-

Posts

359 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Dowmer

-

-

Thanks Bill for the Update.

By the way, I too am in Chantilly. 😀

- Canute, Ryland Craze, mtaylor and 1 other

-

4

4

-

Bill, any updates? Whatever happened to this build?

- Ryland Craze and Canute

-

2

2

-

9 hours ago, Fernando E said:

Saying the above I plan to do the HM Endeavour next and I'm not sure whether to get the Occre Kit or the Caldercraft Kit

Based on the survey done for kit quality on this site under the kit forum I'd say Caldercraft quality wins hands down for quality. There are several builds on this site you can check as well.

- lmagna and Fernando E

-

2

2

-

Dave, thanks for dropping in to my thread.

I’m glad you appreciate the nuances of the PNW longboat from the standard kit. 👍

- lmagna, paulsutcliffe and mtaylor

-

3

3

-

-

Thanks Lou, great to hear from you. This little project was something to wet my appetite to get back into ship building. It did its job. 😀 I'm really enjoying it.

The best part is learning all the different and new techniques on this website. Over course the motivation aspect of seeing all the incredible work by the masters here help as well. I wish I had this resource when I started 30 years ago. It would have prevented a lot of head scratching. 😟

-

-

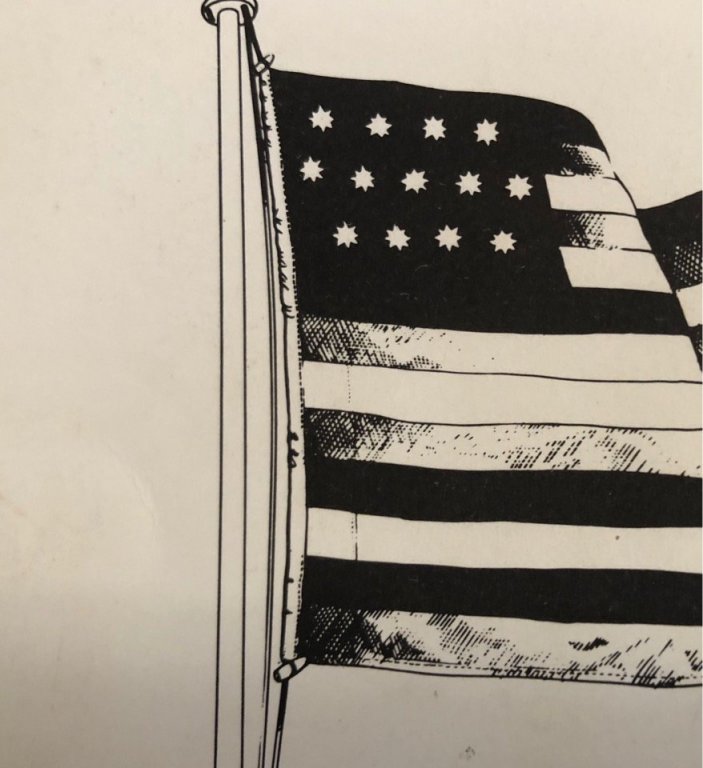

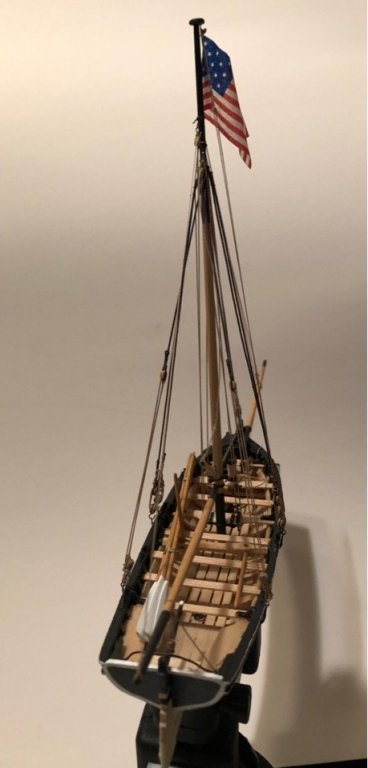

So I needed a flag but I needed to figure out how they attached the flag to the halyard. After a lot of searching around I referred to an old Jean Boudriot book and found a depiction of one in his book of the BonHomme Richard.

