-

Posts

2,032 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tlevine

-

Echo by davec - FINISHED - cross-section

tlevine replied to davec's topic in - Build logs for subjects built 1751 - 1800

I don't know about historically accurate but if you want that holly to stay white-white finish it with clear dope. That is the advise given to me by David A. and it worked wonderfully. After a year there is not a hint of yellowing.- 127 replies

-

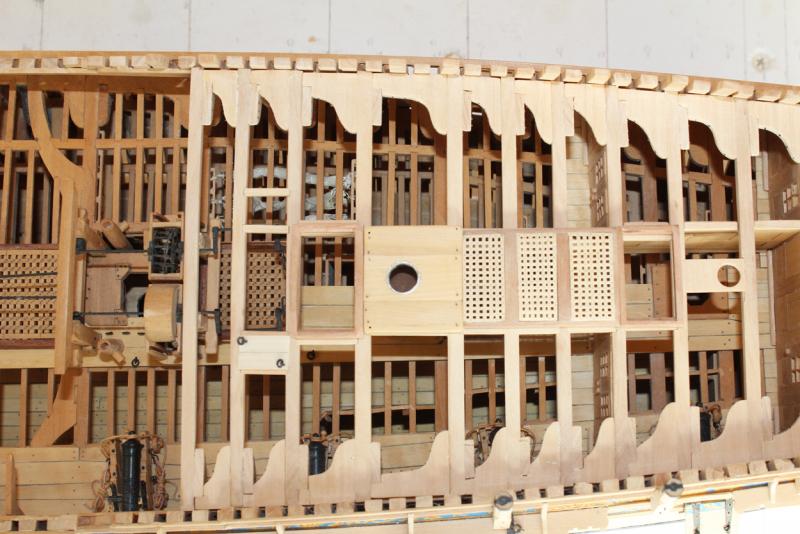

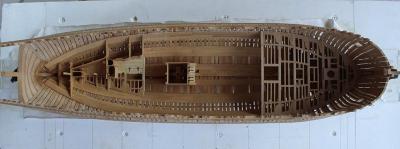

Time for a bit of an update. The quarter deck framing is completed. There are several openings in the midline which need to be addressed. Most forward is the ladderway, followed by the upper capstan step. Behind that are three gratings panels. Each of the gratings is designed to be different in width, so they needed to be made individually, rather than making a long strip of grating and simply cutting off the length required. This leaves a final opening in front of the mizzen mast. On the deck plan there is a dotted line within the outline of the hatch, suggesting that the was a structure inserted into the opening. The openings for the grating do not have the same dotted line; therefore the structure was not a grating. David states that it is possible there was a companion over this opening. On the plan view there is no structure visible above the hatch coaming. Below this opening is the salon...officer's country. I doubt they would have wanted to get wet or, even more so, have their conversations overheard. So a companion will be made for the opening. Finally, there is a scuttle for the topmast tackle in front of and lateral to the ladderway opening.

- 1,449 replies

-

Remco, you and your Kingfisher have been sorely missed. We all understand burnout and dreaded parts of a build. My downfall has always been rigging. Welcome back!

- 1,214 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Happy New Year's to everyone. Brian, I am using mica for my windows. Pat, I actually have put flexible scopes into the hold. There is a lot of sawdust down there! Druxey, the closest I would get to spars would be stub masts. I find rigging horribly tedious.

- 1,449 replies

-

Thanks for rubbing it in, Greg. I'll bet they look almost as good as yours!

- 1,449 replies

-

I kept wondering why I did not have your problem with Atalanta. In Chicago we have wide variations in humidity, even with A/C in the summer. Then I realized what I did differently. Because I was planking one side of the hull, I deliberately left off some of the spacers out do allow a little light to enter the lower reaches of the hull. This picture is from page one of the resurrected build log.

