Charter33

-

Posts

451 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Charter33

-

-

Hi Ron,

When I had a parts problem I found that phoning Jotika directly was the best method of contact. That broken part you have looks like the lower curved rail for the bow. Once fixed in place it's not under any load and is supported all along the back. It also will need trimming in length to fit properly. You might find that it is still usable...

Great progress with that second planking and squaring up the corners of those ports - keep up the great work!

- Bill Morrison and kiwiron

-

2

2

-

Coming along very nicely!👍

- The Gimps Chimp and kiwiron

-

2

2

-

Well ....... turns out it's one of those instances where half a dozen lines of instructions in the manual proves to be deceptively vague and a bit more thought is needed ........

I managed to bend the brass profile to the correct shape to match the curve on the top part of the Quarter gallery but then found out that it was a compound bend and needed to also curve slightly upwards.

Got a bit creative with some bits and pieces that were to hand and came up with this solution

.... successful, but not very elegant.....

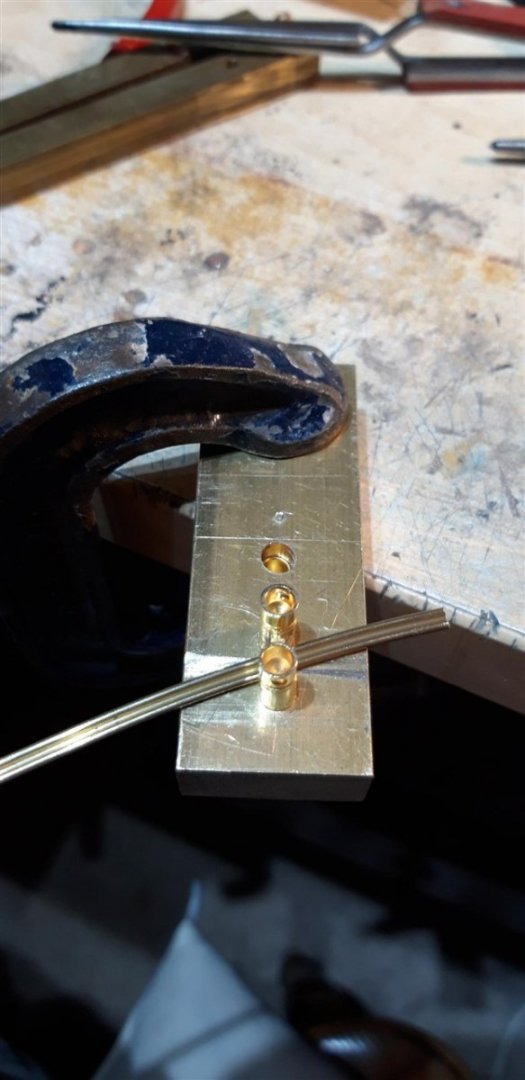

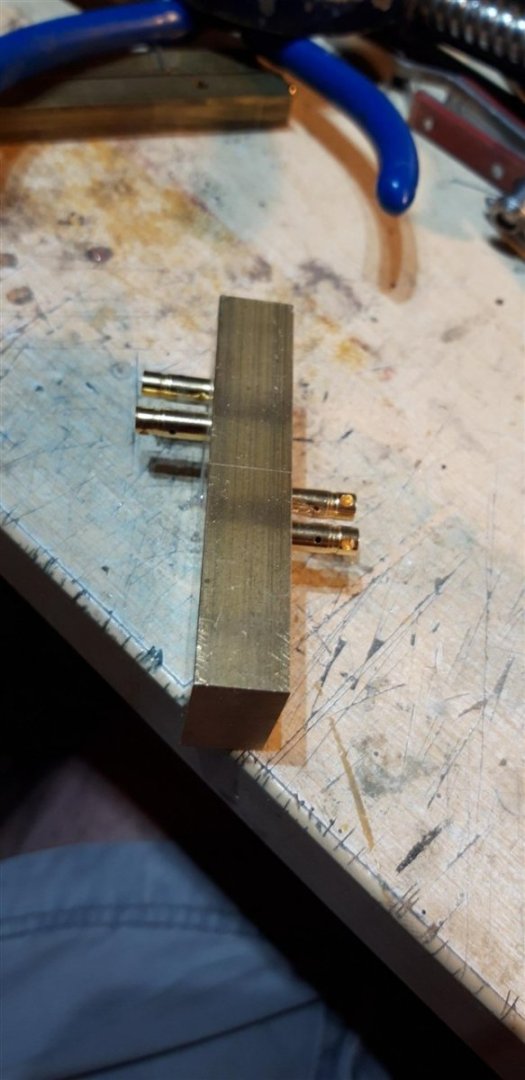

There had to be a simpler way ...... time to go back to the drawing board. Rummaging through the 'odds and s*ds' box I came up with a random block of 'bound to be useful one day' brass and four 5 mm dia. brass connector pins.