Im assuming this is how they typically secured them and it makes sense.

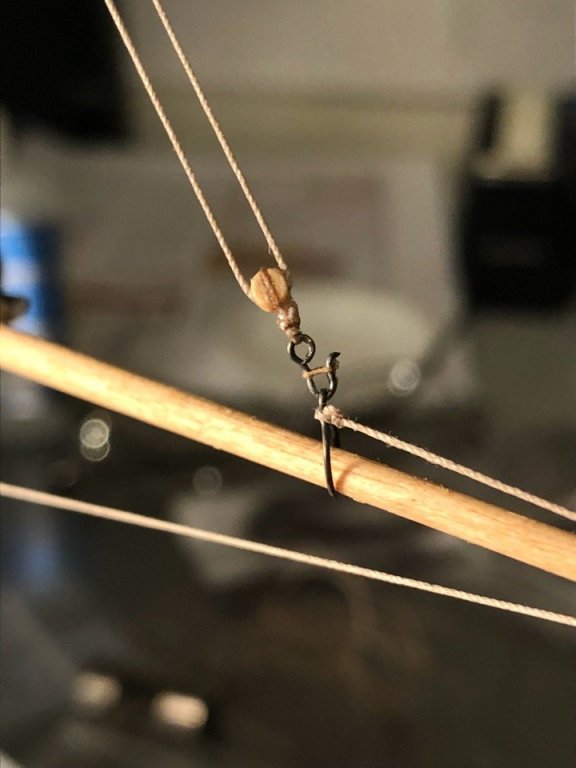

The period is correct so I gave it a try. The hardest thing to make was the toggles. At this scale they were about a mere 1.5mm. I turned down a piece of hardwood and wrapped the .008 rigging line around it. The Hoist of the flag (the vertical part) was left white and folded over the line and glued with thinned white glue.

The flag was made using Chuck’s method of tissue paper. Here’s a link to his thread for the Cheerful. Cheerful Link

I chose a 13 star flag representative of the era circa 1790. I used some some tissue paper the wife had squirreled away for Christmas. Cut a small piece and taped it onto a sheet of 8x11.5 office paper. This acted as a carrier to feed the tissue through the printer. Printed the flag then cut it to shape and sprayed some Krylon fixative. After gluing in the toggles I sprayed some more fixative on the flag to soften it and shaped it. Viola La!

I attached the halyards and hoisted the flag to the truck. Secured to the starboard deadeye. Here’s some pictures of the finished product. Making and attaching the toggles was fiddly but worth it in the end.

Next up is to make some rope coils and hang them on the boat and I’m done.

Cheers landlubbers 😁

-

Chuck,

I'm playing around with the flag technique you detailed earlier (see below). It works amazingly well BTW. 👍

My question is, how did they (18th century) attach the flag to the halyard...or how did you attach it to the Cheerful? Toggles?

Thanks for the great tips,

On 4/24/2017 at 5:46 PM, Chuck said:Anyway here are the photos. The flag is just a test and I am living with it for now as I try new things. I like it but I dont know how much. Its printed on tissue paper for wrapping gifts with my inkjet. Then its sprayed thoroughly with flat clear fixative. It is soaked pretty good and molded before it completely dries. This stiff may be too thin though...but lets see what others think once they see it in person. It does shape nicely with various size paint brush handles.

- paulsutcliffe, lmagna, archjofo and 3 others

-

6

6

-

-

B.E. a wise and sensible choice me thinks. I would have come to a similar conclusion. Nicely done. 😁

