-

Posts

193 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Toolmaker

-

-

2 hours ago, Oldsalt1950 said:

Soldering is a skill that must be practiced in order to master. I prefer a soldering iron that I can adjust the temperature on for all my soldering, some like resistance soldering others use a torch still others a gun. For ship modeling and at the scales we work at, a fine tipped iron with adjustable heat is all you really need

My thoughts entirely. It takes some effort to become proficient but after that it seems so simple. I believe I could teach anyone to solder small brass parts within an hour. The quoted paragraph is what I do, using a gas soldering iron. I have never considered a flame since.

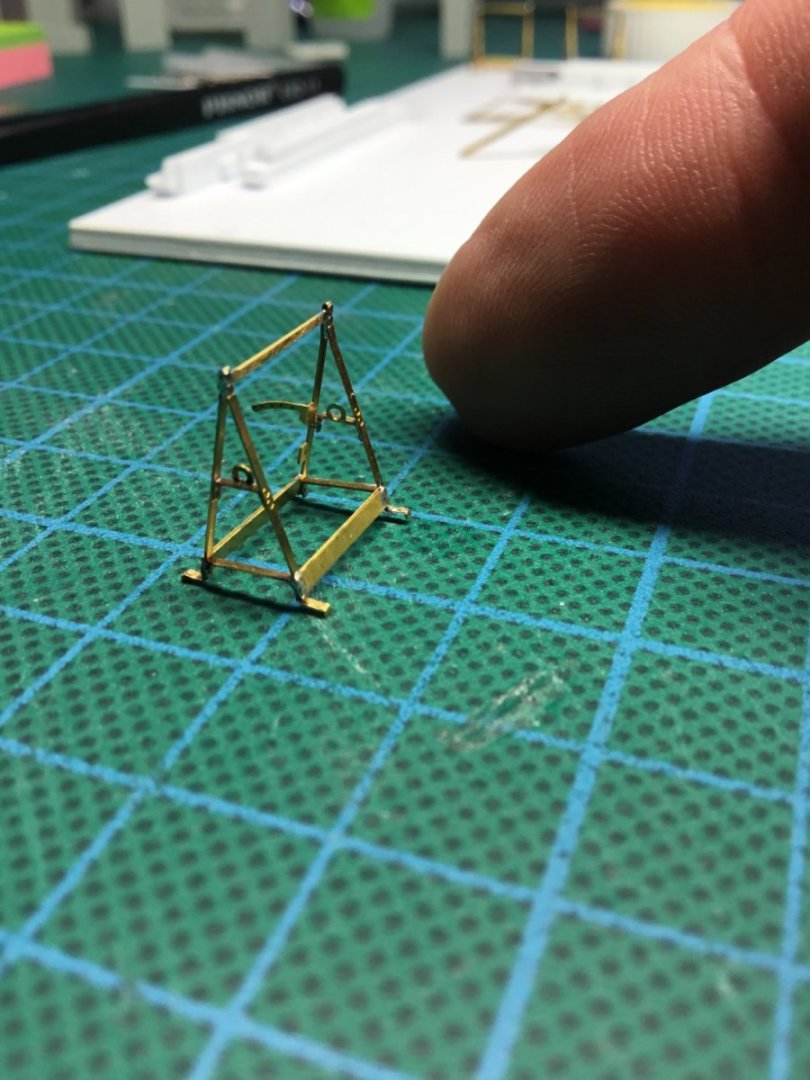

This component is 10 individual parts, I can’t imagine taking a flame anywhere near it, that would be a scatter gun approach.

