-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Aww come on Greg the rigging will be a doddle after your Endeavour Seriously though, some lovely detail you have add tis this little beauty. cheers Pat

-

No error Mark, just a 'clarification' Well, after all this I think you have graduated from Jedi Master to 'redo Master' - may the 'wood' be with you! cheers Pat

-

You,ve been hiding your progress John, She's coming along very nicely. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Another fine update Druxey; a very interesting log and great build. As a matter of curiosity, you mention using acetone to remove the gold finish - how do you get it off, especially out of the crevices, without damaging the detail or the wood itself? cheers Pat

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Hi Dennis, great update; glad to hear you are feeling so much better. That material really does look the part (canvas) for the wind/splash breaker on the stanchions- really taking shape now mate! cheers Pat

-

Great progress mate; she looks terrific - you have every right to be proud of your efforts. cheers Pat

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Looks really good Mark; good luck with the top-down approach to the collar. cheers Pat

-

Build and learn in the extreme hey Mark I hope you're logging these 'lessons learned' - sadly i didn't and will probably repeat a few (another lesson learned ). I am sure you will find a solution to your collar issue when you least expect it. I am also recalling a muuch rum befuddled memory from MSW 1 (I think) where someone used the inner foil from cigarette packets for this task also??? cheers Pat

-

Hi Mike, to a large degree (generally speaking) the line colour was similar with any difference to the colour ususally based on the material from which the rope was made - Hemp, Sisal, Manilla etc. Most seizings (based on my time in the more modern navy) most seizings were done with sailmakers twine. As Mark said, the protective tarring was applied later. cheers Pat

-

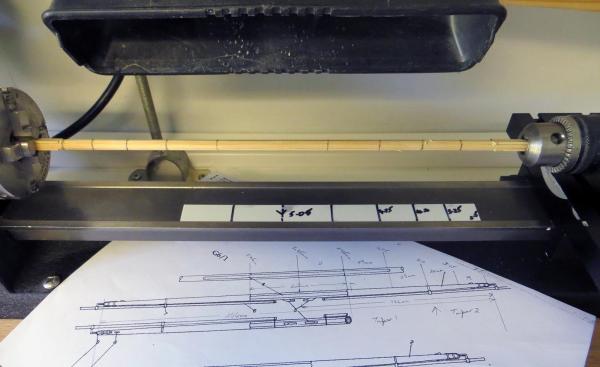

Hi Wefalck, some very nice machining; but, we have become accustomed to that from you This is a well designed and made compact tool for the precise sanding of small pieces/parts. One question though, if I may? How do you secure the piece be sanded so that it does not move while sanding. The mitre will assist, but even the slightest movement can have disasterous results on very small pieces. Do you intend fitting hold-downs or such or do you use a non-slip under-pad with the part? cheers Pat

-

That's two of us Dave Mine are permanently fitted now so will need to live with the "extra" cheers Pat

-

Mark, I was able to get some chamoise leather (very very thin) from a modelling shop here in Aussie - this might do a reasonable job but I think there were canvas? For my Endeavour I used some calico (well washed; put it on, wet it with a very diluted PVA/water solution, shaped and let it dry. Not perfect but... cheers Pat

-

Looking forward to the Bridge Cabin equipment and furniture if previous builds are anything to go by cheers Pat

-

Even up close (zoomed) this model is flawless; a testament to the skills applied! cheers Pat

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Ron, try a fabric stiffener (more robust than starch) which is usually available at an arts and crafts, or sewing supplies (Spotlight if in NZ?) - an alternative might be "stop-fray" . You will need to position the ropes initially, spray and reset where necessary. Just a suggestion not sure how permanent these will be though? cheers Pat

-

No stopping you now mate; good progress with some excellent details - looks great"! cheers Pat

-

I actually thought that was a lovely piece of burl before I read your text - extraordinary! cheers Pat

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Great detail Greg; so much better than those original resin details. You must have good steady hands - they are soooooo small. cheers Pat

-

Wow - thanks for the interest and likes folks - appreciate the encouragement. Greg: yeah does help a tad Thanks for the comments Mark and Chris. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.