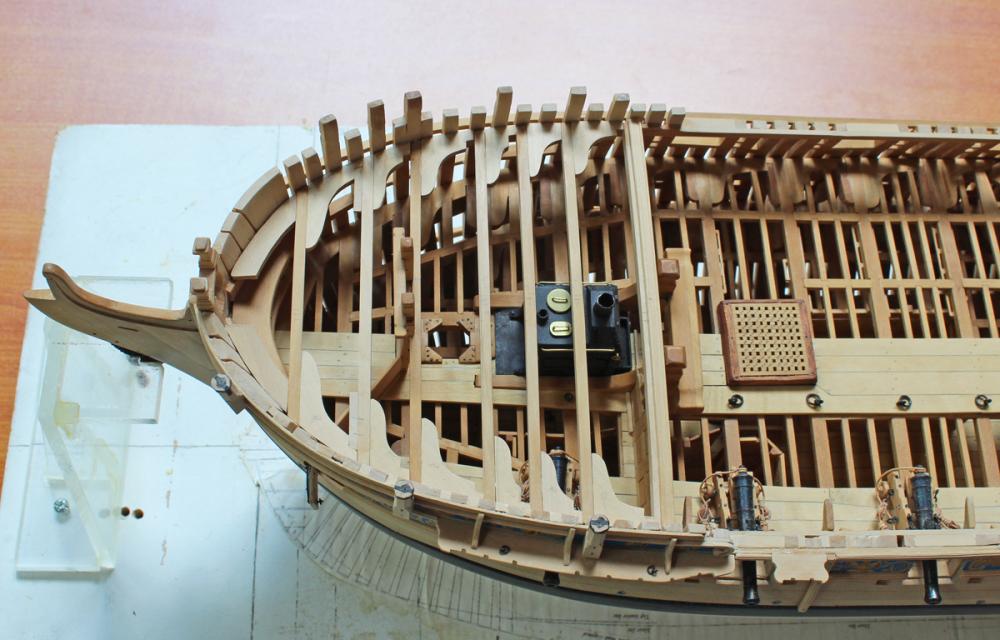

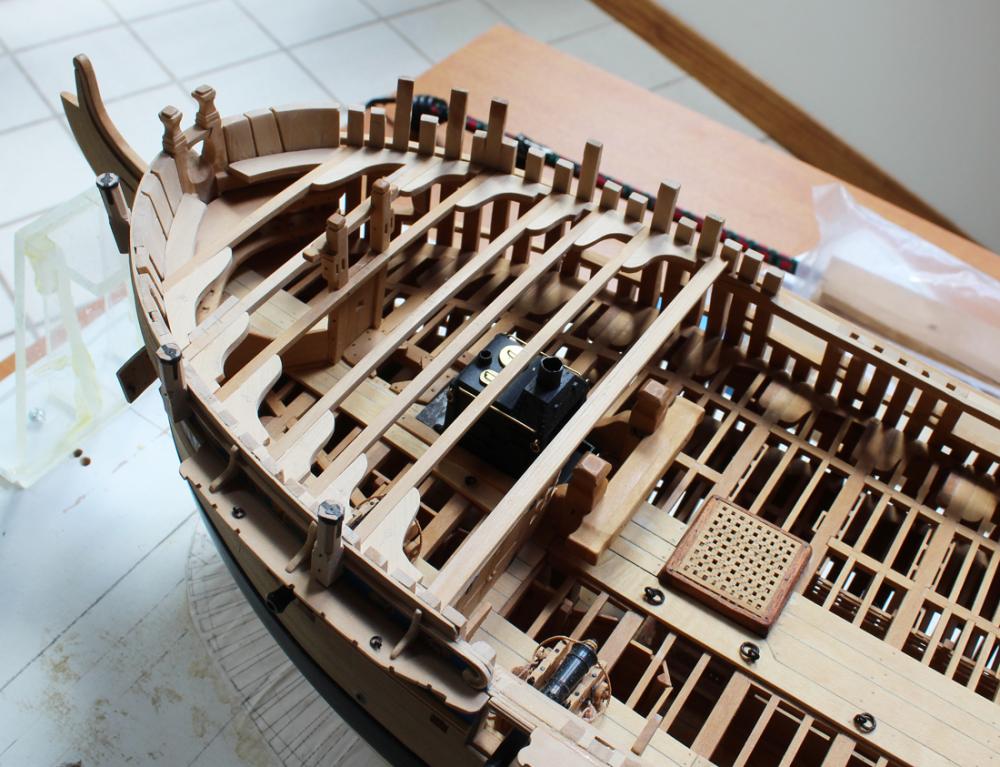

Work progresses on the forecastle framing and installing the catheads. There are two 9" sheaves in the cathead. These were made by drilling a series of holes along the length of the sheave opening perpendicular to the water line and then connecting the holes with an 11 blade. The sheaves were made from round brass stock, cut off on the Preac saw. These were then drilled for a pin. The cathead was also drilled and after blackening the sheaves and pin was inserted. The cathead was inserted under the third beam and glued into place. Then the second beam with its associated knees were installed. Bolts were inserted through the two beams into the cathead. The first beam was then installed. Finally, the knee between the first and second beams was installed. This was initially fabricated as one piece. With the cathead in place, the middle portion of the knee was removed for a snug fit. Carlings were inserted between the deck clamp and the first beam to support the bowsprit partner. Mortises were made for the half hook laterally and the partner medially. Finally, the half hoods and partner were installed. I have been practicing carving the cap for the cathead. Let us just say that it is a work in progress...

- 1,449 replies

-

Now comes a scary part, cutting a hole into the hull. Mark the location for the hole based on the plan. Since the port side is fully planked I had to cut out a segment of the frieze and some of the molding. On the starboard side I removed a piece of ribband and one frame top. Once the cathead is installed, I will replace that frame top and secure it with filler pieces on either side. The cathead is inserted at an angle so the opening is directed downwards. Referring back to the plan, note the angle that the cathead takes, insert it into the hole in the hull and place it under the third beam. Mark the beam location on the cathead and cut out the mortise in the cathead. Replace the cathead and temporarily place the second beam assembly on the deck clamp. Mark this beam location on the cathead and cut the mortise for this beam as well. On my ship, possibly because of my previous measurement errors, the cathead crosses very close to the deck clamp. As a result I needed to notch both the first beam and the under surface of the cathead to get it into place. The unexpected benefit of this is that it locks everything securely into place. With the cathead secured, the outboard face was sanded to make it perpendicular to the water line. All the exposed edges were chamfered and the aft end was smoothed over, following the angle of the third beam. Still to go are the holes for the sheaves, the sheaves themselves and the decorative cap.

