-

Posts

3,168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

spare parts for hull

Gregory replied to Bo Button's topic in Building, Framing, Planking and plating a ships hull and deck

Is that the Occre kit? Someone having just the hull parts to spare is unlikely. Your best shot would be finding a kit someone wants to sell. -

The builder can make as much visible as they want to.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Dying/coloring rope; sources for purchase of quality rope

Gregory replied to Tomculb's topic in Masting, rigging and sails

In this topic, Chuck said: Hard to argue with that.. -

Dying/coloring rope; sources for purchase of quality rope

Gregory replied to Tomculb's topic in Masting, rigging and sails

I suspect Chuck sold thousands of feet of the stuff. We should have some feedback on the sag factor.. -

Dying/coloring rope; sources for purchase of quality rope

Gregory replied to Tomculb's topic in Masting, rigging and sails

I feel like the baking tones that down somewhat.. -

Dying/coloring rope; sources for purchase of quality rope

Gregory replied to Tomculb's topic in Masting, rigging and sails

How much time? Isn't just bout any material going to change with humidity if it is not sealed in some way? -

Dying/coloring rope; sources for purchase of quality rope

Gregory replied to Tomculb's topic in Masting, rigging and sails

Thanks for checking it out and reporting back. -

What kerf are you looking for?

-

The one on the right is looking good.. Just take care to remember the holes are square, so the battens should be shaped to make that happen.. I'm not sure what the pluses and minuses are for the increased tooth count.. Someone with more info would have to chime in..

-

While I am well aware of the qualitiies of boxwood, the cedar has more of a glow. I look forward to seeing how it ages.. I wouldn't want to wait 200 years for the boxwood to take on the amber look that looks so well.😁

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Allan, I think Don is looking for a source.. Do you have one? I would be interested also.. Thanks

-

I get the cutting blades from Malco. On my last orders a few months ago, they have required $100 minimum order. I don't see any thing in the 200 tooth range. I know I have made super fine cuts with teeth in the ~100 range. Byrnes also sells blades Not sure about the arbors, but they also sell arbor adaptors.. For the gratings look for a thickness that suits your job.

-

Cutting pre-scored deck

Gregory replied to Stevinne's topic in Building, Framing, Planking and plating a ships hull and deck

At that scale, and with all the fittings and deck furniture, I don't think the center line will be all that obvious. However, I understand how that sort of thing can eat at you. -

Importing STEP files from ServoCity

Gregory replied to Ian_Grant's topic in CAD and 3D Modelling/Drafting Plans with Software

Have you tried changing the file extension to .STP and see if Tinker can see it? You might consider installing the free version of Fusion 360, import the STEP files, then export them in a format TinkerCAD can use.. Meanwhile you might want to up your game by playing around with Fusion360.. -

Dying/coloring rope; sources for purchase of quality rope

Gregory replied to Tomculb's topic in Masting, rigging and sails

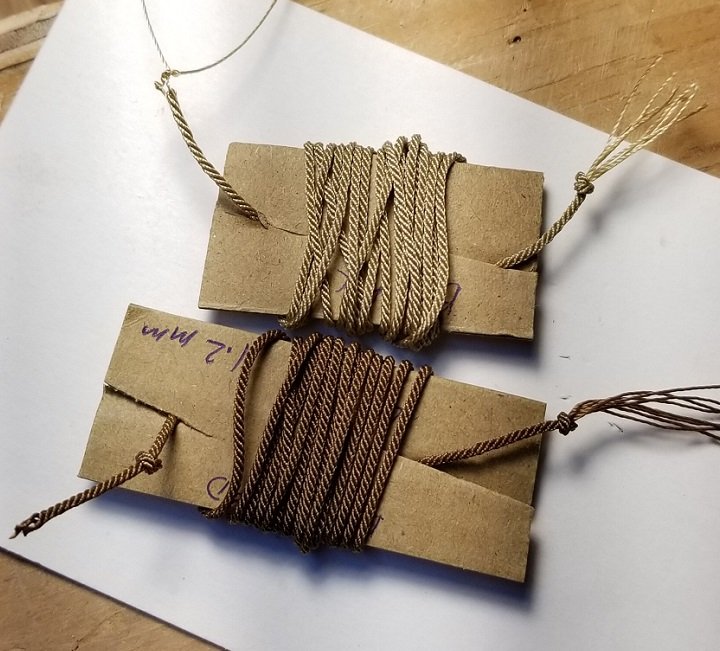

I'm revisiting this in response to the original post. There was a discussion about staining/dyeing boxwood where it was agreed boxwood doesn't take some stains very well. One or more people mentioned dyeing with an alcohol based stain. I proceeded to get some Fiebling's dark brown shoe dye to experiment. It actually worked pretty good to make my boxwood blocks darker. I had thought, and mentioned above, that I didn't think synthetic/polyester would take dye very well, with the idea that it was like trying to dye plastic and wouldn't stick. Well, I was wrong. On a whim, I dyed some of my home made polyester rope with the above mentioned dye and it really worked pretty good. Top is before, bottom is same rope dyed. ( Please ignore the unravelling.. That happened before I baked my rope.. ) Getting the color you want could take a lot of experimenting, and have a lot to do with the color you start with. For home rope makers, I see it as a way to avoid getting different colored thread for standing and running rigging.. Find a good light color you like for running rigging, then dye it dark for the standing.. Note: The dye can be very messy, but it cleans up pretty easily with alcohol, depending on how long it sits before you get to it.. -

Bow & Stern blocks

Gregory replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

When I described extra bulkheads, they don't have to extend to the backbone like the original framing. All you are looking to do is fill out the outer profile to provide a surface for planking. Just add what amounts to shims to the edges of the existing bulkheads. Create as many layers as you feel necessary. It is a lot like adding blocks, but laminated so you can reduce the amount of shaping needed. -

Bow & Stern blocks

Gregory replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

I would use bass. I personally wouldn't go for a solid fill. I would add what amounts to several additional bulkheads, using maybe 3/16 -1/4 sheet. Use the plans/existing bulkheads to interpolate the shape.. -

I'm going to toss this out here.. I can make what I feel is very acceptable model rope.. However, I do not think I want to go into the model rope making business.. If someone has a particular project, with details in color and size, I would enjoy working with them to provide the rope they need. The cost would basically be postage and materials. I do not have the space to create 20 foot lengths like Syren used to do. It would be more in the 4 to 5 foot range. Of course, I could provide as many 5 foot pieces as someone might think they need. I never made anything for my own use that was more than a couple of feet. No one line in a project was ever longer than that. Send me a message if you would like to discuss this or get a sample..

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.