Four drilled holes and the light application of a hammer later I now have a double sided jig to to form the brass in both axis'. 2 mm gap between pins on one side, and 3mm on t'other.

A long way still to go, but I'm a bit more confident that it's do-able......

Cheers,

Graham

- kiwiron, AJohnson, Bill Morrison and 1 other

-

4

4

-

I'll join you down there, Andrew, for a pint of 'heavy' - it's been a stressful day....

-

Thank you for all the positive responses, always a great motivator!

Totally agree with you about the windows, Robert. I'm really pleased with how they came out. I also followed your example and added those two extra wooden mouldings under the false baluster pieces on the Quarter galleries using 1.5 mm pre-rounded strips cut from some unused first planking material. Another great suggestion - thanks again.

Andrew - you're so right about the effect of adding extra detail. It not only improves the appearance, it also adds to the enjoyment of the build. Time well invested, as you showed with your superb 'Nisha' 👏

Working on the stern lamps I was tempted to add a new tag to this thread - 'misadventures in modelling' or 'a comedy of errors'........

Having successfully drilled three of the lamp base castings for their supporting frames, the 0.7 mm drill bit started to bind on the final one and before I could turn the Dremel off the casting had twisted out of the vice, bending the drill bit, and was projected across the room. I did see a couple of the rebounds it made off walls etc. before it finally disappeared into a parallel universe. Time spent looking for it proved unproductive. The only saving grace was that the lost base was from one of the two middle sized lamps and its twin could be used as a pattern. Having dug out the Delft clay and associated equipment the mould was created and some metal (pewter) melted and poured.

Did it work? oh yes......

Not as crisp as the original, but serviceable after a little fettling......

Lamps assembled prior to gluing and painting,

but first I fabricated the fames to support them based on images found on-line.

Once painted it was time for a dry fit before removing them and adding them to the growing collection of parts being stored until closer to the end of the build for their own protection.

Time to start work on shaping the brass profiles to finish the stern facia and Quarter galleries.

