-

Posts

517 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by knightyo

-

-

-

When it's time for me to make my rope, I'm going to purchase Chuck's rope making device. He published a tutorial for it, and it looks like it would be very satisfying to use.

Alan

- Captain Poison and Chuck

-

2

2

-

-

-

On 3/26/2021 at 2:11 PM, Landlubber Mike said:

Not to add to the pile of aftermarket, but take a look at this guy's build - you can see why getting your hands on the Super Detail set is going to be worthwhile. PE experience a must!

http://cs.finescale.com/fsm/modeling_subjects/f/7/t/185042.aspx?page=-1

Man I wish the photos on that site enlarged more. The detail on that model is insane! Just stunning detail when looking under the deck at the structures at the bow and stern.

Alan

- mtaylor, Landlubber Mike, Canute and 1 other

-

4

4

-

-

3 hours ago, DmitriyMarkov said:

Thank You very much - I try to do my best, however I'm no good at removing glue buildups )

Thanks, RGL - I find inspiration in your works!

Well, my pace is quite hasteless : good modelling projects are like wine - better when aged😉 Now I see things my quality control in 2011 considered as "passable" : some seams here and there, some molding joints, etc. If I was less patient and finished this little model then - it would suffer form those imperfections. Also by 2011 I haven't read Tameichi Hara's "Japanese Destroyer Commander" - which is motivating reading for a modeller I must admit 🙂

Best Regards and happy modelling

Your build looks great so far! And after looking up the book you mentioned by Hameichi Hara, I purchased said book, as it looks great.

I've been "building" my Syren model since about 2008, so it's nice to see another modeler who is deliberate with his work.

Alan

-

-

-

I think it depends on how "tight" the outside planking is, and whether or not the plank fits perfectly in place without really needing to be glued to the underlying surface. If it were me, I'd probably dremel out the underlying filler and reinstall a new plank on top of the "old", and sand to the correct depth to ensure the outside planking had a solid and long-lasting surface to adhere to.

Take my opinion with a grain of salt tho. I'm famous for going with the most difficult and unwieldy approach whenever possible.

Alan

-

-

1 hour ago, Chuck said:

Guns!!! Guns!!! and more guns....

Yessssss...... There can never be too many guns. 😁

I love the capstan as well. It really looks fantastic.

Alan

- FrankWouts and Elijah

-

2

2

-

1 hour ago, Gahm said:

Wow, that takes some courage!

Thomas

Well, it did take me about 13 years to pull the trigger on that decision. 😉

-

That deck is absolutely gorgeous.

Alan

- Stuntflyer, bruce d and FrankWouts

-

3

3

-

-

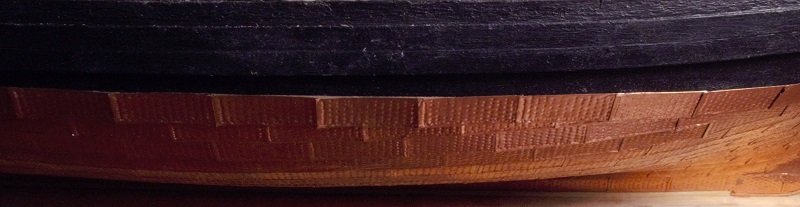

So I've done something a touch drastic with the model, but first I have a question for the group. Take a look at the below photo. These plates were made out of copper tape and installed circa 2008 or so. The are now starting to peel. Any thoughts on solutions? There is a sick part of me that would like to place extremely small rivets in each hole in order to secure each plate; I've made larger bolts out of wire, but something this small? We'll see. My OCD level is indeed high enough that I'd follow through with it, if it turned out to be a viable solution. I definitely want to be careful not to do anything which would cause the plates to "crinkle" tho.

And now it's time for my confession. Ever since I planked this ship years ago, I was never satisfied with the hull appearance. As the log reflects, I've done a number of things to the planking to try and make it "good enough", but it's never hit the mark. Sooo..... You can see what I've done. Isn't it beautiful? 😁 Hull re-planking with swiss pear has begun! I believe this will make the model look far and away better than the poorly stained basswood I'd installed previously. This also makes sense, as my quarter galleries, stern decoration and figurehead are also all made out of pear, so everything should blend together. You can see the first plank I've re-laid on top of the wale. Once the planking has been laid, I'll be applying an aging medium I procured from Canada (after extensive testing on scrap strips).

-

I'm at a good stopping point in my "real" work today, so am taking an early lunch in order to post a few updates. Below is the start of my new deck planking. The deck of the kit had zero camber, and was a straight line fore/aft. I've remedied both items with a lot of sanding. Then graph paper was glued to the deck to ensure the planking was installed evenly, and planking commenced below. It really was satisfying to plank the entire deck from front to back. I'm glad I made the decision to take the plunge in cutting off the quarterdeck.

