-

Posts

1,621 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by SJSoane

-

-

Hi Peter,

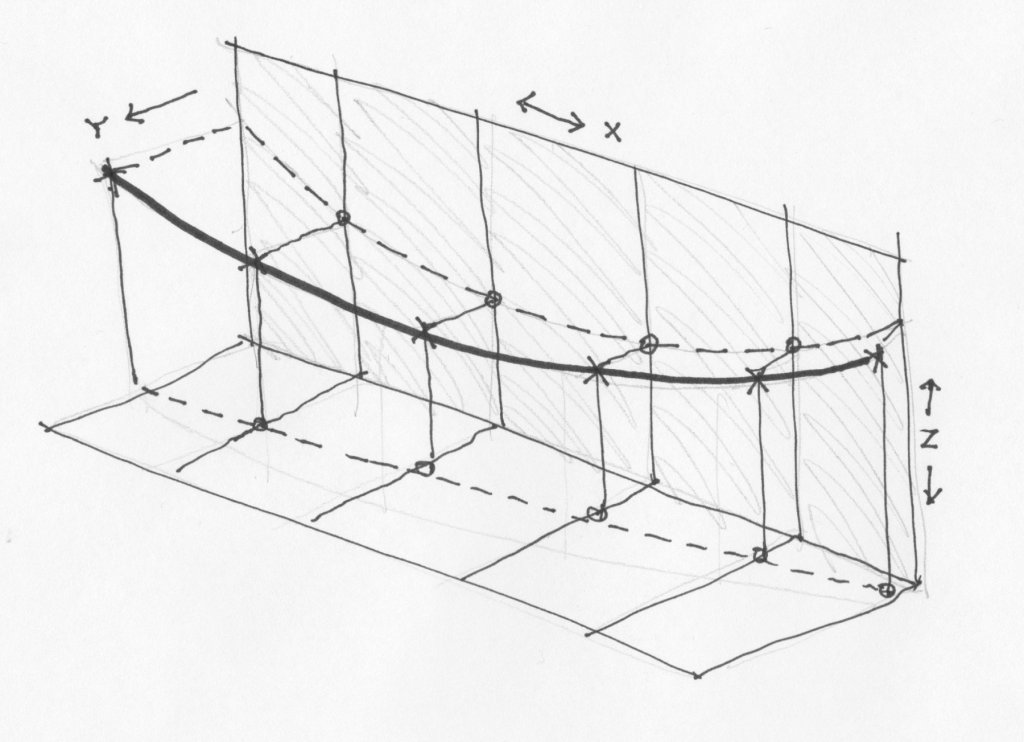

I don't understand how you managed to get the curve in three dimensions in Fusion. Looking at my drawing below, imagine measuring up along a station line in the X-Z plane, then measure out in the Y plane to locate a point on the thick black curve. I have not seen how to switch from drawing in the X-Z plane to drawing on an X-Y plane at right angles, and selecting where the first point on the X-Z plane is located. How did you do this? I could not see how you used the "project/include" tool to find the intersection.

Best wishes,

Mark

-

Wayne, that makes a lot of sense. I look forward to seeing how it works for Peter's hull. I am learning while watching!

There is a Fusion tutorial online that shows how they constructed a curvy plastic housing for a reciprocal saw. It shows how they try to line up the contour lines to be even all around the form, as you suggest, and they are able to add in additional points as needed to do so at tight curves.

Mark

- paulsutcliffe and jud

-

2

2

-

-

I look forward to seeing how you resolve this. I don't understand lofting yet. But I did discover that the construction planes can be resized by pulling at their corners. Admittedly, annoying that they keep growing in size by default....

Mark

-

Hi Wayne

I tried it and it worked! Thanks. Using that method you can choose any axis to align the texture to.