- 1,449 replies

-

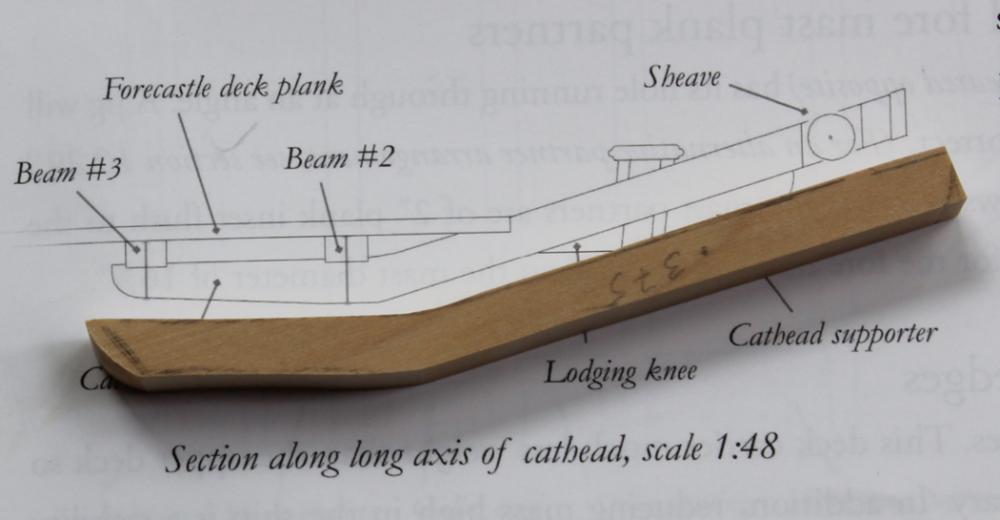

I will try and demonstrate how I made the cathead. Sorry for the picture quality but I was more interested in showing the technique than in cleaning up the model after each step. I went to the plan to determine the length and lateral bend of the cathead. TFFM has an excellent drawing of the upward angle. Because of the size of wood available to me I decided to transfer the drawing from TFFM onto a piece of 0.375 wood and cut this out on the scroll saw. I cut this overlong for final sizing later. After that was done, I drew the lateral bend from the plan onto the blank. Please remember, these are mirror images of each other. As you can see, the port is cathead is already notched for the beams. My goal was to make them as similar to each other as possible.

- 1,449 replies

-

Thanks everyone for your support. Greg, I still have the sheaves to mess up so don't jinx me.

- 1,449 replies

-

The model is stunning. It's unusual to see four different Arizona modelers on the same page. Now all you need is someone from Tucson and Flagstaff.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

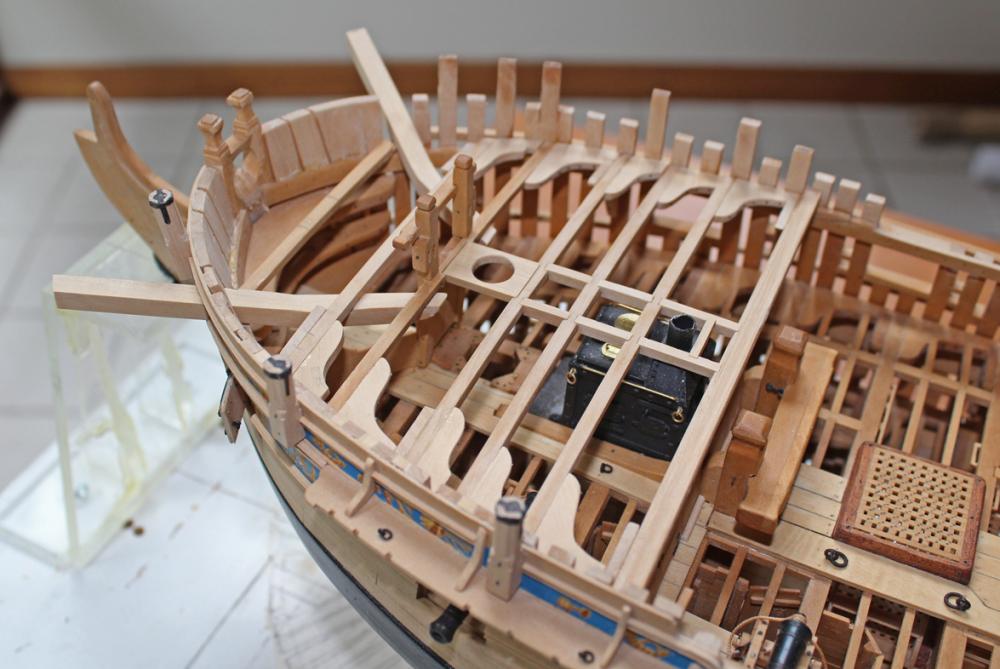

Work has started on the cat head. This one piece has taken me over three hours to plan and fabricate. I still have to install the sheaves and finish sand it. I will show a few pictures today and will describe the steps of construction as I make the starboard one.

- 1,449 replies

-

Beautiful work on the captain. I am envious of your workbench. All I have is the kitchen table.

-

What is that saying... A thing of beauty is a joy forever. Thank you for sharing this with us.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Thanks for the moral support,gentlemen. And thanks to everyone for the likes. I promise, the next ship will have the correct length!

