marktiedens

-

Posts

1,737 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by marktiedens

-

-

Hi Michael - thanks for your nice comments. Regarding the windows - they are vertical. It`s just the camera angle. I sometimes have to take a few pictures with my low tech camera to get a decent shot that isn`t blurry & out of focus. Another picture from the side - the bulkheads are vertical. They look slanted because of the sheer of the deck.

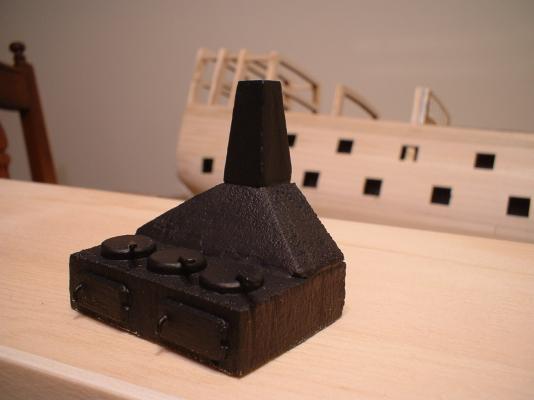

Meanwhile,I thought I would build a little ship`s stove. I made the base out of balsa & the chimney out of some 1mm thick walnut scrap. The "pans" were pieces of dowel & all the handles were made from brass wire with the pan handles hammered flat. It`s a little rough,but the only thing that is easily visible is the chimney. The rest of the stove is hidden under the forecastle deck.

Mark

P.S. - Regarding the deck planks I must give credit to Vince P for the bleaching idea.

- canoe21, Keith_W, Seventynet and 4 others

-

7

7

-

Thanks everyone for looking in & hitting the "like" button. Finished the main deck planking & one coat of poly applied. I just darkened the edges with an HB2 pencil. I simulated the nailing by using a half twist of a #78 drill bit to make a tiny indentation. I like how the final color came out.

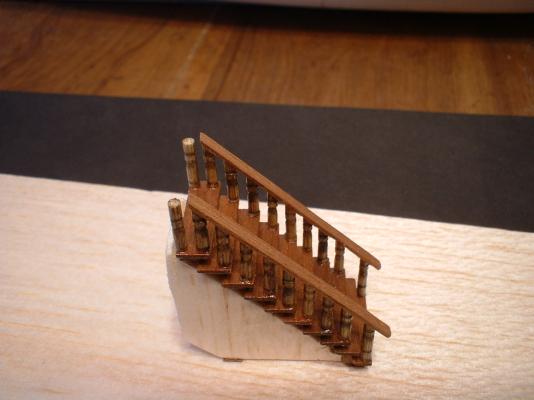

Meanwhile I thought I would make a staircase for the main deck. I glued the steps onto a balsa former angled at 45 degrees. While thinking of what to use for hand rail posts I found some toothpicks with grooves cut into the end & only 2mm in diameter - seemed perfect for the job. After staining them I cut them off to the correct length & glued them on & added the hand rails from some 1mm by 2mm walnut strip. Not perfect but I thought it came out ok. I will finish the railing around the opening in the deck later.

Mark

- avsjerome2003, canoe21, Seventynet and 2 others

-

5

5

-

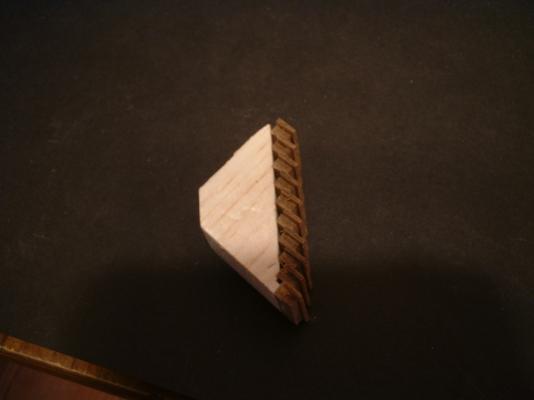

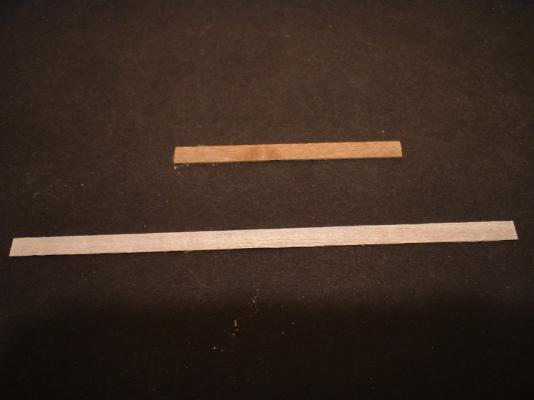

After gluing the metal bulkhead on I thought it would be a good time to plank the main deck - it will only be planked from the metal bulkhead forward because the deck behind it will be enclosed by the other decks & won`t be visible. The wood supplied for the decks is walnut ,which is a little too dark for the decks. I decided to try the soaking in bleach method to lighten them up. After soaking in bleach for 45 minutes & then rinsing very well with water I set them on some old towels to dry. After drying they had turned to a very light gray - much better. I was very pleased by the way they turned out. The first picture is before & after bleaching.

