-

Posts

629 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Matt D

-

I’ve been working on the upper planking on the starboard side. I’ve had to back up and fix this a couple of times. It’s not perfect by any means, but I think it will look fine with the frieze over it. I just discovered that I did not fair the stern quite enough. I’ve tried just sanding it down, but I’m not sure it’s enough. Luckily, I haven’t gotten up that high on the port side, so I still have time to fair it more before planking. If I understand the rest of the construction, the difference will be completely hidden.

-

This is going to look amazing, Ben! Chuck, I’m really looking forward to the cross section project!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The high level of detail you’re creating is incredible. She’s a beaut!

- 222 replies

-

- sultana

- model shipways

-

(and 1 more)

Tagged with:

-

It’s looking excellent! This looks like a really nice kit.

- 171 replies

-

- artesania latina

- bounty

-

(and 1 more)

Tagged with:

-

Chuck, I just stumbled across this today. Is this still a project in the pipeline? Will this someday be available in your store? I’m asking because I’d really like to do a nice quality cross section some day and a Syren semi-kit would definitely be my first choice.

- 130 replies

-

That looks great, Peter. With your deck weathered to match the real thing, I had to look twice to tell which pic was the model and which was the 1:1 ship!

- 222 replies

-

- sultana

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you for the extra details, Rusty.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Rusty, thank you very much for showing how you fixed this. I imagine others will run into the same problem. Could you please edit your photo with a circle or arrow highlighting your fix to help the remedial students such as myself? I can see the effect of your fix, but I can’t see where you put it. Thanks. It looks great!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

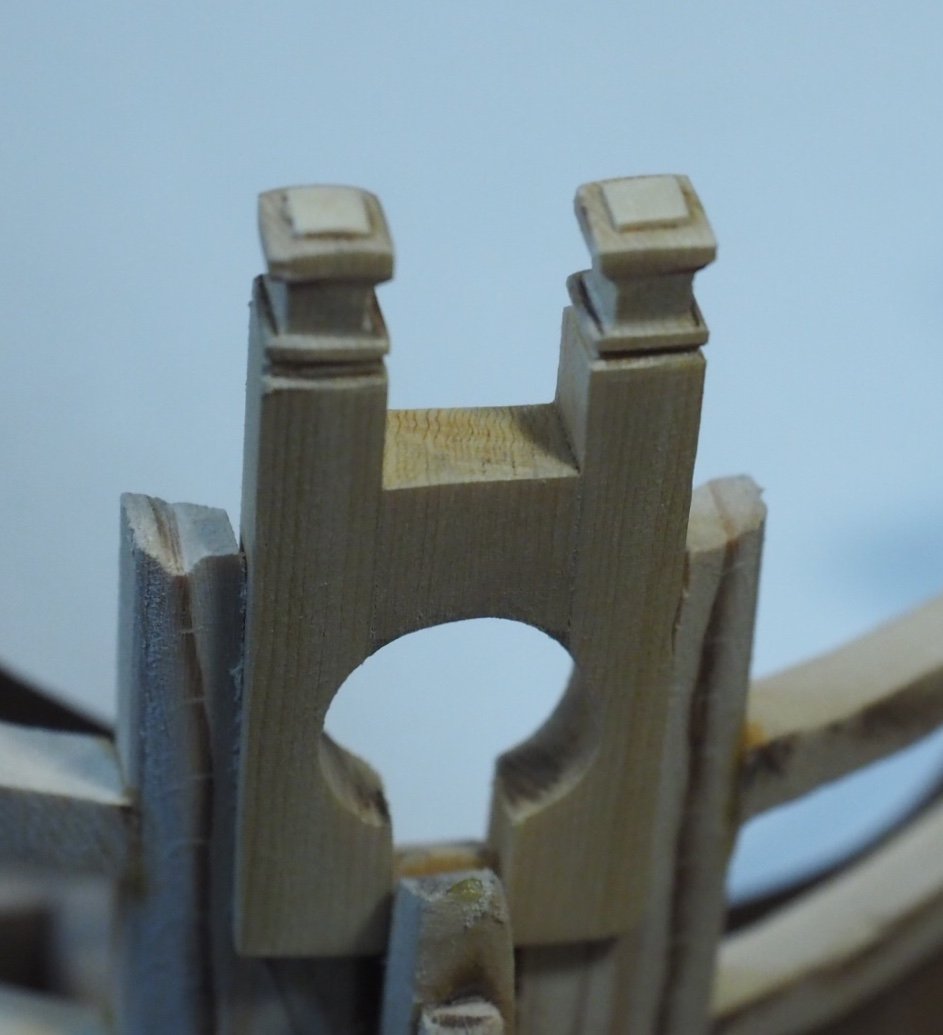

Bollards: Chuck, thank you for including extras of the bollard blanks - I used all of them to come up with a passable pair. I wasted the first three by trying to use sandpaper over a rounded edge to carve out the larger grooves. Then I figured out that I should try to make them more squared using jeweler’s files. That worked much better. I like Rusty’s idea of not gluing them onto the model until I have to. I’d hate to break them after all the work it took to make them. edit: I noticed after posting my pictures that the bollards were sitting high compared to Chuck’s. So I took some measurements and lowered them to the right location.

