mikegr

-

Posts

587 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by mikegr

-

-

-

I am looking for thin but durable wood sheets to make some parts like longer main decks etc. I found only one supplier selling quality wood like lime, walnut, birch Air plywood from 0.4mm thick. But he's somewhat far. So at the moment only balsa is quite available around. While its easy to work with it is sometimes too fragile especially if less than 1.5 mm thick.

-

What is the best way to harden wood? Let's say balsa 1-1.5 mm. CA glue? Epoxy? Polyester?

-

-

- mtaylor, Duanelaker, thibaultron and 10 others

-

13

13

-

8 hours ago, RN77 said:

Hi mikegr

Yes I have some sheets of balsa that I am cutting into strips, this should give a smoother hull once sanded

than if I used mdf. (Out to the shed at the weekend to start gluing)

When sanding mdf I think the fibres separate leaving a “fluffy” surface.

As for this particular model being suitable for a beginner, I am building in stages so if I make a pigs ear of it I can try that section again as I have copied the templates.

I most certainly could not build this model out of card using the original parts, as I would only get one shot at getting it right. My lack of skills, patience and heavy handedness would soon see it in the waste paper basket.Thanks for looking

I am building my first project from a card model to wood and there are some things to be considered for a successful make.

Spare plans is a must. I already ruined a complete hull(for other reason) so i restart now.

One key factor is to adjust thickness of wood accordingly. For example if you use a 3 mm wood for deck you need to calculate this to the total hull height (as paper deck has almost 0 thickness). Otherwise you need to use thin woods. There are quite thin and strong woods to work with starting at just 0.4 mm. However they are not available in many countries and the cost is considerable. Balsa below 1.5mm thick is very fragile unless you harden it with chemicals, like resin or other.

