-

Posts

2,721 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

How long does that cedar stay aromatic?

One of my favorite scents...

- mtaylor, Jack12477, Keith Black and 2 others

-

5

5

-

-

Do you have any links for the YouTube tutorials for Fusion360 based on the drawings in this book.

I could not find any.

All the videos I see are for AutoCAD

The book says:

In fact, it provides no instructions at all for using the interface of Fusion360

It is just a collection of CAD drawings with the dimensions.

It really does not look very useful for learning Fusion 360.

-

-

Allan,

Of interest also, the contemporary drawings earlier in the discussion show one piece and no bolts.

- mtaylor, Keith Black and thibaultron

-

3

3

-

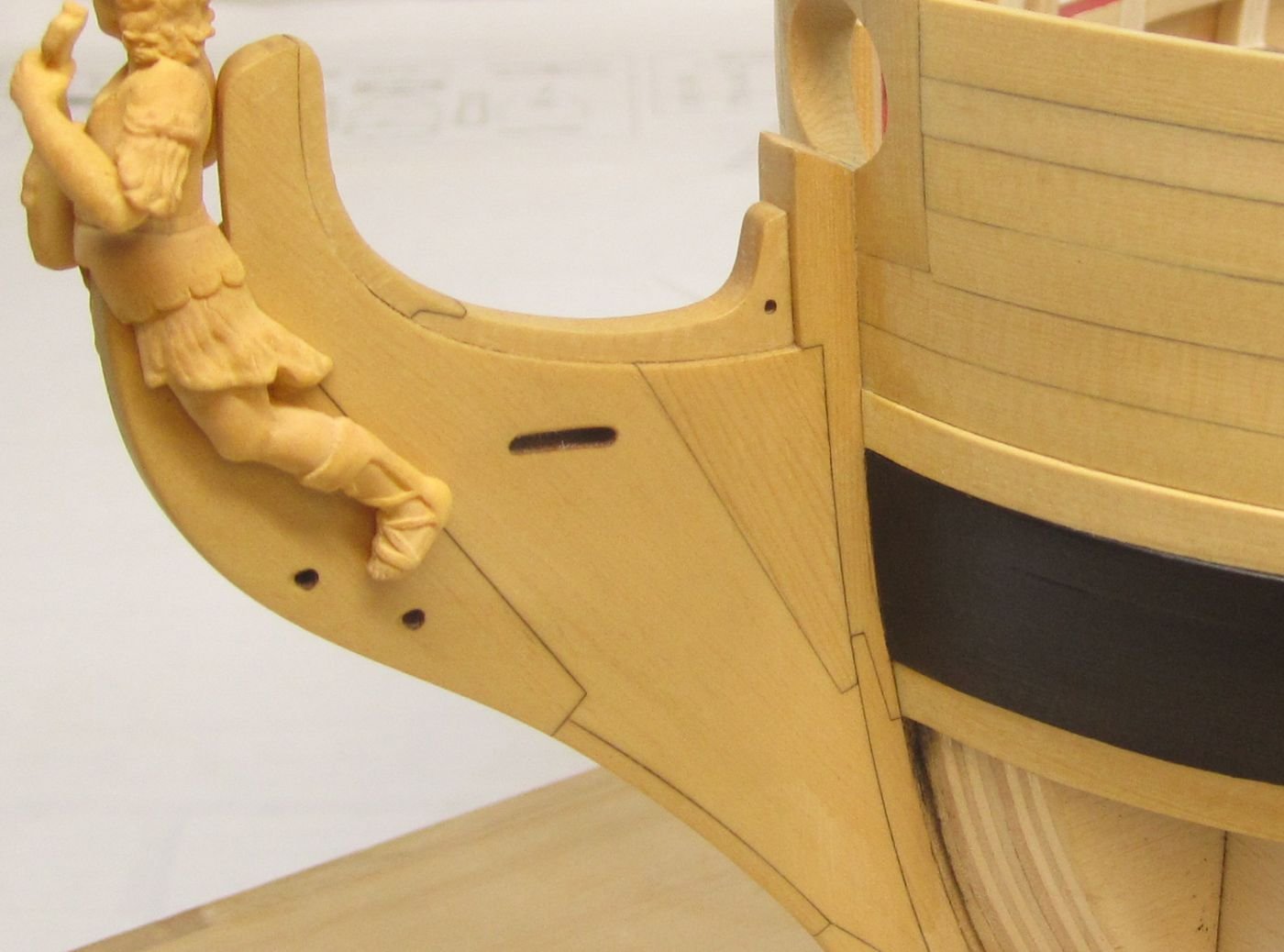

44 minutes ago, allanyed said:

I do not see any mention of the trucks being constructed in pieces bolted together.

This is interesting in that the trucks are often depicted with bolts, which wouldn't be necessary if there was only one piece.

Here is a truck from Victory with two pieces bolted together. However I have seen other carriages from Victory with the trucks being one piece and no bolts.

I realize the current Victory carriages are probably mostly modern reconstructions.

- thibaultron, Keith Black, mtaylor and 1 other

-

4

4

-

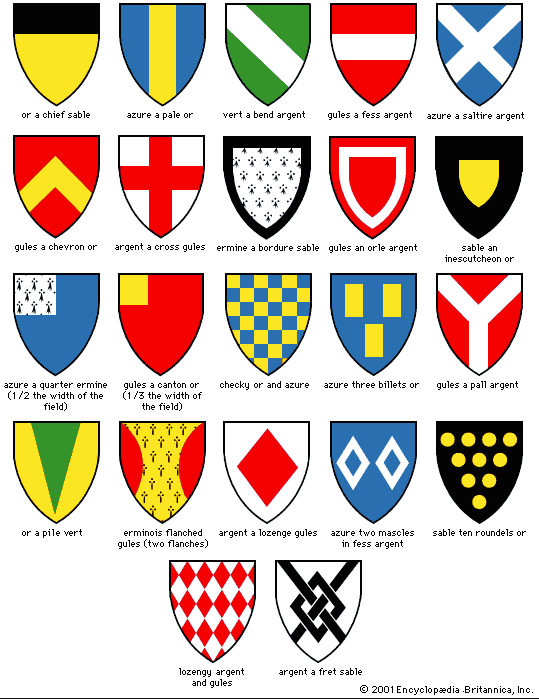

1 hour ago, Nix said:

I also struggled to find the many flags on the sides, and the signification of the one on the top of the mast.

The shields on the side depicts simplified Coats of Arms. Google tells me they may have been derived from any number of countries.

The flags may just be whimsical creations of the artist.

- mtaylor, Nix and Keith Black

-

3

3

-

22 hours ago, CDR_Ret said:

You guys should work up a tutorial for developing laser patterns for things like cabin and roof planking, skylights, and other fine details.

You might even start a small business of doing bespoke laser cutting jobs to pay for your hobby!

Terry

Terry,

My tutorials would be more of a " what not to do " when developing laser patterns.. My experience has been real hit and miss before there was much expertise available.

I enjoy making the stuff I do, and my tools and workflow have improved, but I don't want to compete with the pros. The logistics are a bit challenging, and it needs to remain fun for me.

I am always open to helping a fellow MSW member with a 1-off project if my skills and their needs can find a common ground.

Gregory

- Canute, CDR_Ret, modeller_masa and 1 other

-

4

4

-

Hi Rob B,

FWIW, Mamoli kits do not come with a separate parts list.

All the information is documented on the plan sheets.

Sometimes there is a color chart for the wood on the inside of the box, but as you can imagine it may not be much help.

Your best guide is the measurement of the wood, and the quantity, which can be loosely matched to the amount called for.

It is a bit of a challenge, particularly with a large kit like Victory.

-

Have you checked out LightBurn!

They have an unrestricted 30 day trial.

One of the powerful tools is a bitmap trace that I found a lot easier and more powerful than Inkscape.

Greatest of all is you can have many layers. Each with it's own power and speed setting. You can control the order the layers will cut or engrave, or you can choose a layer to not cut at all.

When I first started using it, it was like I had a new, more powerful laser.

