-

Posts

4,134 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

Thanks for your comment. I exclusively use Tamiya tape, available on Amazon. Really excellent for the tight masking for our models. Multiple thin coats and smooth long brush strokes help prevent build up at the tape line. Hope that helps, main thing is to go slow, take your time, know the first model is about learning (as is my 12th for that matter) and have fun. Check Vanguard Models for your next build. @chris watton offers great, well made kits with quality materials. More importantly his plans and instructions are second to none.

- 55 replies

-

- lady nelson

- victory models

-

(and 2 more)

Tagged with:

-

Byrnes Table Saw Configeration

glbarlow replied to Guyuti's topic in Modeling tools and Workshop Equipment

The mitre bar, extended fence are essential, the cross cut table is of great benefit and a must. Zero clearance inserts are handy, but I seldom use it. The 3 inch, 90T, .03 slitting blade is all I ever use. I’d get a couple of those. I have the micro meter stop and never ever use it. I’ve had my saw since 2008 and never replaced the belt. The other might be useful, but not for me. -

Great work as always BE. I believe the planking problem is as much corrected by adjusting the edge bending (bend up to curve down) as it is with the tapering. I’ve found the third and fourth bulkhead are is the most challenging to get a proper fit, good idea to sort it out early, it only compounds the further you go if not.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

HMS SUSSEX by KarenM - FINISHED - 1:48

glbarlow replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

Amazing work, well done! -

You’re doing really excellent work with this model and with your log, I just stumbled on to it today. You’ve done a great job leaning into other logs for advice. @DelF is an outstanding builder and a great source. For a near first model your workmanship is excellent. Yes those holes are for rigging, easiest way to determine size is to look at the plans for what size rope goes through it and drill accordingly, it will be fairly small. Four anchors is fairly common, two rigged and two lashed on as spares.

- 53 replies

-

- Speedy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks, I’m glad it’s helpful.

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Congratulations on reaching the finish line. A great sense of accomplishment no doubt. Well done!

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you. Yes, absolutely, with my special invisible rope and transparent blocks🤣😂

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Don, I tend to obsess over those details, I appreciate your comment.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