- 1,449 replies

-

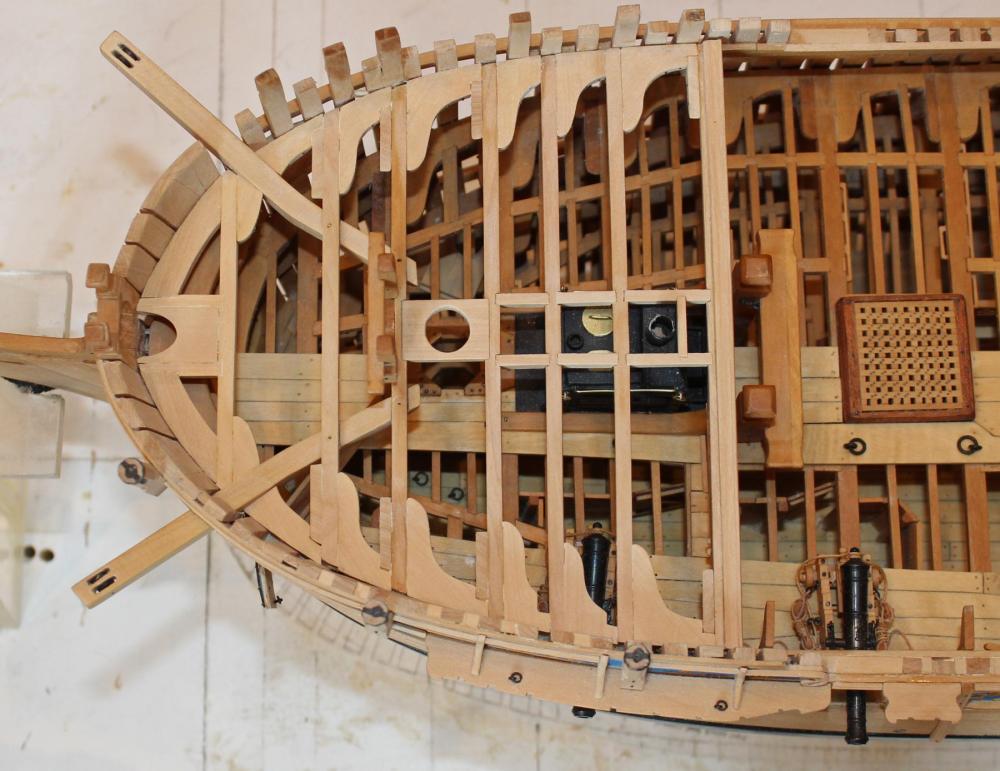

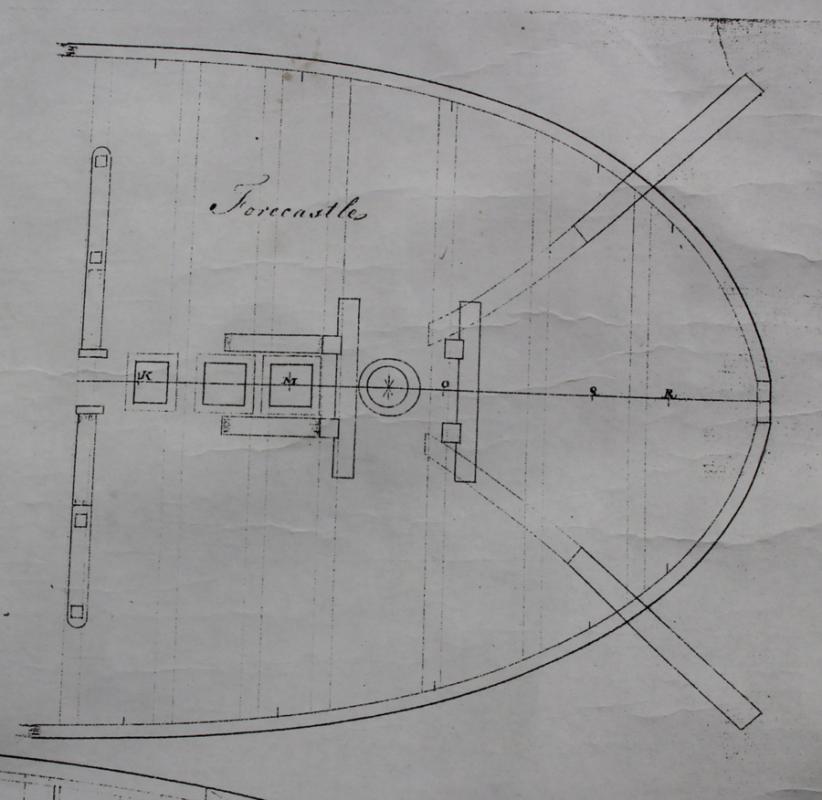

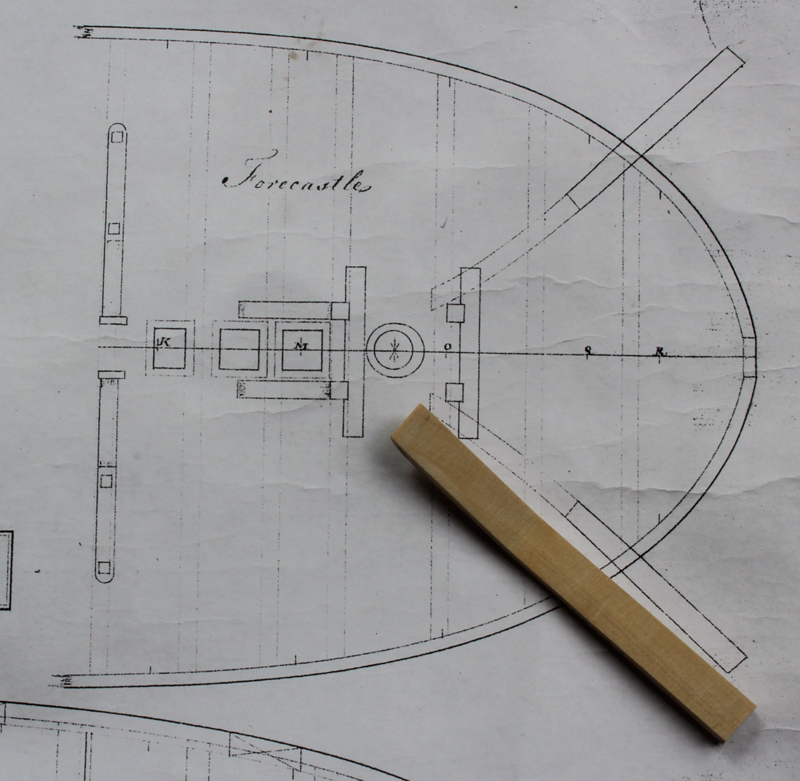

There has been a little progress over the last few weeks. Unfortunately, most of it has been backwards, not forwards. It is time to make the lodging and hanging knees for the forecastle. There are no pillars for these beams. The knees are made of 4.5" stock. They are fairly straightforward to make except that there is no hanging knee associated with the beam over the gun port (between beams 5 and 6). Needless to say, I goofed and cut the lodging knees for the hanging knee insertion. I replaced the starboard knee but left the port one since it will be planked over. Next, I started taking some measurements...and then some more measurements...and then some more measurements. I have become one of the many victims of cumulative error. The photocopied plan which was glued to the building board when this project was started is positioned 9" too far forward, so although all my measurements taken from the dead flat are correct, everything taken from the fore and aft extreme lines is off by 9". Additionally, the location of the cap rails is 4" too high. None of this is truly a big deal from a construction of the hull perspective, although it will be a slightly different ship than constructed in 1775. The problem is that the bowsprit sits at a shallower angle and would cut through the foremost beam. Happily, I was not planning on masting her anyway. After this discovery and the frustration associated it there was only one thing to do. Walk away, have a cold one and come back the next day. Hopefully there will not be any more surprises down the road. I moved the first two beams from the proposed layout in TFFM to prevent a hanging knee from interfering with the fore port opening. All the lodging knees and the first set of hanging knees are in place and tack-glued. The most difficult hanging knee is the one on the fore side of beam 2. The cant is this area is significant so there was a lot of trial and error fitting this in place. The cattail still needs to be made and this cuts through one of the lodging knees and articulates with one of the beams so nothing will be secured until this is installed.

- 1,449 replies

-

Congratulations on another beautiful piece of craftsmanship and art.

