-

Posts

2,982 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hubac's Historian

-

I appreciate your "MythBusters" experimental mentality. I'll be looking for your empiracle update.

- 961 replies

-

Interesting tip on anaerobic glues, Testazyk. Are they onle effective on metal/wood, or good for plastics, as well?

- 961 replies

-

You have to be careful with those CA glues. In my twenties and thirties, none of that stuff bothered me. We were using massive amounts of West System epoxy, and washing it off our skin with lacquer thinner. Stupid. Now I find I am sensitive to funes from curing epoxy. Same with CA glue. I used to use it a lot, but now I find that I can't tolerate the fumes. Make sure you ventilate. And if you are using a lot of that stuff, go get yourself an organic vapor respirator. All that being said - the ship really looks beautiful EJ. Great work! Sorry about the soapbox. I just wish I had taken that stuff more seriously when I was younger.

- 961 replies

-

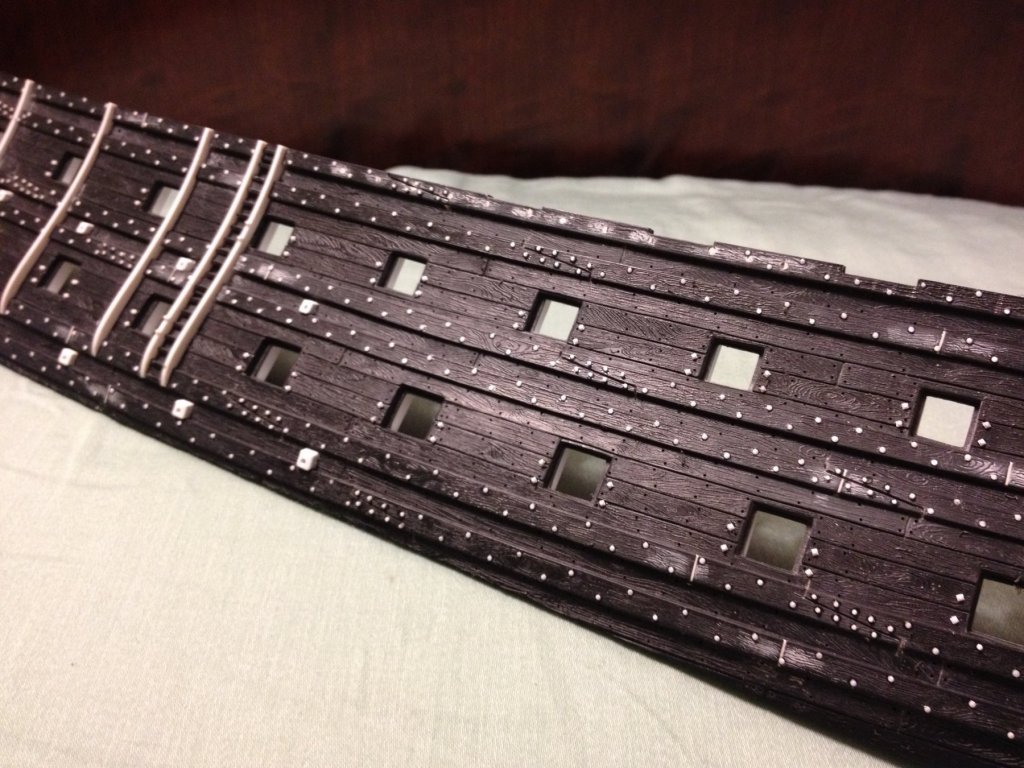

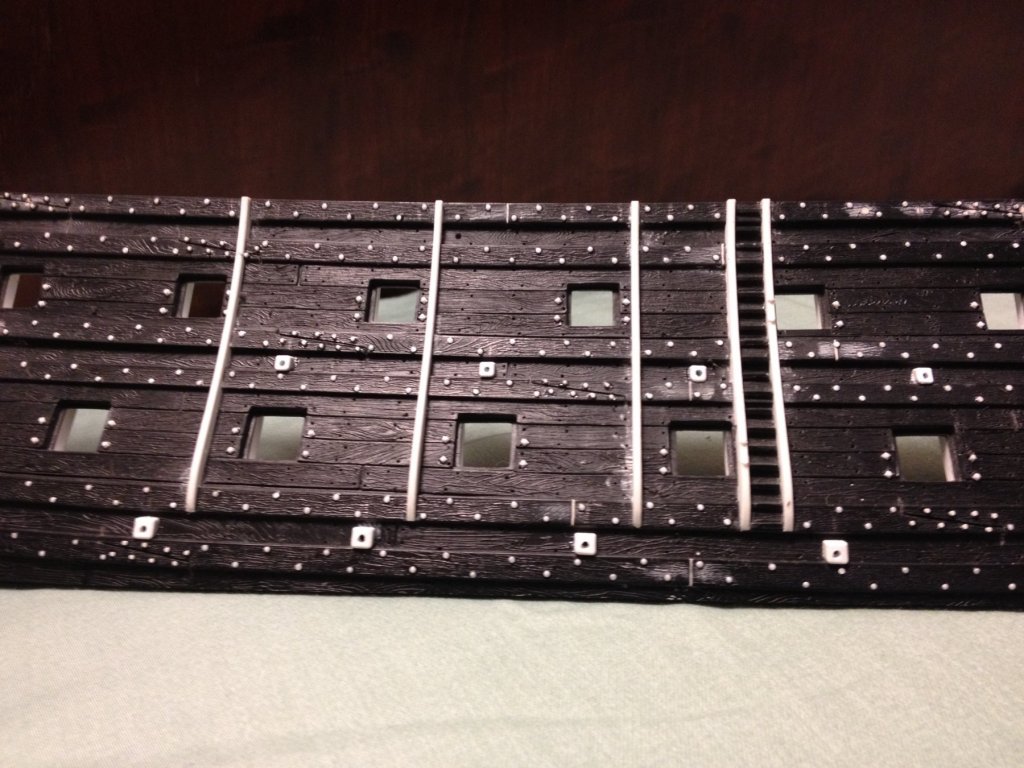

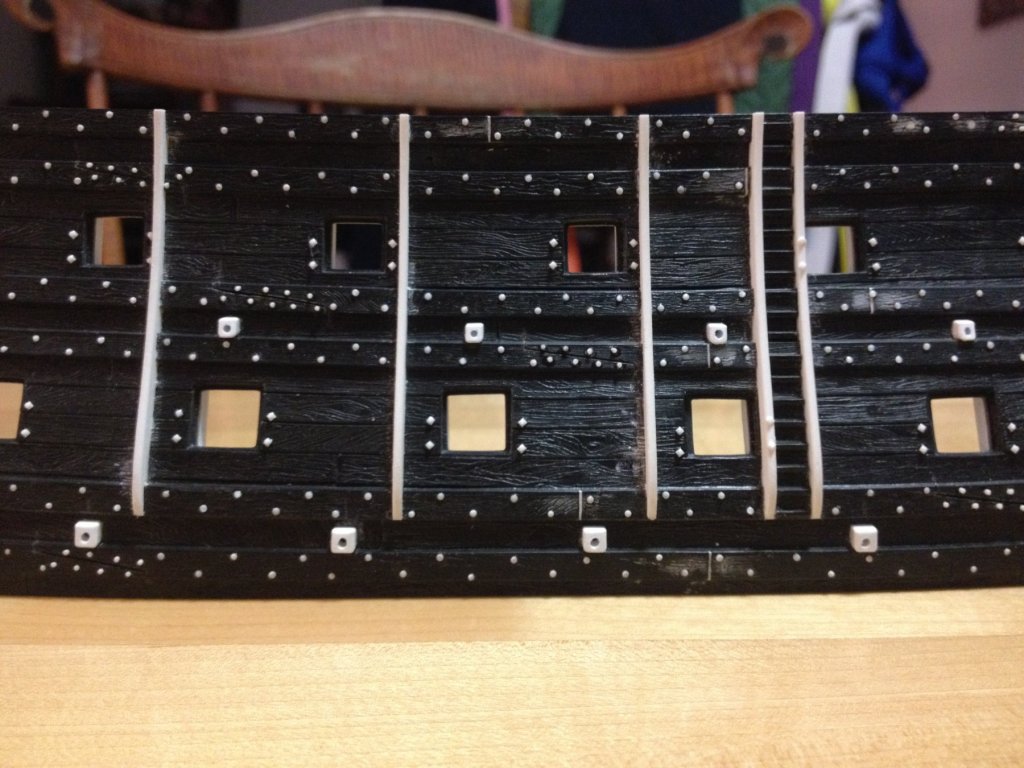

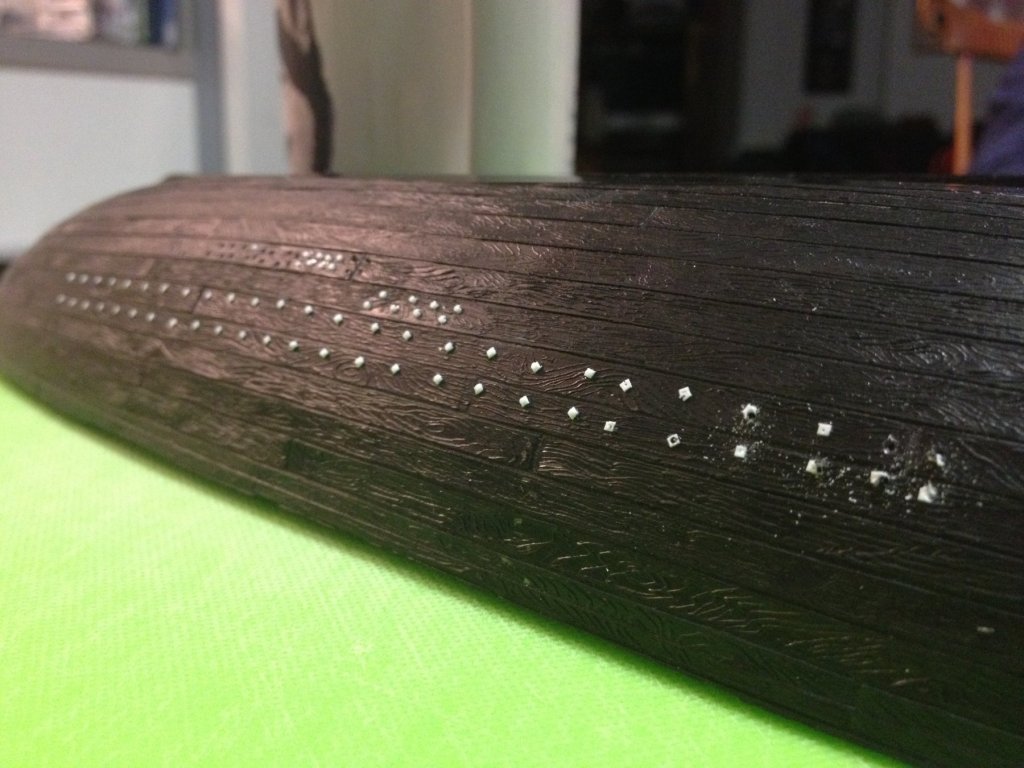

I have been busily mapping out and drilling nail impressions in the deadworks. I haven't put a caliper to the bit I'm using, but suffice it to say that it is near impossibly small. There was some trial and error to arrive at a bit that left a plausible impression, and that didn't overheat and clog with melted plastic too quickly. I still have to stop the Dremel and clear the bit every 15 holes, or so, but that's much better than the 5-8 range. As a quide to my spacing, I am using the exposed timber heads of the caprail. This works out to about 5/16", on center for the most part, but there are several instances where I'll have to