-

Posts

5,885 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by lmagna

-

-

-

On 11/23/2021 at 11:24 PM, G.L. said:

What is the 'handle' on the right wheel?

I was thinking that possibly it was some kind of tension or friction brake on the helm to either cause drag in rough conditions and stop the helm from whipping about as easily or even locking it. But Pat's example seems more logical.

- FriedClams, KeithAug, mtaylor and 1 other

-

4

4

-

5 hours ago, king derelict said:

I have to caution that some viewer may find the gritty representation of WW1 trench life in the early part of the video to be unsettling

Oh the horror!

-

-

Much higher resolution parts Alan.

The better reliability and quality of parts should make this a much more rewarding build for you. For what it is worth I don't think the brass feed wheel was your fault. You have been having problems getting quality prints right from the start.

The better reliability and quality of parts should make this a much more rewarding build for you. For what it is worth I don't think the brass feed wheel was your fault. You have been having problems getting quality prints right from the start.

-

I have used "foam" board in a number of builds over the years.

I have built frames and keel out of both wood and plastic, (Different ships, not mixed) and filled in the spaces with sliced sections of foam like the build wefalck linked. When I used plastic I used a form of expanded PVC called "Sintra". It is in essence a light semi rigid PVC designed for and used by artist's. I find it much easier to use than standard polystyrene. https://www.amazon.com/sintra-board/s?k=sintra+board

I have also used thinner layers of foam and cut and glued them in layers in the traditional bread and butter technique. This method works quite well with a number of ship hull designs and can be much easier and less messy than the fill between bulkhead or frame method.

The last method I have used is the solid hull method and I personally consider it the hardest and messiest of the bunch. Just like using wood, this is comprised of using the thicker versions of rigid foam and cutting away everything that does not look like the ship you are trying to build. It can be done freelance if the hull design is easy or simple like a "Springer" tug or barge. More complex hulls would benefit from the use of templates just as any other solid hull model would. The biggest benefit of this type of construction is that the finished product makes an excellent male form for making fiberglass molds.

If you have a place to work with it and don't mind the mess and extra finishing required to finish the carved surfaces, or are going to plank over it then ridged foam is a great media. It requires very few tools to form and none of them need to be specialized.

- mtaylor, GrandpaPhil and Canute

-

3

3

-

I have always been an admirer of ridged airships, so any diorama with one would be a plus to me.

Why not buy two and build a hanger with the airship being pulled out by all of the antlike people? https://www.ebay.com/itm/294499193020?chn=ps&mkevt=1&mkcid=28 That would also show just how big these ships were without having to figure out how to make it look like it is flying over the ship.

-

-

7:43 and 12:45

Or you could go this route. No decals needed:

http://www.chinook-helicopter.com/history/aircraft/A_Models/65-07992/65-07992.html

- Canute, Egilman, popeye the sailor and 1 other

-

4

4

-

I agree with EG and Mark 100%. I have seen any number of choppers sitting at the end of the flight line getting slowly stripped to keep less damaged aircraft combat ready. For that matter we had a few now and then that looked like that when they were still on flight status! Mismatched doors and other covers were common. If it didn't involve keeping it in the air it didn't matter. sometimes "pretty' was only used when referring to the girls outside the parameter.

EG is also right, in that one of the first things to be commandeered after the avionics was the main blades! I say don't give up and to go for the diorama.

-

-

Welcome from Everett Dave.

- mtaylor, Ryland Craze and Keith Black

-

3

3

-

A very striking and impressive display and model. I hope you have found a very prominent location suitable to showing it off.

- modeller_masa, Egilman, Canute and 3 others

-

6

6

-

It is always enjoyable to be able to build a model with a personal connection.

Yours certainly came out nicely.

-

I think that in some circles it is referred to as Card Stock and normally refers to paper used for structural use rather than writing or printing.

- Edwardkenway, mtaylor, Egilman and 4 others

-

7

7

-

-

Your work on the Bismarck is looking fantastic HOF. Sorry to hear about the surgery.

I know they don't like doing Rotator Cuff surgery except as a last resort and recovery can take some time. Hopefully you will be back up and running soon.

My wife goes in for knee surgery next Friday, and she is in a complete panic!

Good luck, I'll be thinking of you.

-

-

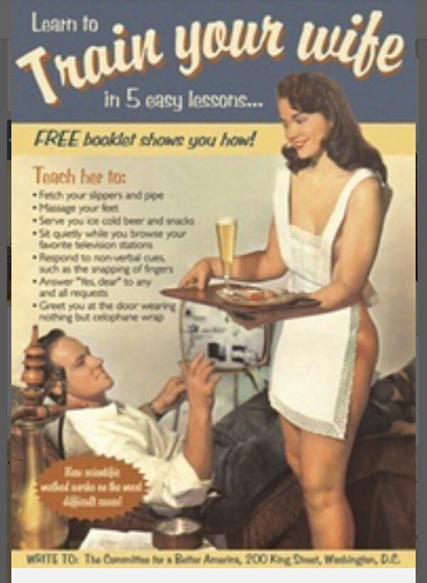

I thought that went, "Happy wife, HECTIC life!" I think I may have been doing it wrong for the last 40 years!

-

A real pleasure seeing your progress again Ken.

- KenW, mtaylor and Edwardkenway

-

3

3

-

1 hour ago, CDW said:

other more important chores

?????????????????????????? What can be more important than getting a chance to model your favorite latest subject?

- mtaylor, Canute and Old Collingwood

-

1

1

-

2

2

-

10 hours ago, Egilman said:

What you want for a mirror shiny finish over paint is diamond finish,

Sounds like what I would want if I decided to take down one of my stash of 60s racing sports cars and build it.

- Canute, Egilman, Old Collingwood and 2 others

-

5

5

-

Another review gauged toward the UK user.

- shipman, popeye the sailor, Egilman and 2 others

-

5

5

-

It seems to match in the description, but also seems to be rebottled and renamed in smaller containers and priced ten times higher.

The stuff I have/use is a household size bottle that when I bought it still said 'Future' on it. It has been through many label changes over the years, but is appears that SC Johnson has settled on 'Pledge' as the name. They keep saying that the contents have not changed only the label. I think the current US label looks like this:

But it could also be This

One of the most aggravating aspects of the product is the constant label changing! It was so bad that a guy named Matt Swan wrote an article, "The

Complete Future" that covered the many names of the product, including the names used in other countries. If memory serves the UK name was "Klear" or something like that. It was a great article but seems to be missing these days. There are those who feel that the days of 'Future' are in the past and that there are better purpose designed hobby products available to the hobbyist these days, your product may be one of them. But dated or not I still use the original stuff partly because it works and partly because it is hard to beat $10 or less per gallon in anything that is usable in model making.

It is not the in depth original article but I was able to find this: http://www.arcair.com/tnt1/001-100/TNT096-Future-Swan/00.shtm

led

- popeye the sailor, Canute, Egilman and 1 other

-

4

4

British WW1 Whippet tank by king derelict - FINISHED - Emhar - 1/72 - PLASTIC

in Non-ship/categorised builds

Posted · Edited by lmagna

Very nicely done Alan.

I do have one question though. I thought that the flat panel to the right of the forward gun was the drivers viewport. Wouldn't that be clear? Or did they have a steel cover that could be dropped into place and just used the tiny gun viewing slits for navigation?