-

Posts

2,468 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dvm27

-

Really nice job Jamie! I think I tackled that model 50 years ago with very poor success. Those pine hulls needed a lot of work. Hope you're putting it in a case.

- 41 replies

-

- thermopylae

- scientific models

-

(and 3 more)

Tagged with:

-

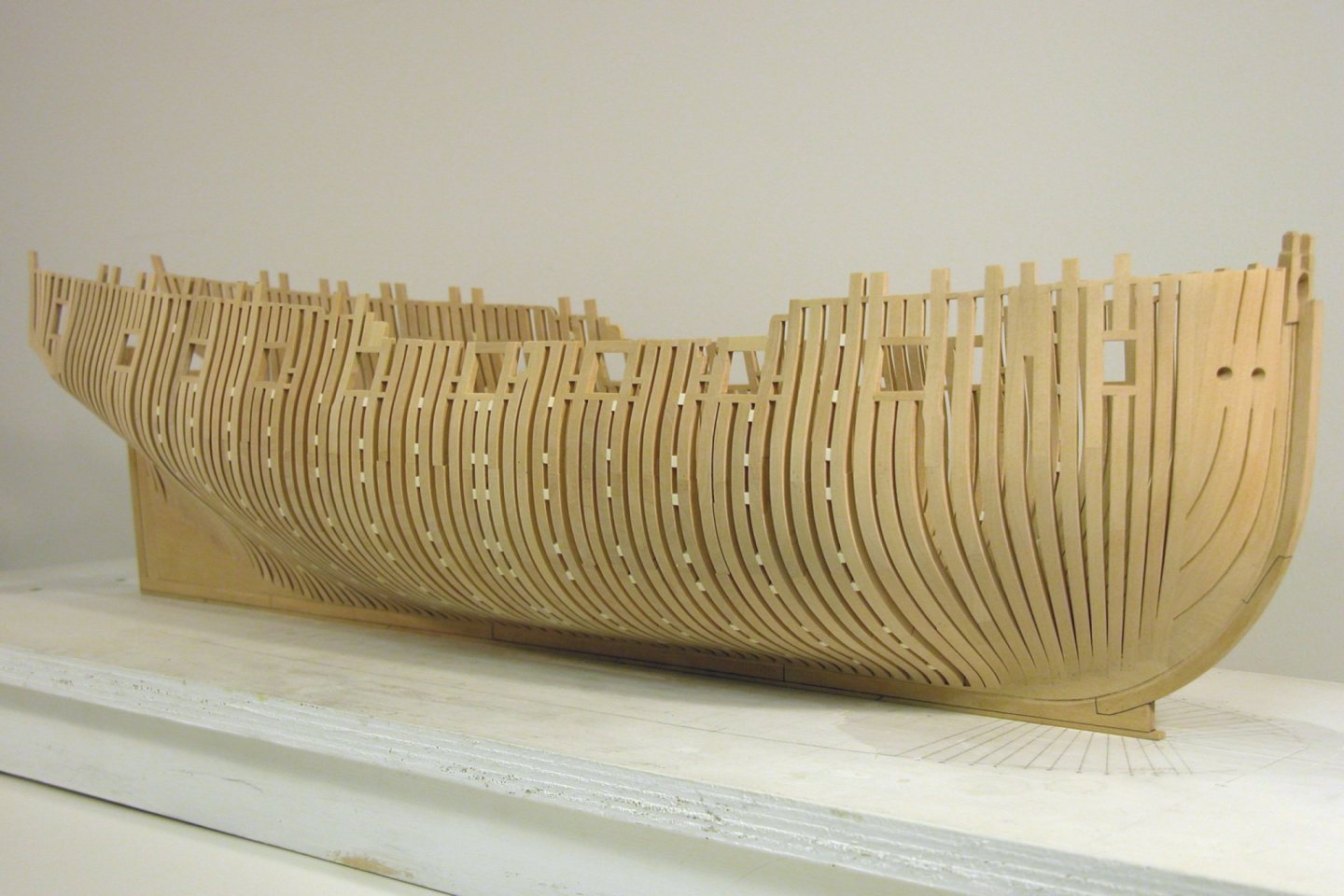

Have you laid out the station lines on your building board? On the sheer plan each floor/lower futtock is inked in. Make sure all these lines are transferred to the building board. Only at each station line only will you be adding the fillers. They may vary in width as the sided dimension of the futtocks also varies. Sided means seen from the side (or lateral view in your medical parlance). The spacers are generally 3" sided at the keel and narrower higher up. There is one triple frame at the dead flat. So in the photo below all the spacers are at the station lines and are easily seen as they are holly (in contrast to the boxwood frames). In addition, there are fillers between the floors/first futtocks). It may be convenient to fit them before raising the frames. I did no do this but it would have been easier. Feel free to PM me if this is not clear.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Swan-Class Sloop by garyb - 1:48

dvm27 replied to garyb's topic in - Build logs for subjects built 1751 - 1800

By all means Henry, post a build log. As well, study the build videos posted by Kevin. They are very detailed and he happily shows his mistakes and how to correct them. In addition check out the many Swan class logs. Amongst them are Dan, Toni, Remco and Ben. They may already be tagged. If not perhaps Chuck can show how it's done. Greg -

