-

Posts

7,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Hello Lawrence, thanks for dropping in and catching up, I`m glad you like it. In the moment there are some lines for which I`m trying out the best functional rigging solution, also I ran out of blocks, but order is placed with Chuck`s shop already. Nils

-

Many thanks to Crackers, Bob (Rafine), and Pete48, and all the likes, Crackers, nice words, much appreciated Bob, (Rafine) I`m glad you like it, many thanks Pete48 thank you very much, a nice comment... Nils

-

Hello Karl, hav`nt heard from your side quite some time, but what you present in your update is highest notch of masterly shipwright work. Am very impressed, it looks like the actual thing. I love the character of natural wooden surfaces, the wood speaks for itself, and your finish is fantastic..... Nils

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Many thanks for your nice appreciatians and comments to Patrick, Carl, Boyd, Popeye, and all the recent likes...... Patrick, yes, I guess its turning in on the final run, I`ll have to order some more blocks though.... Carl, you`re not alone with the feeling that the ship is larger, but please be assured its strictly scale 1:64, and sowith not larger that the kit based models here at MSW Boyd, before I began, I once saw a model of the "Bounty", partialy unplanked with view into the ship. The fact that the model was carrying a full set of sails impressed me so much, that I knew what I was looking for with the Swan Class Popeye, thanks for your word, the case will be appr. the size of the one for the "Gorch Fock" Nils

-

Very nice model Mehmet, it realy looks historic, together with the nicely done sails, the fitting out, and the ancient wrapping and cargo containments, well done ! Nils

- 32 replies

-

- kancabas

- cargo ship

-

(and 1 more)

Tagged with:

-

Update Build log part 84.... All sails are rigged on, at the moment clearing the lines to the belaying points Nils already thinking of the size of the glass case all the port-bow sprit related operating yard- and sail lines are belayed to the appropriate pins at the port bow bulwark. Stb. side will be likewise dry-fitting the anchors to the fore port channel as long as I´m working from the weather side the leeward lines are kept slightly taught by the weight of the pegs belaying the lines from this side, before the yards are braced to the other side

-

HMS Alert 1777 by Jaekon Lee - 1/64

Mirabell61 replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

well done Lee, must be several hundreds of special suit taylored joining parts already, very good looking, a real "gem" Nils -