The interesting thing about drawing the boxing joint is that I found out how to shape curved surfaces in Fusion. I drew the taper of the keel in plan, and then extruded it down to the keel's thickness. And then I extruded it up above the Top of Keel line to the top of the boxing joint, to provide enough material to include the curved up surface. I then drew a box in elevation above the Top of Keel whose lower edge is the shape of the upper keel surface, extruded it sideways, and then used it to trim the keel. Really easy. I imagine this can be used to shape transoms that curve in both directions, etc.

Mark

- Jolley Roger, paulsutcliffe and Castos

-

3

3

-

I have been playing with Fusion 360 off and on, once I discovered that it is indeed free for hobbyists. I need to do some additional drafting for higher decks on my Bellona project, and thought I might use this to learn a new skill at the same time.

There is a big learning curve for someone coming from 2-D drafting, but it is very powerful, drawing in 3-D where views do not have to be projected one from the other. Here is the beginning of drawing the boxing on the keel for the Bellona.

I haven't figured out how to orient the wood grain in the right direction. In my architecture software, there are separate textures for both horizontal and vertical surfaces in order to align the grain, but I haven't found this yet in Fusion...

Mark

-

I just experimented with Fusion 360 after working with TurboCad Mac for a few years (the latest upgrade for TurboCad includes CAM, I understand; my version does not). Fusion is definitely more elegant and powerful. It is still not clear to me from the website that the free license is renewable, and so I am a little hesitant to invest a lot of time into creating models with this if it eventually goes away. It has extensive and free training videos.

Mark

- thibaultron and mtaylor

-

2

2

-

-

Hi Paul,

Now that is an interesting idea. The highest quality one would cost $26.40, maybe an interesting investment to see how it could turn out. I have heard that the best still have slight lines where the layers are formed, but cleaning up just one for a master would not be as dreary as cleaning up 74! I will reflect on whether this gives me anything better than just manually turning a master on the lathe, as I did before.