How small can you go using this method? Less than 0.4mm

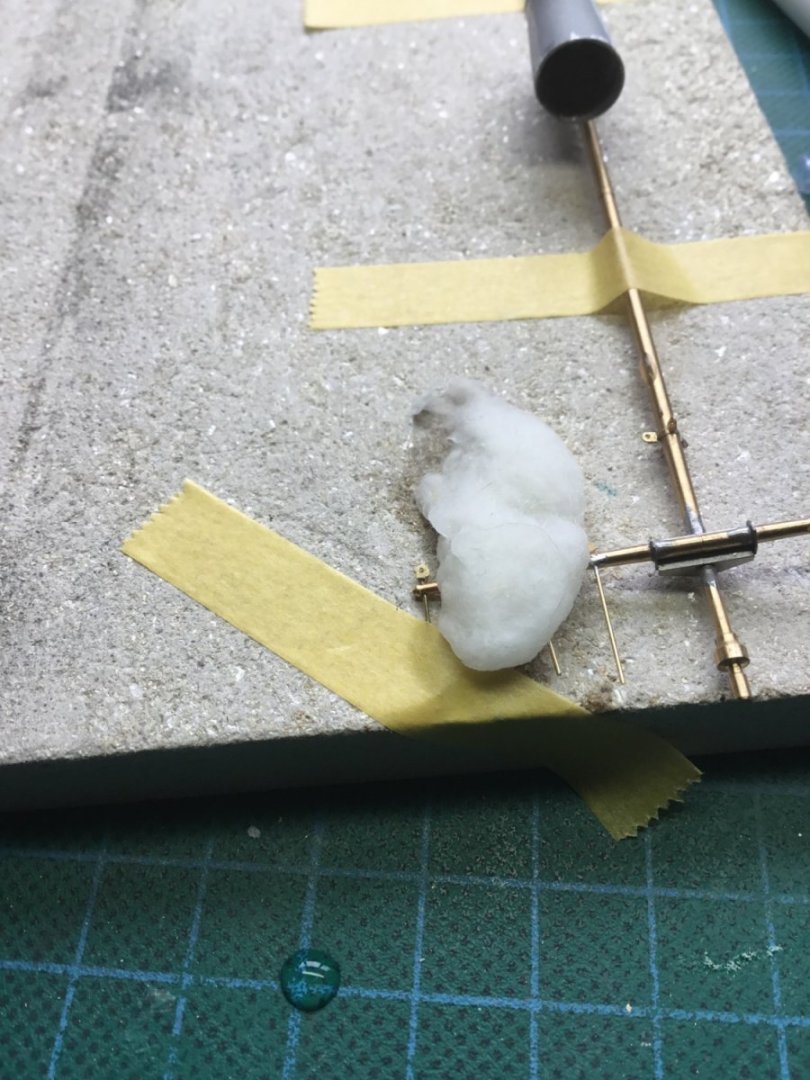

Getting close to other parts requires serious heat sinks. In this case it’s just wet cotton wool.

