-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Looks great Glen, but you have me intrigued. How in the world will you get those larger pieces (such as the wall) into the bottle? cheers Pat

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Thanks Craig that is the shape I was looking for (that the fore edge wrapped up the front of the axle) - I know I have, or have seen, a version like that somewhere in my reference material - I will keep looking. The version I saw though, had the same thickness metal wrapped up the front rather than tapered as you show - either could be correct. cheers pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi Grant, sorry I missed your question. If you are OK with it, I'll get back to you once I am happy with one as I don't want to lead people astray if it doesn't work. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

As Keith has hinted, I think you made an editing error Glen - the penguin text was crossed out " Oh no, not the penguins, not the penguins!" Seriously though, that wall is coming along really nicely, are you going to do any weather and/or scum line etc? cheers Pat

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

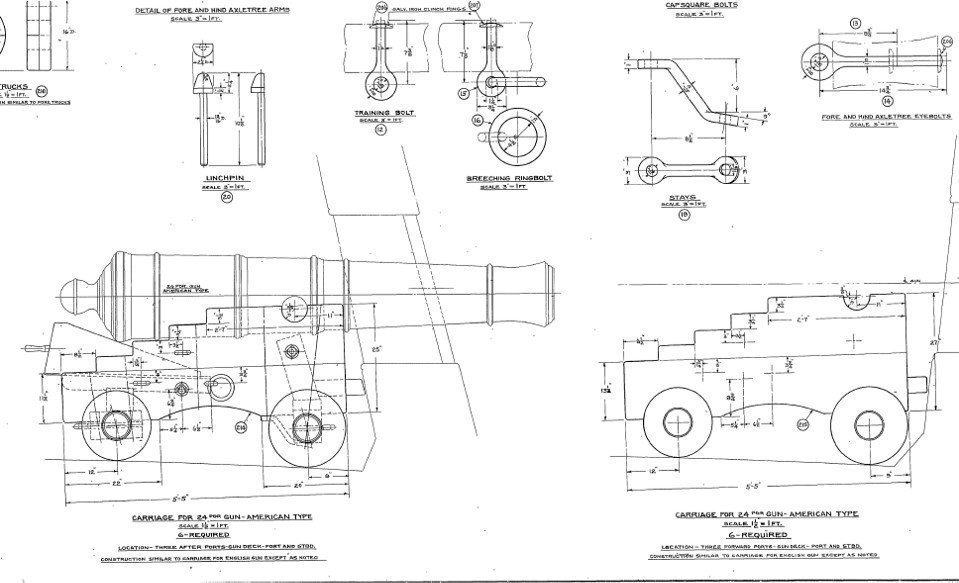

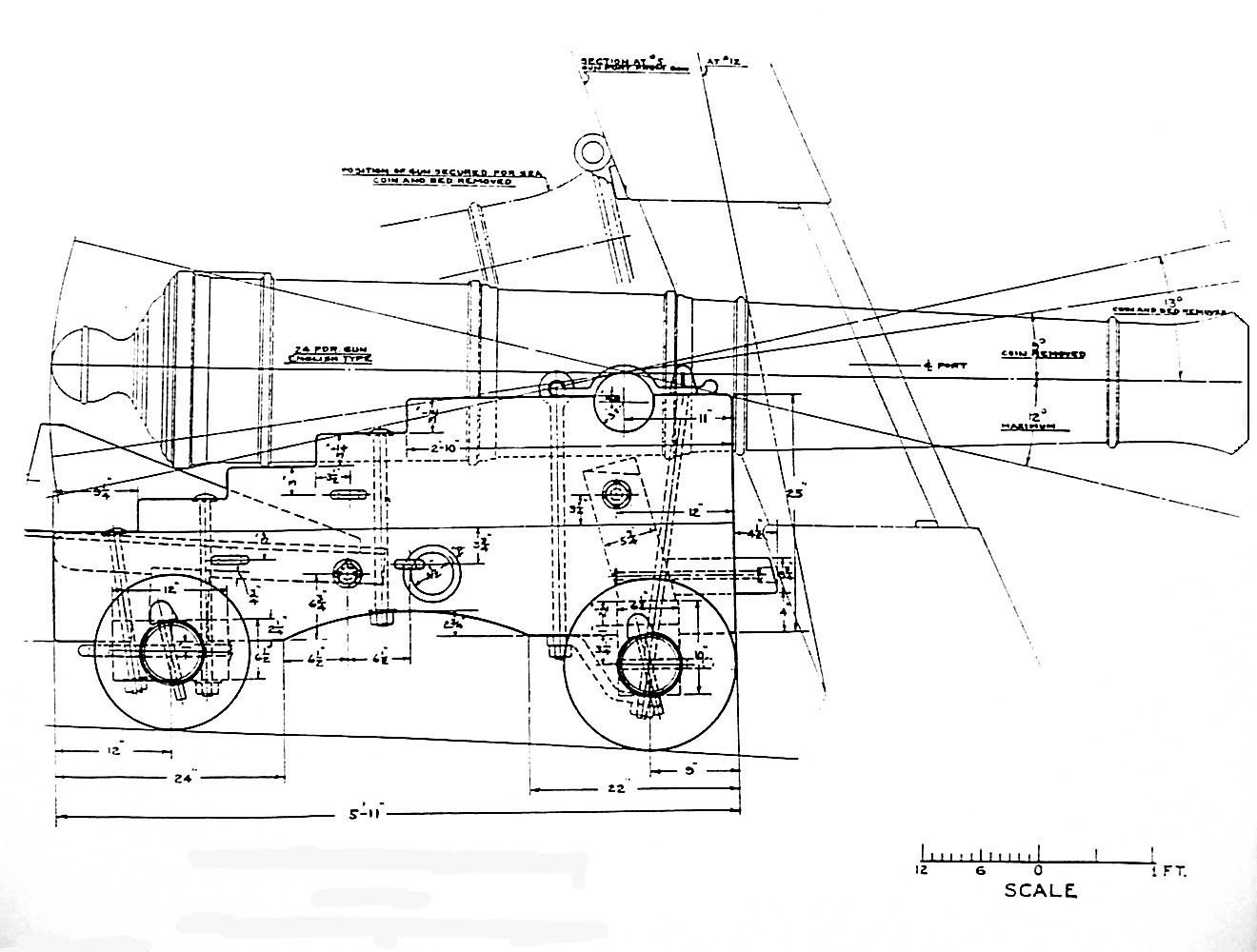

Unfortunately, they are the best resolution I have Allan. I can send the files I have, just in case MSW's file formatting changed the res, but I don't think they do that? Let me know if you still want them? In the meantime, I will make a crop of similar size as yours and try some of the image software I have to see if I can improve it. (Sorry Allan, I tried that, but the original is of very low resolution, and I cannot improve it enough to read the dimensions). Perhaps contacting them may allow you to get the dimensions or a better resolution copy? Another option may be to import the improved image of the gun (second image) that has a scale, into CAD, scale to get the image to proper dimensions, and then measure them? cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

I thought I should add some photos to also help explain how I go about the process. The first shows the tools I use for the metal forming part, which include a pair of pliers with serrated grip jaws, a couple of needle files, a small 0.5mm spade bit used in my mill (next photo), a jewellers type metal block (can't remember the name) but it allows me to hold tubes of various shapes at 90, 45 and 30 degrees and cut off small pieces to width, and the JB Tools grab handle making tool. The second shows the set-up with the band on the wood mandrel in the rotary indexing attachment for the Sherline mill. The last shows the band, which has now been drilled to indexed angles at 020, 100, 160, 200, 260 and 330 degrees, being held in my alligator jaws in a soldering station I have cobbled together (still being improved). cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Allan, I will have to search through my reference material again, but if I recall correctly the straps, or more correctly stays, are two metal brackets that were used to secure/support the axle which was morticed into the brackets. The strap (stay) replaced the lower washers for the brackets bolts that also served to secure the cap square on the upper side of the brackets. Note the bottom part was straight not curved and aligned with the squared part of the axle. (Edit) I found this which sort of explains the 'stay' a little better - I cannot recall at the moment where I found this but may be connected with the "USS Constitution". It is possibly from the Naval Historical Foundation. cheers Pat