Mark

-

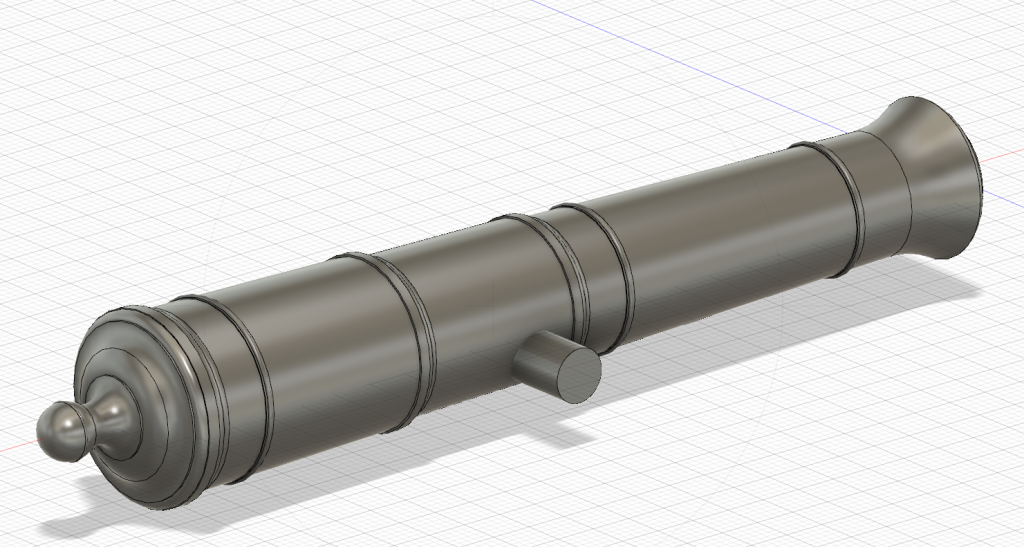

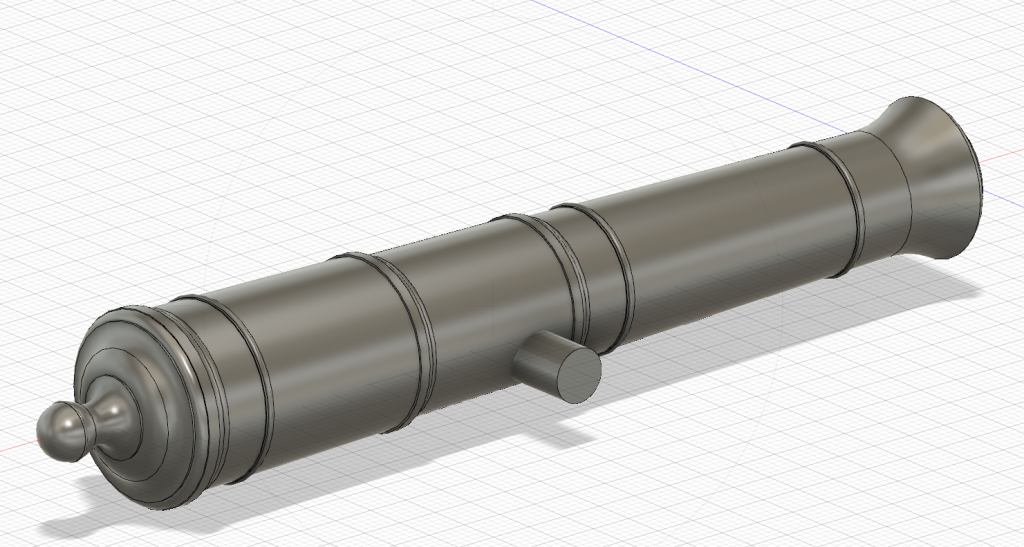

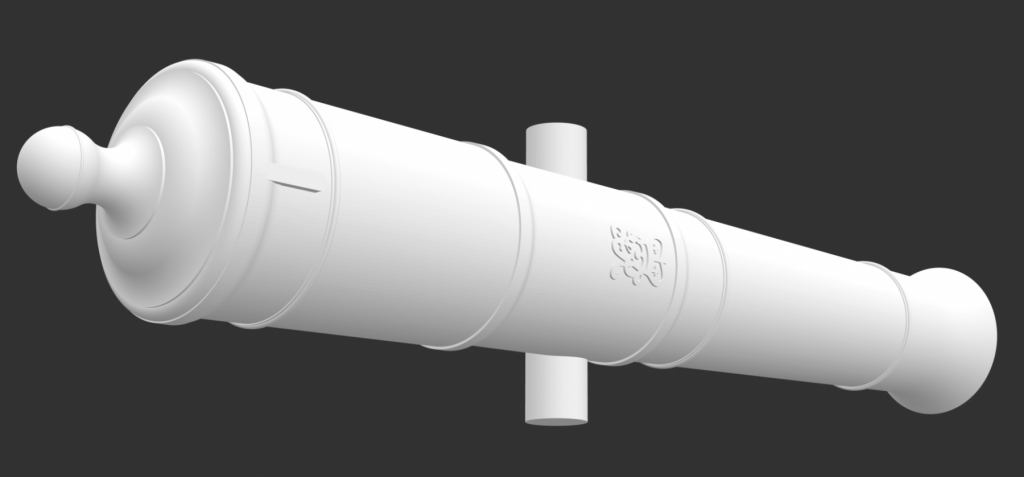

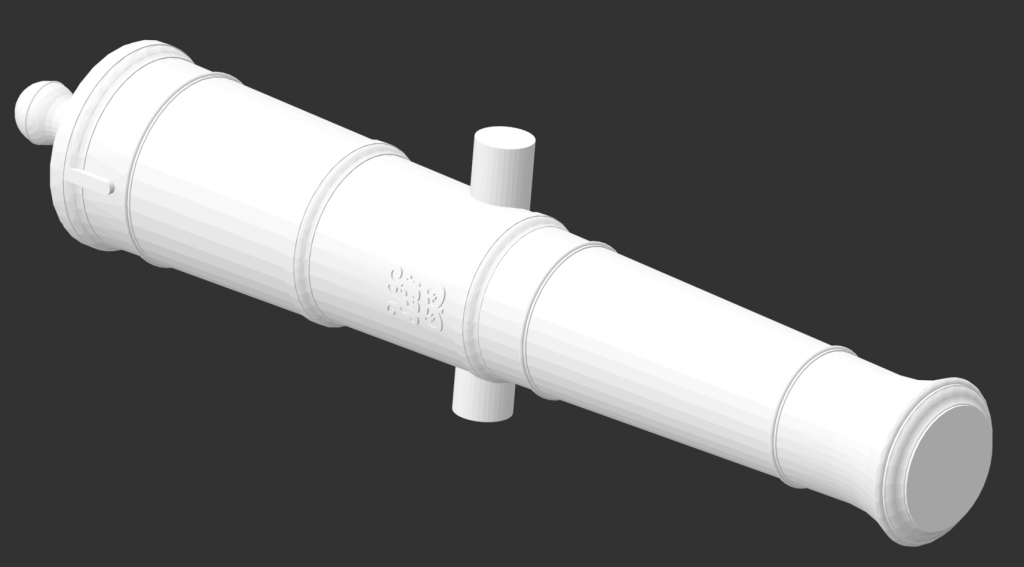

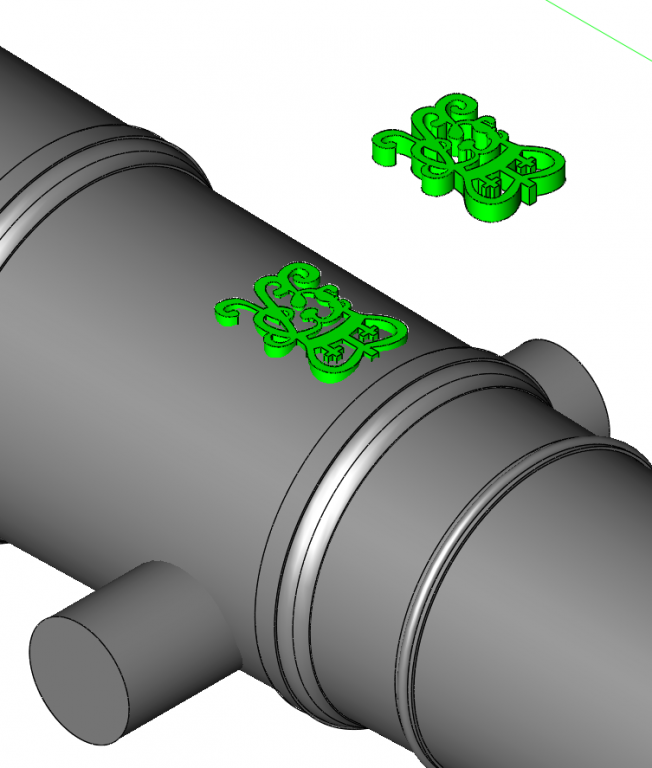

Thanks to the members on the CAD threads, I tried using Autodesk's Fusion 360 software to build a second version of the cannon, and it was very high quality; I also converted the earlier model with the insignia to the STL file type needed for 3-D printers, as shown below. But, it all came to nothing when I got the quote for 3-D printing at an online service. For the 74 guns it was going to be $556 for the lowest level of refinement, up to $1950 for the highest level of refinement. Way too much for a retirement budget, especially since I have been told that they will still show the layers as they build up. 3-D printing is no longer an option. On to other ideas.

I realize that I was attracted to this because the digital model shows all of the wonderful, nuanced detail of the cannon itself, at a scale that looks real. But when this is shrunk down to 3/16" scale giving a 2" long cannon, most of the nuance disappears. I was disappointed to lose what I know should be there. Perhaps the best thing is to print out a large image of the digital cannon and pin it on the wall of my shop, to remind me what the model cannon represent!