- 889 replies

-

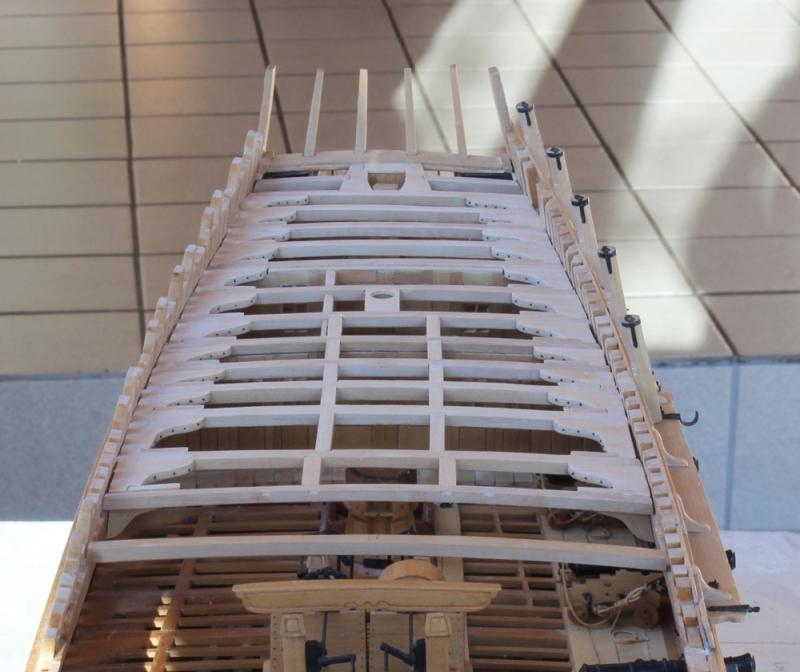

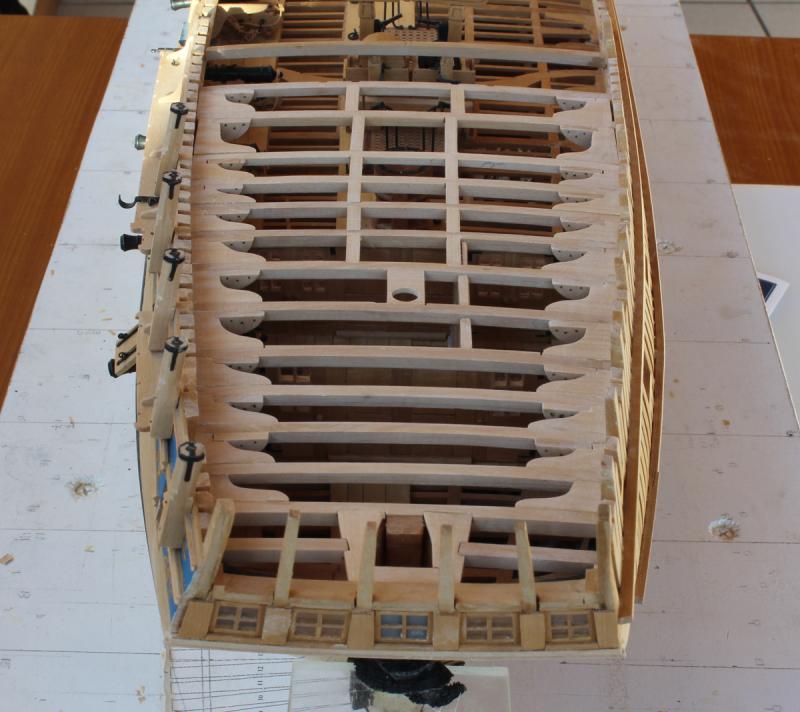

It is hard to believe that it has been over a month since my last update. Work on the quarter deck beams has been progressing very slowly but I hope to have them completed within the week. The pictures were taken before any finish sanding.

- 1,449 replies

-

You mentioned initially that you are restoring this model. Now you are talking about changing the model to match a known ship. Looking at the model in question, I believe it was never meant to be an accurate scale model of any specific ship. It is a souvenir or folk art model, probably made in the Far East. If this is a restoration, then do just that...restore it to how it was when purchased, regardless of accuracy. I am in the process of doing the same thing for a friend who wants his deceased father's clipper ship model restored. You will learn valuable skills which could be used on a future, historically accurate model. If your intention is to create an accurate representation of Tennessee then the only thing you might be able to save is the hull. I do not mean to put a damper on your enthusiasm but you will find that this is a big project and I would hate to see you abandon it because it is more complicated than you expected initially.

