-

Posts

3,297 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hubac's Historian

-

Weathering wood

Hubac's Historian replied to JpR62's topic in Painting, finishing and weathering products and techniques

Probably, now that I consider it, an initial base coat of stain to establish the underlying color, then the sealer coat, then the washes, and maybe even powders -

Weathering wood

Hubac's Historian replied to JpR62's topic in Painting, finishing and weathering products and techniques

Very interesting model and convincing weathering. I'm honestly not sure what was done, here, but if I had to guess, I would say that the first step would be to seal the wood with either lacquer or shellac - whichever would be more compatible with the series of semi-opaque washes that would be hand-applied over the seal coat. I would guess that each layer of wash gets sealed under a fresh mist coat of clear sealer. Whatever they did - even managing to represent the iron staining of the fasteners - they did a superlative job. -

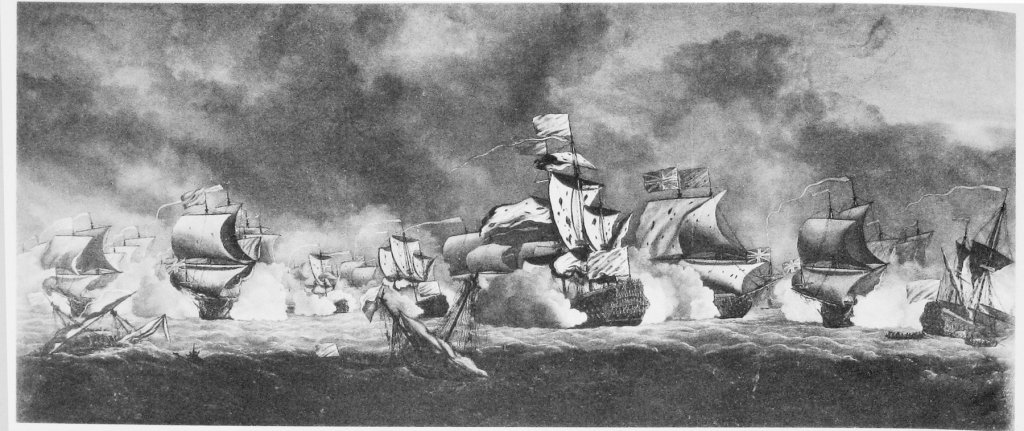

Your choice to add two additional pillars to the outermost corners is a good one, I think, because for all practical purposes, the ends of the stern balcony would need support. I think that the reason you only see two pillars in Berain’s drawing is that the stern balcony on this quarter deck level was not intended to extend all the way out to the quarter pieces, at the ship’s sides; as it’s drawn, this balcony only appears to span the central two of the six stern windows. The kit representation of a wider balcony with only minimal support is a common divergence that is found in the Heller kit, as well. Whether or not the quarter deck balcony extended out to the ships sides is certainly debatable, but providing extra support there is sensible. I am still searching for a location for the following painting of SR st the battle of Barfleur. Extrapolating from the known size of the painting (4’x8’), it seems that the portion of the painting occupied by SR is about 1’ fore and aft, by 2’ tall. If I could just get a clear closeup of the ship, I think many of these questions about the arrangement of her stern could be reasonably put to rest: Given the connection to the Van de Velde studio, this work has more credibility than most representations of the ship. I recently put these images on my Pinterest Page, milk carton style, to see whether anyone out there in the interepace knows the whereabouts of the painting. Maybe the internet will come to the rescue! What interests me most about this painting is that the main deck (middle balcony) supports of “Winter” and “Fall” appear to be closer to the outer corners of the main deck stern balcony than drawn by Berain. Again, for practical purposes of support, this makes sense , but it would be a significant divergence from the generally accepted design of the stern. All debatable. All interesting in my view.

- 961 replies

-

Spectacular carving, Drazen! The thinner profile is excellently rendered and your lettering is really superbly done. I am very impressed with this!

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Hi Dan and Vic! Yes, thank you for the kind words. Vic, the scraping is a process: Dremel round burr, Dremel bottom cutting straight bit, scraping with chisels and knives, and finally, smoothing with the coarse side of an emory board. The most time consuming aspect is cutting away waste around the borders of what’s staying. This old plastic is, for lack of a better word, chewy and tough to work with knives. As always, thanks for looking in!