- Canute, mtaylor and Keith Black

-

3

3

-

-

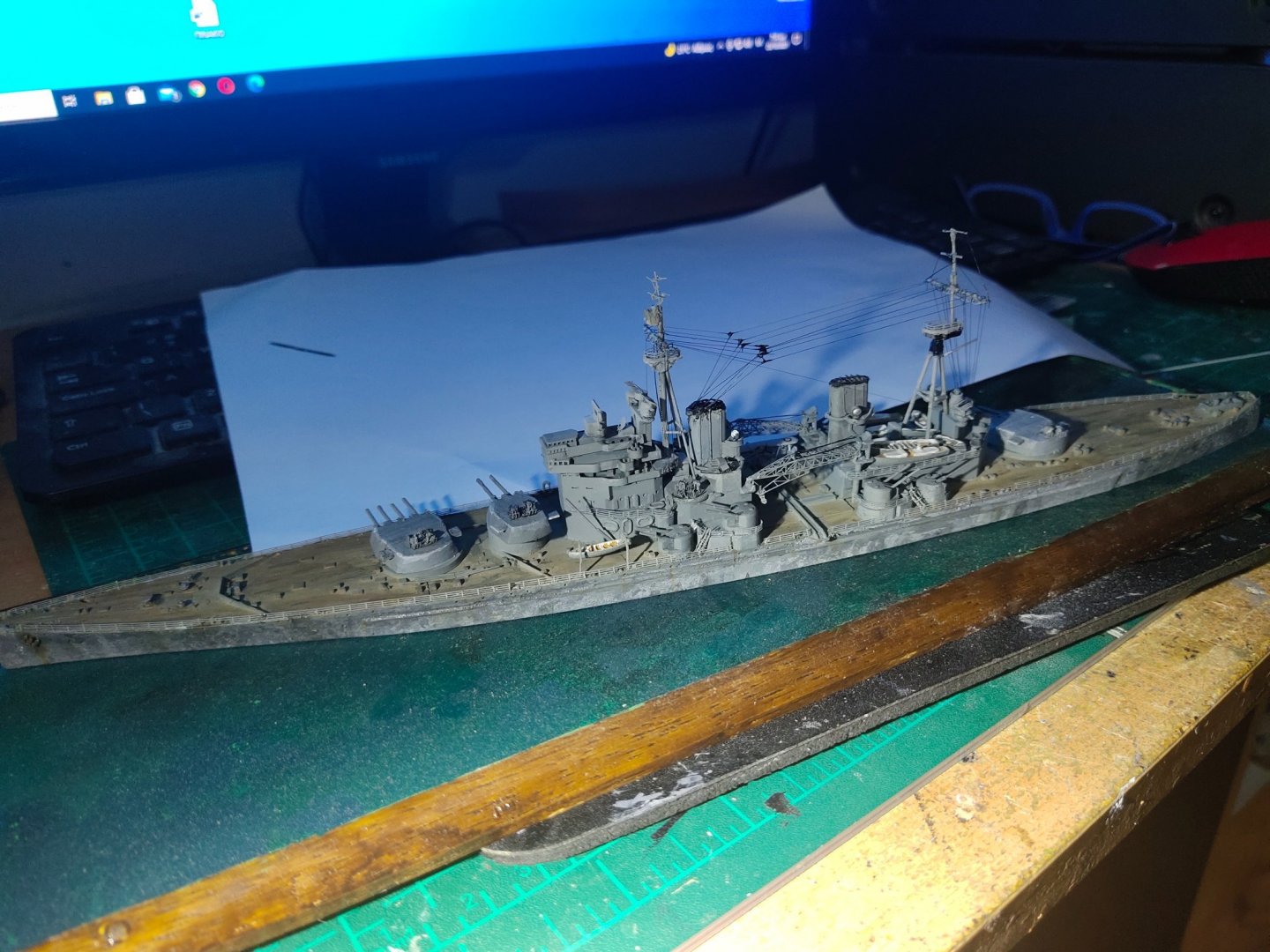

Japanese WW2 ships are unbeatable in details if you can handle them.

Competition in 1/700 has lead the companies to offer products almost identical to 1/350 scale. This is very welcomed for us. Of course this has lead to some overscale like rivets and porthole frames. But at the end, its up to the builder. It is a hobby for personal recreation and he is the one who needs to feel comfortable with the outcome.

-

nice clean work. Hull looks not easy for a beginner. I suggest you work with balsa than MDF for plating the hull as the latter has some issues with humidity and need some special treatment. Balsa is the no1 alternative for us that our modelling wood market is restricted.

