-

Posts

517 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by knightyo

-

-

3 hours ago, Jaager said:

I can imagine that instead of a raised iron bolt head, because of rusting, the bolt would be counter sunk, then a packing of waterproofing gunk, then a wooden plug. The plug grain oriented with the standard grain, so that only an outline would be visible and if painted, that detail hidden by the paint?

As far as authenticity - nothing may be closer to the mark?

As far as modelers convention - a trunnel - if belt and suspenders is your want - or a brass or copper pin for show.

I think you might have hit the nail on the head with that summary (I couldn't resist). I'll bet that's exactly what we are seeing on the replica Pinta as well.

-

Thank you Allan, that was exceptionally helpful, and explains why there were only bolts shown on the bottom parts of the standards on tlevine's work. I might do two bolts on the bottoms of the standards, and trennels on the tops. Below is what I'm approximating, (working replica of Pinta), but it's hard to tell how they were constructed there. I don't see any bolt protrusions, but for this working replica, they might not have been trying to replicate the original to that degree. Or, they were, and trennals are just the way to go all around. Decisions..

Alan

-

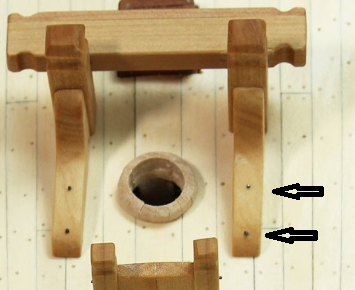

This might be a fairly obscure question, but regarding a photo from tlevine's Swallow log below... Are "fasteners" to be inserted ONLY on the bottom portion (see arrows) of the standards? I'm close to attaching similar components on my 1492 caravel (bottom photo), and am not sure of how I should reflect the fasteners; for that matter, I'm not sure if they should be trennails, or raised nails. Any guidance on this would really be appreciated. I do know that the standards are currently too thick, so will be adjusting that, but I'm really wondering about the fasteners. Initially, I was thinking that I'd apply fasteners to the upper sections as well, but now I'm assuming that tlevine's fastener's are correct, and that I'd I'd install two of them, both on the bottom section of the standards, but wanted to pick the collective brain of MSW on this one. - Alan

- Keith Black and mtaylor

-

2

2

-

My palms became sweaty while reading this thread. I never would have made it in the navy. Ironic, as building models ships is my passion. lol

Alan

-

-

Wow! That water turned out great!

Alan

- Old Collingwood, Canute, mikegr and 4 others

-

7

7

-

Ok, so working at my usual pace, but incremental progress is better than none, I suppose. The entirety of the hull inside and out is now planked with pear. It's dusty in this photo, but compressed air and brushes should remedy that before any finishes are applied. I'm considering applying tung oil and/or shellac, and will be experimenting quite a bit with both.

The replica Pinta had a unique looking capstan which caught my eye, and which I wished to replicate on the Nina. Who is to say that the original Nina didn't have this type capstan as well?

Below is a start, but will need to be "skinnier" to match the replica; especially the center "X" sections. Not pictured are a few more brass parts I've cobbled together which will need to be blackened.

Time to start working on these little guys. Making these at this scale is quite a challenge, and I'm having to make these under magnification. It's still a satisfying exercise, however.

- Montaigne, Canute, Knocklouder and 1 other

-

4

4

-

Thank you both! I will start performing some fairly vigorous experimentation with both shellac & renaissance wax. Ironically, scraping is indeed how I started out finishing the rails; however, I was clumsy and ended up with numbers of fine "cut" lines that I ended up sanding out with a very high grit wet/dry paper. What I'm left with is burnished large surfaces and unburnished small pieces, recessed pieces, etc.

Alan

-

As I've been toiling over my small Nina project, I've ended up basically burnishing the wood in numerous sections. The rails for instance, are swiss pear, and in a "burnished" state really have a nice look. Are there any recommendations regarding what to apply over burnished wood? My Google searches have made it pretty clear that standard finishes are out as the pores of the wood are effectively sealed when the wood is burnished, which makes sense. Has anyone experimented with applying any type of finish over burnished wood?

Alan

-

-

I'll bet I'm not alone in my modeling process. If I build something and the joints look magnificent, I'll leave it as natural wood. If what I've built needs filler or is sub-par, it gets painted in order to hide my sins. 😊

Alan

- Victoria, Canute, Chuck Seiler and 4 others

-

7

7

-

If it were me, I wouldn't give them away. I might pin them up in my hobby area as "art" or find some other use. If giving them away, the person who they were given to would be less likely to purchase the plans from someone who should receive legitimate payment for their work, etc.

Alan

- thibaultron, KentM, mtaylor and 1 other

-

4

4

-

-

-

Hi Dave,

This is a very good topic. Just about everything I do is scratch, and my tools over the years have primarily consisted of fingers/sandpaper/x-acto blade, coupled with occasional usage of a mini-saw and files here and there. I will say that I purchased a mini-lathe in order to turn cannons however, as that's incredibly fun.

But you seriously don't need to spend a lot of money in this hobby. You can, and you can save a lot of time by purchasing dedicated tooling, but it's not strictly necessary. The most satisfaction I get from this hobby is by retreating into my cave and slowly shaping objects with sandpaper while lost in my own thoughts; it's definitely the process, not the destination that brings me happiness. When I'm working with machinery, it feels more like work and isn't as enjoyable.

Alan

-

I'm not even building the model as I have about 300 others in the works, but when that figure/table/accoutrements goes on sale, I'd love to buy a copy. I'm envisioning a little cabin scene diorama under glass that I can place under my monitor while I work.