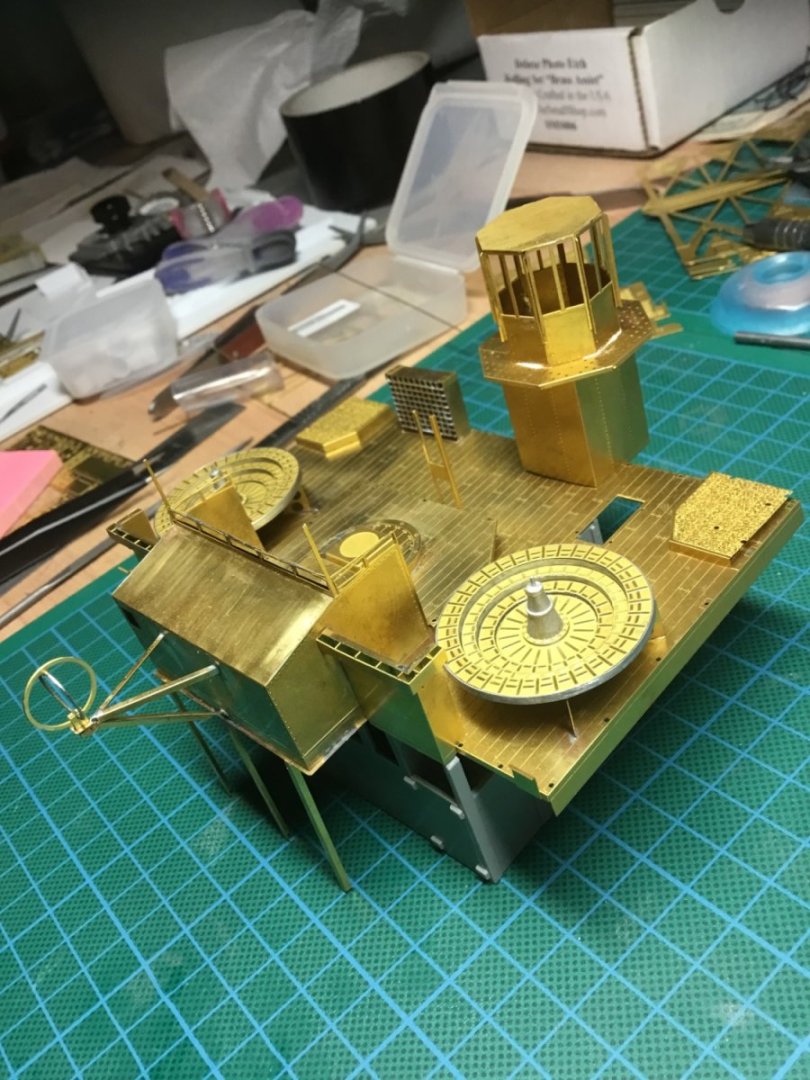

The same method copes with bigger size parts equally well.

If it wasn’t for the thousands of miles between most of us, we could set up a little soldering workshop.

Thank you

Paul

-

On 2/12/2023 at 8:13 AM, jfhealey said:

The sort of approach a teenager takes to tidying his/her room.

This brought back memories and had me chuckling.

As for your fab build, it has become one of my favourites to follow. This is another aspirational build, the sort that creates a rush of kit buying. For me it’s the complete package, great woodwork, painted to the same level and now equally impressive fittings and rigging.

Wow, I certainly have my work cut out trying to catch up with you fella’s.

Thank you

Paul

-

Both inspirational and aspirational, which translates to, that’s beautiful work which I hope to match one day.

- FrankWouts, glbarlow and Dave_E

-

3

3

-

https://qmro.qmul.ac.uk/xmlui/bitstream/handle/123456789/1703/PIETSCHShips'Boys2003.pdf?sequence=1&isAllowed=y

I wasn’t sure if the document should be embedded or just linked?The link is to a large research document written using the records of the Marine Society. Still operating today, at the time in question the society was responsible for approximately 15% of Royal Navy recruitment.

Page 149 shows a graph regarding Boys ages.Although only one portion of a larger picture I hope it is of some use.

Thank you

Paul

- Hsae, vossy, thibaultron and 2 others

-

5

5

-

During the second half of the 18th century the London Marine Society registered around 4500 boys for sea service. Their stated minimum age was 14 although it was accepted that many boys younger than that may have been accepted.

- mtaylor, Keith Black and thibaultron

-

3

3

-

5 hours ago, DocRob said:

maybe do a combination of brush painting and masking and airbrushing

Hi Rob, yes spot on, that’s what I did in the end. The top half of the legs are hand painted although I had painted those curved railings prior to fixing them on.

It’s at this point you end up thinking why didn’t I just stick to armour, ha.

Ship building is so much more challenging. I went to 1/700 scale for a short while before moving to the wood stuff. That sure demands a steady hand.

Regarding my own Arizona, at the moment there are just a few pictures in the gallery here. I did a build log on another forum some years ago but it has since gone. I may eventually repeat it on MSW as a retrospective log, but for now I will happily continue to enjoy yours.

cheers

Paul

-

You’re really knocking this into shape fella, it’s hard to see that and not be impressed. Great stuff.

Just to add another level of awkwardness, when I did mine (in the easier 200 scale) I found during some research that the demarcation line for the paint colours wasn’t always as helpful as it could have been.

Keep going, it’s fab to follow.

Thank you

Paul

-

“It’s inside a cowling”

Ha, now why didn’t I think of that 👍🏼

- Canute, popeye the sailor, FriedClams and 3 others

-

4

4

-

2

2

-

I’m appreciating your attention to detail, the kit looks very good, but your additions will make all the difference. The only thing I can think to add is you might have looked at thinning the fan blades. When I built a universal carrier the manufacturer had added etch for that particular item to offer better scale reproduction;

Paul

- RGL, Egilman, Edwardkenway and 9 others

-

12

12

-

I would endorse the advice for uncoated hss bits from a reputable manufacturer. As has been said, at such fine diameters and without having the required rigidity, hand drilling with carbide is likely going to result in breakages.