- Blue Ensign, Martin W and Ryland Craze

-

3

3

-

-

-

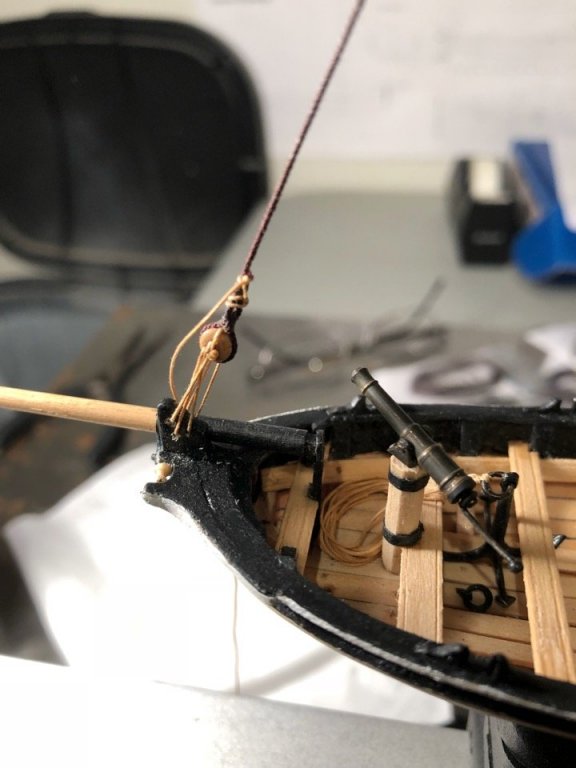

Thanks Lou for dropping in. It’s always nice to hear from you.

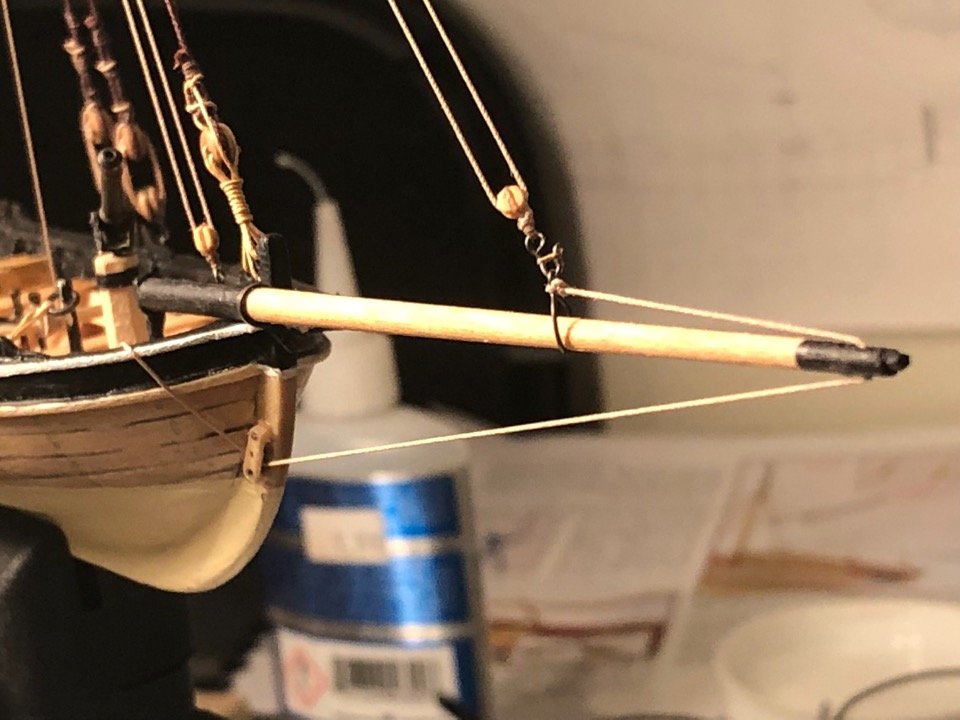

I decided to rig the bowsprit and traveler. I made the traveler out of wire provided in the kit and attached the jib halyard with the small single block and hook. At this scale the hook is tiny, but I was able to mouse the end of the hook to keep it secure as it would have been done. I know, I have a sickness. 😃

The outhaul was rigged and passed through the sheeve on the end of the bowsprit then through the block on the stem and up into the bow to be secured to the forward thwart with the support knees. With the outhaul acting like a bobstay the bowsprit is surprisingly steady.

On to the boom and gaff after the holiday weekend.

-

Thanks Chuck, that will be a good compare contrast.

I incorporated some of the changes you added to your 1:24 version to my current build of the 1:48 version....unwittingly of course. I guess great minds think alike. 😀 The hull shape is what it is, so I kept that or I would have built the hull from scratch. My build link is in my signature line. It isn’t the quality of your build, but then again, few are. 😉

cheers

-

Looks great Chuck. I like the more full and round bow and stem as opposed to the smaller 1:48 version. The increased sheer is also a nice touch.