Mark

-

Pete - thanks for your kind words.I had my reservations when I started this kit because I haven`t done much scratch work before,but I am really enjoying it. The closer I look at the castings in this kit the more I am impressed - the detail is better than any kit castings I have seen in other kits.Everybody has different build methods so each one should look a little different.

All the best to all this holiday season.

Mark

- alan baker and NMBROOK

-

2

2

-

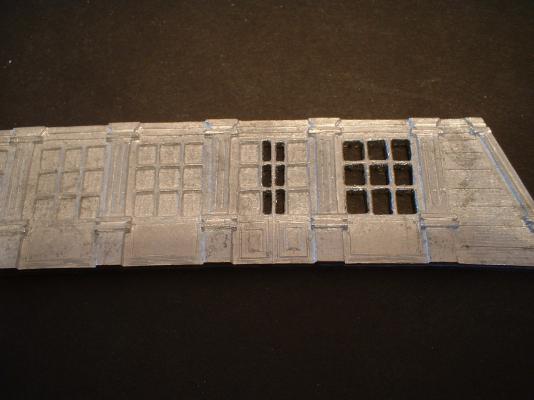

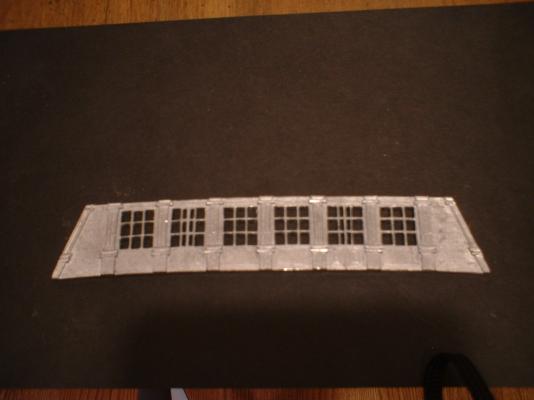

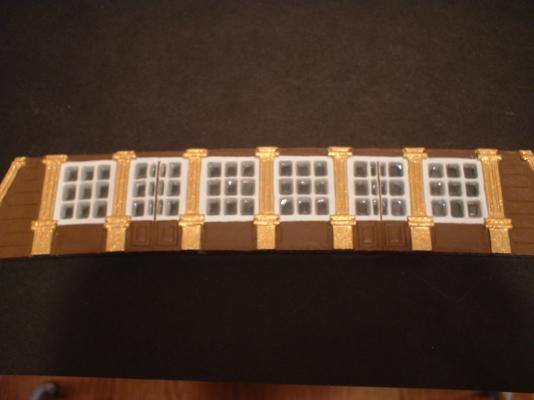

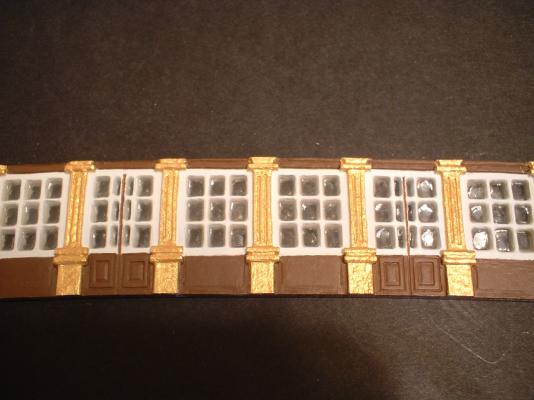

Started working on the cast metal bulkhead which is located under the quarter deck. The detail on the casting is pretty good,but I din`t want to just paint the windows.I got out my little mini drill & micro files & proceeded to open up the window openings. It was a little time consuming but not too difficult. Then I painted it with a medium brown with white window frames & gold trim.I thought it came out pretty good.

Also I want to thank every one for there looks & likes. Thanks also to the other RW builders - I refer to your build logs frequently. And a big thanks to Pirate Pete for his very helpful interpretive info. Also forgot to mention I used a product called Micro Kristal Klear to make the window panes.

Mark

-

Congratulations on completing your fabulous ship

.

.Mark

- Piet, Mirabell61, Dimitris71 and 2 others

-

5

5

-

- Seventynet, canoe21, avsjerome2003 and 3 others

-

6

6

-

A small update - getting ready to install the main deck. I glued some small strips to the bottom of one of the deck halves to better keep the joint even when gluing.

Apparently the top of bulk head B is supposed to be cut off before installing the main deck,then later on after installing the forecastle deck a beam needs to be made to support the rear edge of the deck. After test fitting the forecastle deck I see that it would not quite cover the top of the bulkhead,thus the need to remove it. I had another thought

- I could cut the bulkhead down the center so the end would be a couple of MM behind the deck edge.Then I could put on a thin veneer to hide the plywood. That way I would not have to build a beam. I am installing the main deck before building up the bulwarks & leaving that bulkhead in would give the planking a bit more support. Any thoughts to this idea?