-

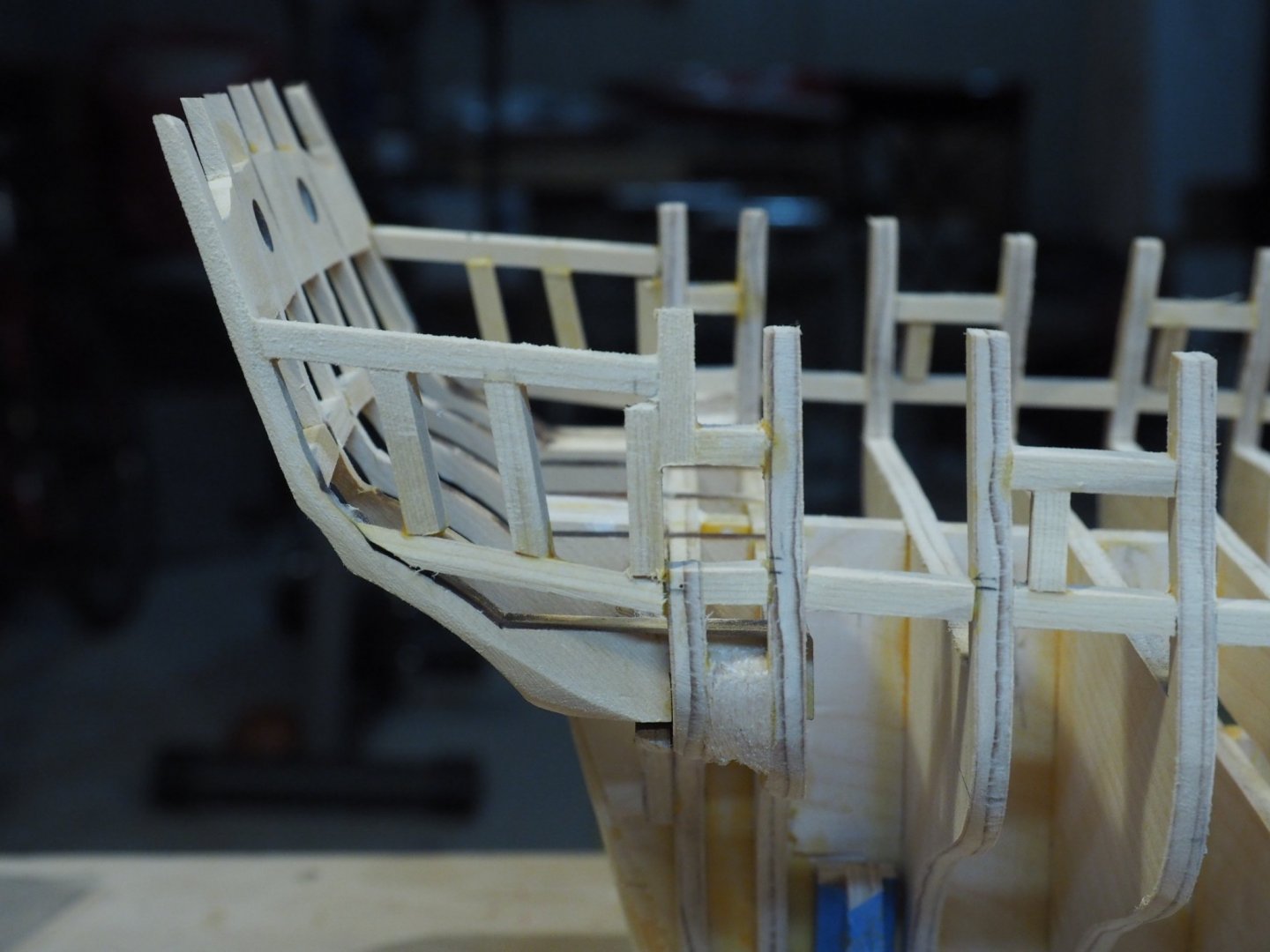

I’ve made some progress on the stern. I’m not quite sure how to use the other two stern filler pieces. It looks like they should go on the bottom of the stern frames horizontally. But I haven’t quite figured out how they fit. Do they need to be sanded a lot? I was thinking about using the stern planks to guide me a bit. In case you noticed, I changed the white balance on my camera from “auto” to “incandescent”. My shop lighting is mostly soft white LED fixtures. This still isn’t quite right, so I’m going to try using the custom white balance setting. But I need to read up on it a bit first.