- EJ_L, lmagna, thibaultron and 3 others

-

6

6

-

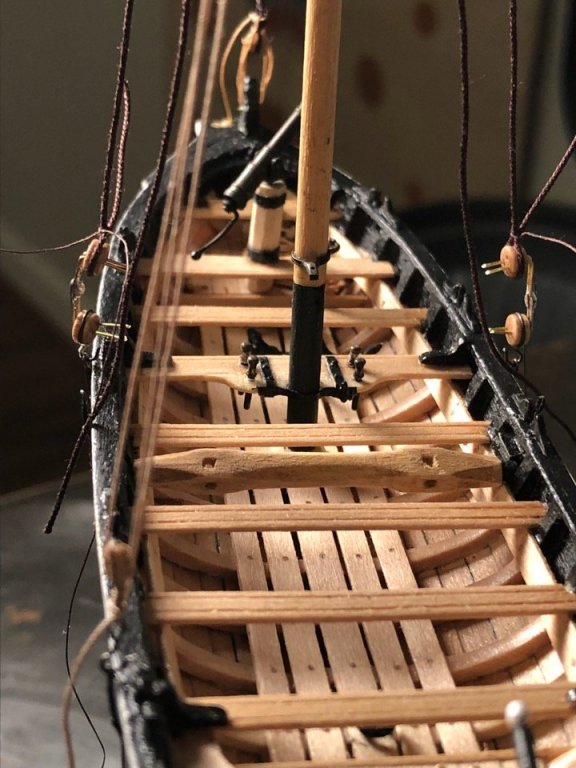

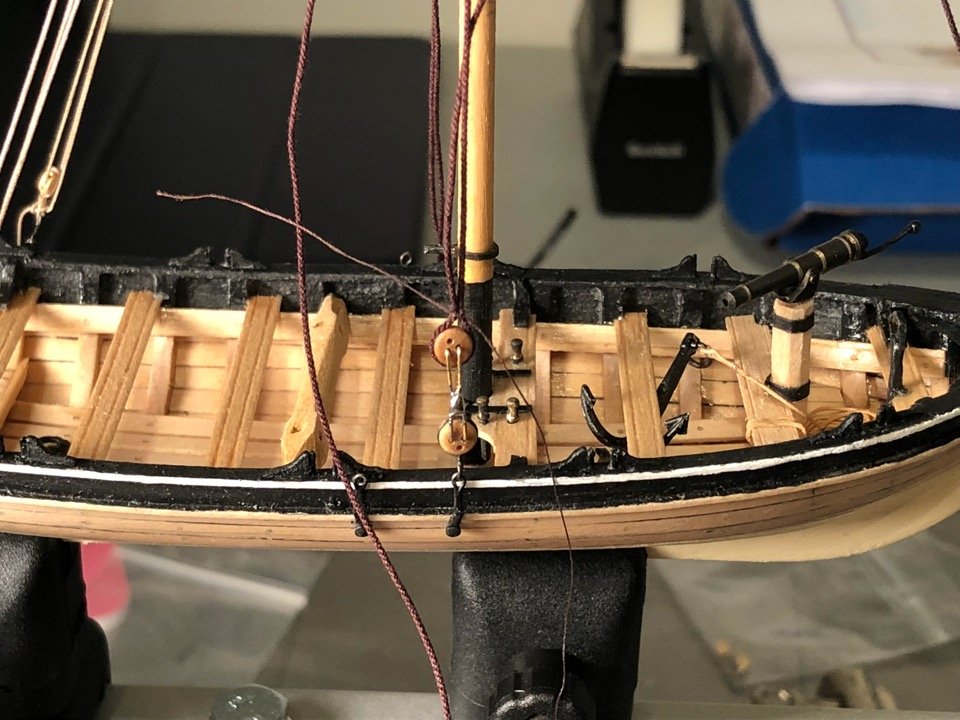

Standing rigging done today. 😀 On to the running rigging. This is such a small boat, the running rigging won’t take long.

View from the bow. You can easily see the block on the stem for the outhaul and the grapnel and swivel behind the forward stay.

View looking forward. You can see the backstays tied off and the rigging lashed to the block and hook. This was shown on the NMM Model and makes sense so I copied it.