How to sew sails on your wifes sewing machine

Mirabell61 replied to Mirabell61's topic in Masting, rigging and sails

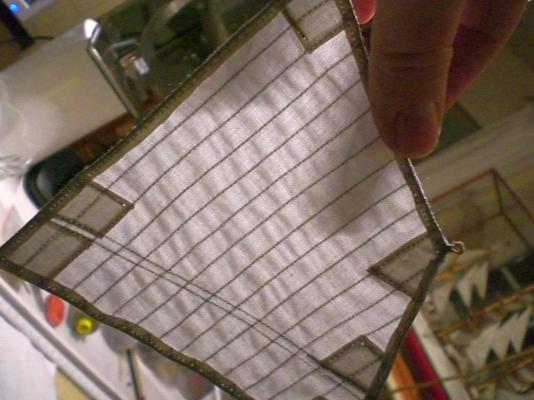

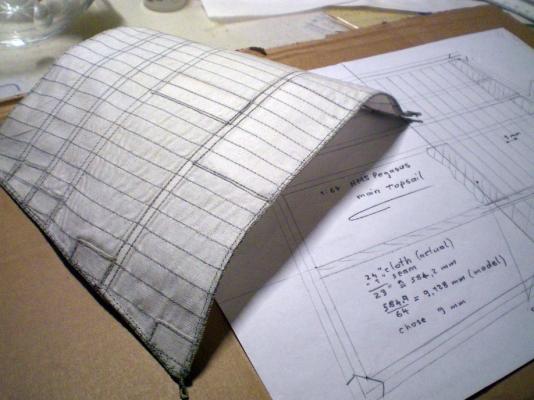

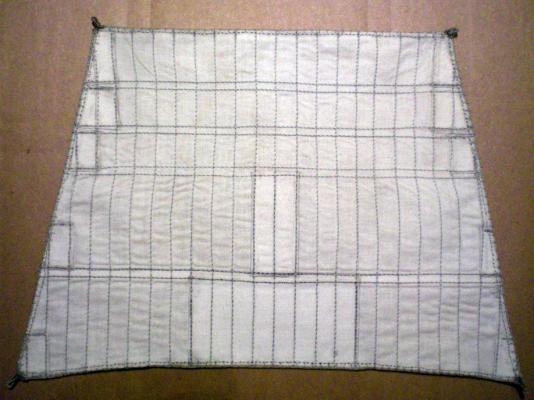

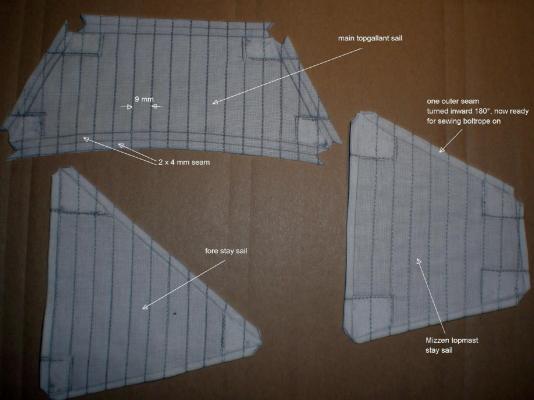

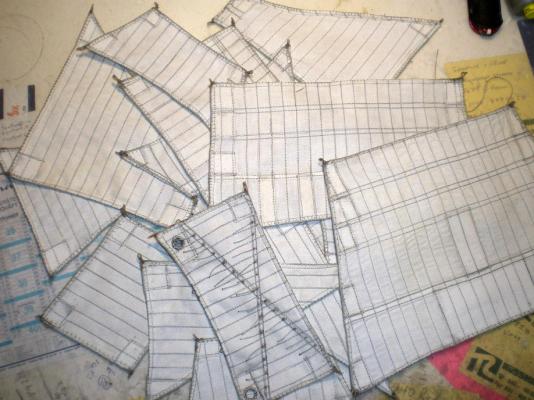

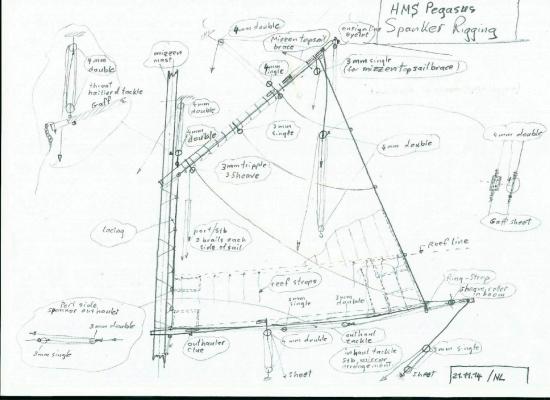

Update some of the recently produced sails by the same method, but without steelwire reinforcement in the bottom boltrope Nils [Attachment = 230.580: CIMG0556.JPG] rough prepared sail with sewed on reinforcement patches [Attachment = 230.584: HMS Pegasus spanker riggimg.jpg] hand-scetch for overview, lines blocks and arrangement [Attachment = 230.577: CIMG0527.JPG] bolt rope all around and fastening loops at the corners [Attachment = 230.578: CIMG0531.JPG] topsail shows a natural bow [Attachment = 230.581: CIMG0571.JPG] once started, make them all... [Attachment = 230.582: CIMG0572.JPG] [Attachment = 230.579: CIMG0533.JPG] topsail with reinforcement patches [Attachment = 230.583: CIMG1423.JPG] rigging sails to the ship -

Hi Piet, the little tourch was bought at the "Bauhaus" crafter chain, but I also saw it at Amazon, see link.... http://www.amazon.de/Rothenberger-Pocket-Torch-Piezo/dp/B002YHA8MW/ref=sr_1_1/280-6113016-5205109?ie=UTF8&qid=1429170994&sr=8-1&keywords=rothenberger+brenner My main application is first of all for soft soldering brass sheet made structures whereby I clip off a small piece of soft solder wire, lay it in the corner of the metal connection surfaces and heat the whole structure with the flame..... and secondly for melting on the polyester thread rigging line ends (thinning out between two fingers) for sheaving through the mini block sheave holes. I contacted the original maker, Rothenberger, because the usage temp was given with 450° C if they can confirm usage for fine silver soldering. They`ll send me a small piece of flux-coated silver solder wire, and I`ll give it an actual try. If I hold a steel wire end (appr. 1,5 - 2 mm) in the flame end it becomes cherry red hot, which normaly would be OK for silver soldering small parts. I`ll let you know asap how the outcome is Piet Nils

-

Bob, a super build, fine Details and very clean and excact built. Hammock nettings, ships boats and deck Fitting out give a good Impression of your high skill with this Project.... Nils

-

Beautiful built heavy frigate Sjors, a delight to look at.... Nils

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Lovely build Bruce, the Fitting out of deck Details is super looking, I love that whale-blubber cooker, also the lav. houses, the pump-Spill, and others... Nils

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

very nice rigging Job Bob, so many familiar sequences from your (builds) pics,........Yards, the one with the parral tyed to one side, hanging down, etc..., been just a couple of days ago.... Your process is performed masterly and exactly, very good looking. Its going to be a "eyecatcher", that rigging of yours Nils

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Daniel, your messenger-and anchor cable handling crew is a real tutorial for all who intend to rigg the anchor cables. Beautiful illustration work ! Looks like tere are always enough hands on a heavy ship like HMS Victory with training, dicipline, and a strong command Nils

-

A well appreciated comment Martin,... thank you very much, I do hope your HMS Fly has meantime received some progress, (pics available ?) wish you all the best with it Nils

-

Mike, I read once that the Colin Archer hull- and sail design allows a perfect ballanced straight (even hard at wind ) course even without giving reasonable Support rudder, asuming the common sail lateral Center is set right...... Nils

-

Bob, probably that was the pulley man !? the Little gas tourch fills with ordinary cigarette lighter liquid gas, Im using this tourch with piezo ignition for many years now for all my soldering work ( soft- and smaller silver solder application, appr. 1100° C blue Turbo flame) For rigging Im using it to thin out the lines Ends to half ist thickness, otherwise I`ll get a heartattack when when trying to sheave in those 3mm blocks Nils

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.