Blackening brass advice

dvm27 replied to Bossman's topic in Metal Work, Soldering and Metal Fittings

I agree with Alan. Second attempts have not turned out as well for me. Go back to bare metal using a wire wheel to get in all the nooks and crannies. Congrats on the good results for the other batch! -

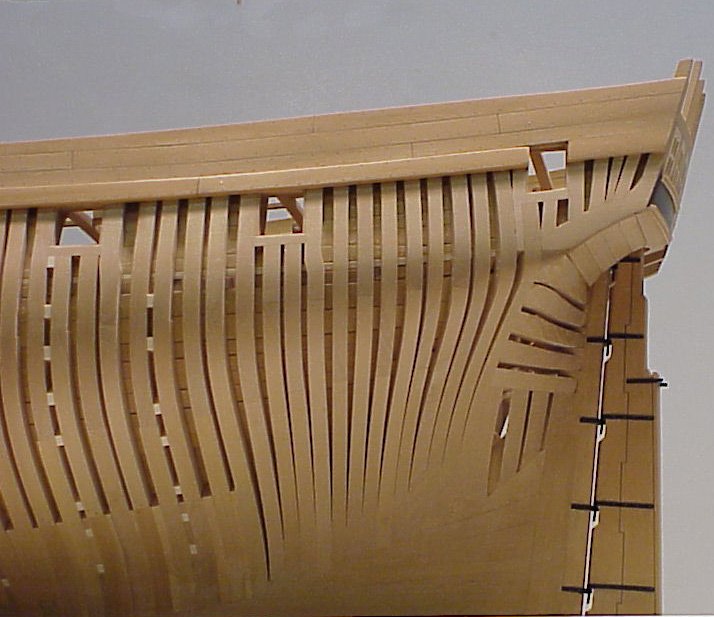

Your beautiful run of planking and ports with nary a wave or undulation to be seen reminds me of...the Navy Board models I worshipped as a teenager at the Naval Academy. Although the original model shipwrights might harumph at the amount of time it's taken you to get this far I'm sure they would wholeheartedly approve of the result!

-

Lower cost (?) shiny metal parts

dvm27 replied to Patrick Matthews's topic in Metal Work, Soldering and Metal Fittings

The Shapeways part is a roller coaster. After painting I am placing it in an epoxy resin cube and making a lamp out of it for a grandson. Lots of cool epoxy resin videos on YouTube with 3D printed parts inside. -

Lower cost (?) shiny metal parts

dvm27 replied to Patrick Matthews's topic in Metal Work, Soldering and Metal Fittings

My last Shapeways product was painted then immersed in epoxy resin. The paint leached into the resin, ruining the project. I just read where direct sunlight will cure the resin so I will leave the next one out over a sunny day, then paint it. Perhaps a varnish after to seal? -

Haven't seen your log for awhile Michael. She's looking beautiful. Will be quite a showpiece when you're done.