Alan

- chris watton, thibaultron, Dave_E and 3 others

-

6

6

-

-

This looks like a fun model! When the hull planking was attached, was it glued in addition to having the pins? If so, I'd strongly recommend removing the pins before starting the second layer of planking. Once the pins are removed, filler is applied to the hull (including any damage incurred during pin removal), and the hull sanded smooth, you should have a very good surface in which to apply the second layer of planking.

Alan

-

Thanks Gregory. I actually really did go straight online to order a copy. I appreciate your offer, however! The nice thing about not having any definitive plans for these ships is that it sure gives me leeway to model what I like, and not have to worry about being proven wrong on anything. My model is a real hodge-podge of what I liked most about the Nina and Pinta replicas.

Alan

-

Thanks guys! I was thinking the head would be wood, and had already been shaping it to fit the "boxy" structure; I was just really given pause when thinking about the stress that tiny piece would be under as it was being turned. Gregory, I have the Mondfeld book as well, but unfortunately don't have the AOTS for Columbus' ships; I'm a little embarrassed to admit that as I'm building one of the models. Guess who's now going to go book shopping?

I admit to also being curious about the structure of this thing; I think it's actually the capstan from the replica Pinta; it was just more interesting than the one on the replica Nina, so I thought I'd go with it.

I admit to also being curious about the structure of this thing; I think it's actually the capstan from the replica Pinta; it was just more interesting than the one on the replica Nina, so I thought I'd go with it.

Alan

-

Hello,

I'm building the capstan for the Nina, and am trying to determine whether the capstan head in this photo would be wood or metal. Any thoughts? It's hard to tell what is metal, and what is wood on this one!

At present, I "think" the discs and baseplate are metal and everything else wood, but it really doesn't seem like the head would remain intact under strain if it was wood as opposed to metal.

At present, I "think" the discs and baseplate are metal and everything else wood, but it really doesn't seem like the head would remain intact under strain if it was wood as opposed to metal.

Alan

-

Was the impossibility of making them out of wood that you had referred to based upon drilling correctly spaced holes? You could also use the metal deadeyes you made as templates to pass a pin-vice through in order to create perfectly spaced holes in a blank of wood the thickness you desire, then carefully sand the wood blank to shape around the outside. I've been using boxwood strips to make things lately, and it's been great to work with. It can be held between your fingernails while you sand it, and it's hard enough that your fingernails don't "dent" it while you are sanding (I look through a cheap magnifying unit while working). If there are dents, they will be shallow and can be sanded out pretty quicky.

Alan

- CaptainSteve, Gregory, NenadM and 1 other

-

4

4

-

I think the mystery has been solved. I very gently felt the areas of concern under my magnifying station using a few different instruments, and could not feel any "edge" to the discolored areas at all; I could have sworn that there would have been edges. I think the hypothesis that the plating has been affected by accidental contact to some other substance is correct. I also worked around one of the edges to see if I could get it to flake, but there was no discernable transition from area to area.

Now I feel comfortable moving forward with trying to "age" them a bit more, especially if something can be applied which will slightly fill the dimples bringing them a little closer to scale. I still have the jig used to create these plates; I might press a bunch more plates and then experiment on them with different mediums.

Thank you everyone for your help with this! I sincerely appreciate the input; especially for something that I should have been able to figure out on my own.

Alan

-

1 hour ago, wefalck said:

Did this foil tape have a paper backing, or just an adhesive, but on a paper carrier? From the first photograph it appears, that there is some paper from which the copper has been flaked off, correct?

I am curious about this, as I have some very thin copper tape, but it is self-adhesive on a protective paper-backing.

There are probably different varieties, but there is also one that is used in making stained glass windows or 'Tiffany'-work - the pieces of glass are framed with the tape and then soldered together. So the adhesive should be pretty good.

The tape does indeed have a paper wax-type backing. The copper peels off of the backing for installation, and has an adhesive on the back side; there's definitely nothing but "sticky" copper on the back side. I've tried to replicate the flaking on a sample piece I just took from the roll, but ironically could not get it to flake. I'm a little mystified. If I can get the nerve up, I might try to further "flake" that section of the hull when I get off work.

Nina by knightyo (Alan) - Mini-Mamoli - 1:106

in - Kit subjects built Up to and including 1500 AD

Posted

Ok, still plugging away on this one. The below parts have been burnished a bit to see what the final look might approximate. They are still a bit thick however, so will be thinned out a bit, and the recessed areas near the tops will also be thinned down more. Then they'll receive trennails along with the adjacent knees. I'm still building up the back quarterdeck area, so not really affixing anything to the deck yet which could be knocked away.

Binnacle! I've been building up the binnacle, which I'll be able to install after the masts have been installed, and the quarterdeck complete. Below is the drawer, and a little knob which was almost impossible for me to make. They are resting on my drawplate next to the smallest hole. I couldn't see what I was doing with these pieces unless working on them under magnification, but I'm happy with them now that they are done.

Below is the main body of the binnacle with the drawer hanging out. If my printer will do it, I'm going to print a scroll with my name and build date, and will then place in the binnacle drawer which I'll leave slightly ajar. The "pegs" sticking out of the sides will be clipped off and sanded down; they are just trennails which have just been glued in and are drying. There will actually be 4 more attached lower on the legs. Once that's done, I'm going to be cutting a circle in the top of the binnacle for a light to hang down into it, which will illuminate a very small compass, providing my printer can print it small enough. Since the backside of this binnacle will be resting against a mast, I'm thinking of installing a very small led up through the deck and between the binnacle/mast, and into the back of the binnacle, which can then provide light. Hard to explain, but I'll post pics.