Port side view

Starboard side view

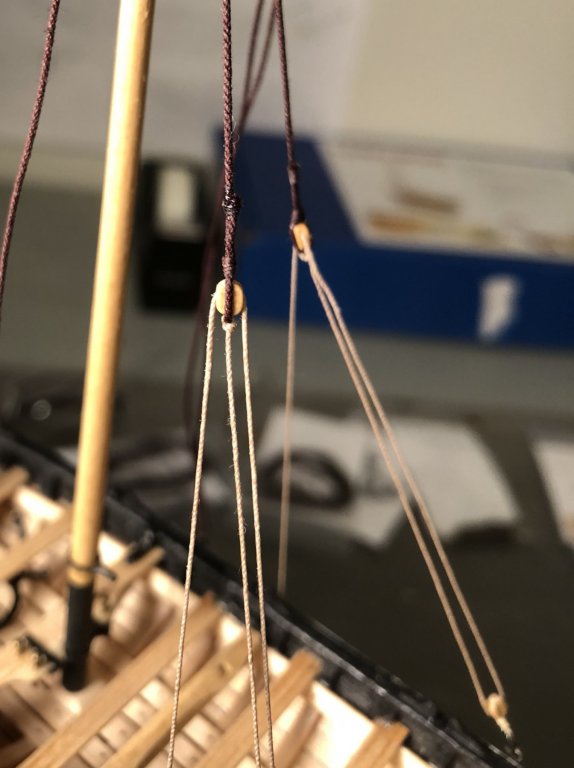

Standing rigging at the mast hounds

Overall view. Now time to finish it up. Boom and gaff next with the jib halyard on the bowsprit.

-

Excellent job BE! I like the careful and methodical false deck installation. Preparation and planning makes all the difference.

- lmagna, Martin W, Seventynet and 1 other

-

4

4

-

-

To give everyone an idea of how Alaskan Cedar ages, the below pic is of a ship I started in 2001. I then put it away in 2003 in a box. No sunlight on it, but it does have a light coat of Tung oil. You can see it has aged to a soft golden yellow. Very pleasing.

The rest of the wood is ebony and holly.

Let’s just say the ship has “weathered in frame” as they used to do. It’s about time it made it back to the lumberyard and onto the shipways to get finished. 😊