Cheers,

Graham

- Bill Morrison, Wacom, robdurant and 2 others

-

5

5

-

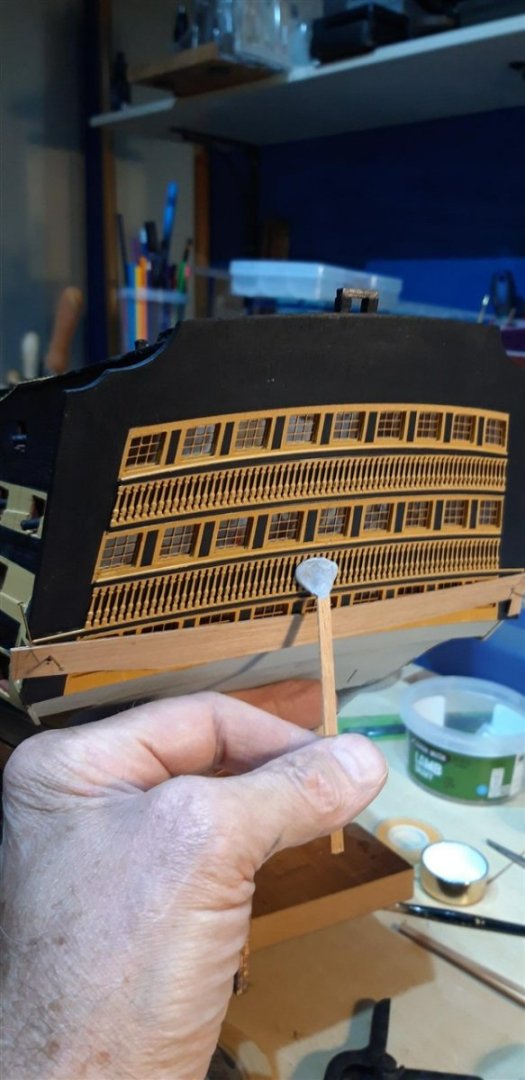

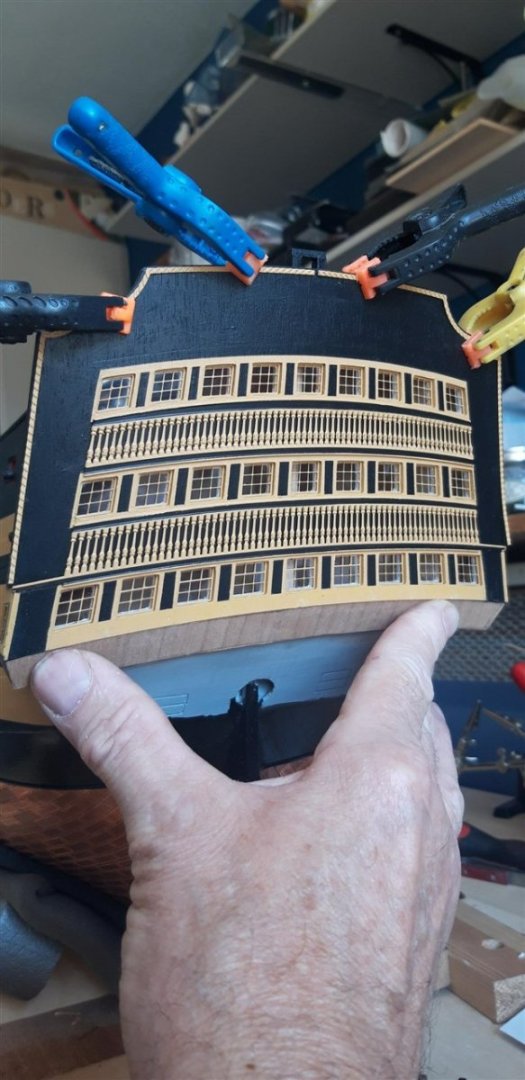

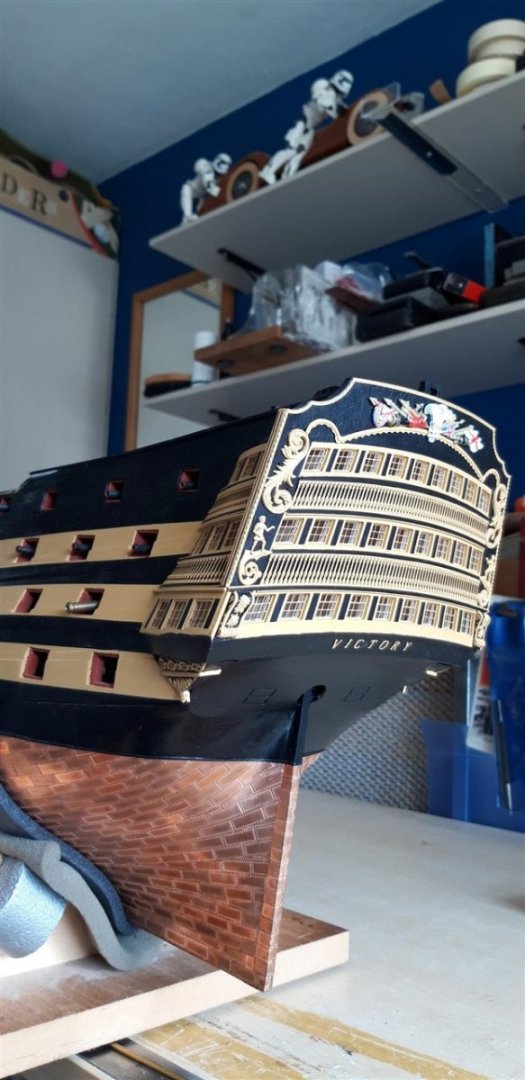

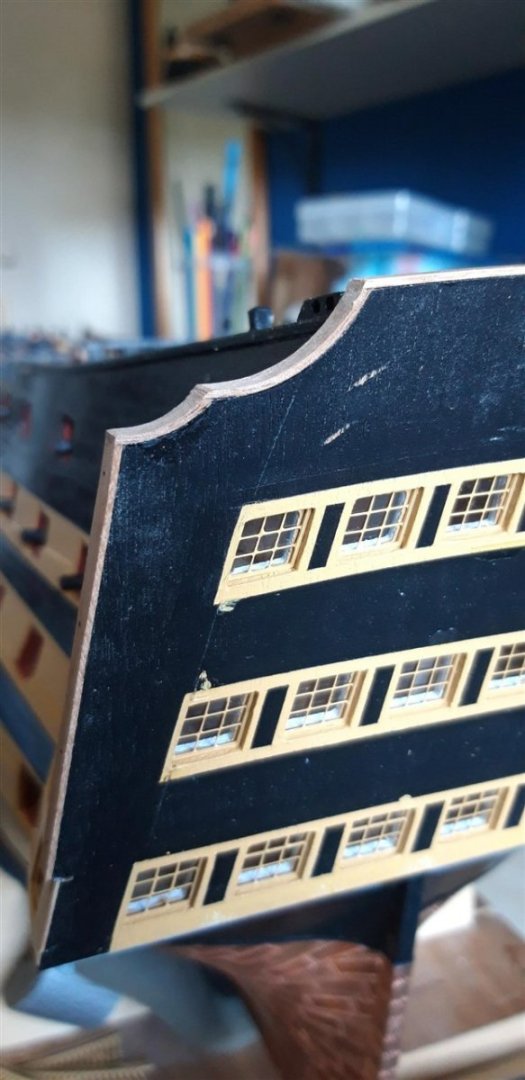

I've been focusing on the stern facia and quarter gallery decoration details. With the facia windows I have followed advice to mount the frames from the back of the outer stern facia to give the windows more depth. To achieve a similar effect on the Quarter Galleries I used Robert's innovation of adding an additional 0.5 mm layer to the three window skins.

The two false baluster patterns were fixed with C.A. adhesive. With very limited time to align them I opted to temporarily pin a scrap strip across the facia to help. The simple 'tacky stick' gripped the pattern as it was placed in position.

The gap between the facia's surface and the transom seemed a bit excessive, putting it mildly....

.... so I made an additional piece to improve things. I never throw away any off-cuts and found a piece of the 2 mm walnut ply big enough for the job. The hole in the remnant of the original transom ply made a perfect template. Edges bevelled as required .......

...... and the new piece glued in place. The lower edge was then blended in with carving knife, file and sandpaper.

To create the black panels between the Quarter gallery windows it was back to careful masking

I wanted to add additional detail to the vertical edges of the facia so, after cutting strips of tape down to about 0.7 mm wide, these were put in place together with masking on the front and back surfaces, and the unmasked areas over painted yellow.

To get the Quarter gallery false baluster patterns in place I used rapid epoxy to provide more adjustment time. Brass pins were pushed into the skins as an alignment aid.