Below is the finished main deck planking, with sawdust included. Sorry for such stark lighting in the photo. The lighting in my den was too dark, so I thought I'd head to the kitchen for brighter, natural light. You can tell that I'm not a very competent photographer. Anyway, now I just need to plank the very front piece in the bow, and of course re-make the quarterdeck.

But not so fast! So here's my dilemma. As I was cleaning up the deck and getting ready to shape the waterways, I was viewing my stock of photos of the replica of the Nina.. To my consternation (extreme consternation), I realized that the replica has scuppers (below) all the way down the hull, and not only did my version NOT have scuppers since I re-shaped the deck, if I cut scuppers out at the new deck level, they'd no longer match the wales of the ship on the outside; they'd go right through them. So guess who made the

insanedecision to remove the wales and all associated "bumpers" in preparation for scupper installation? Yea, I know.. But it's yet another thing which would have really bugged me now that I knew about it. For giggles, since the exterior hull is now "clean", I'm also going to very carefully scribe down the middle of each plank as well, as the initial planks were far too wide to be in scale. I might also take the opportunity to add more "meat" to the bow section, as it has quite a sharp rise at the bow, which my version does not. Might as well add that to the list; we'll see on that point.I think I might need to re-name this model "Pandora's Box", because I've certainly opened said box a long time ago when I thought "wouldn't it be cool if I did X to the model before I apply the finishing touches". It pains me to know how much I could have gotten done on my Syren/Triton by now if I'd just finished the model a long time ago, but I'm in it, so am moving forward. I have to admit it is fun to be putting this much detail into such a tiny model, but fully acknowledge the insanity of "upgrading" a model which was never meant to be very accurate. It would have been FAR better to have built from plans, or to have started with a more accurate kit.

- GrandpaPhil, Canute, Louie da fly and 1 other

-

4

4

-

2 hours ago, Keith Black said:

The problem with wax, it dries out and shrinks leaving cracks.

You rhymed. 😁

-

I really like the look of pear. This will be a beauty. What are you thinking of filling the gaps with, Mark?

Alan

-

From your rope tutorial: "Hope this helps.........start making your own rope. It’s rewarding and FUN!!!!!! Until you have to make 1000 feet per day for seven days every week".

This gave me a good lol. I hope you are able to move more into the areas that you gain the most satisfaction from (such as designing the Dutch Boyer, etc). 😁.

Alan

-

I would pay $1,700 for tools, not for kits, as with the tools you'll be able to create a FAR better looking model (and many in the future) than relying upon what is in the box with a kit. If it was me, the first kit I'd ever buy would either be from Chuck at Syren, or Chris at Vanguard. I can speak to Chuck's instruction, and it is absolutely superb. I suspect that Chris' instruction is also fantastic just by reading his posts.

Alan

- Roger Pellett, mtaylor, Ryland Craze and 1 other

-

4

4

-

Hi Mark,

I'm sure it's been mentioned, but I can't find what kind of finish you are going to apply to the planks. I've actually ripped the planking off my Syren and am replacing it with swiss pear along with the Pentart Patina discussed in the "Bitumen/asphalt" thread (found a supplier in Canada who still has a stock). I'm going to test it on a number of scrap planks first with mixture of mineral spirts and compare against tung oil, and probably a third candidate of some type. I'll give you a heads-up on the results if you have an interest.

Alan

- Canute, mtaylor, Keith Black and 2 others

-

5

5

-

I was surprised to see a post by someone from Boise, and then astounded to see someone else from Boise post as well! Welcome! My wife thinks I'm the only person in the world who is nuts enough to enjoy this hobby. It would be nice to prove to her someday that others do indeed exist. 😄

We have a number of posters/vets who also have PTSD. As you read the logs, you will be able to see who they are; there might be good opportunity for like-minded dialogue there.

Take a look at this thread for how to maneuver throughout the forum, , etc -> https://modelshipworld.com/forum/47-how-to-use-the-msw-forum/

Below is how to start a scratch-build log.

Alan

-

La Belle Poule 1765 by mtaylor - Scale 1:64 - POB - French Frigate from ANCRE plans

in - Build logs for subjects built 1751 - 1800

Posted

Another thing you can do is experiment with the type of finish to apply over your pear. Below is a pic of an experiment I ran on mine. The left column is just unfinished, the middle column is pear with Formby's Tung Oil Finish (which I learned isn't actually Tung Oil), and in the right column are pieces which had Pentart Patina liquid (50/50 mix of mineral spirits/Pentart) applied over the top of dried Formby's. I'm going to keep experimenting to see if I can get something between the middle and right columns. Maybe starting out with a 90/10 mix of mineral spirits/Pentart; it was surprising how dark and strong that medium was.

Alan