- Landlubber Mike, lmagna, Canute and 12 others

-

15

15

-

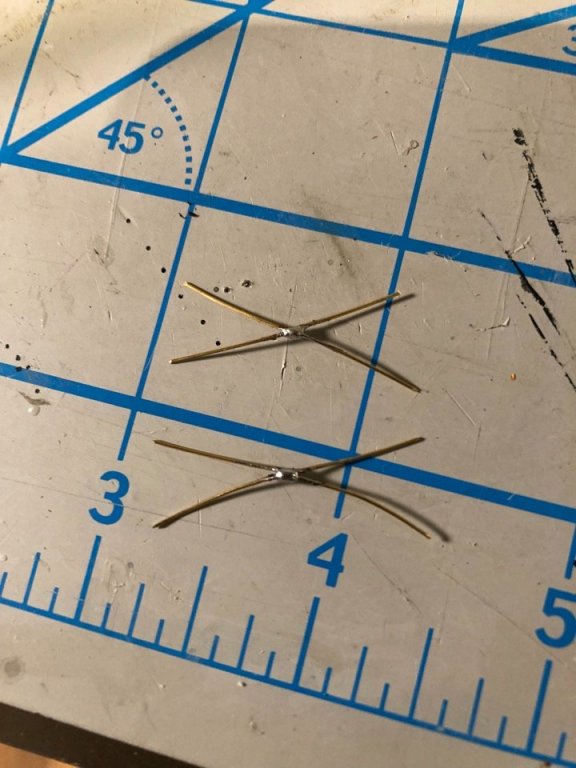

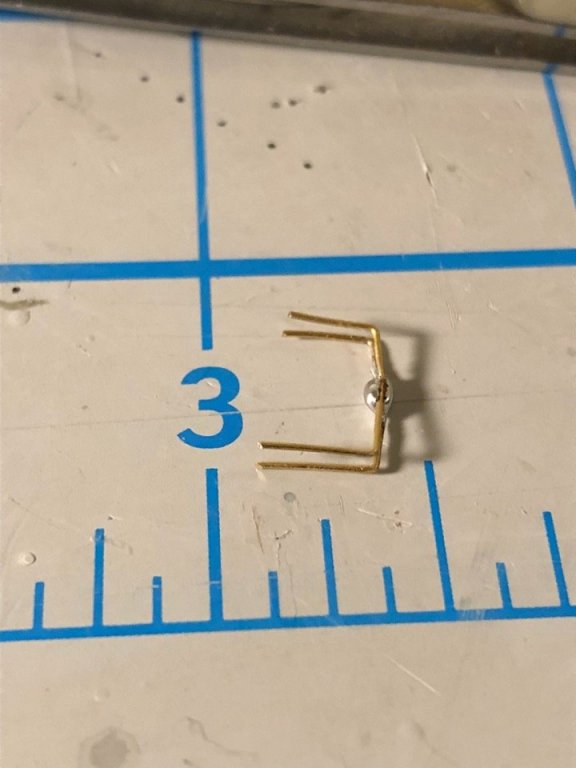

A bit of an update. Deadeyes seized on the port side and starboard side forward. One more to go. 😃 I made a convenient jig to hold the deadeyes in place. I know this has been covered in other threads before but for those that haven’t seen it I show what I did.

I used some 26 gage wire that just fit in the holes of the deadeye and cut some short pieces about 1.5 inches long. Then put about a 30-45 degree bent in the middle. The amount isn’t important but it should be enough to separate the ends when you put the two together. I then soldered them together. See pic.

Next I straightened them out and wrapped them around two small nails the distance I wanted between the deadeyes.

This created the holding jig. I only made two, one for each side, but you could easily make more. It only took t minutes to make them.

A pic showing them in action. Very convenient.

A few more

Then time to rove the lanyards. There are some good discriptions on how to set up the deadeyes in contemporary works. One of them is “The young Sea officers sheet anchor” by Darcy Lever. As the shroud cables cross each other and are seized at the top of the deadeye at the top, the short end should lay on the aft side port and the forward side starboard. The stopped knot of the lanyard will be placed on the opposite side and reeve though the deadeyes and lashed to the shroud above.

The pic below is not finished on the starboard side. The lanyard is only tight to check the tension and spacing. But you can see the bottom deadeye hooked to the chainplate. These extreme closeups are very unforgiving. 😥

I also drilled another hole in the stem for the stay lanyard. After close inspection of the NMM model I noticed there are three holes, not two. Lanyard set up and seized to the stay.

A couple of other spare pics for setting up the deadeyes.

Enough for now. Enjoy.

-

Thanks Lou, I appreciate your kind comments.

32 minutes ago, lmagna said:One thing you may have forgotten in your original description though is that sometimes the trading ships carried their smaller boats as lumber in the hold, not assembling them until they reached the PNW.

You are correct, but these generally were not longboats, but larger sloops or schooners around 40 tons that they carried as frames in the hold. The Columbia carried the Adventure in her hold and it was assembled South of Nootka Sound, B.C during the winter of 1788. The first ship built on the PNW coast. All the other timber was sawn on site by their carpenter. Wow, what a job that must have been! 🤪

-

Nice job Lou,

i think one of the reasons edge bending becomes too difficult is when the planking is thicker than 1/32”. I seem to remember Chuck saying that he typically uses stock that is about that thickness. Much thicker than that or more than 1/16” gets real difficult. It’s better to spile then I believe.

-

I forgot to mention for the rigging line and blocks I’m using parts from Syren Ship Model Company. The stuff provided by Model Shipways in this kit are about the cheapest, crappiest stuff I’ve seen. Definitely low grade nylon rigging line. So it helps to upgrade these or make them yourself for a much better look.

Heres a pic of Syren upgrade items.

- Jim Rogers, lmagna, billocrates and 4 others

-

7

7

Cutting Planks

in Building, Framing, Planking and plating a ships hull and deck

Posted

Shawn, if you are talking about the short pieces between the gun ports, I cut them slightly long, then install them on the ship. The plank will protrude into the gunport slightly. Once all the planks are installed for that side of the port, I then use a small fine file. With careful strokes I file it flush being sure to keep the file 90 degrees to the side. Depending on the size I can also use a very sharp xacto blade or scalpel to trim if needed until the blade is held flush against the side of the gunport frame. I hope that makes sense?