At this point I began work on the Trophy of Arms, carving the groove where it intersects the top stern facia moulding

This was then primed together with the other white metal components - and all the associated tales of woe explained earlier in the 'What have you done in the garden today' thread 😖. Once painted yellow these castings were glued in place, once again using epoxy adhesive.

...the errant scroll was the one bottom left!

The Trophy of Arms was painted up using images found on line. The left hand draped flag was re-worked a couple of times, and I'm still not completely happy with it. I'll probably go back to it in the future

Ship's name added,

A couple of daylight pictures with the drop decorations in place.

and finally I made a start on the lanterns.....

Cheers,

Graham.

-

Magnificent work Robert. The detail you're achieving is truly inspirational.

-

A beautiful, well executed and unusual project - thank you for taking me through it. I have a feeling that the black and brittle wood in post #6 is probably ebony...

Graham

- mtaylor, Egilman and Old Collingwood

-

3

3

-

The secret lies in using a good quality filler, careful sanding, then you only need light coats of paint😀.

Have you seen the treatment Robert did to the Quarter Galleries, Ron? Adding an extra layer of 0.5 mm thick strip around the windows makes a much better job of giving a slight recess to the frames when fitted. I've just finished this on my build - will be posting pictures soon.

Keep up the good work!

Graham.

- kiwiron and Bill Morrison

-

2

2

-

That's a really impressive amount of detail on such a small model, as is the detail in the water base and diorama back drop. Fantastic work - well done!

- mtaylor, Dave_E and Glen McGuire

-

3

3

-

-

Those decals are fiddly little devils with minds of their own! I resorted to clamping each bucket in my Proxxon mini vice

