-

Posts

5,965 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Thanks again all for looking in and the likes. Chris - no worries - just cost you a couple of 'frosties' Popeye - thanks mate - slowly getting there. Mark - now you have me thinking - Not sure to be honest - I thought the beads (wooden balls) just created a bearing type effect and were smaller - need to research now - John - now that would be a challenge - but, I need to try some of that privet you provided first. If the saw survives then maybe.... cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

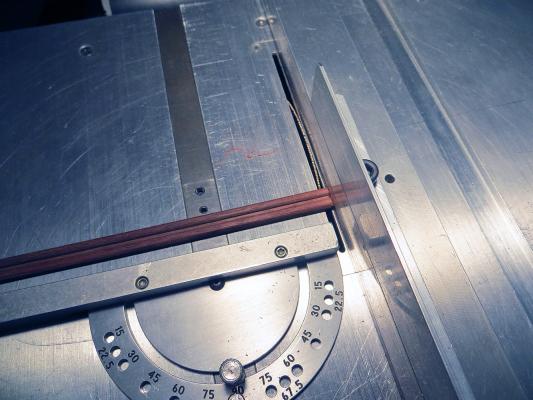

An update on the parrels - still experimenting so the following is not the actual completed product. For example, the beads I used are just as they happened to come out of the packet. Being cheap they are not graded to the same size and many are not evenly shaped etc. For the real deal I will sort/grade these to get a consistent spacing. The parrels are 0.75mm thick and the burning on the parrel pieces are caused by the saw blade - need a new one but will not ruin it cutting this hard wood. I have sanded off some of the char, but then realised these would have been 'greased/tarred' and would end up looking blackish anyway - saved some effort . I also found that stacking the parrels in the temp fixing jig caused the bottom ones to split and crumble when I was drilling so I have reverted to drilling and contouring the holes (for the bearings) individually; more time consuming but less breakages. Anyways - getting there. The parrels are actually quite smooth; the close up and contrast I have added make them look quite rough edged I am also going to try some privet (in the Boxwood family) to see if I get a better finish. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi Greg - looks great mate! Too late now I think, but the only option I could think of is to lay the red first then a single strip of masking tape of the appropriate width over it, then paint the other colours either side masking as required? Alternatively, you might consider auto pinstripe (red) and apply it like a decal then a coat of flat clear over it to seal it? cheers Pat

-

WOW - thanks for all for looking in here and 'At a Glance' - much appreciate the interest and comments folks, they keep the mind positively focused.. yep John, that was for you Keith, very many thanks for your kind offer the other day. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi John, thanks for looking in. Hope all is well. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi Per, yep it is indigineous to Australia. Being so dense it is resistant to termites and very long lasting wood - they use it for railway sleepers, bridges and fencing due to these properties. Lately, some talented woodworkers have been making some great furniture from it also - but boy, tough on the tools take a look at this link - http://www.kropf.com.au/timber-furniture/river-red-gum.htm cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

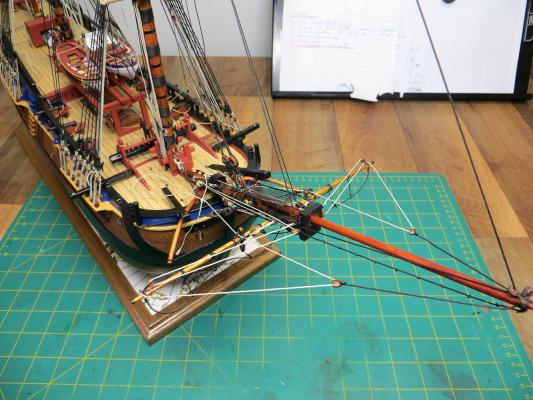

I made some further progress with the boom and jib but I have come to a temporary halt while I wait for some more beige line. I had purchased the running rigging thread prior to getting my ropewalk and cannot match the colour, so until my new supplies arrive in the next couple of weeks I have statred on making the parrels. The following photos show Endeavour at her current level of completion and in her display cradle. The top of the cradle is a copy of Cook's Chart for the East Coast of Australia that he drew while surveying his discovery of this part of our country - this has been sealed under a couple of layers of clear poly. There are still many lines/ropes that are only temporary secured waiting for final tensioning and the footropes still need to be stiffened into their final position. I am holding-off doing the final adjustments until I have stopped working in this area so that I don't knock them our or shape, or have to move a rope to fit another etc. The parrels have been made from Red Gum which is a very dense timber, so it will allow me to cut thin clices from the milled shape shown n the photo. I will drill the rope holes with indents for the parrels by hand using a template. The photo shows the stock after thicknessing, the milled shape and the beads I will be using. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Great news - a significant New Year milestone cheers Pat