- 268 replies

-

Didn't hurt at all, Druxey. The embarrassing thing is that it took someone else to point it out to me. That is the beauty of MSW. We are a community that really cares for the quality of work presented.

- 1,449 replies

-

- 1,449 replies

-

Thank you for pointing the discrepancy out Mr. Rotten. Oh well, back to the carving board!

- 1,449 replies

-

- 1,449 replies

-

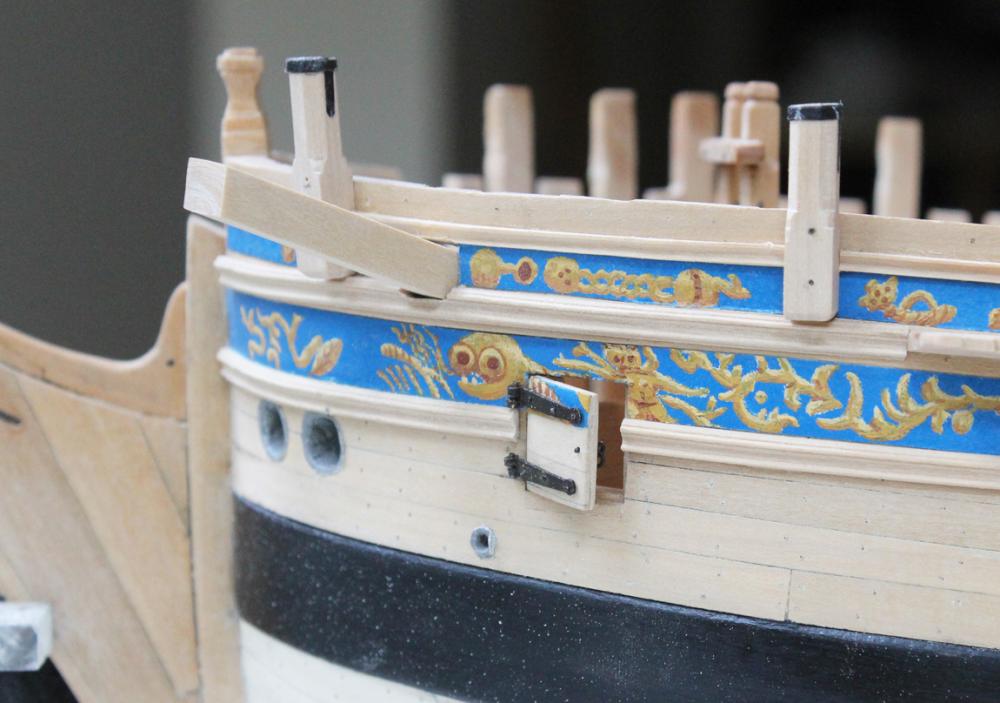

Thank you Albert and Druxey. And also thanks for all the likes. The next thing to attack was the drift rail and their scrolls. This is the topmost decorative rail and runs on the top edge of the frieze. It is interrupted by the channel brackets and swivel gun mounts. It is made in the usual fashion with the pattern carved into a razor blade. Now it gets interesting. The rail drops down between the fifth and sixth gunports. A rounded corner was needed to accommodate this drop. There is nothing terribly difficult about this or the scrolls. It is time consuming and fiddly but not hard to accomplish. I traced the shape on a wood blank and scraped the straight section with the razor. Then I carved the corner piece with tiny chisels and needle files. I would suggest to anyone doing this to make the vertical limb over-long at this point as it is prone to tear-out. One the shape was correct I fit it to the lower section of rail already in place with a 45 degree miter. The scrolls were approached similarly. The shape was traced out on a blank and roughly shaped with chisels and an eleven blade. This blank was glued onto the back of a piece of sandpaper. The sandpaper helped prevent slippage on my cutting board during the shaping process. The straight section was scraped and the scroll was cut in. The thickness of the scroll diminishes as it drops down and increases again at the "ball". For the aft scroll this means that from 11:00 to 6:00 the thickness tapers in and from 6:00 to 3:00 it tapers out to the original thickness. Sorry about the picture quality. They actually look better than the pictures suggest.

- 1,449 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.