- 2,697 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

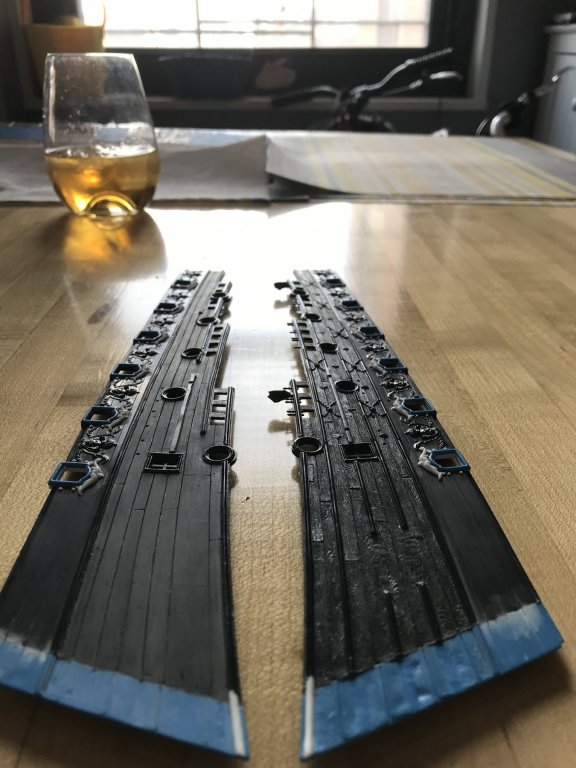

Well, it has been slow-going and it may not seem that much has changed, but actually quite a lot has been accomplished. All of the main deck port enhancements are now in place: It is interesting to me that, despite being cast from the same single master, most of the enhancements are different enough to appear as though they were individually carved. This owes to varying finger pressure while sanding away the backgrounds, as well as the gouge and knife cleanup around the scrolls. And, ocassionaly, specific scrolls were deliberately shortened and/or flattened to better fit the space they were going into. The effect is not unpleasing to my eye. I, however, will strive for better uniformity for the cast pieces that make up the frieze ornaments; because these pieces are much smaller, any variations in their size and profile will be much more evident. Here is a closeup of the area surrounding my new chesstree. This illustrates how the chesstree and skids, which serve a functional purpose, take precedence over the purely ornamental port enhancements; in accomodation of these functional elements, the ornamental scrolls have been shortenned, where necessary. I can only imagine that this must have been what was done, for all practical purposes, on the real ship. In the following shots, you can see how the port stern quarter, upper bulwark has been scraped clean of the stock bulwark frieze. All that remains are the necessary sheer strakes that frame the caprails and the basic, round ports of the quarter and poop decks. I now have a clean canvas for building up the new frieze and adding in the round port enhancements. One detail that I found necessary to include were plank lines in place of where the standard sheer strakes had been. To do this, I took centers between the two existing plank lines and engraved a new plank line between them (work in process). I was able to use curves, for the aft-most 3”, or so, but the rest had to be cut by hand and eye. As the existing plank lines are, themselves, a little wobbly and less than fair, my new lines reflect those irregularities. I have tried, though, to minimize that as much as possible. In the end, though, these imperfections will be mostly concealed under the lattice of the new frieze. It will only matter that plank lines are represented. Lastly, I’ve cleaned up the cap rails by removing the tree sprues and all traces of the pins, which will eventually be re-centered on the soon to be thicker caprails, with something better and stronger. The inside faces of the bulwarks are also now scrubbed clean of any remaining evidence of the injection moulding process. This is a step that is often ignored on this kit, but shouldn’t be. In Maslow’s Lower-archy of tedium, this task is actually not as horrible as many others on this build - like, say, assembling all of those gun carriages. As a side note, I discovered that the starboard upper bulwark assembly is a good 1/8” longer than port. This is a bit of a mystery to me, as the lower hull was extended by the same 3/8”, and the upper bulwarks were indexed on the lower hull, according to the location of the mid-ships gangway ladder. The pieces should have just lined up with the ports in their correct place, but in fact, they did not. I had to shift the starboard stern bulwark forward by 1/16” just so that the ladder would align. this adjustment accounts, in part, for why the starboard upper bulwark extension appears longer than 3/8”. When I put the lower hull halves up to each other, I could see that the starboard lower hull is 1/16” longer than port. I suppose this is all reflective of the 1970s handwork involved in creating the kit, in the first place. They weren’t using computers, back then, to design the model. Anyway, these differences shouldn’t be apparent in the finished model. So, I’ll just keep on keeping-on, and I’ll repeat that process for the other three upper bulwark pieces. Fortunately, the forward pieces, that include the forecastle, do not have much surface area that needs to be scrubbed.

- 2,697 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

WOW - these funnels really are the stars of the show and you are nailing it Dan! Beautiful work, ingeniously done.

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

Okay, Mark, if stain provides the blackened finish you are after, then what about this: First, thoroughly mask off the wales that you want to stain, so that you have a very clean tape line of demarcation between what will remain natural and what will be stained. Next, spray a few mist coats of the same thinned finish you intend for the unplanked lower hull, in order to seal the grain along your line. Next, tape the lower hull right up to the wale taping. Burnish the new tape. Finally, remove the first tape so that you can mist light coats of your stain onto the wales until they are sufficiently blackened. This is all theoretical, on my part, but this would be an experiment I would try, if I were attempting to blacken my wales with stain. I think that by scribing your line with a sharp knife you are only inviting stain to bleed unevenly into the grain fibers. I have no experience with doing this, though, so I can only guess.

-

Well, another great build of yours to follow, Mike! Your change of wood only underscores your dedication to what you think is best for a project. That's why your builds stand-out. I'll be following along with great interest.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Sorry, Druxey, I just read your comment more carefully, in which you basically answered my question. Thanks for that.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Is it fair to say that canvas would only be used on the roof, or upper/lower finishing, while the sides would still be light board or paneling?