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Hi again all. Thanks for the pointer to the painting jbshan. On closer inspection I think it does accord with Druxey's observations. I found a higher res of the painting at https://commons.wikimedia.org/wiki/File:John_Cleveley_the_Younger,_HMS_Resolution_and_Discovery_in_Tahiti.jpg The foot of the hoist appears to be in exactly the same sort of relative position to the rail as RMG painting? edit: oops - on review (zoomed) it appears this Ensignis larger in physical size BUT... it is being flown from from the gaff halyard and not the Ensign Staff. I think, for my purpose, that the proposed rule-of-thumb will suffice? cheers Pat

-

Thanks all, appreciate the feedback and pointers. I think the best estimate I can make is to follow Druxey's advice and base it on the visual evidence of conntemporarty paintings, drawings and models which equates to the 'hoist' being approx. 2/3rds the length of the staff. Once I have calculated this for my model (at 1:60) I'll see if Model flags has an existing size (they do 10 sizes of the Red Ensign for this period, so I should get something fairly close (I hope) Once of have established this size I will order a jack that equates to the same size as that used in the selected ensign. Thanks again all. Pat

-

Thanks for the rule of thumb Druxey; appreciated. Thanks Mark, a handy site. Once I work out the approximate scale size using Druxey's guidance I will order something close to the size. cheers Pat

-

Hi folks, I am starting to research the appropriate flags to fly from my HM Bark Endeavour (c1770) depicted in harbour - so Ensign to be flown from ensign staff aft, andUnion Flag (Jack) from the jack staff fwd. From other discussions in this forum I have established the correct ensign to fly (as shown below): I am assuming the design of the Jack will be the same as depicted in the top left corner of the Ensign - that is, NO red diagonal cross? From the CRW Flags website and BR 20 (thanks for the links in your other postings Beef Wellington) I have been able to determine that the appropriate ratios for size (width : length) is: 1:2 for the Ensign, and 3:5 for the Jack What I am trying to establish however is whether there is a standard/rule for the actual size of the flags (per ship rate/size) etc? What would be the actual size for the Endeavour to fly? Any help will be most welcomed. cheers Pat

-

Agreewith Greg; I think that is why Marquardt shows hooks and tackle for these stays rather than fixed rigging as in other publications - so they can be removed. cheers Pat

-

Steve, could you post a piccy of those cutters please. I have a pair of electronics flush faced cutters, but they mangle the thread at the edge of the cut - perhaps the brand (quality) may be crucial? Neat solution to the eye; I'll try that. cheers Pat

-

That is one heck of a "work of art" delivered by a very talented artisan Remco - a wonderful legacy you leave us mere mortals to follow cheers Pat

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

More than a little impressed Steve; that is a major undertaking repeating that level of detail over 12 shroud sets! I tried at scale 1:60 but just too fiddly for my 'fat' fingers and had enough issues with clove/restrictor hitch terminations. cheers Pat

-

What is the name for the netting under the bowsprit

BANYAN replied to HKC's topic in Masting, rigging and sails

Thanks Steve and JB. Steve that photo is perfect - many thanks for that - much appreciate the rapid response. I was a bit puzzled by marquardt's depiction as i could not see a 'seaman' like way to utilise a central line either end; the spreaders make much more practical sense. cheers Pat -

Thanks Dave, that's the plan re Endeavour (and a couple of frosties of course ) cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

What is the name for the netting under the bowsprit

BANYAN replied to HKC's topic in Masting, rigging and sails

HKC - I hope you don't mind me high jacking your thread after such a long period of inactivity? In the Endeavour AOTS, this netting is referenced as being for the staysail ( to hold the 'bundle' when lowered). My question is how it was rigged circa 1770. the AOTS shows only a side view. In this view there is a 'horse' which I am presuming is one each side. I initially assumed the netting was fixed between these but there also appears to be a small eye ring centrally placed at either end fixed to the boom collar (fwd side) and boom cap (aft side) to which the net was attached. Would I be right in assuming that it was fitted between the horses (hitched) to act as spreaders and the central eye rings to give fore and aft support to the net? OR was it hung more like a hammock? Any pointers/suggestions appreciated as there is nothing in Lees, Lever, Marquardt, Harland or Falconer (that I can find) to provide this detail. cheers Pat -

Thanks all for looking in. ca shipwright - More ships??? Flat out keeping up with what I have in the shipyard Good to see you back in the dockyard Mike. Greg, Popeye - unfortunately retiring 5 years earlier than planned for health reasons - get some quality of life in while I can. My complaints however are minor compared to many! cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Thanks Mark and back at you - I hope you and yours had a great festive season With the Death Star commissioned I am sure 2016 will be a great modelling year. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

You too mate - 2016 will have to be better - now retired cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.