- Keith Black and Canute

-

2

2

-

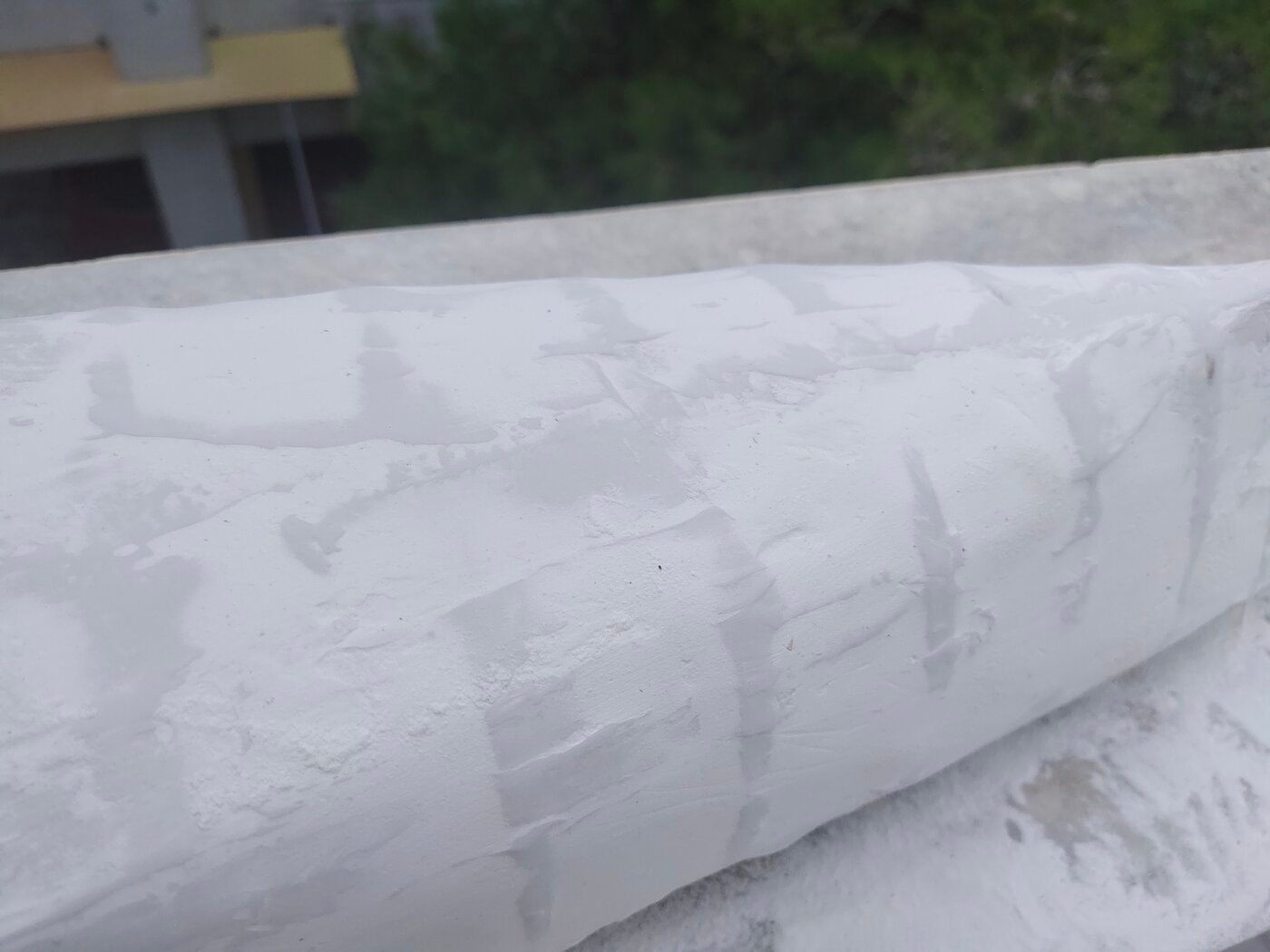

I was thinking to cover the hull with thin aluminum 0.20 mm stripes then use automotive filler. This would reduce the sanding and shaping hull time.

As i started the process i decide either to enlarge the metal pieces to reduce work load or skip it at all and go straight to smooth the hull using car body filler, sanding and repeat the process unit I get the desired effect. Which I did. It would be proved a disastrous decision.

Even hull didn't have any great imperfections, it took around half kilo of filler to cover it all. Then after a few minutes the hull area between frames collapsed. I have seen this happen on another project while using rubber adhesive glue. Probably catalyst heated polystyrene and forced it to shrink. I added locally some acrylic putty to fill the gaps. Even it was easy to work with, body filler on the other hand is not. So working with hard and soft ingredient at the same time is not an option. Another layer of car body filler will do the job although this would require lots of extra sanding effort plus will increase even more the weight of the hull.

