-

Posts

2,941 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Hubac's Historian

-

-

Ian, if I have confidence in anyone, I have confidence in you. Your version will probably float, tack close to the wind, and keep the combined Anglo/Dutch R/C flotilla at bay. I’m excited to see what you do because I know it will be awesome AND innovative!

Also, a very Merry Christmas to you!

- Ian_Grant, Bill Morrison, FriedClams and 3 others

-

5

5

-

1

1

-

I can’t remember who, exactly, but a while back someone very astute pointed out that a 17th C. lower mast of this time period would not have been equipped with either front or side “fish,” or re-enforcements. It is a Hellerism for them to be moulded into the fore and main masts:

They are nowhere to be found in the work of leading authorities like Boudriot or Lemineur:

And so, for a long time I debated whether to shave away these details. My main argument against it was a concern that doing so would make the lower masts appear too spindly - this, especially, because I had raised each mast footing by about 1/2” for better scale.

The primary argument FOR doing this was that it would enable me to properly represent the wooldings with their top and bottom retaining mouldings. To apply these mouldings over and across all three fish would just look completely wrong and weird.

Now that at least one big holiday is out of the way, I was looking for something to jumpstart the project again, so I decided this was a good task to finally tackle. I started with the coarse Dremel drum sander to remove the bulk of the material:

The challenges with this little project are two-fold. The first is to carve-in the missing segments of the iron bands (between wooldings. The other is to maintain a smooth continuous mast taper between the bands. The pictures basically tell the story:

I think this was a success, primarily because the masts do not appear spindly. Going forward, I will try to be somewhat more present with this project. Our CYO basketball schedule kicks off this weekend, and there are a lot of games in the first few weeks. Then, of course, there is Christmas to contend with. Who was it that said “life is just one G’damn thing after another!”?

Anyway, I think that’s me saying that. Thank you for looking in and for your continued interest in this project.

- Bill Morrison, Archi, archjofo and 15 others

-

18

18

-

-

This is all completely fascinating, Peter, and your idea to divide each station into three parts is ingenious. I have one curiosity, though. The side parts of each bulkhead, that taper into frame shapes above the lower gundeck - why not make these from solid timber like maple, boxwood or pear? Is it mainly a consideration of radial shrinkage of solids, joined to stable plywood?

- CiscoH, Katsumoto and Paul Le Wol

-

3

3

-

You are off to a smashing start, Michael. How's the condition of the plastic? Do you find that it is at all brittle or still pliable? As for square vs. round tuck, I think it likely that she had a round tuck. Your mock-up looks spot-on. Planking across the aft-transom ports should be horizontal, though. The tuck planking ends at the wing-transom.

- Bill Morrison, Baker and thibaultron

-

3

3

-

It is all really excellent!

- Siggi52, mtaylor, FriedClams and 2 others

-

5

5

-

-

It is nice to be reminded of this magnificent build. I hope all is well for you, and that you are able to relax and work on your model from time to time.

Best,

Marc

- mtaylor, FrankWouts, scrubbyj427 and 1 other

-

4

4

-

First of all - mission accomplished! Nothing about the way all of the stern elements come together is kit-like. Bravo!

The thing I like so much about the Speedwell is that in addition to her elegant up-sweeping sheer-line, she has such a nice balance of carved work that really bring a lot of visual interest to the model. As always, your engineering of these processes is ingenious.

That is quite an experience you are in for to be involved with a major film production, starring several of the best actors of our time. The recognition and opportunity are well-deserved!

Happy Thanksgiving to all!

- FrankWouts, Freebird, Chuck and 2 others

-

5

5

-

-

I don’t think the running rigging will be an issue, Bill. It was just the stark contrast between the ratlines and shrouds that didn’t work as well.

If it’s any consolation, on my first build I also went for high contrast with my deadeye lashings, jeer block lashings and lower mast tackles:

This is actually stark white line, though, as opposed to tan, which would have been a better choice.

-

-

Congrats, Michael! You have been very low-key in your own appraisal of your work, but I will say unequivocally that this is just so excellent and it is the most unique presentation of this model that I have ever seen. It begs the question: what can't Michael D do? I love the way you push yourself to do really difficult things like a full 17th C. rig with fairly flimsy styrene spars, and yet - everything is tensioned where it should be, slack where it should be, and there is ZERO spar deformation. All details in perfect scale. Just incredible!

It goes without saying that I'm looking forward to your next build.

-

9 hours ago, Ian_Grant said:

Electronics skills really aren't required; one simply plugs servos into receiver, plugs battery into receiver, powers up transmitter and receiver, and the entire RC set works. You only need to plug an ESC (Electronic Speed Controller) into a receiver servo slot, and connect the ESC to the motor, and your entire drive system works.

But it is a different "endeavour" from static building ........

You’re on a [d]roll today, Ian!