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

ancre Frigate AURORE 1697 by s.v.atanasov

dvm27 replied to s.v.atanasov's topic in - Build logs for subjects built 1501 - 1750

Lovely work. Is that the Dr. Mike method of hull construction? It certainly is very different than some plank on frame models done here but gives excellent results. -

To add sails or not? What is your preference?

dvm27 replied to Bill97's topic in Masting, rigging and sails

Unless you are building an Admiralty style model! But personally, I find that very few kit sails look realistic. They are usually over scale and don't hang realistically. I think properly furled sails can greatly enhance a model but these are also difficult to make in a realistic fashion. Obviously, Rob's example above is an excellent representation of what they should look like. -

French prisoner of war models are still on the market for the well healed amongst us. For example, recently sold for 48,000 pounds: https://www.charlesmillerltd.com/auction/lot/261-a-large-finely-carved-and-well-presented-early-19th-century-napoleonic-french-prisoner-of-war-bone-ship-model-for-a-first-rate-ship-of-the-line-traditionally-identified-as-hms-caledonia/?lot=12815&au=46&sd=1# A more modest 4000-6000 pound bid might get you this smaller model: https://www.charlesmillerltd.com/auction/lot/73-a-napoleonic-french-prisoner-of-war-bone-model-for-the-74-gun-frigate-illustrious-circa-1810/?lot=13707&so=0&st=&sto=0&au=51&ef=&et=&ic=False&sd=0&pp=48&pn=2&g=1#

-

Unimat or Sherline... your feedback, please...

dvm27 replied to Jorge Hedges's topic in Modeling tools and Workshop Equipment

Sherline for sure. The quality is fantastic and their service department, should you ever need it, is first rate. I use the mill far more than the lathe but when you need a lathe...you need a lathe. I'm self taught but there are now excellent videos on just about every aspect of machining on the Sherline site and internet. One terrific series is by Blondihacks - https://www.youtube.com/blondihacks. She has numbered progressive series on the use of the lathe and mill for smaller machining. -

Lovely work, Olha. I think a clinker planked hull is much more interesting than a carvel planked one. The notched frames method would seem ideal for laser cutting but I also note that M. Frolich, when he built his Coureur, was able to cut these notches by hand (in case one doesn't have access to laser cutting). I just subscribed to your chanel and there is some great content there. It's also a pleasure to welcome a younger member here. Stick to your guns. Just because we old timers have done something one way for decades doesn't mean that's the only way. Technology and innovation in ship model making will hopefully recruit younger, tech savy people to this aging hobby.

-

Byrnes thickness sander vs Micro Mark's

dvm27 replied to twintrow's topic in Modeling tools and Workshop Equipment

The Proxxon planer is a superb tool. It uses blades for smooth cutting. But is can only plane to a thickness of @0.060" unless you use a sled underneath. I use my Proxxon planer to remove large amounts of wood quickly and the Byrnes thickness sander to dial in the final width. -

ancre Coureur by cafmodel - 1/48

dvm27 replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Really like those shaped barrel staves, Tom. Just like the real thing. -

It's like a chess game. You have two think five moves or, in this case, two decks, in advance. Beautiful work ben.

- 889 replies

-

Well, it's all conjecture anyway, Dave. Nobody really knows what the keelson looked like here. If you lightly affix a strip of 120 garnet paper to the flat and curved keel surface you can very quickly determine the bottom of the keelson shape by using a scrap piece of wood rubbed over the sandpaper until it glides.

-

Does the 1/48 Chuck have a cigarette hanging out of his mouth? Just curious - are you fitting her with guns?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Love it! I suspect it will be much harder to do precision work at this scale but I'm sure you are up to it.

-

Great question, Mark! The answer is that I either cut a very deep score at a transition under another fitting (for example within the mast caps) or did not dye some items like the bibs that should have been. I found that even with deep scoring and tape some of the Fiebings dye invariably wicked up the boxwood on the other side. But those bibs and other items are now properly blackened courtesy of my writing partner (David Antscherl). The trestle trees were all dyed off the model. Now I just need the US/Canadian border to reopen so I can retrieve Speedwell and get to rigging! BTW Volume Two of our Speedwell book is now at the printers and should be released soon.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.