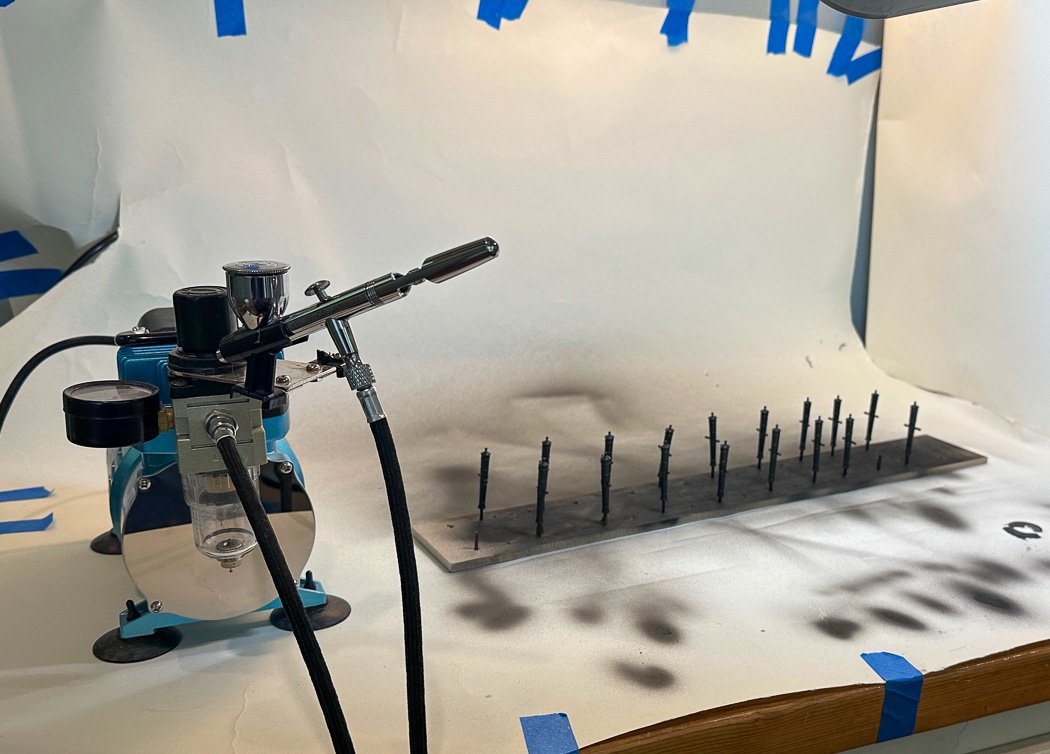

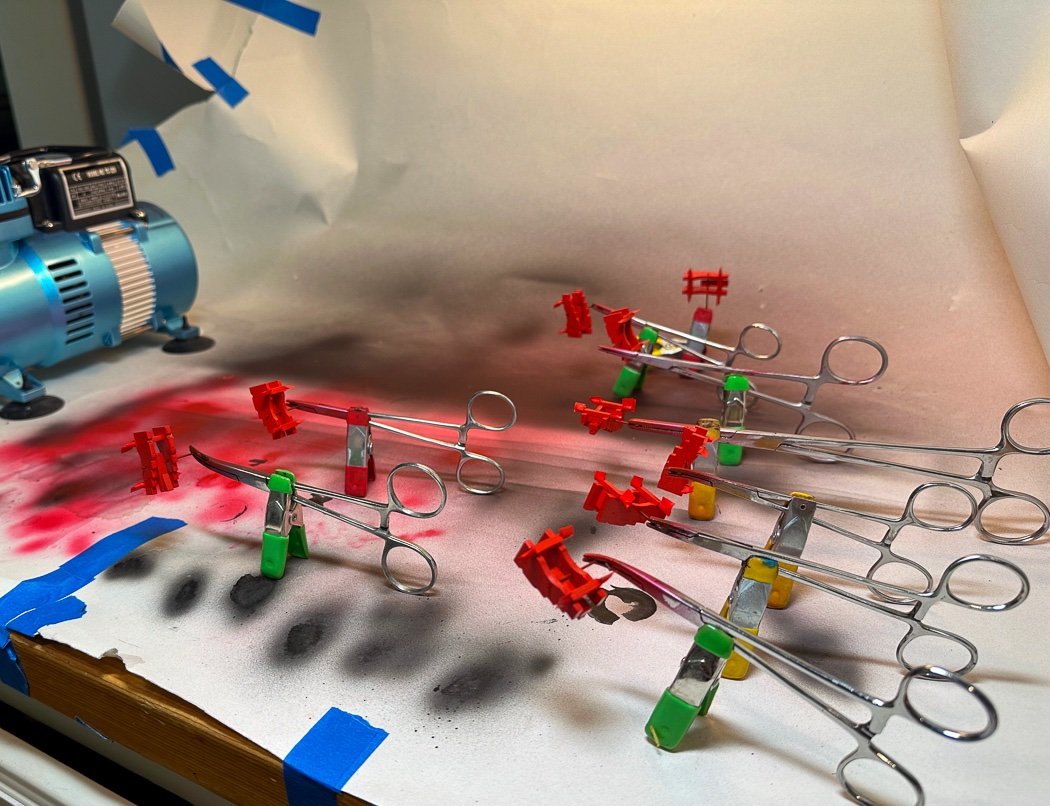

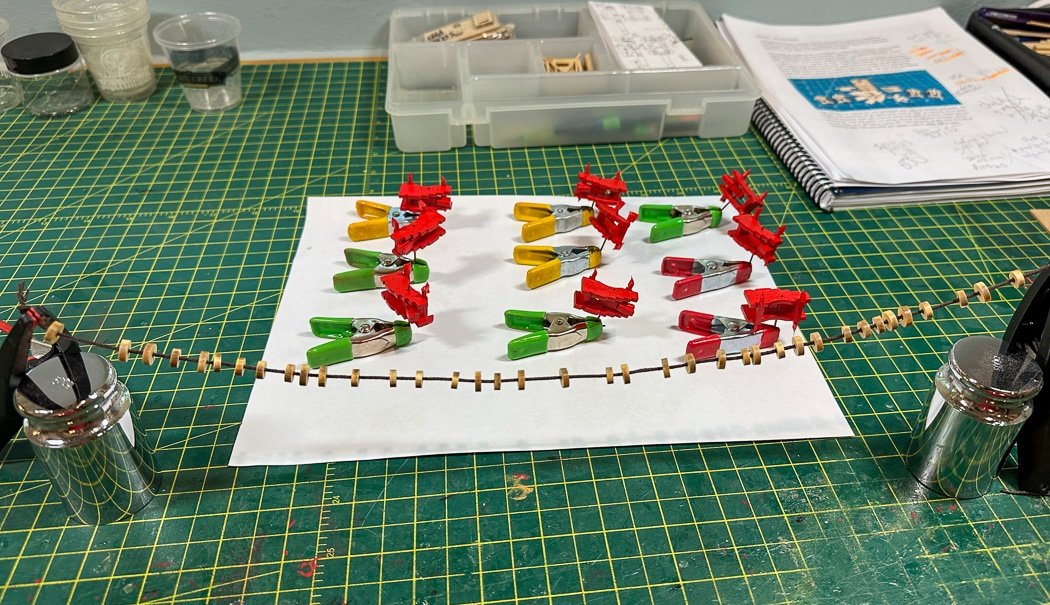

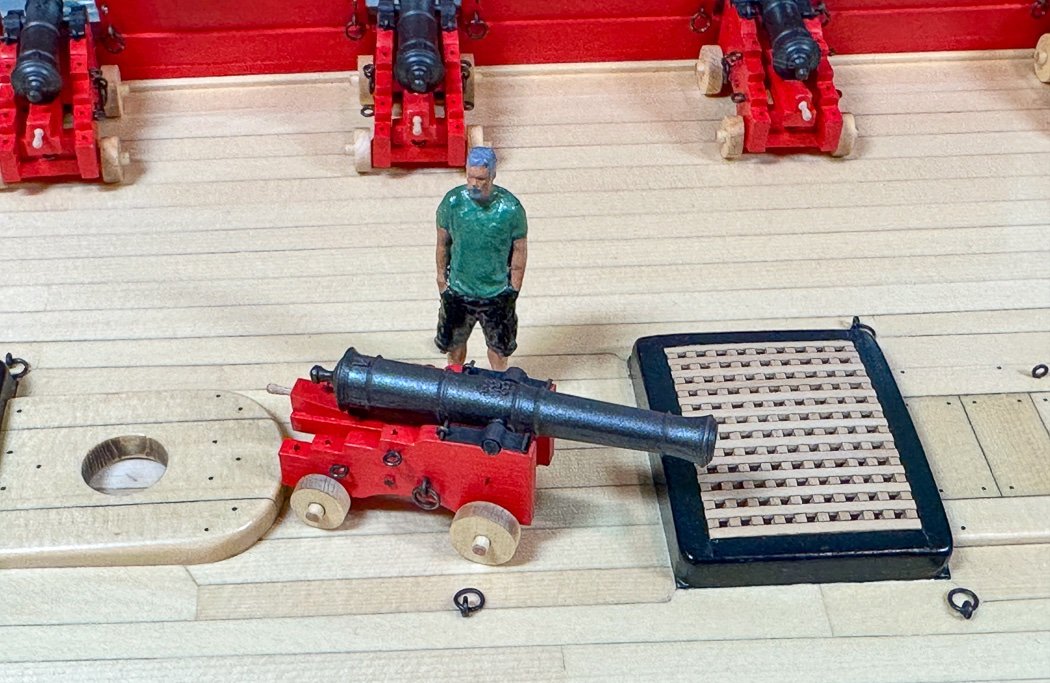

Phase 2 - Cannon I’m still here, I haven’t a lot of ship time lately due tog lots of summer activities and travel. I have managed to complete another group of nine cannon bringing my total to 17 with eight more to go on the main deck. This is how I’m thinking of mounting them 😄 A coat of Admiralty Ironworks Black, followed by Doc O'Briens Rusty Red weathering powder. Completed carriages airbrushed red. I was surprised how much fine red dust ended up in my air filtration system - it even gave me a clean filters warning. I of course wore a mask and saw first hand the reason why. Adding WOP to wheels and hanging them out to dry. One thing I can’t seem to sort out is how to get completely clean wheels without removing too much wood, at this point thought it’s more important to me to be consist with my dirty wheels. I won’t bore you further with my process again, I covered it in detail back in post 361 if you’re interested. I just did it all again for nine more (one is for my 6 year old grandson, he asked me to make him one) and will again for the remaining eight, and once again later for the eight q-deck and forecastle guns. Perhaps of passing interest, each cannon consists of 28 separate parts. No shortcuts here, just gotta get in and do it. One thing I brushed over in the earlier post was the capsquares. Doing them with the hinge, latch, and pin is a bit of a fun getting the four pieces consisting of 30 pound black monofilament, 24 gauge wire, and black paper to come together to fit there properly on top of the carriage. I can’t say enough about the power of powder in the form of Doc O’Briens Weathering Powders. Somehow Rusty Red combines with the plastic cannon and Ironworks Black paint to create an nice gun metal finish. I took it one step further and also added it to the capsquares after first also painting them with the Ironworks Black. Once buffed up it brings all the plastic, wire, and paper into a uniform appearance creating a nice looking brushed metal appearance (at least mini-me thinks so). A lot of time spent making these in addition to assembling the cannon - well worth it. It’s starting to look like a warship (they’re just sitting there temporarily). I was going to take a break from them and build the capstan or the stove, but now I think I’ll go ahead and make the remaining main deck guns while the steps are fresh. Thanks for stopping by, hope you’re all enjoying the summer. I’m having eggs for breakfast these days since I can just cook them out on my Texas driveway.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I’m a fan of Chris and fully support what works for his business. Hopefully all those that said they wanted Indy have their order in and if not in now order it soon. I’m sure Chris’s investment in such a detailed model is significant Revenue provides the capital for future models. His kits are such a level above all others.

