-

Posts

13,353 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Echo by Maury S - FINISHED - Cross-Section

druxey replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

Those beam arms look nice!- 324 replies

-

Actually, that is a very good 'teaser' for what we hope will come! Thank you for your history, both personal and that of the Museum. The web site is interesting and informative, but might I suggest proofreading the text?

- 33 replies

-

- warspite

- battleships

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

druxey replied to albert's topic in - Build logs for subjects built 1751 - 1800

Lovely work, Albert! And a very nice workshop as well. -

What this means is that the line of the change in plank thickness is continuous, and doesn't jog up and down with the actual edge of the sheer strake. It's your 'other interpretation', Toni.

- 1,449 replies

-

Now, that looks brilliant, Chuck!

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The NRG annual Conference in St Louis 2014.

druxey replied to Chuck's topic in NAUTICAL RESEARCH GUILD - News & Information

I guess we'll recognize each other by our avatars? -

Meillieurs souhaits a votre vernissage, Gaetan! (Congratulations on your exhibition, Gaetan). Looks terrific. I hope you had a good audience and turn-out to your show.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

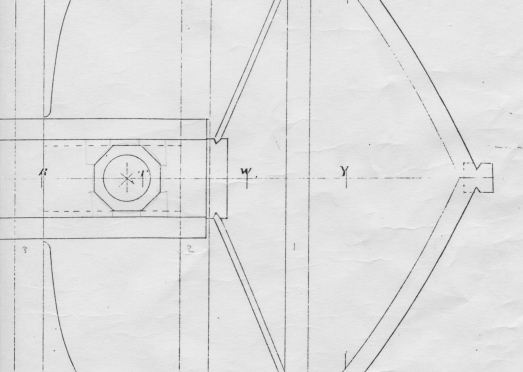

I agree with Gary's assessment. Look at the rabbet as shown on the deck plan. It appears within the width of the stem, rather than at its aft edge. What is unusual is that the stem/apron joint line is shown as a dashed one on the sheer and profile. Usually joint lines are delineated as solid lines on these draughts. I think that is what threw us. I suppose it was the draftsman's way of demonstrating that the rabbet progressively moved forward of this joint as it moved up the stem.

-

John: that's an interesting photo; the holes are on all faces, but offset from each other. As you say, later; but a nice example!

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Deck plans of Revenue cutters I've looked at show (where bar holes are indicated at all) that these are on every other face. If you think about it, it makes sense. Holes in every face would weaken the windlass when strain was placed against one side of the hole and there was little wood between it and the next hole. The few models where photos show the windlass: the same applies. However, it's your call, Chuck.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I'll do some digging, Chuck. Either way, it's a beautiful windlass!

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Enjoy the movie, Dad: your optic receptors for pink and purple will probably burn out.... That is an ingenious solution to making a windlass. Well done! However, are the bar holes on all octagonal faces or should they be only on alternate ones?

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I'm not happy with the explanation, gentlemen. If the difference between the dashed line and inner rabbet line is the thickness of the frame - or bollard timber - one would expect the distance between those lines to increase the further down one goes, not have it taper out to nothing. This need further examination.

-

Can i live without a BYRNES TABLE SAW

druxey replied to shihawk's topic in Modeling tools and Workshop Equipment

Never buy a cheapie. It's a snare and delusion. You'll never regret getting a quality tool, be it machine or hand tool. -

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

druxey replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Best wishes as you seek a new job, Doris. The model(s) look lovely.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.