-

Posts

3,168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

This is what PRS asked, and it looks like a couple of owners have responded with relevant information.. I can only echo what tkay11 says. The tilting blade and micro adjustable fence are great to have without having to assemble or disassemble anything. Of course, the heart of a good saw is the blade, and I don't care for the options offered by Proxxon. I have been using blades from Malco Saw. I'm sure there are superior machines but I have no reason to purchase one if the FET is doing what I need to do.. If you have any specific questions Pail, I will try to answer based on my experience.

-

Do you feel it is all you need without any of the add on's?

-

The oil looks very nice and you might apply more coats as time goes on.. To protect it as you go forward, you will see a lot of builds where the stem and keel are covered with painters tape until the major hull finishing is done.

-

@PRS This 1/2" arbor adapter from Micromark works on the FET and will increase your blade options..

-

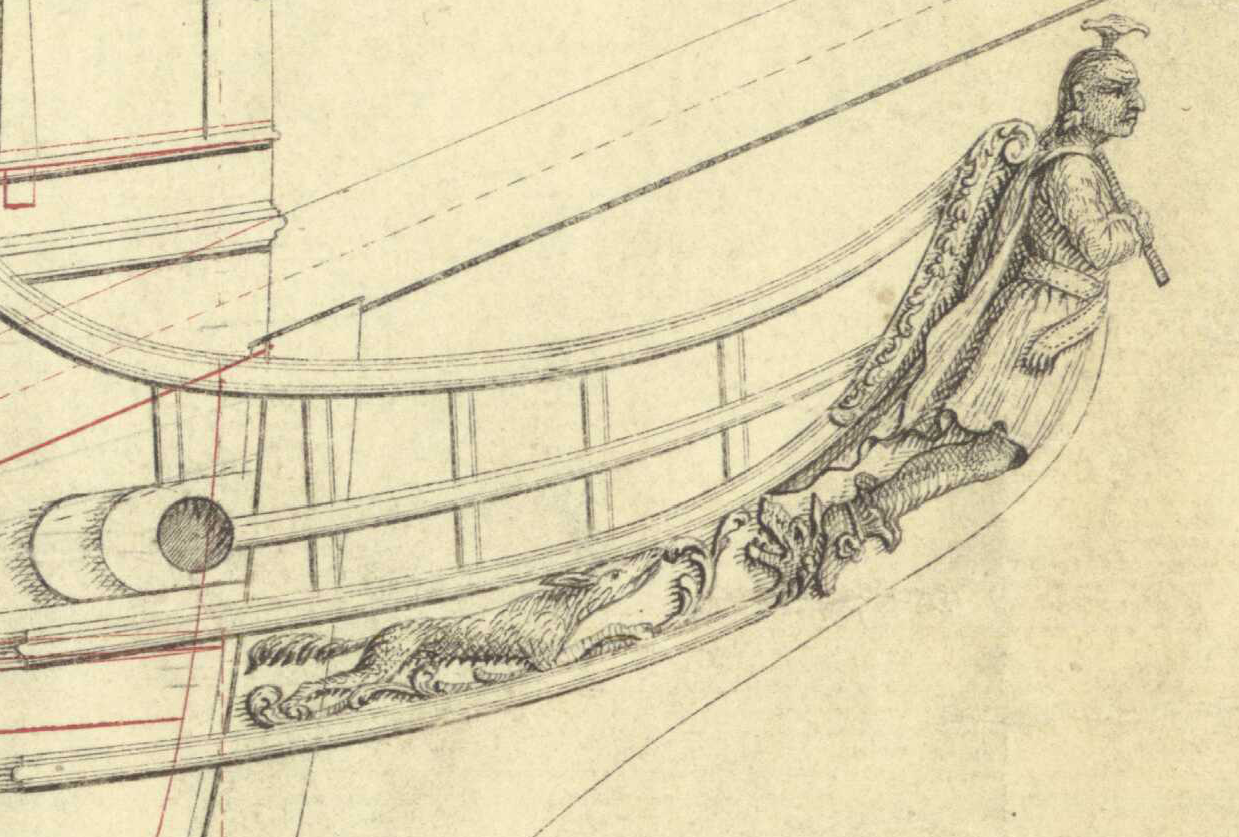

You might find the high resolution plans of Cormorant at Wikimedia commons helpful.. There are several different sheets.. You can click through them at the link provided. All Rattlesnake kits are based on these plans. The plans do not show any quarter badges, but they make a nice extra touch.. The carving detail and figurehead are very interesting..

-

Le Coureur by PC52 - Mamoli - 1:54

Gregory replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

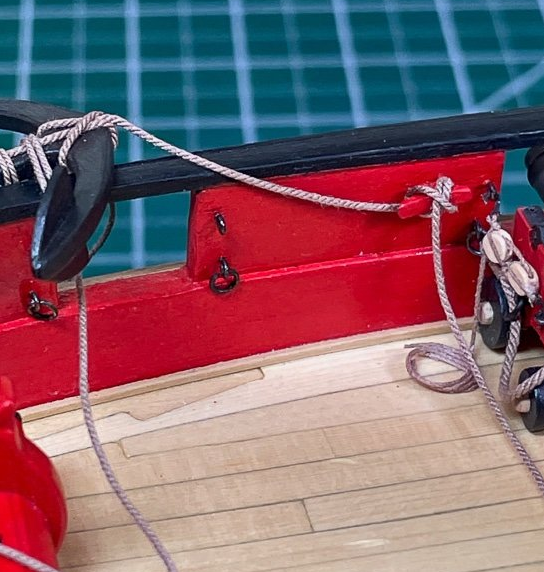

I think you should go with what works and looks good to you. Is there some room to add a cleat to the bulwark? -

