-

Posts

654 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dziadeczek

-

-

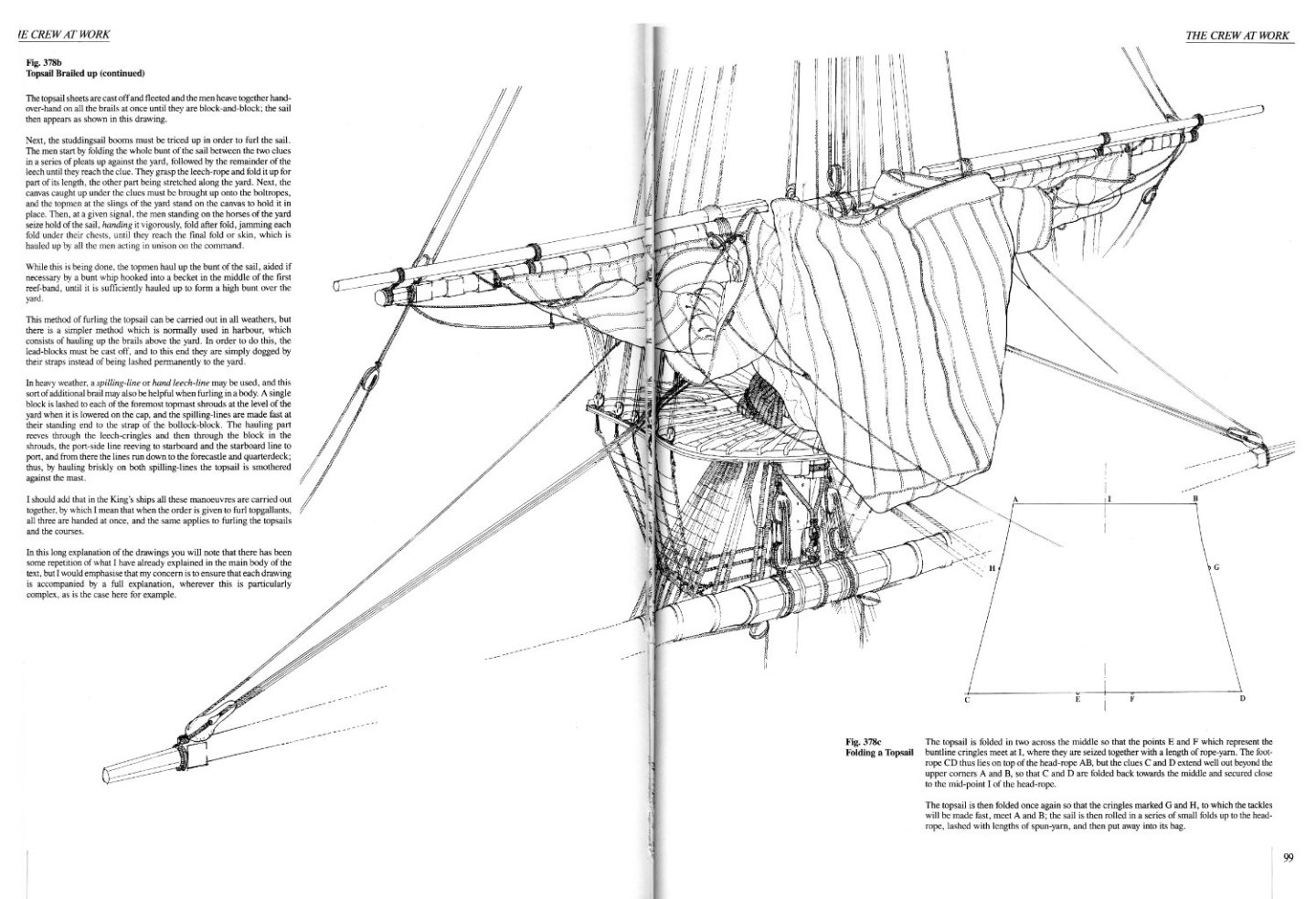

Hi, I too am building a model with sails attached. Very tedious and time consuming work! See the link below (post # 80): However I used thin cotton fabric - beige muslin, instead of silkspan, because I wanted to actually sew my sails and model all details on them, and with silkspan it would have been nearly impossible due to the thinness of a material. I show a sail configuration, known as "brailled up", that is only partially raised sails, instead of fully furled. I thought that fully furled sails would look too invisible, thightly wrapped up on the yards. On the other hand, fully unfurled sails would obscure some details on the decks and masts. So, I chose a compromise. Far from being an expert on this topic, I think I partially succedded with this detail, but I accept it, it is good enough for me... I think that the particular locations of all blocks, deadeyes and other details of running rigging, were on both, forward and aft sides of the sail, depending on the type of a ship, the time period and nationality of the vessel. These things varied considerably. See detailed instruction of your particular vessel. I am lucky that Mr. Boudriot was soo nice to include those details in his books, so I rely on him. Happy modeling! Thomas

-

Introduction - André Dethioux

Dziadeczek replied to Wonko the Sane's topic in New member Introductions

Awesome models!!! I used to live and work in S. Africa, in Natal, not too far from Pietermaritzburg and Ixopo. Worked as a medical officer in one of the Catholic missions. Sweet memories...! Greetings, Thomas -

I have some left over supplies of great boxwood blocks made by Lloyd Warner (unfortunately he doesn't make them anymore), which I am using for my French 74 gun ship model. Some of them, especially the smallest ones (2 mm), have holes that are a bit too small for my ropes. I enlarge them by gently drilling them with an appropriate drill bit held in the pin vise. The original hole will provide a guide for the bigger one. After I pass the rope through the new hole ( I stiffen the end of the rope with PVA glue to facilitate passing it through the hole), the bigger hole will be invisible in the block, covered by rope.