Mark

-

- Castos, herask and Jolley Roger

-

3

3

-

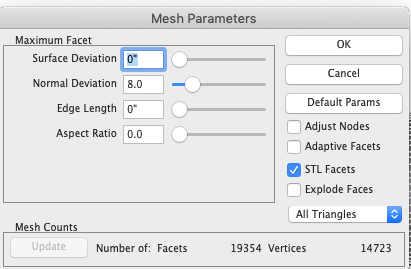

a little more research on STL files today, and I found a much finer setting. I put all setting at 0 except normal deviation which I put small at 2.25. Putting this at 0 really messes it up, for reasons I don't understand. But this file size is 24 MB. I will have to find out the max resolution for the printing company tomorrow.

Mark

- thibaultron, druxey and mtaylor

-

3

3

-

I just came across this thread while posting another topic in this area. After struggling with some of the idiosyncrasies of TurboCad for Mac, I am intrigued by the videos for Fusion 360 a number of you have pointed to. But I don't find on the Autodesk website how much the subscription is after the free trial period, for hobby use. Has anyone subscribed to this, and can you tell me how much it costs you?

Mark

-

- AON, Captain Poison, mtaylor and 2 others

-

5

5

-

Nice, Alan, I upped the surface deviation from 0 to 45. Much better. Thanks for the suggestion!

It turned into a 2.2 MB file, so too big to show here.

Mark

- thibaultron, mtaylor and druxey

-

3

3

-

druxey, I was thinking the same thing!

- thibaultron, druxey and mtaylor

-

3

3

-

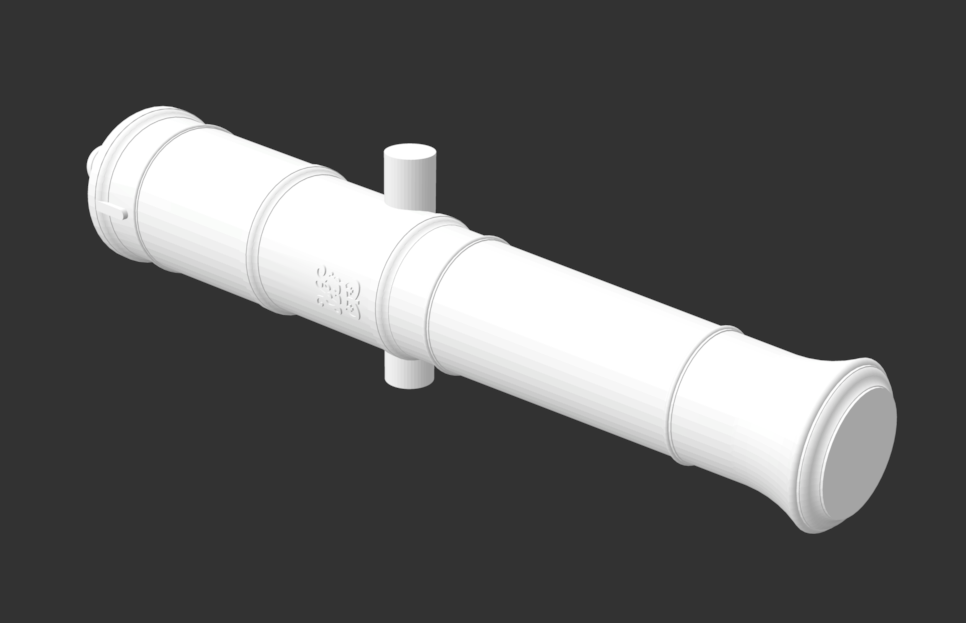

I just converted the file to STL, which is what Shapeways asked for. But it is quite faceted. Is this the best I can expect for a 3-D file? I saved it as a Binary file, although there was a choice for an ASCII file. There was also a choice for number of facets in the Binary option, I have shown the default that I chose.

Apologies for the dumb questions; this is my first ever effort at 3-D printing, not quite sure where I am heading.