-

Meet Your NRG Directors and Officers

tlevine replied to tlevine's topic in NAUTICAL RESEARCH GUILD - News & Information

Mitch Michelson I have been an NRG member since 1989 and a Director for the last 8 years. In my professional life I spent 40 years as a petroleum engineer and part-owner of a family-owned oil & gas business in my home town of San Antonio, Texas. My interest in the nautical world began as a teenager on a visit to the Hyde Street Pier in San Francisco. As is true of many of us, I was a confirmed model builder in my youth and began to return to the hobby as a young adult. I discovered the NRG on a return visit to San Francisco during a discussion with a park ranger at Hyde Street on my 30th birthday. It took me a few more years to get up the nerve to actually join. My actual model building has been limited due to the usual professional and domestic distractions. I became interested in the early American Navy, primarily the War of 1812, and have spent a lot of time researching the era. In doing this I have accumulated a fairly extensive library along with the requisite must-have volumes on building models of sailing vessels. I have attended almost every annual NRG conference since Boston in 1997 and doing so has really broadened my knowledge and expanded my horizons. Because of conferences I have met and become friends with some really outstanding people. My NRG Board experience has been very rewarding and I am (so far) most proud of how each member of the board has become a fully integrated part of the Guild’s operations. My user name is “mmichelson”. -

Thanks for posting the step-by-step process for the capstan. Fantastic work.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

Consider replacing the plastic sails with cloth. I have used fine weave cotton saturated in starch and used the plastic sails as a mold to form new billowing sails.

-

Guidance, Encouragement, or just a Sanity Check

tlevine replied to RFP's topic in Wood ship model kits

Definitely, go for it. The worst case scenario is that you wasted a little money for the kit purchase. But I think you will find that your skills are up to the challenge. -

Do you have central vacuum in your home? If so you can run a line to your new work space. Since the unit is in the garage (typically) the noise is minimal.

-

In the past I have always stained the wale planks. Chuck uses several layers of thinned artist's acrylic paint on his models. I tried the same thing on Atalanta and am very pleased with the result. After fours coats of paint I burnished it with 4000 grit sand paper to make it stand out from the matte finish of the rest of the hull. What is very nice is that touch-ups are easily blended into the rest of the wale.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Those gears look great. I hope you are not planning on covering them up with too much planking.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Thank you gentlemen and thanks for all the likes. I hope to get a few more beams in place this weekend.

- 1,449 replies

-

I cannot believe it has been so long since I posted. Amazing how life gets in the way. I was finally able to get some work done this weekend. There is an iron knee connecting the transom with the inside of the hull. This is not a simple "L" shape. It needs to twist inferiorly to clear the undersurface of the quarterdeck half-beam. I made the knee out of castello and then painted it black. There is nothing unusual in the construction of the quarterdeck. There are no stanchions. The only carlings are related to the capstan step and the deck fenestrations. I find it easier to begin aft and work forward (ie narrow to wide) for better access. There are hanging and lodging knees for each beam except there is no hanging knee at beam 14 as this would have interfered with the quarter light. The framing above the sternpost appears to be at a different angle than the rest of the deck in the last picture. This is an optical illusion. The plans show the bulkhead on the fore side of the beam, not underneath. Because this is a laminated structure I glued a thin shim on top so it would look neater.

- 1,449 replies

-

Just be sure to "borrow" the stuff we want to replace with something nicer anyway!

-

Chuck, I would love to see something on polymer clay. I was considering making my figurehead with it (when that time ever comes). There is also a regular #12 blade (aka tonsil knife) with the cutting surface only on the inside. Personally, I would rather load two scalpel handles to get the same effect as the #12D (#12 and #15 or #10). Much safer.

-

I want to be in your club! But then I'd have to move to Jersey...

- 452 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.