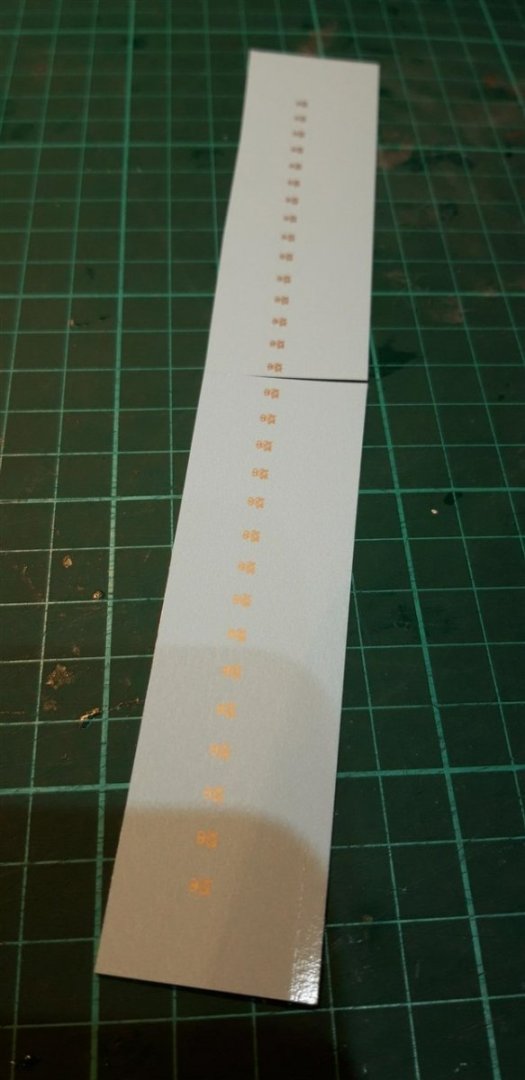

There's a strip of double sided tape across the fixed jaw to help set the front surface of the bucket on top, and yes, that tiny gold spot just about the handle is just one of the decals that got away 😒. I needed 21 decals, ordered 30 and have 4 left......... at 2.8 mm high and about 2 mm wide juggling the monogram into the correct position with a wet paint brush kept me gainfully employed for a long evening.

I no longer have access to the CAD and CAM software and hardware I taught with unfortunately, so producing my own art work and using a good quality printer myself were no longer an option. (Never thought I'd miss the smell of freshly laser cut MDF, but I do....) Can't fault the product I received and the customer service was brilliant.