As for the pcb type drills, they are just not suitable for our modelling needs. They need very high revs and controlled feed rates offered by cnc machines. Without the controlled feed rates they tend to screw themselves into wood and any thin walled plastics and other sheet materials. The prices are very attractive but the results often disappoint.Thanks

Paul

-

-

-

1 hour ago, mtaylor said:

Paul, try using what suggested here:

Mark,

Thanks for the help. I’m not quite there yet and it’s not an important issue, but at least I am no longer just a T in someone else’s alphabet. I whatsapped myself which compressed the picture. Then saved it and used it here. It ended up half the allowable size.

It’s a start and can wait until another day to refine.

Thank you

Paul

-

Hi folks,

I am managing fine to upload photo’s in topics, replies etc. However when I try to upload a picture to my profile I am told that the file is too large.

Can I edit the photo on an iPad and upload it direct as I do with other photo’s. When I have uploaded photo’s from the iPad to other topics and gallery’s it has done so without any request to re-size.I hope that makes sense to at least one able person.

Thank you

Paul

-

Lovely 3D printing detail and the opportunities for a diorama seem endless. I’m looking forward to seeing what you do with this beauty.

Thank you

Paul

- FriedClams, Egilman, king derelict and 5 others

-

8

8

-

Another high bar Winchelsea build to follow. I’m feeling blessed to have so many excellent examples to learn from.

The planking looks superb.

Thank you

Paul

-

Hello Glen,

I’m fairly new to wooden ship building and this is my first comment on your build, so hence the formality.

Your log is both inspirational, educational and a pleasure to read. Yes, there are multiple wonderful builds of this model, but the detail you show, whilst not being over repetitive is a perfect fit for me.

I hope you don’t mind but I have a question on the use of the monofilament fishing line, used to represent bolts. So far, I can only see the “size” given as the breaking strain. I was hoping you could measure the diameter used and quote that either in MM or English. My concern is that different manufacturers will offer varying diameters for a given breaking strain so a known size would be useful. Of course if I knew the size of the ship builders bolts/nails etc, I could scale them myself.

I intend to commence with my own build of HMS Winchelsea later this year and your build will be my favoured mentoring resource.

Thank you

Paul

- Dave_E, FrankWouts, Edwardkenway and 1 other

-

4

4

-

Still cheering and willing you on from the sidelines.