run a row or two at 1/4" spacing, in order to maintain overall consistency. In the waist, and for about six ports aft of the waist ladder, the nailing pattern runs perpendicular to the waterline. With the hull half sitting on the table, I simply use a try square to align my blue painter's tape guide for keeping my lines nice and straight. As the sheer rises, further aft, it has become necessary to skew my tape guides ever so slightly, by eye, so that my nailing pattern doesn't run too far askew of the gunport framing, with which it should remain parallel. After much deliberation, I have decided to mimic the alternating nailing pattern that Dan Pariser used for his very thoroughly researched and excellent Queen Anne's Revenge. I have known Dan for a long time now, and there is nothing he does without considerable thought and research. Here are a few pics of my progress, so far. They are hard to make out in the black plastic, and after priming and painting they should just barely show as faint impressions.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Thanks Daniel! As far as Soleil is concerned, the shame of it is that they do an incredible job of copying the ornamental details from one of the existing original cannons, but as I say, they do not capture the appropriate sense of girth that is so evident in every Van de Velde portrait ever drawn. For carriage and rig updates to the guns, I am looking very closely at Popeye2Sea's excellent build log. His carriages look amazing. I'll have to look at those links for photo etch; thank you for the info.

-

Hi Daniel, One question about the guns:. The scale of the barrels looks really good. While I have this kit, it's siting in a basement in PA and I can't readily look at it. Are these the stock cannons, or did you make/buy something closer to scale? One of my issues with Heller's Soleil Royal is that the muzzle/barrel width, and bore diameter are too narrow and spindly looking. I will have to do something about this, and am searching for a way to perhaps recycle the kit's stock barrels by, perhaps, dipping them several times in some sort of resin, in order to increase their breadth. I could then drill out the appropriate bore diameters. I am wondering your thoughts on this subject. thanks, Marc

-

Okay Daniel, I'm only on page 3 of your build log - and I'm going to stop hitting the like button, so that you are inot completely innundated with notifications, but... I am completely BLOWN AWAY by your attention to detail and your willingness to re-work the smallest details until they are RIGHT. My German half is crying meticulous tears of joy! Gonna keep reading

-

I hopscotched through another member's (who had visited my build) history log and found your highly intriguing build of the Heller Victory. I so like the excellent modifications and scratch-work on this main top, that I'm going to go back and read through your whole log. It seems that much of what you are doing might be really helpful to me, even if we are building in different centuries. So nice to see such excellent, clean work. I'm looking forward to catching up!

-

Thank you very much, Cedric! I believe it is now possible to see the hidden potential in the Heller kit, in order to make it a better model than it already is. So I will keep plugging away. I'm very excited to see your progress, Cedric!