Best wishes,

Mark

- druxey, aviaamator, paulsutcliffe and 2 others

-

5

5

-

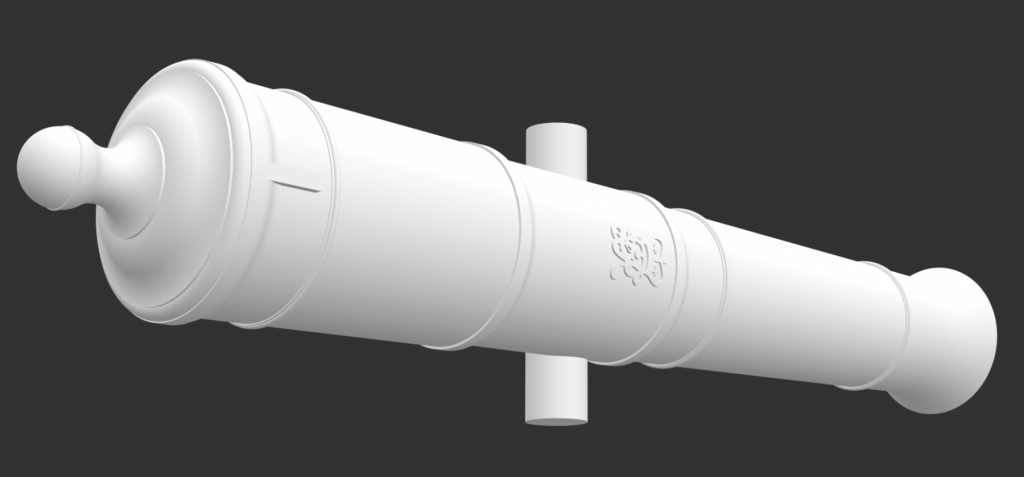

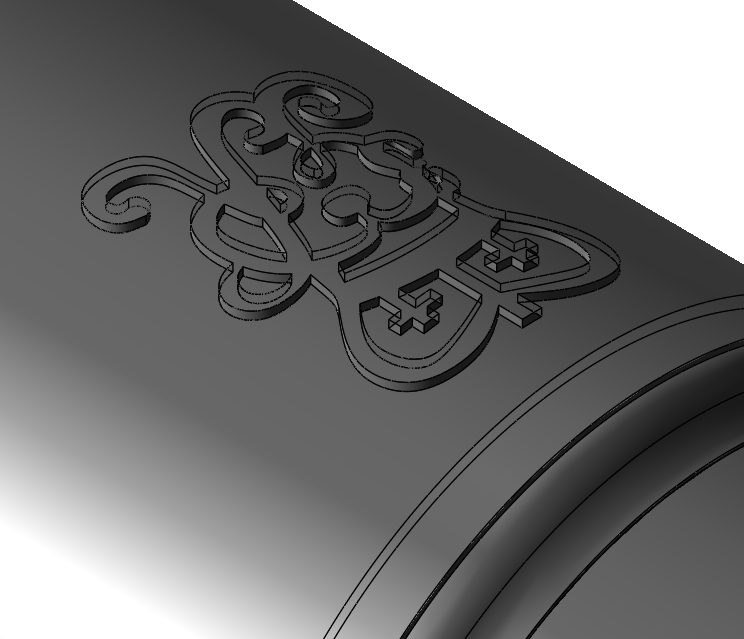

Thanks to great help from our colleagues on the CAD section including Alan, I managed to create the king's insignia in the digital file.

I will try getting a 3-D print of this, just to see the quality. Although I have heard that 3-D printing is not quite up to snuff at this scale.

And while waiting for that, I will continue with the duplicator...

Mark

- albert, michael mott, Bob Legge and 6 others

-

9

9

-

Aha! Got it. Not quite sure how. I had to create a cover skin of the line drawing, then pull the skin into a solid, then subtract from it a female mould of the barrel shape + ¼" radius. Then add to the barrel.

druxey, if I can figure out how to profile this with rounded edges, I will come out of retirement and start a CAD business!☺️ But thanks for the photo; it is great to see what we are trying to approximate here.

Mark

- mtaylor and thibaultron

-

2

2

-

- thibaultron, tkay11 and mtaylor

-

3

3

-

Thanks, everyone, for these helpful suggestions.