-

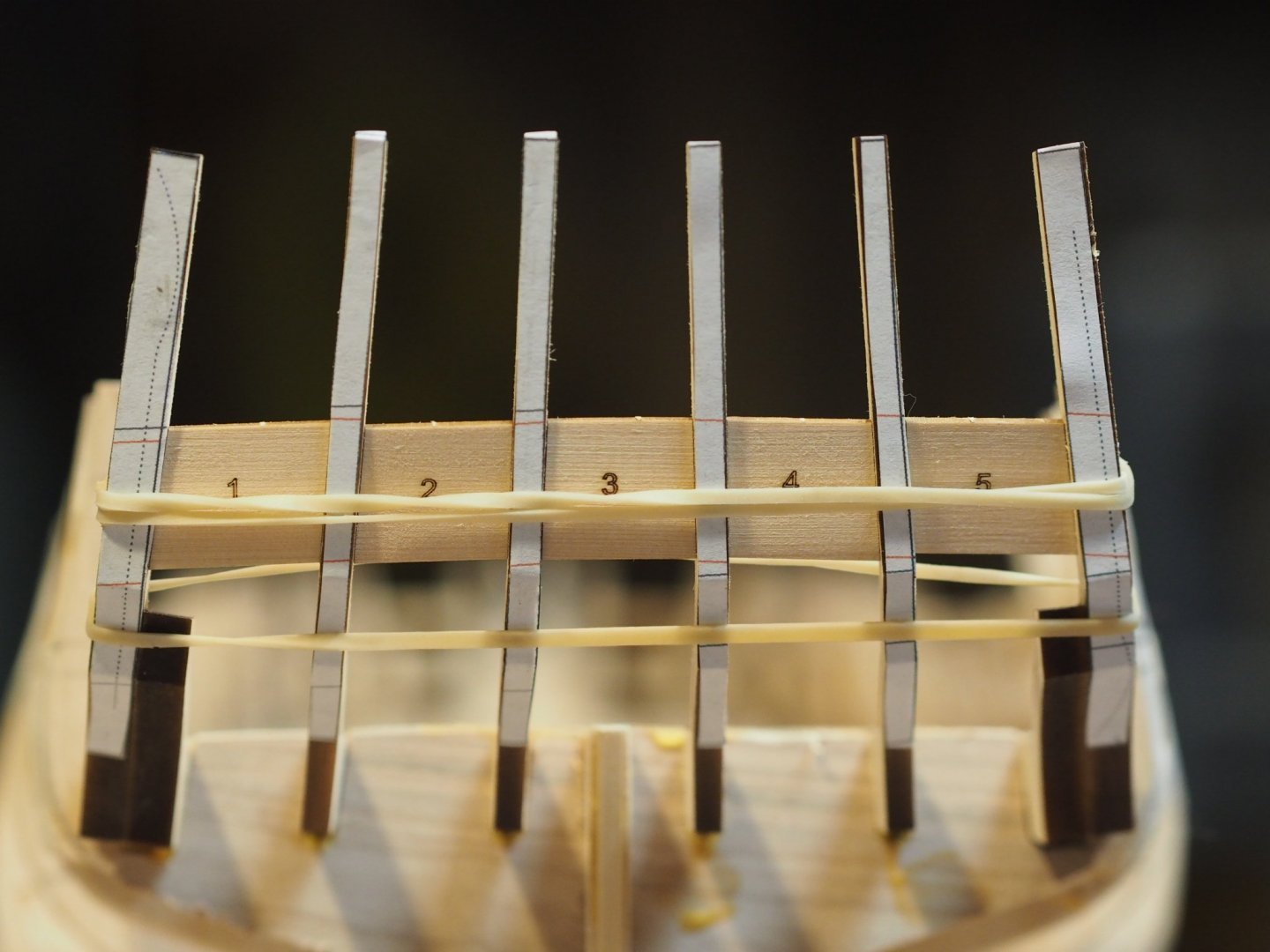

It was a beautiful day here in southeast Michigan today: 50 degrees and sunny with just a little more breeze than I would have liked. So I pulled my table saw out of the garage and milled my chapter 2 lumber. My saw is a Jet 10” contractor grade saw with a pretty good blade, but a crappy fence. So I used a piece of 3/4” birch plywood to make a false deck that I clamped on top of it and screwed a 1/4” thick piece of basswood onto that to use as a fence. That gave me good results. Unfortunately, my blade kerf is thicker than a band saw blade. Thirteen 1/4” billets yielded about 150 planks. So I’m sure I’ll be short. I’ll wait to order more until I get an idea of how short I’ll be. I’m very happy with my results. I made a ton of pieces today and kept all of my blood inside me. Table saws are very unforgiving, so I took my time and did it very carefully.

-

It looks like you're off to a great start! That Santa is a great guy, bringing you an airbrush! I'm sure you can find good help on using it in this site. You'll probably get some good replies, but you might dig up more with the search tool.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

That cherry looks fabulous!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck, thank you for putting in the effort to show this several ways. My favorite is the natural wood shingles withe the top painted to match the frieze.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks amazing, Chuck.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great, Doug. Does that mean the deadeyes will snap into the eyebolts?

- 79 replies

-

- marisstella

- barque

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)