-

Your artistry in hand painting these is amazing, well done!

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Sorry that happened, just another opportunity for creative problem solving. It seems you already have it well in hand. Enjoy your week off.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I was looking at the edge, didn’t see that. I’d guess Chuck would send replacements, he’s excellent about doing that. I’d recommend PMing him. Based on the many Winchelsea logs I follow it’s an exception and an uncommon problem.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

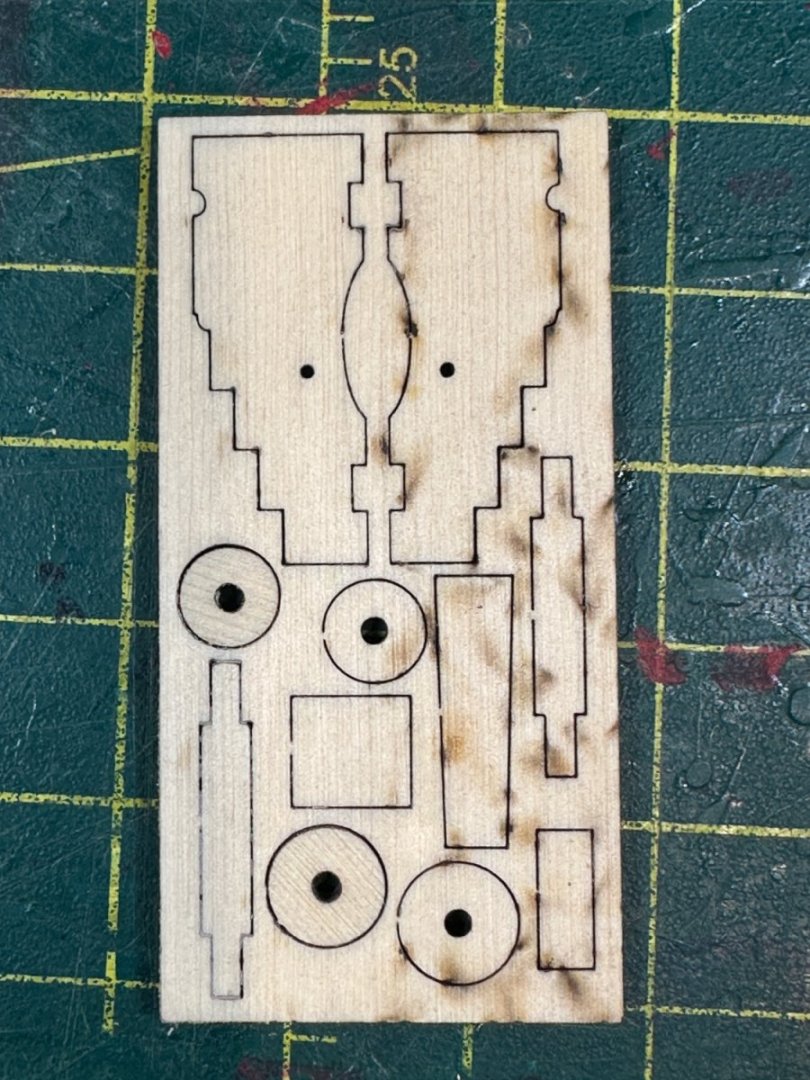

Sand them before removing them. It’s not uncommon. Here’s an example cannon carriage half sanded, half not.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Excellent planking Derek. I’m a big fan of the Proxxon mini-sander and the various end tips that come with it, comes in handy a lot. The curves at the stern are such joy. My only disappointment is I didn’t see any new tools I just had to have. I was a bit behind on your log, I’m really impressed, as I often am with your work, with how you scratch built your ladders. Very clever.

-

Thanks Don. I’m enjoying following yours as well.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.