-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

I have been on holiday and only just found your wonderful build Druxey; add me to the list of enthusiastic followers. A great subject for a model also. cheers Pat

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Great progrees Dave, and glad to see you have very quickly come to grips with resistance soldering - it's the ant's pants once you work out the right power settings for the various types of jobs cheers Pat

-

Somevery nice detail emerging Dave; will really add to the model presentation when complete. cheers Pat

-

Swee-eet work Danny, looking very good. Great to hear you will be back in your 'office' again mate; must have been a real pain with all that moving. Impressed that you have been able to achieve what you have given the circumstances. cheers Pat

- 268 replies

-

Removing Blacken-It from Brass

BANYAN replied to mtaylor's topic in Metal Work, Soldering and Metal Fittings

Mark, try rubbing with a fibreglass pencil brush then soaking them in Muriatic (brickies) acid for a while. I was able to use this method with a bit of scrubbing with a toothbrush to remove some blackening (I used Birchwood Casey blackener) which had not worked so well in parts. This got them back to near clear brass but it certainly was not as shiny a surface but a scrub with fine steel wool certainly resolved that Please note this was not a deep blacken process as I notice the mottled effect before the full process had not completed. cheers Pat -

Make sure to drop in on Melbourne while you're here Mark cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Great to see some progress mate - will be great to see your build underway again, Really frustrating when you can't get getthe rightbits of materials huh? You may have to setup your own shop Dennis cheers Pat

-

Some nice additions to your little lady John; she is starting to get her Character now. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Excellent joinery Dan- looking very tight! cheers Pat

- 268 replies

-

Keep on rattlin mate; you'll get there Love the effect you have created on the lines (close-ups) which reallygive the effect of grease heavy (tarred) lines. cheers Pat

-

Nice save mate, they look good especially considering the scale. Pity about the attitude from Eduard - I won't purchase anything from them if that is the way they treat customers when it is their problem Question: How do you glue your stanchions, especially the singles - both glue & jigs to get them to stay in place and look perfectly aligned from the horizontal and vertical perspectives - and get them to stay there? [Edit - I realise that these ones still have the base fret attached, I am assuming you have done singles as well where required? The type of glue is applicable to all please] cheers Pat

-

My of my John, she is really looking a treat. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Thanks all for looking in and kind comments. John, yep - that is the downside as it does cost significantly more to set up. But I would argue that if doing a lot of soldering, and some of that may be on or very near the model at times (fixing breakages etc ) then it is still a WHOLE lot cheaper than rebuying/redoing the model if it catches fire The real advantage though is that I can do several different joints in very close proximity without de-soldering the others to get a new one ion place. if you can afford it, I would very highly recommend it. cheers Pat [Edit: I should have been a little clearer that the gun barrels are after-market - these are some of Chuck's excellent products.]

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

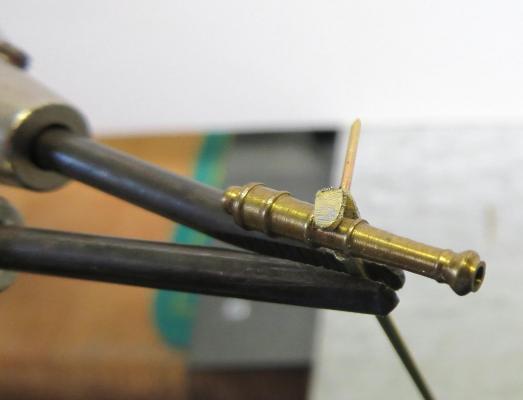

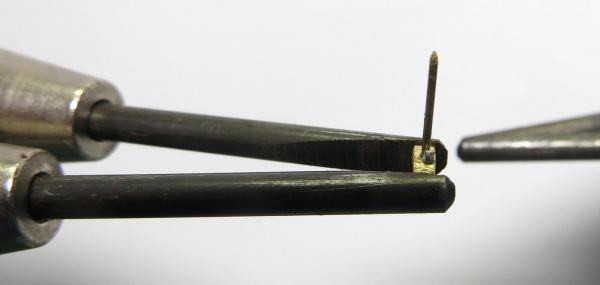

Part 2 of the Swivel gun assembly process with some partially completed units in the last photo. I still need to clean these up, blacken them and add the control arm knob/timber (not sure which way to go yet). I am also looking foe pointers/advice on what to use or how to create a fixed circular pate about half the way down the spigot that would sit on the gun post and stop the spigot going further down the hole. This then allowed to gun to rotate in the hole. This will require a very small washer type part to be soldered in place which at about 1.5mm may be a tad small to achieve cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Part 1 of the Swivel Gun production line These show my soldering set-up and some of the tools I use. Also the first stages in preparing and soldering the cradle for the gun - one photo shows the part in place with flux applied and bead of solder ready to for the heat. As you can see a relatively clean joint with minimal clean-up required. Please note the part is only 1.25mm x 4mm long x 3mm high. I have moved to Resistence Soldering as it enables me to really control the soldering heat and restrict the area that is intensely heated for the solder to flow. The anchor ring above was soldered in-situ with the puddenning in place with no problems. this will also allow me to solder chains, plates etc on the model if required; but some care is still required. A lot better than putting a naked flame anywhere near these materials. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.