- I could cut the bulkhead down the center so the end would be a couple of MM behind the deck edge.Then I could put on a thin veneer to hide the plywood. That way I would not have to build a beam. I am installing the main deck before building up the bulwarks & leaving that bulkhead in would give the planking a bit more support. Any thoughts to this idea?Mark

- fmodajr, avsjerome2003 and canoe21

-

3

3

-

I think those are called fenders. I will check them before going any further. Thanks again for the info.

Mark

-

Thanks Frank - I would say it`s a little more difficult,only because there are not a lot of pre-cut parts. The detailed plans are pretty good though.

Mark

-

Thanks Keith,I will keep that in mind. By side strakes do you mean the wales?

Mark

-

A little progress - I figured it was time to cut out the lower 2 rows of gunports. I have some wood squares on sticks made up of various sizes to mark out the ports.

After marking out the ports I drilled a number of holes around inside the lines,cut out the center with a small keyhole saw,& filed them out to size. The lower row are 14mm & the middle row are 13mm.

After that I thought it would be a good time also to cut the openings for the side entries. I ran into one small problem - apparently the gunports are a couple of mm too far forward. The side entries should be almost directly above the gunport at bulkhead 1 amidships,so what I did was after marking the bottom of the entry to be level with the second gun deck I simply cut part of the bulkhead out where it interfered. So not really a problem - just a little more work. I don`t know where I was off when marking the gunports because I triple checked the positions before cutting them out

.Maybe the positions on the plans were slightly off.

.Maybe the positions on the plans were slightly off.Mark

- Rainbow, md1400cs, Beef Wellington and 9 others

-

12

12

-

Thanks Mike & Ian. The wood is the limewood that came in the kit. It`s just the first layer - the second planking is still to come.

Mark

-

Thanks Mike & Vince - I can hardly wait until I get to the galleries

.

.Mark

-

-

-

-

Hi Rob - I put the lower planks on in 2 pieces for ease of assembly. It was too difficult to make the severe bend at the stern with the bow portion already glued in place. The framework is really solid so the strength of the hull is not compromised. The only other pictures I have of the planking are in post #24. I did use more CA than I really wanted to - I did a lot of edge bending at the bow & there was no way I could clamp them well enough for PVA to set up. The glue between the planks was some PVA & some CA.

Mark

-

I built the old version of SoS way back. I don`t have the plans anymore but I believe they were dated from the 70`s or early 80`s. I remember that it was advertised as 43 inches long. From what I have seen the older kit version is a much nicer kit than the newer version - less pre-made parts but better quality materials. there was no balsa in the old version. I don`t remember the scale.

Mark

-

Thank you all for your kind words - I would rather spend more time on the first planking than trying to fix it in the middle of second planking. Mike - I have a number of those plastic containers from previous builds. Due to the number & size of the castings if they put them in hard containers the box would probably need to be twice the size it already is. By the way - the castings are top notch except maybe the windows. Photo etch would have been nice for those.

Mark

-

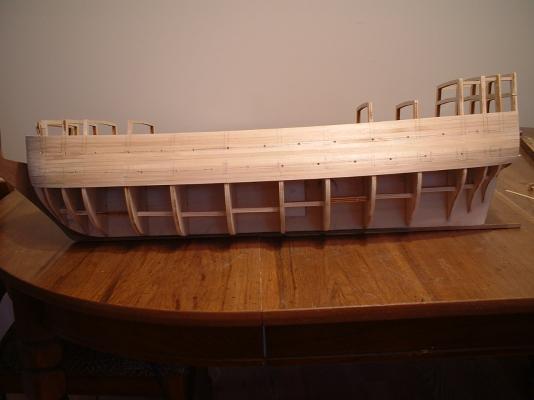

I haven`t posted for a while - been planking. The first planking from the main deck down to the keel is now done & sanded. No filler was needed

. I was careful to add small shims & file a little as I planked. next will be cutting out the gunports & adding the mounting blocks for the cannon barrels. I will probably not be adding guns to the ports that are blocked by the bulkheads.

. I was careful to add small shims & file a little as I planked. next will be cutting out the gunports & adding the mounting blocks for the cannon barrels. I will probably not be adding guns to the ports that are blocked by the bulkheads.Mark

-

-

-

A little update - before starting on the planking I thought it would be a good time to make the hole for the bowsprit. Planked down from the main deck to just below the lower gun deck. After triple checking the gun port positions vertically & horizontally I drilled pilot holes for marking & cutting the gun ports out, I am trying to decide whether to cut out the gun ports now or finish planking down to the keel & sand the hull first. I`m thinking it may be easier to plank the lower part of the hull first so I don`t snag the sandpaper on all the holes.

Mark

Royal William by marktiedens - FINISHED - Euromodel - scale 1:72

in - Kit build logs for subjects built from 1501 - 1750

Posted

Thanks Keith - I tend to make a lot of sawdust so I blow the dust off quite often. However,my table is still quite messy .

.

Mark