-

-

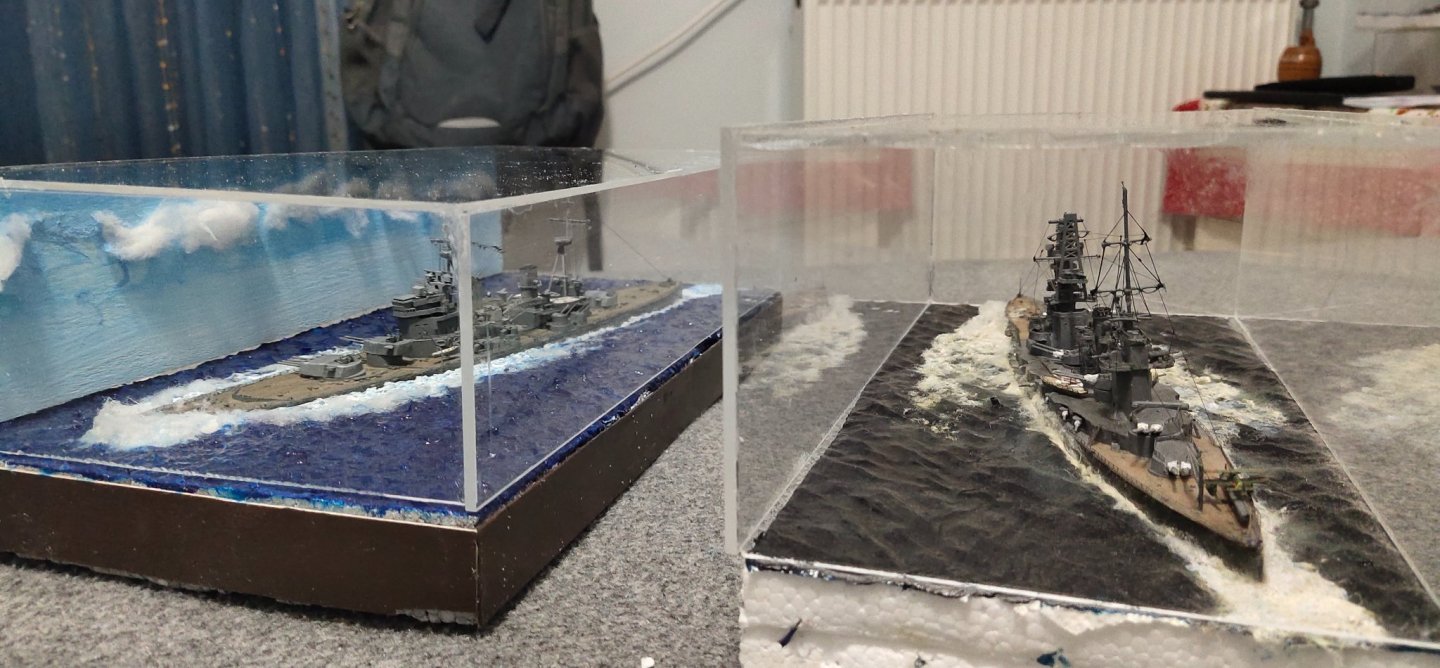

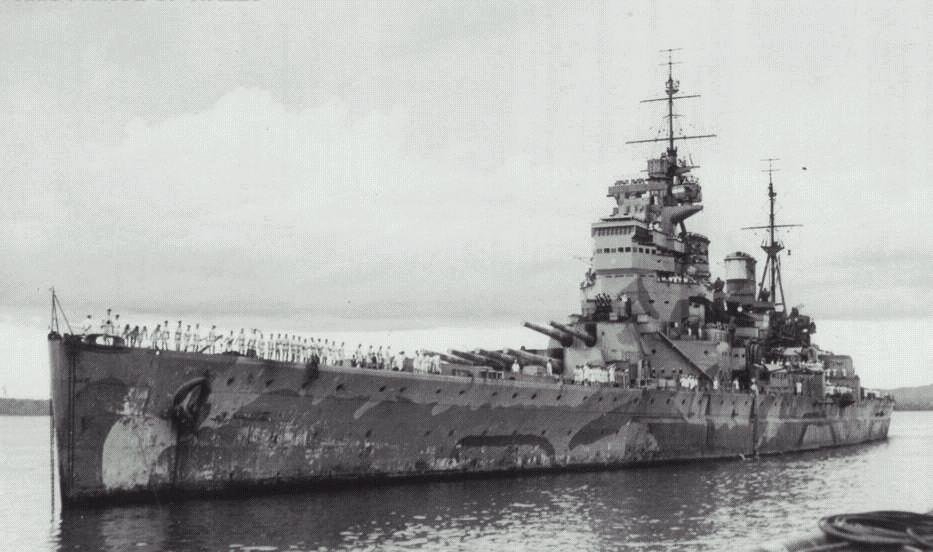

Done. POW training her turrets during heavy swell.