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Tonight, I finished up the gun carriage tackle through-bolts. The following series of pictures attempt to show the impact of adding this detail. Only the second picture manages to capture the bolt within the washer, such are their size. I'm not sure whether it is a correct detail, but I also decided to bolt the edges of the anchor lining. Although, I now realize that the linings would have simply been a double thickness plank trimmed to the shape of the lining, I decided to bolt the "edges" anyway. Next, I will experiment with some sort of shallow nailing pattern for the rest of the planking. I think if I chuck the tiniest drill bit I own into a pin vise, and simply make a few turns into the plastic, such that the bit's point just makes an impression, that that might be enough to show some kind of fastening pattern. The linings will be "nailed" between edge bolts. P.S. I'm not sure why the above text is underline formatted, because I did not do that deliberately, and underline in the toolbar is not highlighted, when you select text in that block. I can't seem to correct it, so there it is. If you look closely, you'll see that I even placed carriage tackle bolts on the skids that frame the ladder, because the skid frames took up all available space, immediately next to the affected ports. I'm not sure whether that is a correct detail, either, but it seemed like the sort of accommodation a builder would make under the circumstances. I'm approaching the end of my lower hull modifications. Those are a lot of tiny bits of plastic! After the "nailing," I'll do the bow and stern extensions, re-locate the hawse-holes, and then I will probably focus on making the alterations and additions to the upper bulwarks. After that, I will have to figure out my drawing problem.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

I'm glad to see you back in your shipyard Doris. I think your modifications are good, and I'm looking forward to your updates. Regards, Marc