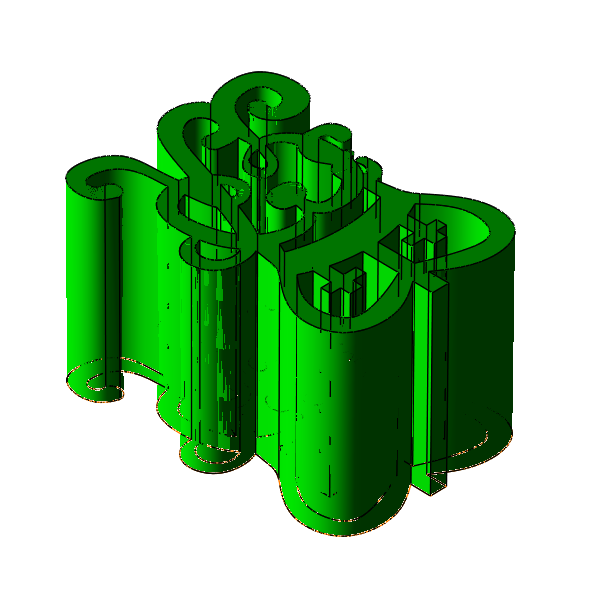

I am making a newbie mistake somewhere. However I try to extrude or project the insignia, I get an ill-formed solid, as seen below.

Turbo Cad Mac is not very good at identifying the problem areas. When I first attempted to create a solid out of the line drawing, it said there are duplicated or overlapping curves and will not proceed. Unfortunately, sometimes it showed me where the offending problem is, sometimes not. I thought I had fixed them all when a tool like extrusion allowed me to proceed instead of calling an error. But when I proceed, I get these ill-formed solids.

This image below is based on a drawing of control point splines. I have tried converting this drawing to interpolate splines, simple curves, etc. but the solid is still ill-formed. I will keep trying edits to see if I can at least get a clean solid from which to try the good suggestions above.

I just wanted you all to know where I was with this....

Mark

-

Pat, thanks, I was wondering about that. I will have to see if I want to invest in an upgrade. I am not sure how far down the road I am going with this 3-D printing quest as it gets more complicated and expensive! I will contact TurboCad and find out more.

Thanks again,

Mark

- mtaylor and thibaultron

-

2

2

-

Thanks, Alan, I will look for something like that in TurboCad...

Mark

- thibaultron and mtaylor

-

2

2

-

I am working on a digital file for 3-D printing cannon for my Bellona project (in the scratch-built section). I am using TurboCad for Mac Deluxe version 10.

I have made the insignia a solid, as you can see below, but I can't figure out how to curve its upper surface to match the curve of the cannon. Also, how to merge the insignia into the cannon so there are no gaps or intersecting solids between the two. I assume this would be a bad thing when creating the file for the 3-D printer.

Can anyone help with this?

Best wishes,

Mark

- Moab and thibaultron

-

2

2

An attempt at hull modeling with Fusion 360 Loft + Rails

in CAD and 3D Modelling/Drafting Plans with Software

Posted

Hi Peter,

I look forward to learning what you find out about using Sculpt and T-Splines. A whole new world to me.

I apologize for not being clearer in my drawing. Let's assume the thick black line in my drawing is the top, outermost edge of the hull in 3 dimensions. The traditional way of locating that would be to go to each station line, and measure up in the Z direction on the X-Z plane the height of the line at that point above the base, top of keel usually. Then you would measure out from that point in the Y direction to find its distance away from the center line. I was hoping to do this at each station point and then link the points together with a spline to form the curve in three directions. I was then assuming I could use a series of lines like this to form the surfaces.

This is how my ship was originally drafted, and so I assume this would be the right approach to using Fusion.

The problem is that I cannot get Fusion to find the point I just drew on the X-Z plane when I turn to drawing on the X-Y plane. Nothing will click on it. I am wondering if I need to do this with solid bodies rather than just lines in space, so I can find them...

Mark