-

Agree with you about the securing - I did not note that the after pin did not penetrate the deck. However, I thought the bolt you drew looked OK based on the end of a forelocked bolt protruding from the inboard end? The artist may only have shown one as the other might have been obscured being in line? That way, two bolts passed from outboard through the bulwarks and forelocked with pins inboard would secure the head. Gary's model from the NMM does not show these, but the rest of the model fits the idea? I think that is the only way the fighting head could be secured? Other models of gun models I have seen also omit some details so I think another drawing would be useful to prove/disprove these bolts? cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks Rob, appreciate the kind comment. I don't blame you for avoiding the soldering. (see following comment) Thanks Grant, appreciated. To be clear on the soldering, I use solder that has silver content rather than the full-on silver solder. These come in various melting points which allow me to place items close to each other without disturbing the earlier higher melting point joints where I do that (not in this case). The other big advantage, and relevant to Rob's comment, is that some time ago I invested in a resistance soldering unit (American Beauty) which allows much better control of where and how much heat you place. If it wasn't for this unit, I also think I would not attempt anything this small (especially with the shakes in my hands these days ). I am also starting to experiment with heat gel to protect some joints (heat sinks) but at this size a little difficult to place it properly. I find that dialling down the current of the solder unit to minimum, I can solder wire down to 0.2mm or so. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Allan, looking at that side view is it possible the bottom timber is a fighting head (I think that is the timber at the front of a carriage is called) which is locked in place with the shorter pin. The head would be hard up against the waterway/spirketting and then becomes the timber on which the slide proper would pivot using the longer pin? That way the whole assembly could be removed when required. In this configuration both pins could be on the same axis also? Just a thought. cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Good question Rob, and a good pick-up - thanks for keeping me honest . I should have been a little clearer in my descriptions. The fore and mainsail booms were about 3.5mm to 3.8mm ID; the Driver boom is only 2.8mm (in my haste I left the decimal out) - BUT it is frustrating and very fiddly trying to get those fitting on. That particular band is testing my patience at the moment . The eyes and ears are made from 0.3mm brass wire for the Driver band, and 0.5mm wire for the former ones - BTW the ear's ID is only 1.5mm long with less than 1mm gap. My description was intended more for the Driver boom spiderband, as I need to make that one the same way for them all to look alike. I was simply trying to point out the risks in 'fixing/making' the bands using the drilling method. I learned this through some major frustration in having to remake the jibboom a few times as I tried that at 3.25mm and it kept breaking - hence my reluctance. Sorry for any confusion folks. The way I make them is:- I find the nearest size (ID) thin-wall brass tube under the circumference of the boom at the fitting point then stretch it to size to thin the wall further. I thin fit it to a wood dowel mandrel to hold it while I put it in my mill holding the mandrel in the chuck of my horizontal indexing tool. I then drill the holes using a 0.5mm micro spade type drill bit (which I found in England) at the appropriate spacing. I bend the ears using a JB Tools tool (used for making grab handles etc in trains and tanks etc) at the appropriate size to form 'U' shaped ears that I then manipulate (to get the appropriate leg angles) and with a LOT of frustration eventually get them to sit in their holes (that's why there are pliers grip marks on them). The eyes are twisted using very thin diameter brass wire and placed in their holes. I then apply the flux and solder chips and solder all in one go. The inner dag ends are then cut away and/or filed to smooth and clean the inside of the band. Hopefully this clarifies the situation a little? cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for looking in Glen and Keith, I very much appreciate your supportive comments. It's actually good to be getting back into it Keith. One benefit of the slow down though is that I have been able to refine some of the research. Whereas I initially believed the spiderbands to be located at the Given Diameter (GD), or hance, of the boom, it eventually proved to be located much further out. If I had rushed in and glued them in situ at the GD, I would have had to remake the booms (for a third time ) cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for looking in and suggestions Rob, much appreciated. I did the former. After placing the eyes and the 'ears', I soldered everything in one go, then cleaned out the excess by grinding and filing. I had to be careful there as in my test piece I was little excessive and filed some corrugations into the band by thinning the edges too much. I couldn't use the second method you suggested as the boom is less than 2mm at this point and drilling four holes will probably have broken the boom at that point. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Glen, don't forget you still have the penguins to do also Seriously though, that is quite the achievement, she looks great in her glass home, and is a tribute to your patience. cheers Pat

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks Tony, very fiddly little things indeed. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Okay, I finally committed to attempting some of these fittings. Attached is a trial piece (blackened) which was sized for the mainsail boom, and the actual spider band for the topping lifts and sheet blocks of the foresail boom. With the test/trial band you might notice the ear loops are different sizes where I experimented with what looked best/more correct - I also got a little too aggressive with the filing (removal of the solder etc). I still have some clean-up to do on the loops of the actual piece to try ad polish out some of the 'jaw marks' as I had to forcefully manipulate the ends into their receiver holes before soldering them. The booms have been made and the jaws fitted to them, but I am still determining the best material to use, and the easiest way to form the reefing combs before finalising the booms. Still ahead are the boom hoops for the jaws, and the hoop at the very end of the boom. Slow progress but getting there. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Looking really good Steven, those mock-ups are a good way to bowl-out any issues before fitting the actual. cheers Pat

- 508 replies

-

Wow Glen what an effort, and the result is well worth the prolonged 'fight' you endured - it looks great in its new home. I admire your persistence and 'never give up' attitude. 👋 I also liked your boxing match analogy, very appropriate in this instance. Now Rocky Balboa, slap some ice on those bruises and have a good rest cheers Pat

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Good luck Glen, hoping all goes well. cheers Pat

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.