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Okay, then what about this: Mask your line, top and bottom as perfectly as your eye enables you to do - having cut sufficiently long strips of masking tape to make nearly one complete run, stem to stern. The complicating curves at the bow and stern need to be dealt with in shorter lengths. You will have first ripped your tape into no more than 1/8" strips, this will enable you to easily stretch and adjust your tape to move as needed, with the sheer, etc. Once you have the line masked the way you want it, thoroughly burnish the tape with a straight piece of stiff card. Then mask as near to the line with a wider swath of masking tape. Then mask off everything else above and below the line with paper. Here's the critical step:. Spray the, as yet, uncolored line with a clearcoat that matches the desired sheen of the rest of the model. Once that's dry, airbrush in your color wih a few light coats. If, after removing your masking, you see any areas where the clearcoat has blead under the tape - simply mask off your line in the affected areas, level the clear coat, and when the time is right in your process - spray the whole .thing one last time with that matching clear coat. Failing all that, pour me a glass of bourbon on a slow evenning, and I'll tape off your lines to perfection.

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

Dan, why is it that you won't mask and airbrush the green striping?

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

The funny thing is that I just sent Marc a PM, discussing this paint issue, among other subjects. But, I had not yet read his last entry into my build log. For the sake of the public conversation, I will copy and paste the relevant portion of that message - the irony can't be beat! ~~~ it seems that a number of well-known French models make use of the color (ventre de biche), as a painted color, on the dead works: Le Fleuron (red, yellow ochre, ventre de biche), Le Temeraire (Tusset model), and Le Ville de Paris are three well-known examples. But then, I was looking at the replica of Hermione, and she too appears to have her deadworks painted in this brownish, yellow color. And then, I looked once again, at a second Peter Monamy painting of the destruction of SR, which focuses on the bow: Here, too, ventre de biche appears to be a deliberate and applied color. What all of this means for me is that I will have to work up a series of paint samples; one that is a lightly weathered, natural wood tone, one that is VDB freshly applied, and one that is VDB lightly washed to show a little sea grime. As this is going to be a diorama model, I just want to avoid an overly painted looking model; sort of the way a girl wants to look as though she isn't really wearing make-up, if that makes sense to you. ~~~ And, by the way, I also agree with Marc that one must first understand what was, or likely was, before taking any divergent paths. The question of combining yellow ochre for much of the moulded work with gold for the important sculptural work would be an artistic decision for me on the basis that those golden ornaments would then stand out better, in relief; they would be more impact-full.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Exquisite work on the guns, Marc! I agree with you, also, that Victor really captures the essence of what a sailing man-o-war must have been like, on the water. To me, his ships are perfect miniature recreations. And on launch day, your miniature Tourville will spring to life and take command of his reborn Royal Sun. Well done, my man! Well done!!

- 208 replies

-

- le soleil royal

- 104 guns

-

(and 2 more)

Tagged with:

-

Thank you, Marc! I will tell you that I have been thinking about your suggestion for the anchor lining - that it should fill-in completely between the lower main wales, right up to the stem. After looking through my image database, virtually all French models confirm this detail. I will do so, as well, but only after I add on the bow extensions. The anchor lining will provide the added benefit of making this joint a little stronger. I am also now changing my mind again and leaning towards representing only regular iron nails in the deadworks, but I will have to arrive at a method that suggests a believably subtle pin-prick. Dan's earlier suggestion to draw-in the nails with a mechanical pencil does not work well on this particular model because of the pronounced moulded grain. For the sake of comparison, I will also try to simulate tree-nails with a sharpened syringe needle. What I choose may depend upon which effect reads better visually. In that instance, even if the type of fastenner isn't correct, there has at least been some attempt made to show fastenners in a sensible pattern. I will find a way. Herbert Tomesan suggests very shallow nail holes on his models. The trick is to find a repeatable method that will look good thousands of times.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