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

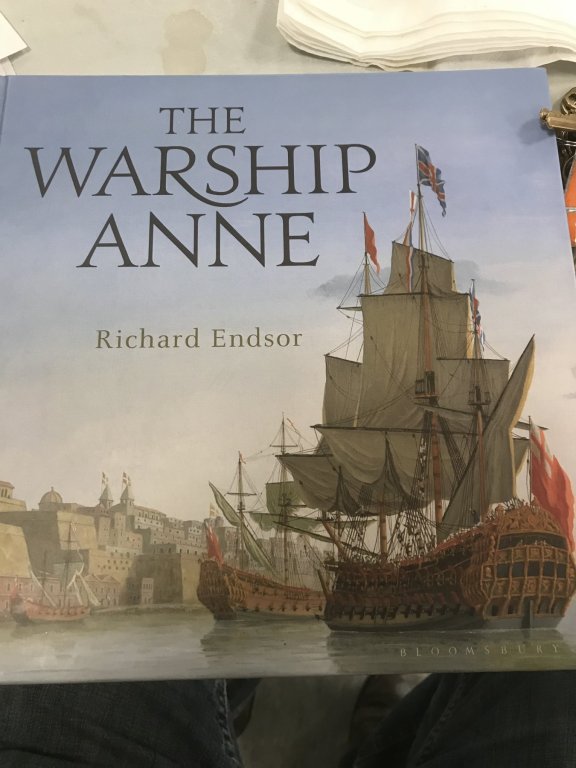

Hello Doris, First if all, thank you very much for taking the time to make that video. This was incredibly instructive and interesting in that you only need the small steam from a cup of tea to do this shaping of the card. I was envisioning a boiling kettle, or something like that. And the results are so perfect! I am reading, now, Richard Endsor’s excellent book “The Warship Anne”. In the book, Mr. Endsor makes mention of canvas purchased for the covering of the quarter galleries, during the construction of the ship. This detail of the text made me wonder whether it was this flexible medium (canvas), that could more easily be stretched over the light framework of the QGs, thus creating these complicated, faceted shapes - maybe, at least, for the top upper finishing. The canvas could then be sealed with paint, or some form of “black stuff” for water proofing. I had always assumed that the “skin” of the QGs was made entirely of wood. Anyway, not sure what to make of that, but an interesting possibility. Perhaps you understand this more completely. The other detail that is of particular interest to me, Doris, is your round-up of the stern - from the counter timber, up through the tafferal. Let me preface the following observation by saying that this is not a criticism, but merely my desire to more fully understand what I am seeing as it relates to known period practice. My observation is that the arc of round-up, in the hotizontal plane, is most pronounced at the stern counter, just above the stern post. As your eye travels up, toward the tafferal, this arc APPEARS to flatten out a bit, yet it is still there. I can see the upper arc of the stern, as it is reflected in the aft deckline of the poop. What I can’t figure out is whether this arc actually diminishes, as the stern rises, or whether this is just an optical illusion created by the rising tumblehome of the ship sides cutting the arc on a continuous taper towards the centerline of the ship; in other words, as the ship’s sides rise, the segment of arc at any given point gets smaller and smaller, thus, perhaps, appearing flatter when, in reality, they are all arcs of the same curve. How’s that for a run-on-and-on sentence?! With all of the ornaments in place, I think that this apparent difference is not noticeable at all, really, but the bare architecture makes it more visible. What you are doing, Doris, looks right to me, but I’m just trying to understand why so that I can re-create it on my model.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

That’s a fearsome broadside, Mark! I apppreciate the excellent work you have done on her so far. Incremental progress; little by little you are getting there.

-

Excellent detailing, Dan! That pool slide is impossibly small. At first, I was thinking that you should keep trying to install ladder rungs, but then that dime put everything into perspective for me; at that scale, ladder rungs are just are not necessary.

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

Beautiful work, Sigi! The black alder gives nice tonal variations that would be evident in a full size ship - at least while on the stocks. Eventually, these wood tones will pop even more next to the painted lower hull and upper bulwarks. Beautiful lines, and lion and super clean work!

-

MONTAÑES by Amalio

Hubac's Historian replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

There are so many truly excellent models on MSW, right now. While I am partial to the very excellent work of Marc Yeu, AKA Neko, this model that Amalio is making is simply the most astounding, IMO. Everything from the uniqueness of the subject, to the fairness of the hull, to the completeness of the detailing, to the total care with which every single detail is consistently rendered presents a feast for the eyes! -

Aaah, now I see! The eyeball test says that’s too short a span to fair the bulkhead - for the sake of glue surface - and to also have a fair run of planking to the transom; you would definitely have to fair the two preceding frames, IMO. If you didn’t do so, I strongly suspect that that would result in an abrupt and awkward rise of the planking to meet the transom. I would, instead, add material to the bulkhead and fill the gap.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.