-

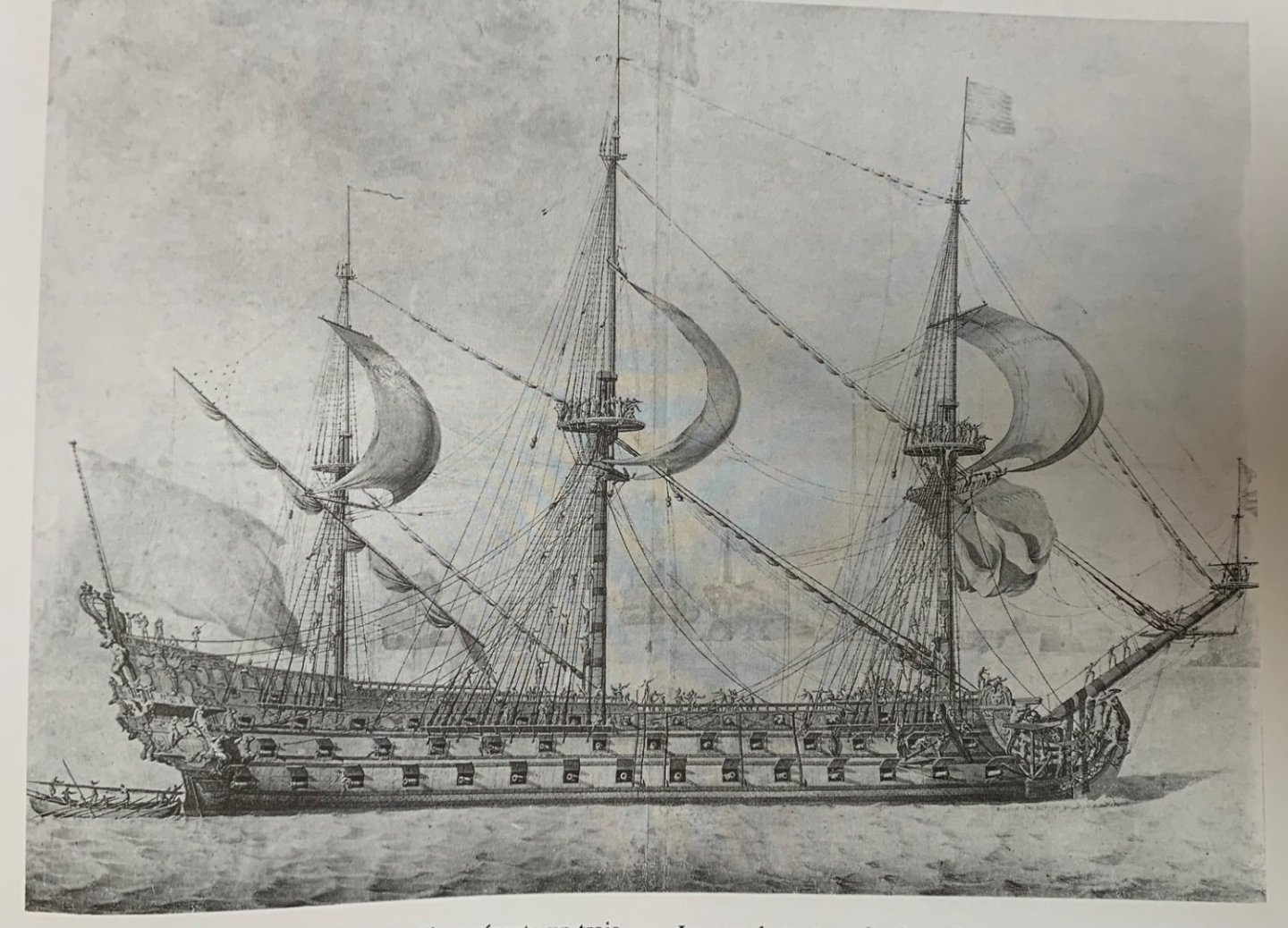

From what I can gather, from at least the mid-1680’s onward, the French were single-reefing main courses and double reefing topsails.

Here, evident on RL 1692:

The men loosing the fore course appear to be standing on foot-ropes, but the same are not discernible on the topsail yards.

Jean Boudriot shows reef points and foot ropes for his L’Ambiteaux of 1680. Lemineur shows reef points, foot-ropes and lower course bonnets for his St. Philippe of 1693:

Lastly, the Malaga Scroll (1704) representing SR 1693 shows reef points:

- Ian_Grant and GrandpaPhil

-

2

2

-

I am completely naïve on this subject myself, but I was always under the impression that Hide glue (ground up horse hooves, or so I believe), was a simple matter of adding the glue flakes to a melting pot and then they melt right in the pot.

You might want to research “furniture restoration/conservation techniques with animal glue,” as this is one arena where these glues are still in use.

-

-

I think the greatest value in sharing what we do here, is re-enforcing each, our own understanding of process and the many different ways to approach a problem. That is what I find personally satisfying in the hobby - the how - and the thing that I enjoy reading most in other people’s projects.

Before your Gustav lion, it would not necessarily have occurred to me to model the under-water degradation of the statue surface. Now, though, I find that a cool idea that I might incorporate into some future project.

Also, personally, I find that maintaining build-logs is a good motivator for actually getting the work done because I am simultaneously motivated to share the process as it unfolds.

-

I do not think representing the stun’sail booms is a necessity.

-

-

-

-

Simply incredible, Ian!

- mtaylor, Ian_Grant and Glen McGuire

-

2

2

-

1

1

-

I really like the darker frieze for all the reasons preciously mentioned. It’s good to mix things up from time to time.

- mtaylor and FrankWouts

-

2

2

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

in - Kit build logs for subjects built from 1501 - 1750

Posted

HitchHiker’s Guide?