Le Coureur by PC52 - Mamoli - 1:54

Gregory replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Look through this anchor rigging on GBarlow's Cheerful.. I don't think you can go wrong by using this information. ( follow the arrow at the top right of the post quote.. ) -

Martindale 4" Saw Blades

Gregory replied to HReardon's topic in Modeling tools and Workshop Equipment

Mark, ' Martindale ' would not search at either of those sites.. -

Martindale 4" Saw Blades

Gregory replied to HReardon's topic in Modeling tools and Workshop Equipment

If Googling doesn't turn up a retailer, I would be surprised if anyone here knows of a source.. For years, the go-to blades here were Thurston, then when they went out of business, Malco is the preferred source. Why the Martindale blades? -

Martindale 4" Saw Blades

Gregory replied to HReardon's topic in Modeling tools and Workshop Equipment

https://martindaleco.com/store/product-category/circular-saws-cutting-tools/solid-carbide/ -

I thought I had seen it called the " in-haul " tackle, and used to pull the gun inboard, and also restrain the gun from rolling when hauled in.. A true train tackle would be attached to either side of a carronade on a swivel mount. The only way to train a carriage mounted gun would be to pull the rear sideways across the deck, not from a tackle to the rear of the gun.

-

No reason to hate.. Times have changed. I bought this on a whim just to check the quality, knowing I could return it if I had a problem.. Getting a decent board, or combination of similar pieces from Gilmer would probably put me at least $30 before shipping costs.. Our sponsor Modelers Sawmill has some nice sheets for what seems a reasonable price..

-

Another easy place to find them without having to pay shipping, are places like Walmart, Michaels and Hobby Lobby. Look in the jewelry crafting department. It is easy to resize them if you need to..

-

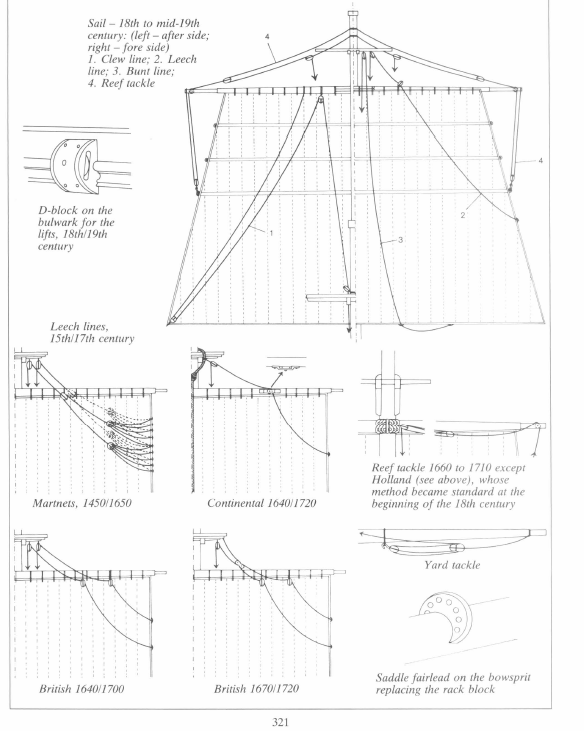

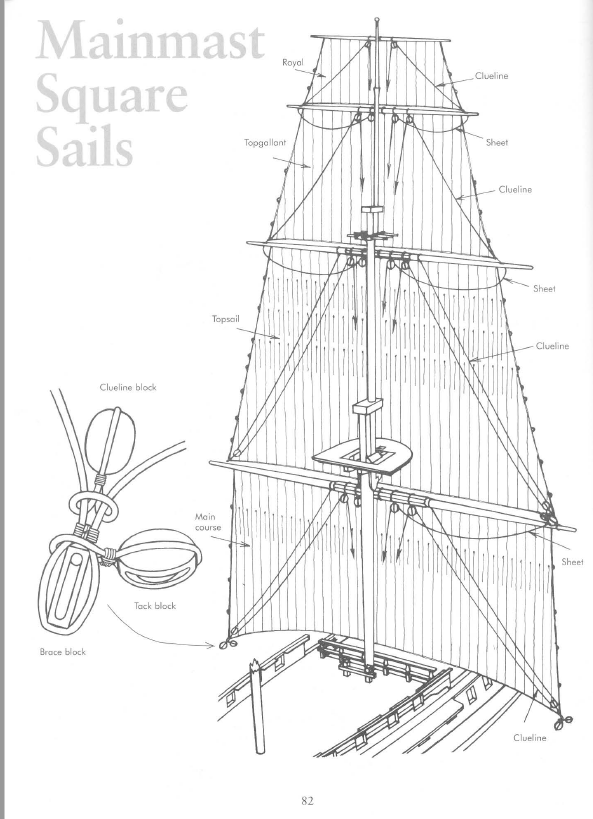

Your question would take a lot of answering that would probably lead to many more questions, and I'm sure you will get some help.. For something so essential to model ship building you need a good reference like Historic Ship Models where you will find drawings like: Or Rigging Period Ship Models.. where you will find a diagram for every line on the ship..

-

Knowing you were in the doldrums for a while, I'm looking forward to seeing your progress on this kit.. I know you will do it justice..

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Here is what I received.. It looks like other castelo I have, and have seen in the past. It is very dense and fine grained. The finish is marble smooth. May be a while before I see how it saws and carves.. The big pieces are 15cm long and 5cm square. I have yet to see anything compared to this price in this type of size.. Here are a couple of eBays: South American Castelo Boxwood turning blank 1-7/16" x 1-7/16 x 6 $13.25 shipped. Boxwood Logs for Knife Handle Scales Blanks Wood carving, 15cm Length, 1 piece $37 shipped Those prices seem pretty outrageous, but I guess someone is buying it..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.