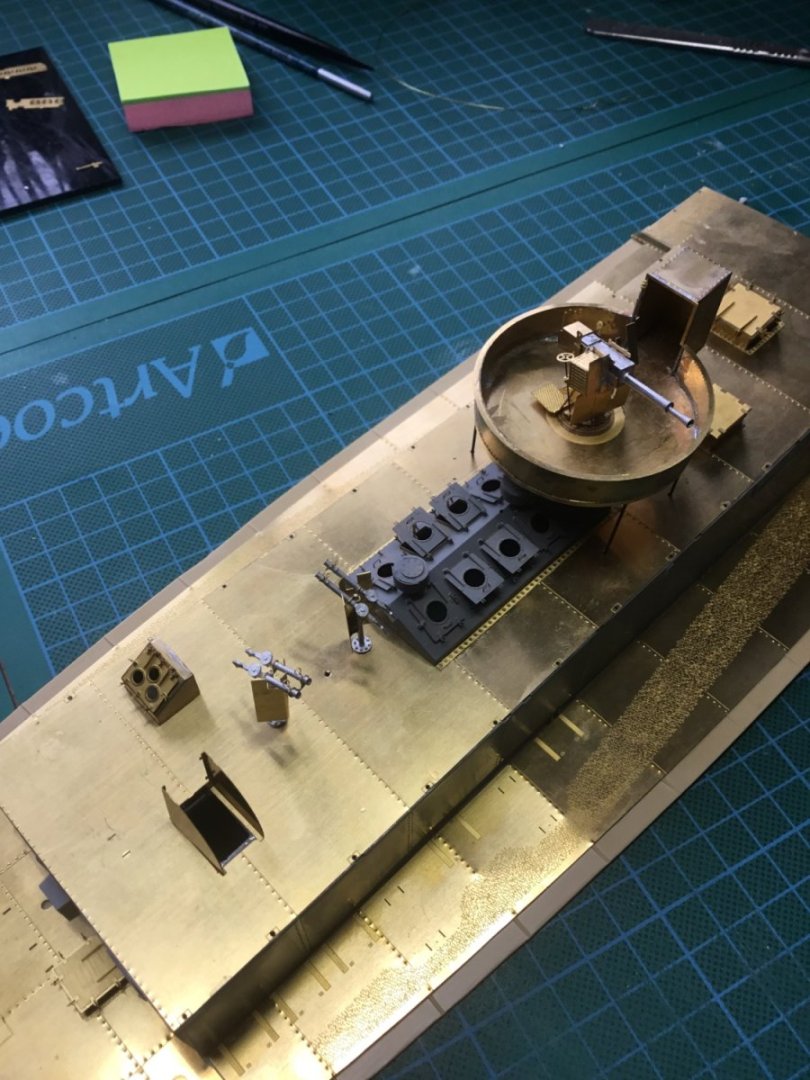

Your words about the integrity and how delicate the build is, bought back uncomfortable memories of my own efforts. I actually did experience blowing parts from the build with an airbrush and did also lose parts only to find them up a finger nail.

If you remain determined to continue this madness for years to come you may also conclude that taking soldering to an art form becomes a must. Like yours, my Arizona etch to etch was all held with super glue as it was also my first ship build. However, after that, any subsequent etch to etch build was going to be soldered. After some practice I found I could solder the tiniest of pieces and the smallest of diameters. Once learned, the stress levels plummeted.You are also on the money when noting the demands of planning for painting. Unlike many modelling subjects, ships have a lot of fine detail above decks, requiring careful planning. Many detail parts need painting off the model and adding after.

Enough waffle from me, keep up the good work.Cheers

Paul

-

I would have been happy to have the wooden ones when I did Alert. A bit of paint and it will look great.

I shall watch how you get on with the build. I thoroughly enjoyed building mine.

Thank you

Paul

-

-

Sometimes it appears that nothing is straightforward in modelling. It’s often not hard to find conflicting advice.

When I built the Flower Class Corvette using all the David Parkins “Great Little Ships” sets the two most important aspects for me, were to be able to solder and to be able to keep the paint on the brass. After all, most of the build is brass.

After much research I used the 2 pack etch from this company.

You can see that not all the instructions match other advice. I made my decision based on the company generally supplying into the model engineering sector and large scale train builders.

I realise I am referencing a UK based supplier but I’m sure similar suppliers are abundant in the US and other countries.

I hope this adds to the discussion.

Thank you

Paul

- Canute, Ryland Craze, DaveBaxt and 1 other

-

4

4

-

- No Idea, Keith Black and mtaylor

-

3

3

-

I was probably the only person wondering why you wanted wooden cannon barrels! duh!

- Keith Black, No Idea and mtaylor

-

3

3

-

I’m an Iwata user generally, but when I needed to spray 2 pack etch primer it was a Badger airbrush that got me sorted. They had a 0.8mm nozzle airbrush and it performed perfectly where nothing I had came close.

Like others have said, to a great extent choice will be dependent on what you want to achieve.

Thank you.

Paul.

- kurtvd19, Ryland Craze, thibaultron and 3 others

-

6

6

Silver soldering

in Metal Work, Soldering and Metal Fittings

Posted

Cheers, thanks.

That combination build really leaves you with no option but to solder. To try and ca the David Parkins sets just wouldn’t bode well.

The last paragraph that Dr PR (coincidently, my initials!) wrote sums up my method beautifully. It has to be said that almost all the soldering on that build is fairly thin photo etch but comparable to what many of us require in our modelling.

Its a different story when working with solid machined parts and silver solder.

Thanks

Paul