Not the thick rigging from rear mast top to stern. I put it here temporary to correct the mast top forward inclination cause by elastic rigging. Lessons learned:

1. Always control its tension when use elastic rigging with fragile masts.

2. Best CA glue simply can't compete with soldering in strength if you want to make brass mast.

- CDW, Baker, Bob Fraser and 7 others

-

10

10

-

I think the lower rope on the first pic is a bit more realistic.

-

8 hours ago, king derelict said:

Mike

It looks great. The details are beautiful.

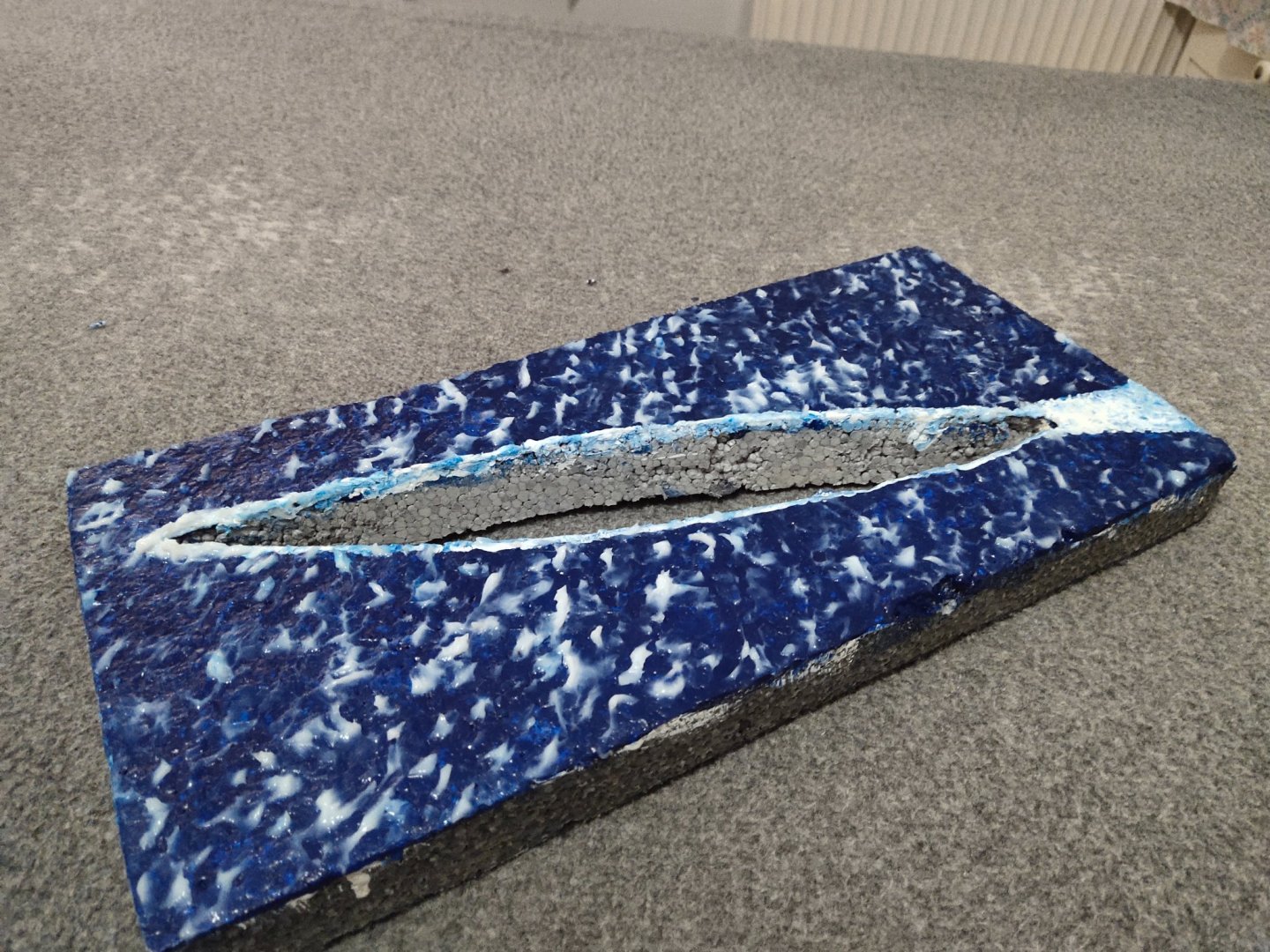

I like the 1 inch thick extruded foam. Extruded foam is a bit .more rigid than expanded foam and doesn't disintegrate into beads when you attempt to cut it. It cuts nicely with a hot foam cutter or a sharp knife (including kitchen knives - don't ask me how I know). You can buy it in one foot squares at Home Depot at a $1 each. Currently it seems to be light green.

Alan

in fact the thinner the blade, the easier the foam cut.

-

- thibaultron, Bob Fraser, lmagna and 6 others

-

9

9

-

- CDW, Old Collingwood, Canute and 1 other

-

4

4

-

-

- Old Collingwood, Baker, thibaultron and 5 others

-

8

8

-

Looks like Bismarck in big scales is a very popular model.

- mtaylor, popeye the sailor, Canute and 1 other

-

4

4

-

how does this react to plexiglass? Does it keep it clear or make it whitish?

Professionals are using a chloroform based glue which keeps the plastic 100% transparent. But this is extremely hard to be found and usually comes to 1 kg bottle sold for 60-80 euros.

- Canute, Old Collingwood and mtaylor

-

3

3

-

On 10/18/2021 at 2:56 AM, CDW said:

1:700 scale is getting exponentially better. I guess most everyone needs more display space. I know I do, so 1:700 is so much more practical for me.

Nowadays kits in 1:700 are so advanced that can be almost comparable in details to their biggest cousins.

- mtaylor, king derelict, CDW and 3 others

-

6

6

-

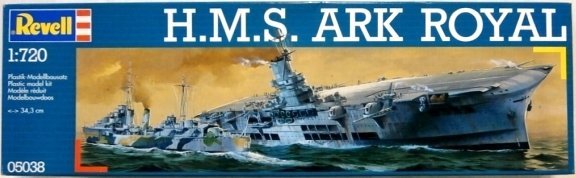

I remember this kit at 90's

There was a toy store on my way to school had it along with Matchbox Seasprite as well as few other kits. Price was approx 10$.

Finally I built it in 1/600. I have to say those double hangars made the ship look too tall. Definitely not the most handsome model, at least in my eyes. Maybe in waterline version looks better.

- Old Collingwood, mtaylor, Canute and 1 other

-

4

4

-

- mtaylor, thibaultron, Tom E and 4 others

-

7

7

-

what glue did you use for the case?

- mtaylor, Old Collingwood and Canute

-

3

3

Wood hardening.

in Wood discussion...Where to use it? Where to get it? What types are best? How to Finish it?

Posted

I am based in Greece. Best access to wood is from North Europe, mostly Germany. Shipping though can be prohibited because of their size and the recently increased rates.

Note that i work on modern ships so "quality wood" appearance is not an issue for me. In contrast, i have to convert all wood texture to a totally smooth surface before paint. I also avoid to use styrene for large surface parts, i prefer wood.

From my theoritical research one way to reinforce big and thin surfaces is by adding cloth and polyester at the back side of them, of course i need to experiment as i haven't use resin/liquid polyester before