-

Posts

13,301 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

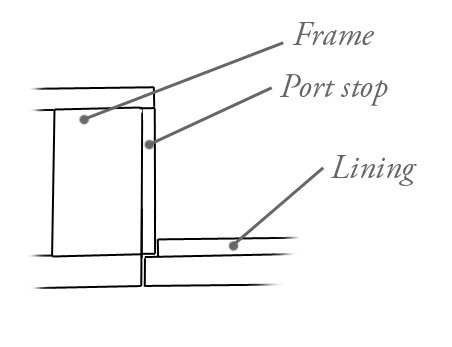

Mark P: I'm interested as to why you think that the stop was not a separate piece when Steel spec's it as such. (He does not call for a rebate to be cut into the frame.) My reasoning for the frames being 1" greater sided on the sides of the ports is for extra strength when driving and fixing the ringbolts for the breeching and gun tackle.

-

Interesting. I believe that access to the magazine was by a passage with two separate doors that opened outward. This was a precaution against accidental sparks or detonation from outside blowing in. The doors would blow shut in such an event. Direct access from above via a companion ladder would be very dangerous!

-

Longridge's Midget Universal Woodworking Machine

druxey replied to SJSoane's topic in Modeling tools and Workshop Equipment

Thank you, Mark. Since I first read Longridge back in 1955, I'd always wondered what the 'Midget Universal' was like! Your post and link made me smile this morning. Thank you! -

Impressive at all scales! I imagine the car runs beautifully as well.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Siggi: in the tables, Folio XXV and XXVI, it states: Port lids. - Every gun deck port to be fitted with a substantial lid made of English oak - Stops of the ports not less than (measurement in table 3 1/2" or 3". Well seasoned linings fitted into the stops (measurement in table thickness 1 1/4" to 1") Fitted into the stops implies that the linings overlap, not abut, the stops. I've certainly shown this - rightly or wrongly - in my own models.

-

HMS VICTORY 1765 by albert - 1/48

druxey replied to albert's topic in - Build logs for subjects built 1751 - 1800

'Cant frames' in English. Those look very nicely made. Only a few more needed! -

A very interesting form of construction, nicely executed as usual, Dick.

- 263 replies

-

- nave tonda

- round ship

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

druxey replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

And a happy festive season to you also, Pat!- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Well, obviously the limit is because of the tools available, not the skill of the model-maker! Perhaps Santa will be kind....

-

Gunshot proof, no; but weather/waterproof, yes! Certainly Steel (British, 1805) describes the rabbeted style of port lid clearly. Either way, you are building a very lovely model.

-

The thing is, in different countries and at different time periods the way things were done were not always the same. Also, secondary sources (modern books and models) can be misleading. Check contemporary models on sites such as: http://collections.rmg.co.uk/

-

The inner layer of lid planking (the lining) is vertical and the outer layer follows the line of the outer hull planks in thickness. The inner layer is stepped back or rebated by the thickness of the port stops. The stops are the lining pieces attached to the lower port sill and frames on the sides of the port opening. They are set back by the thickness of the outer planking. Your photo shows these rebates clearly. There is no taper as shown in your sketch.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.