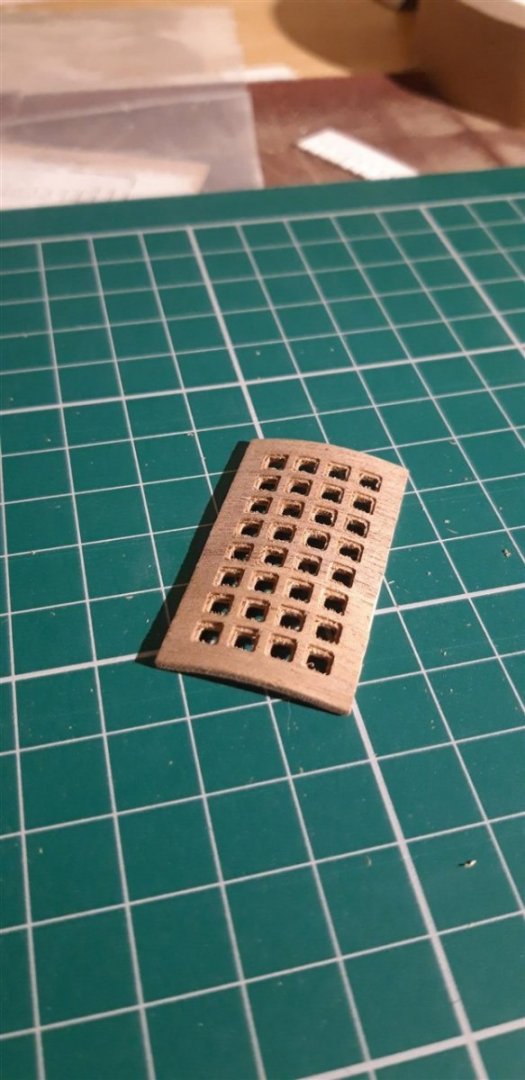

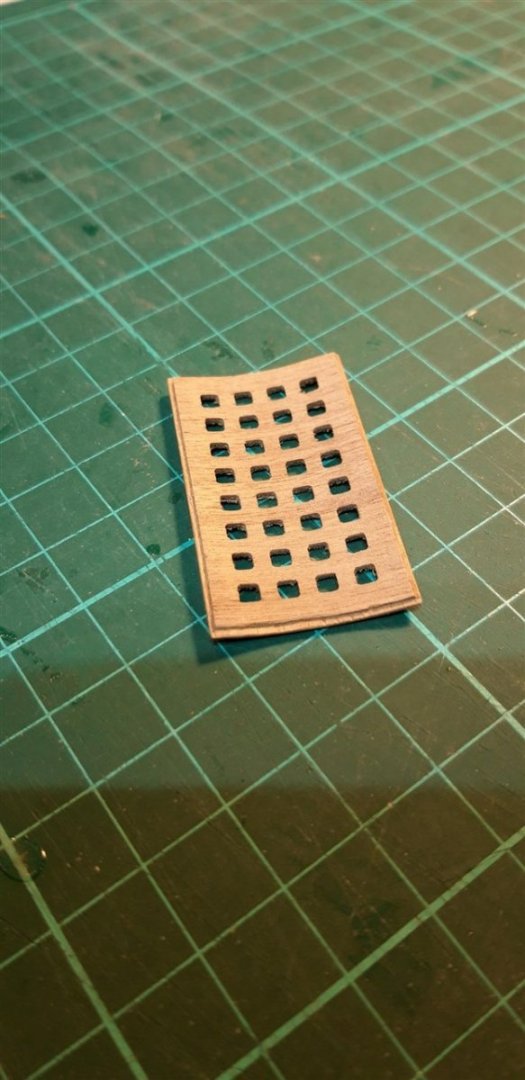

A couple of pictures of that simple jig for making the bucket handles. A 4 mm hole for the bucket body, and a 0.5 mm hole, 5 mm from the bucket's centre, for a needle.

Tying reef knots with two pairs of tweezers gets easier with practise, a skill that will no doubt become useful sometime in the future.😏

Cheers,

Graham

- Robert29, mort stoll, Ian_Grant and 1 other

-

4

4

-

Thanks Andrew - and 2005 was the year that I embarked on this build too Mort. 😁

A slight delay in progress. Before tackling the stern facia I decided that it was time to re-organise the work area as it was getting a bit too cluttered. Space is a little tight, in fact I managed to knock off the starboard cathead when turning the model to access the other side one evening. Heard something snap, couldn't see any obvious damage so ignored it. Next day, with that awful sinking feeling, I spotted the problem. Couldn't see the assembly anywhere. The carpet has consumed many tiny components in the past, but a whole cathead? Eventually found it. It had pinged down the back of the workbench and then bounced under a set of draws - panic over...... and easily re-fitted.

Then the pandemic finally caught up with me, fairly mild fortunately, but it still knocked me for six. All good now.

When I trial fitted the fire buckets a couple of posts ago it was clear that there was an issue with the copper wire handles I had given them. They were too short and it was difficult to get the buckets to hang correctly. Only solution was to remove these handles and replace them with the recommended black .25 mm thread. Not easy.... First attempts with the thread tied to each eyelet was disappointing with the knots looking a bit 'tufty'. Solution was to tie the thread in a complete loop, a simple jig to ensure consistent size, and the knot in the loop being pushed down into the bucket to hide it. Buckets were then pinned to a piece of foam to pre-shape the handles which were given a light coat of matt lacquer to set them.

Next job was to source the GR and crown monogram decals to enhance the buckets. With international postage rates so high I wanted to find a UK based supplier. On the advice of a good friend, a dedicated and highly accomplished model railway enthusiast, I contacted John Peck who operates the on-line company www.precisionlabels.com

His usual range of products is railway based but he also does 'custom' work.

Working from an image I found and sent him he produced the artwork and came up with these little beauties in just under a week, and at a great price too.....

First bucket...

Brilliant! A light coat of Decalfix made the clear carrier layer less obvious.

All buckets now in place.

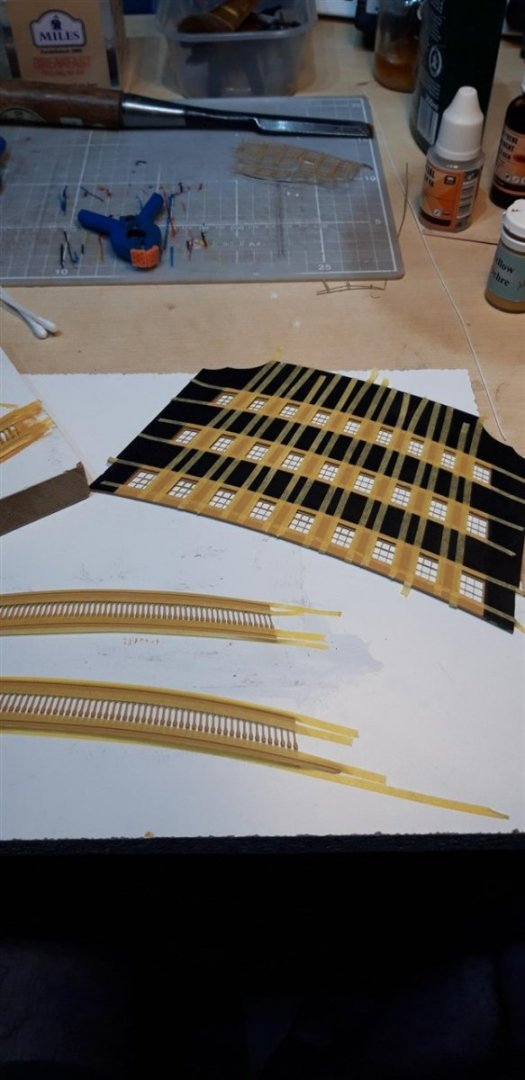

Time to start the stern facia. After an initial painting of the black and yellow areas the window frames were fitted. To create the black panels between the windows I used Tamiya masking tape.