-

Hi Matiz. An awesome model you built. Wasn't it however already built in the past and you are showing us old pics? On the French forum you presented this model finished several years ago. (I was hugely inspired by your model while building my own version of the Boudriot's 74 guns ship in 1:48. Excellent work!!! Congratulations!!!) Thanks again, Thomas

-

Uploading pictures

Dziadeczek replied to wernerweiss's topic in Photographing your work. How to do this.

If you use Windows 10, it has a free, already factory preloaded program, (Microsoft Office Picture Manager), where you can click on "Picture" and than select "Rotate and Flip", and finally "Save". -

I am building the French 74 guns ship of 1780, following the four volumes by Jean Boudriot (the third volume talks about rigging). This source is quite good, although there are a few mistakes here and there Jean did not manage to avoid. But they are minor. I am currently modeling yards, sails and all the running rigging associated with them. Very tedious and time consuming work! In addition, I have Francis Jonet's "Fitting and rigging a 74-gun model ship", which complements Jean's books, especially the pictorial part of it. I am not sure if the monograph on the Gross Ventre is adequate on this topic, but generally those books from Ancre seem to be quite good, detailed and reliable. Certainly good enough to build a model.

-

Wow! Your father must be a genius! Building such a yacht at the age of seven? Barely in the early grammar school years and already getting into such a task??? Unbelievable!!!

-

What's wrong with Artesania Latina Constellation?

Dziadeczek replied to Antti's topic in Wood ship model kits

I have a question for our more knowledgeable members. What's the difference between a corvette and a sloop-of-war? (I have a couple of old magazine articles, where they name the "Constellation" in Baltimore, as a sloop-of-war.) As far as I know, these are two different names (classes) of ships for the same thing and they are used interchangeably. I might be wrong on it, though. -

I generally plank only once, am too lazy to double plank the same thing. What for, anyway? After preliminary shaping (spiling) and heat prebending wetted planks off the model, I first place a plank dry (without glue) on the hull and make sure it fits there perfectly. Then I apply small bead (drop) of glue (Titebond or white Elmer's glue) to the edges of all bulkheads where the plank will be laying on and a thin layer along one of its edges, and place it there. I use ordinary tailor's steel pins and gently tap each one with a small jewelry hammer (3 or 4 taps will suffice) but not through the plank but rather along its lower edge, into the bulkhead. ( I plank from the wale down, towards the keel, one plank on each side) to keep it there while the glue dries. The pins exort enough pressure to keep the plank in place, tightly agains bulkheads. That way, after the plank's glue dries, and I remove the pins, there will be NO sign (holes) from them. Procede with each plank like this and, after pins removal, do the same with subsequent plank until you cover the entire hull. Here is an old pic showing the process during the construction of my MS Rattlesnake model.

-

Planking Help Needed

Dziadeczek replied to JDillon's topic in Building, Framing, Planking and plating a ships hull and deck

You can easily draw such a "pyramid" by yourself. Take a sheet of paper and along one edge draw a vertical line and mark on it a series of equal points, say, every half inch or so. In the middle of an opposite edge of this paper make a point half way on the sheet. Connect this point with all points marked on the vertical line, and voila! You have this pyramid... -

Tapering tool/jig and planer.

Dziadeczek replied to Ulises Victoria's topic in Modeling tools and Workshop Equipment

I think this tool is just a waste of money and an overkill. A mini plane made of ebony? Why? To increase its price? Comparable mini wood plane you should be able to get online for a few dollars (perhaps up to 10 today). From a few pieces of wood scraps in your workshop you should be able to make yourself a simple jig to shape (shave) your planks. See post nr. 27 at the bottom of this link, where I showed this simple jig. Easy peasy... -

You can do oils on top of acrylics, but you cannot do acrylics on top of oils! According to an old artists/painters' principle: "fat on lean OK, but NEVER lean on fat! " (meaning oil paints are fat, but acrylics are lean (thinned with water).

- 399 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

Hi Martin, I don't know about any Czech shipmodeling book, but for a beginner I would recommend three (at least), all in English: - Wolfram zu Mondfeld - Frank Mastini - Milton Roth (the last one is a little dated now, as far as sources of materials, but still valuable as far as some modeling techniques) And there is a bunch of other, more advanced books depending on the specific topic, like rigging, planking, armament, sewing (sails), etc... Plus, you have many monographies describing in detail a specific ship. The best however source of info, I think, is still this Forum, and in addition you have your native (Czech) speaking forum, where among the others, famous Doris Obrucova belongs to. (I don't have their link at the moment - check archival posts.) Greetings, Thomas

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.