- Canute, modeller_masa and mtaylor

-

3

3

-

Update:

I originally tried one of the Atomstack brand 10w machines looking to save quite a bit. but really wasn't happy with the build quality or the performance.

However, if you want to stay in a lower price range it shood be adequate.

I was able to return it and I bought the Xtool 10w machine, which I upgraded to 20w and have been using for over a year now.

The working area is 432 X 406mm but I believe there are bed extensions available.

modeller_masa may be able to tell you more about a larger work area.

Getting a 40w machine will put you in the $2,000 range, but if that is in your budget, I can only recommend the Xtool brand because I haven't had any experience with other brands.

I also recommend you get a Honeycomb worktable and the air-assist feature.

Some type of exhaust system is also a must have regardless of the laser power.

I also highly recommend Lightburn software to drive the laser. It provides a very powerful and versatile interface.

If I can answer any more questions, I will do my best.

-

2 hours ago, PeteB said:

Hi Gregory - which 20W /40W Blue diode laser would you recommend looking at having regard to our modelling needs? Cheers Pete

I'll get back to you later. Just saw this and will get back to you with particulars. I know it is Xtool brand. I really like Xtool compared to some of the cheaper brands..

-

-

Should be able to find them here:

-

-

-

2 hours ago, Ed Ku20 said:

Question: Does anyone know if these steps need to be installed on both sides of the hull or just the starboard?

Just thinking out loud, I would think steps on the port side would make sense..😁

-

6 hours ago, jfhealey said:

The masts of course are not glued in nor are the tops glued to the crosstrees or topmasts glued.

Of course not. They wouldn't have been on the actual ship.😁

Very nice work!

- CiscoH, FrankWouts and dvm27

-

3

3

-

-

-

Regardless of what the kit plans call for, the goal is for the wales to fit into the rabbet at the bow.

Quote

QuoteAnd one other thing I would like to mention. The wales and black strake would fit into the rabbet at the stem. It wouldnt stand proud as is shown on most kits and models these days. Its another typical oversight. To fix this, I simply reduced their thickness gradually up to the rabbet so it looks like it fits into the rabbet. I used a sharp chisel and some fine sandpaper.

This post from Chuck's Winchelsea illustrates it nicely.

- mtaylor, allanyed, hollowneck and 1 other

-

4

4

-

On 7/16/2023 at 12:54 PM, Chuck Seiler said:

Am I hearing this correctly?-

1. If I intend on staining all or part of a model's hull I need to stain the planks BEFORE I affix them to the frames/bulkheads?

2. A coat of Minwax stain is thicker than paint and therefore is out of scale?

I'm skeptical on both.

Agree particularly with number 2. The Minwax & Varathane stains I am familiar have a consistency similar to mineral spirits. Unlike paint, there is no obvious build up on the surface of the wood.

How would a layer of anything, measured in microns, appear out of scale?

- Chuck Seiler, Darius359au, Canute and 1 other

-

4

4

-

6 minutes ago, RossR said:

Do you pin the rudder to the ship?

Yes, but I'm not sure it's necessary depending on how you go about fabricating. I didn't document my method very well, but I could come up with something if you are interested.

I will eventually be doing it with my rattlesnake, but can't say how far in the future that might be.

-

You might consider card. It really lends itself to simple shapes like this.

I used black card, but it takes paint very well so the color of the stock is not that important.

- GrandpaPhil and allanyed

-

2

2

Construction of Masts for 18th Century 'Ships of the Line'

in Nautical/Naval History

Posted · Edited by Gregory

When you say " how", do you mean tools and methods, or just design?

Lees shows a lower mast from 1773 to 1800. Note the sections.

Mondfeld shows the cross section of a made mast, but there would be little point and somewhat challenging, in trying trying to model this type of construction, unless you wanted to

score some lines along the mast to to represent the pieces used.

For more details you could get a copy of James Lees The Masting and Rigging of English Ships of War, 1625-1860 or Historic Ship Models by Wolfram zu Mondfeld.

The Anatomy of Nelson's Ships by Longridge is also a good modeling reference for Victory.