All of this detail gets added on before painting. In fact, I probably won't paint anything until the hull is assembled, the lower transom built and interior gussets and supports for the second gun deck are in place. I want to get all the major handling out of the way before I put finish colors on. I will probably even have built up and installed the quarter galleries, up to the main deck level, before paint.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Hey Dan, It is not too late. In fact, I've only done these few tests. I like your idea, and I can see that it would produce fine results. The trouble I see is that, without a drill press set-up into which you could chuck a .033 bit, it will be nearly inpossible to keep the bit on track, and within the narrow confines of the styrene strip - which itself, would have to be double stuck to the table. You could greate some kind of sandwich jig with a measured line of holes, but the bit has to travel, square through the jig material - whatever thickness that needs to be to produce a large number - and still hit the strip dead center. Easier said than done. Then there are process considerations. As best I can see it, your process is a six step process: drill the strip, part the strip into squares, part the rod into approximate lengths, glue the rod through the washer onto the hull, nip close, file to final length. My process is four steps: part the washers, glue the washers, slice the rod to a finished length, glue the rod. At this stage, I've gotten really quick at picking things up with a knife point and placing them. There would be something mechanically satisfying in knowing that the rod actually goes through the washer, but the end-result is the same, I think. On an average night, I should be able to place a near full broadside of washers. Another night to do the bolts. Four nights total, which isn't bad for my timeline. A solid suggestion though, Dan, and yet another example that there are multiple good approaches to do anything.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

For my next forray into uber tedium, I'll be affixing the through-bolt and washer assemblies - 4 per gun port. The sawed off lower hull is my laboratory for figuring out how best to go about anything, really. I'm using really thin (.011) styrene strip that is .033 wide, which I slice into tiny squares and glue into position with my toothpick and knife application technique. To the right, you can see that I first applied the squares horizontally, as squares: I wasn't satisfied with how they looked because I felt this layout emphasized whatever small inconsistencies there were between squares, in a negative way. So, then I pitched the squares on their diagonal axis, so that they show as diamonds. In this scenario, IMO, these small irregularities read like what you would expect of a hand-forged washer: I was hopeful that I could use the Dremel tool to drill for the styrene rod "bolts," so I pin-pricked the diamond centers to sort of pilot the drill. This didn't work though. The Dremel was too aggressive, and would jump off center and obliterate the washer. Transfering the drill bit to a pin vice was not much better. Finally, I settled on cutting really thin slivers of the styrene rod, which I DID NOT flash with a lighter, and then dropped them on center with a tiny dot of glue. the circle within a diamond is really hard to make out, but this enlargement gives some idea: I think the detail will pop more when they are darkened with paint and maybe dry-brushed with a lighter gray to pick out the circles. I'm thinking that I might experiment with a few flashed bolts to see what that looks like over the washers.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Last night I closed in the last few planks of the anchor lining. I puttied the joints, sanded the surfaces flush and with texture, using 80 grit paper. Then, I scribed back in the plank lines, following the plank lines of the hull. I even scribed in the narrow lines, despite what I said earlier, because the span without those plank lines would appear too broad. This, in my opinion, was worse than the unrealistically narrow plank line being brought to the surface. Lastly, I refined the profile of the lining with a knife and broke the sharp edges with a few scraping passes if the blade. I was experimenting with a sharpened sewing pin chucked into the Dremel, to see if I could make convincing nail impressions. The results were difficult to keep consistent; either too deep, or too shallow, or the pin would develop an accretion of melted plastic, that would subsequently polish the plastic surrounding the pin hole. I will need to continue experimenting, there. Whether it's wholly right or wrong, I am leaning towards represeting a combination of iron and treenail fastenners in the dead works.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

By the way, the paper is a great read on 17th C. French practice, in general, as it draws upon both the Album de Colbert, other sources, as well as the tangible evidence of what once was. And the paper describes the main determinants for all the major structures that made up a wooden ship of this type. Extrapolating, one could simply expand that knowledge to the size of whatever vessel they are building, and I don't think they could go too wrong. Always - multiple sources must be involved and educated guesses must be made. This paper explains why they believe their guesses were most probably pretty close to accurate.

- 2,463 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.