At the same time I masked the P E baluster pieces, after painting them yellow, in preparation for the black lines. Preparing these with the VMS metal prep certainly improved the adhesion of the paint to the brass - thanks Robert!

P E panels laid in place but not yet glued....

Once the facia was fitted it was time to add the capping. The instructions say to use 3 x 1 walnut strip, but this seemed too narrow. Instead I went for 4 x 1, and glued two lengths of this together to get a piece wide enough for the top piece which curved more than I could get the strip to bend sideways to match. This double width piece was cut to the required shape with a scalpel and sanded to final shape after gluing in place. To bend the curved sections on the top corners strip was soaked for 5 minutes in boiling water and then clamped to a suitable former, in this instance an acrylic cosmetic jar donated by the admiral as a

storage container for small ship components..... Left to dry overnight the resulting shaped wood was cut to length and glued in place.

Last picture shows the capping after it's first coat of paint. Added some more detail to the flag locker - signal flags made from the backing sheet from self adhesive labels, coloured with alcohol based permanent marker pens and folded to fit.

Time to start preparing the stern decorations.....

Cheers,

Graham.

-

Looking good - I found these one of the more challenging stages of the build, just didn't seem to have enough hands....🤔

- kiwiron and Bill Morrison

-

2

2

-

Just a thought - how about using layers of micro ply? Available in thicknesses from less than 1 mm, up to a couple of mm, strips could be cut, glued to achieve the required final thickness and clamped to the bulkheads to form a laminated curve, and no need to make those shallow cuts...

- thibaultron, Canute, mtaylor and 2 others

-

5

5

-

I'm hoping that this is the right place for this comment, and I have no idea who is responsible, but to whoever came up with the idea of including thumb nail pictures as part of the display that shows new site content - brilliant idea!

Thank you......

- usedtosail, The Gimps Chimp, DelF and 4 others

-

7

7

-

More progress......

Mort - good to know it wasn't just me! I couldn't work out if maybe I'd done something wrong. Possibly it was an issue with earlier kits that has been subsequently resolved (my build has been underway for quite some time!)

Going back to the flag locker, I found that there were some different versions of how many sections were blanked off adjacent to the outer transom knees. I changed these from the photographic evidence of a contemporary version, four sections, that I originally included, to that shown in Longbridge's book - just two on the bottom row.

Moving on to the Poop ladder assembly I decided to try to improve the handrail. Rather than fabricating it from 1.5 mm sq. walnut I hoped to be able to achieve the elegant curves in a different way. Option one was to try and steam bend the stock material. It seemed unlikely that this would work so I went for an alternative method that involved laminating the profile using three lengths of 3 x 0.5 mm walnut strip. The press forming tool was made from a piece of acrylic - the forming surfaces lined with double sided Sellotape with one side retaining the protective (PTFE coated?) cover to reduce the chance of the component sticking to them.

This is probably one of the most 'Heath Robinson' forming solutions on this site!.........

but it worked......

After a light sanding and trimming they were attached to the rest of the assembly which went as described in the instructions.

These pictures also show the fitted poop deck termination rail. As commented on by other builders this part seems very plain compared to the the original. Using some of the copper profiles left over from additional enhancements I made to the quarterdeck plus some pieces of soft solder I tried to remedy this -

Additional bullnose mouldings made from the 1.5 mm sq. walnut were also added to the top step.

With the barricade assembly attached I did a trial fitting of the fire buckets....

There will need to be a bit of fine tuning to the handles to get them to hang properly before gluing in place, but I also want to add the GR emblem to each one first, just need to work out how........

The stern facia is next, but first I need to buy some more Dull Black paint as I'm almost out of it, and I have taken Robert's advice concerning VMS metal prep fluid, solvents and flexy ca for all that PE brass. CMB and Scale Model Shop deliveries expected shortly......

Happy days...

Graham

- bruce d, robdurant, Bill Morrison and 2 others

-

5

5

-

Happy to help out - mistakes are there to be learned from, and it's even better when it's someone else's error!

I'm in Bracknell, about 12 miles from Reading. Lived here for 60 years. My eldest son and his wife now live in the west of Reading in the Tilehurst area.

