-

Posts

3,168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

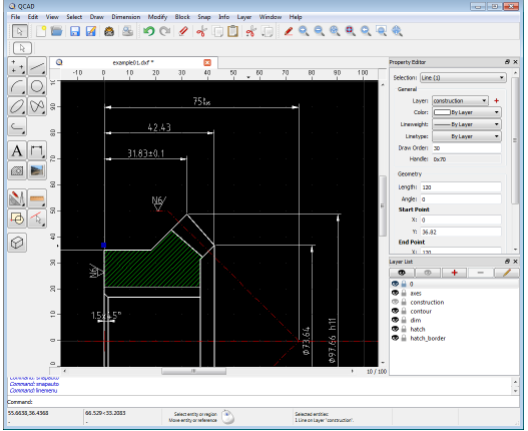

John Fox III just posted this in another topic: I hadn't see this before, but it looks like it might be a great tool for tracing/designing parts for our lasers.. QCAD

-

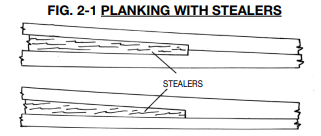

Actually, with this hull form, the planking fans out at the stern for several planks.. This is a snip from the Cheerful plans drawn by Chuck.. Without wider planking stock this is not possible. Your plans may show what are called stealers that are used to fill in gaps that would develop if the uniform planking strips are used..

- 71 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Does the ship just rest in those pedestals, or are they fastened in some manner?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Any other Glowforge laser cutter/etcher users?

Gregory replied to Tim Holt's topic in 3D-Printing and Laser-Cutting.

Something to keep in mind: I rarely include tabs on my parts to be cut after the laser is done. With no tabs, air assist can blow small parts around, to end up in the exhaust or in the path of the laser down range. Air assist is more useful for me on thicker stock, greater than 1/16.. -

Any other Glowforge laser cutter/etcher users?

Gregory replied to Tim Holt's topic in 3D-Printing and Laser-Cutting.

Before I had my 40w C02, I used a low power laser for scoring on anything thicker than 1/32, followed up with a scroll saw, which tended to follow the scoring. -

Have you settled on the Domanoff type machine? While I have seen that it can produce decent scale rope they can be problematic and limited when it comes to making a wide variety of rope. For different size rope, you would have to change the bobbins, and you are limited to four strands of any one size. Which means for a particular size rope made from a particular size thread, to get a larger rope, you would have to make 2 or more lines, then wind them onto bobbins, and proceed to make larger rope from them. With a rope walk like the Syren Rope Rocket, you don't have to worry about bobbins, you just use any length of thread, depending on the length of the line you want to make. You can also increase the size of the rope by adding more threads to the 4 whorls that make up the heart of the machine. It is not as compact as the Domanoff, but is much more versatile. Then there is the Frolic style, discussed here: , but requires a lot of DYI.. There are a lot of satisfied Rope Rocket users here at MSW.

-

Any other Glowforge laser cutter/etcher users?

Gregory replied to Tim Holt's topic in 3D-Printing and Laser-Cutting.

Does Glowforge have air assist? It will reduce charring somewhat. I have found the amount of charring has the most to do with the type of wood and how seasoned it is. -

Frolic style ropewalk plans

Gregory replied to Chuck's topic in Rope Making/Ropewalks's Ropewalk Plans/Downloads

-

Chris, Any thoughts on coming up with display pedestals for your box art and promo pictures that are a little more in keeping with the quality of this beautiful piece of art? I realize display option details will be up to each builder, but I find the base as shown somewhat distracting from the rest of the fine workmanship.

-

I really like your shade of red ..

- 274 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Bob Hunt was once a respected contributor to the ship modeling community, but he has chosen to go over to the dark side and support the theft of intellectual property.. https://modelshipworld.com/forum/149-our-stance-on-piracy-in-the-hobby/ I would not recommend supporting his business.. It's ironic in that he has often complained of people stealing his intellectual and real property..

-

How to stain or dye boxwood?

Gregory replied to tkay11's topic in Painting, finishing and weathering products and techniques

I have seen many contemporary models where the blocks are approaching black.. Then there are these, which I believe may be boxwood, as the color is a lot like very old boxwood carvings I have seen. I have seen similar blocks on other contemporary models. If I could source blocks like this, it would never occur to me to try to stain them, but as I said above, I really don't want to wait 200 years for the color to develop. The boxwood blocks I have acquired from Syren, the quality of which can't be matched from any other source, are too light for my taste. After reading the info in this discussion I have dyed some of my 'Chuck' blocks with some Fiebing's leather dye with results I like. -

Like you, I don't want to struggle with these numbers, but you might find this interesting.. With your Rope Rocket at 26 feet moving 3 feet with tensioning, that comes out to about 11.5%. I checked my rope walk, and with 55 inches of thread, it starts to lay up after the looper travels about 6.5 inches, or 11.8%..

-

Like Chuck says, you can over think it, and gain absolutely nothing.. FWIW, with my set-up, when you have twisted the yarns enough, the rope starts to lay up.. This will vary with the type of thread.. Counting would be pointless.. I have been curious about what the RPM of my whorl gears are.. I might get around to checking it someday..

-

The laying up is only a small fraction of the twisting of the strands, and it also depends on the length of the rope. The longer the rope, the more twists in the lay up. I have a more traditional rope walk with motor driven whorls and a looper that is driven by tension. I would guess the yarns/threads are twisted hundreds of times for each twist in the strands in the layed up rope.

-

There are the trees, and there is the forest.. While the rigging in many ways defines these ships and their models, what the modeler hopes to achieve is worth consideration.. If you are going to model without sails, I feel a lot of the sail handling rigging would detract from what you have in the absence of sails..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.