-

Posts

7,407 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Robert, what about an update on your bone-made Royal Caroline ? "still ruht der See" since May 2014... Nils

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

Hello Peter, your rigging Looks very well, and I again took a dive into your log...... I have two questions, a) noticed that you install a jib stay attached to a traveller (neighther shown nor mentioned in Amati drawing). Is the seperate jib stay always used in combination with the jib sail, instead of attaching the jib to the fore topgallant stay ? I can imagine that Setting the jib (Access to...) is easier when it is hauled out on the jib boom per outhauler lineand over sheave roll in sprit-boom tip. Also the common sail lateral Point can be set a Little Foreward or aft to trim the ship on course by opperating the traveller as the seperate jib stay (when the traveller is hauled out) would require some additional length compared to inhauled Position, you probably have arranged for a sheave roll in the upper foremast, for allowing the appropriate jib stay tension as well as an block supported tackle down on deck ? Nils

- 431 replies

-

- pegasus

- victory models

-

(and 1 more)

Tagged with:

-

Thank you Jeff and Omega, please feel free to to click ( in my signiture) into my "Gorch Fock" build log if you have interest for that tallship..... Nils

-

Saettia Genoese by maurino

Mirabell61 replied to maurino's topic in - Subjects built Up to and including 1500 AD

Looks very promissing Mauro, Interesting rigging with those latin sails Nils -

lovely done stay collars Bob, your bow rails and gratings look very nice Nils

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you Popeye, Nils David, all These applications are done in normal soldering (soft soldering below 400 Degr. C), I trust they will sufficiently withstand rigging tensions Nils

-

Hi Peter, thanks very much for your comments regarding the Yard bracing. There was an answer from Mark, mentioning a loostening of the leeward formost shroud by means of a block tackle in the shroudline, an just this tackle can be seen, wonderful done, in one of Doris`s recent pics on the Royal Caroline rigging on all three masts. Its too late now for me to do it this way, but l`ll adjust the truss tackles accordingly nevermind to the gap Mast / Yard. That book you are Holding of John Harland seems to be quite informative for looking up answers to questions.... as there are hardly 18th century model squareriggers with braced sails shown, this Detail does not Show up accordingly, wether in plans, nor in modeling Performance. perhaps Chris Watton may put a remark on the Amati Plan, which in all I find quite good. I have even missed it in Lennarth Peterssons book "Rigging Period Ship Models" for bracing Details. I often look into your rigging, when I ask myself, how did he do it? Its always good if someone is ahead of you with nice performed build Cheers Nils

-

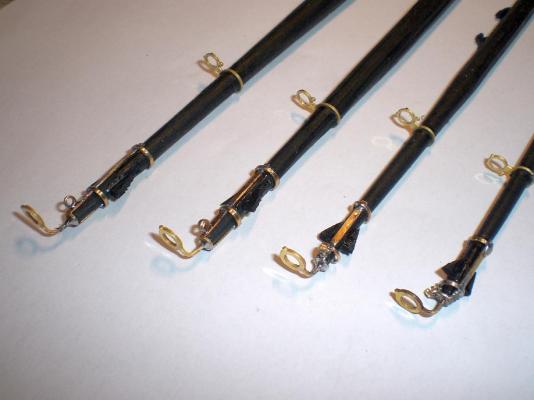

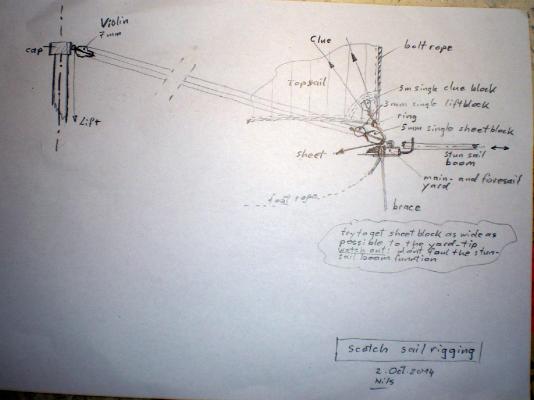

Main- fore- and topsail yards These Yards with their soldering work at the yardtips were the most difficult. today I received the ordered 3,5 mm deadeyes for rigging the upper shrouds and some backstays, shall continue with that sequence next Nils

-

beautiful ship Bob, the rigging with all those fine Details I lke very much it Looks very authentic Nils

- 420 replies

-

Book "Rigging Period Ship Models" What I like in Petersson`s book and can recommend, are the lots self explaining scetch Pictures (actualy illustrations only, no text), in all very informative and in Addition to the shipmodels rigging plan, in every way worth its Price and is fun studying. What I was missing is the rigging of Yards in braced Position, maybe Petersson would like to make an appropriate ammendment in the follow issues of this book Nils

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

Mirabell61 replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Doris, wonderful Job on the Standing rigging like all your work. I noticed that you have fitted a block tackle between the foremost shroud length of every mast. Super Detail, I have learnt that this is the means to loosten the shroud when bracing the lower Yards. Wish I had known this earlier, I would have adopted that one for my own rigging. Nils- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

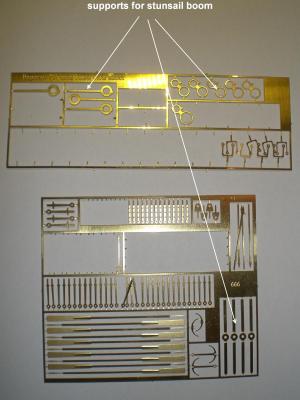

Hi and thank you Jason, I have not used all the etched parts yet, as they are picked from the 9 Panels in total as required. But every time I do use the one or other item I`m very pleased with the good Quality and precise fit. I do`nt know if the fellow builders doing the "HMS Fly" have These etched parts for "Pegasus" in their kit Content, but asume that they can be used there just as well Nils

-

Bob, Mike, and Martin, thank you for your comments on the metal work.... basicly the parts are from the Amati photo etched plat set which I bought together with the plan. The two rings soldered to each of the mast-end tips are sliced off brass tubes 5,5 x 0,5 and 5 x 0,5 Martin, the upper plate in the pic is 0,7 mm thick the lower one is 0,5 mm thick Nils

-

Hi Karl, Hi Bob, I had some doubts with the Yard ends but I think ist allright now. I`ll leave the Fittings in brass, to give a Little contrast, blacken the yards, and leave the stunsail booms in natural Wood to suit the blocks color of the rigging Nils

-

Geoff, thank you very much, I`m happy if it is liked and to share this with others.... Nils

-

Wappen von Hamburg by andy - Corel

Mirabell61 replied to andy's topic in - Kit build logs for subjects built from 1501 - 1750

Hi Andy, thanks for helping Xander along with posting all these log Posts. Regards to her, its a beautiful build Nils -

Omega, very nice Progress on the manyfold Details I Like that railing is going to be a tough Task... Nils

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.