Cheers,

Graham

-

Hi Martin,

Yes - definitely trim off the excess! I made the mistake of not doing so, assuming that because the lateral alignment was fine all was okay. Wrong!

Overcame the problem but it wasn't easy, as you will see in my build log, posts #15 and #16.

Good luck...

Graham

-

Thank you Robert for your kind comments, and for all the other positive reactions my last post received.

Constructing the flag lockers and the skylight proved a bit more challenging than I expected, although those with the latter were, admittedly, self inflicted.......

Assembling the shelving for the flag lockers went alright but I had problems with the carcases which seemed too big with gaps on both sides and top and bottom when the shelf assembly was dry fitted. Grooves are provided on the inner surfaces of the side pieces for the shelves to fit into and my initial plan was to cut down the shoulders of the carcase joints to reduce these gaps. It was clear, however, that by doing this sufficiently to get the shelves to fit in the grooves would result the size of the left and righthand vertical shelf spaces being noticeably smaller than the rest. My solution was to re-make the ends from scrap ply without the grooves.

Once finally assembled and painted the overall length of these units still matched the size shown on the plan.

Additional tapering plinths fitted under the outer half of the base to improve the fit on the deck.

Installed with the inner and outer transom knees, ensign staff support and Horse.

Comparing the design for the model's skylight and pictures of that on the full size version there was several differences, the biggest being the curved roof of the original. To achieve this the roof part in the kit was soaked briefly in hot water, bound with a strip of polythene and masking tape around a suitable mould - in this case a drinking glass, with parallel sides, zapped in a microwave oven for 30 seconds, and then left for a couple of days in the airing cupboard.

It worked.....

There is more of a decorative moulding to the edges of the roof as well and this was achieved by cutting away the lower layer of ply on the underside.....

the tops of the end pieces were shaped to match the curve and the top edge of the side pieces was bevelled prior to assembly.

The Pre-painted brass window frames were glazed and fitted before this assembly stage. Finally additional twin mouldings were fitted to the lower edges of the sides and ends (the upper one curved here} and the whole unit given a coat of matt varnish before gluing onto the deck.

At this point the other poop deck fitting such as the various cleats, snatch blocks, Kevels and the Mizzen Topsail Sheet Bitts were added.

Cheers,

Graham.

-

Looking forward to seeing how this challenging project progresses. Looks like it should be a real cracker!

Good luck.. .

- Keith Black, Glen McGuire and mtaylor

-

2

2

-

1

1

-

Beautiful model .... congratulations on a true work of art!

-

This was just posted on the BBC News website (sorry, my I.T skills are not good enough to add those clever 'links' 🤪!), and thought it worth sharingHope this works.....Cheers,Graham

-

With the fitting of the Poop deck ply it was time for the last section of deck planking for this model, using the same technique as on all the other decks, black thread calking etc. Planking did not go according to plan, however, and it quickly became obvious, half way through laying the starboard side that there was a distinct kink in the plank line developing. With this particular section of decking being very open to view there was no other choice but to rip it off and start again!

Planks were fitted to the same pattern as before.........

with the position of the treenails impressed where required.

The only difference with this deck was the choice of material for the treenails. Where I had previously used slivers of teak veneer this time I used certified oak sourced from wood recovered from restoration of the original. Way back in post #9 I described how I replaced the walnut rudder that came with the kit with this alternative. Loathe to throw off-cuts away I have saved as much as I could ....

The larger piece at the bottom of the picture is destined to be incorporated into the display cabinet for this model as will a piece of original copper hull cladding.

After reducing some pieces of oak to fine 'splinters' these were individually carved to shape with a scalpel and glued into place in the pre-marked holes that were by now drilled to 0.5 mm diameter. The failure rate was noticeably higher than the previous material, with the oak being far more brittle and difficult to work, but if they survived the scalpel they were usually strong enough to be glued in place.

Once trimmed down the whole deck was cleaned up with a cabinet scraper and the given a couple of coats of matt varnish.

The bulwarks have now been lined and attention moves on the the Poop deck fittings including the flag locker and the skylight, the latter of which looks like it provides an opportunity for a bit more 'bashing'......

Cheers,

Graham.

_1280.thumb.jpg.029d031ed36ef22ccd2e53d69760bc9c.jpg)

_1280.thumb.jpg.d50252f8915d620b2c92cd5897d50d2f.jpg)

New workshop and tools setup.

in Modeling tools and Workshop Equipment

Posted

That's a great range of kit you have there John - dead jealous! Looks like an amazing base for some pretty impressive future projects.

Good luck.....