-

Posts

1,690 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

OcCre HMS Victory Limited edition

scrubbyj427 replied to modeller_masa's topic in Wood ship model kits

As a moderate to advanced builder You can spend $1700 dollars on the full Winchelsea build and have a fully authentic model of an English frigate that is not only authentic but perfectly to scale and almost indistinguishable from a contemporary model or you could buy the Indefatigable kit from vanguard for even less than $1700 and still have a better more authentic scale model that accurately represents a 44 gun heavy frigate. As a new builder I’d be looking to cut my teeth on sub $500 models that I wont sweat if they turn out poorly. This model makes no sense to me at that price. -

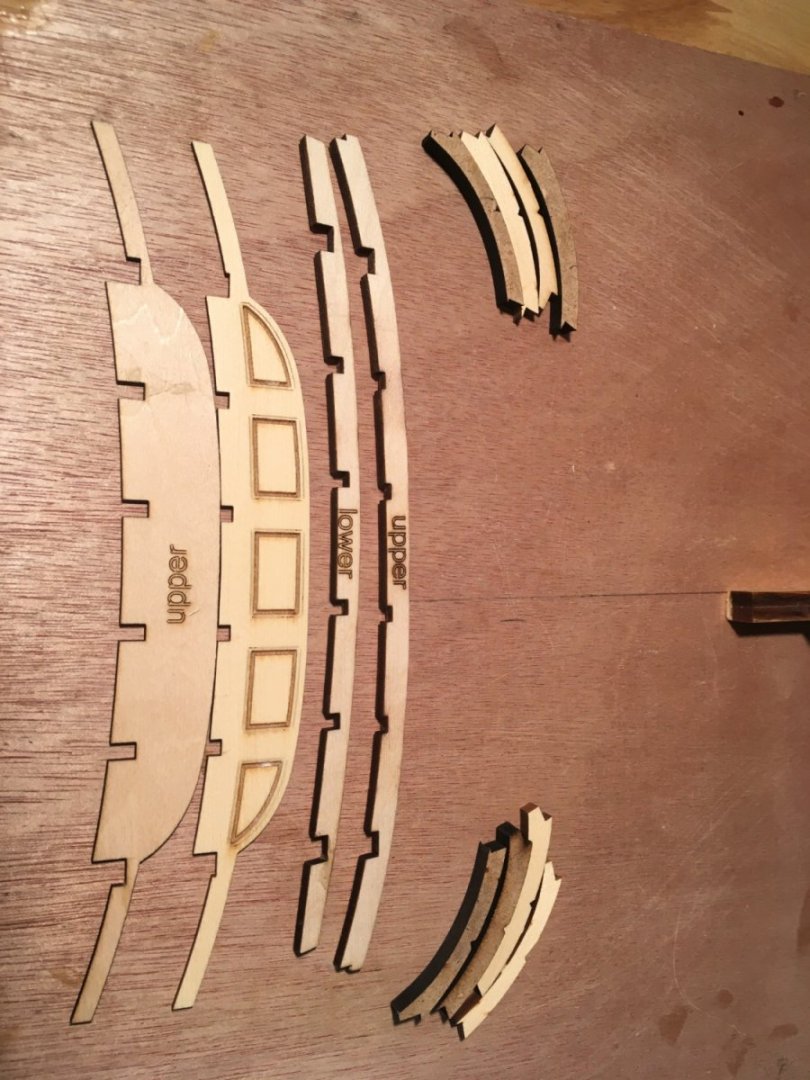

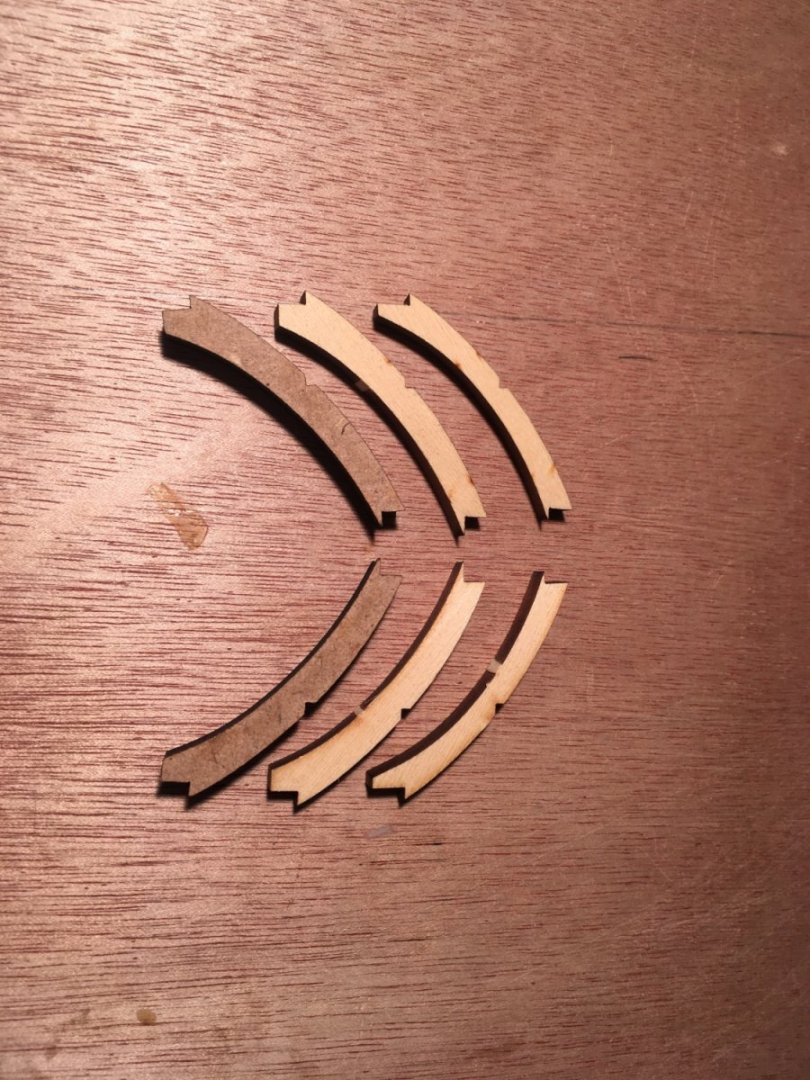

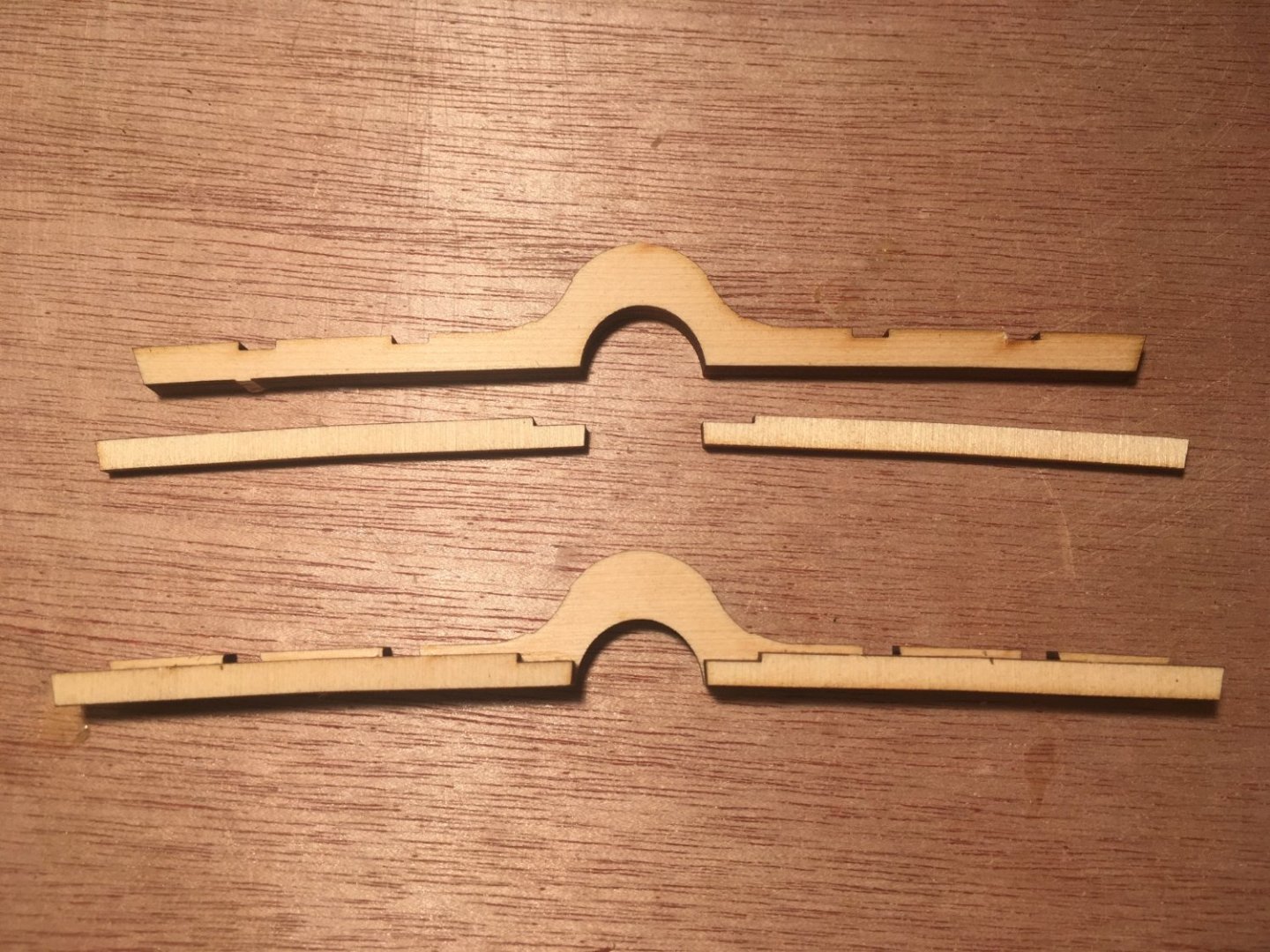

Finishing up the stern structure, there is just 4 more pieces I need to add these are here to help with planking, the lower pieces have a fairing reference line as you can see below the horizontal pieces get installed first and after you have sanded the lower pieces they can then be installed. You can see the notches cut into the top, these just fit right under those frames and should line up with the bottom Of frame 25. now I will completely fair out the stern and prepare the counter for planking. A .25”x.0625” rabbet strip will also need to be added to the stern. Happy sanding! JJ

-

Hi Allan, I’ve carelessly painted cast metal figures in the past with decent results from 10’ away, but I know there is a whole niche of the hobby out there that involves these figures, that with the right camera are almost convincing enough to be real humans.

-

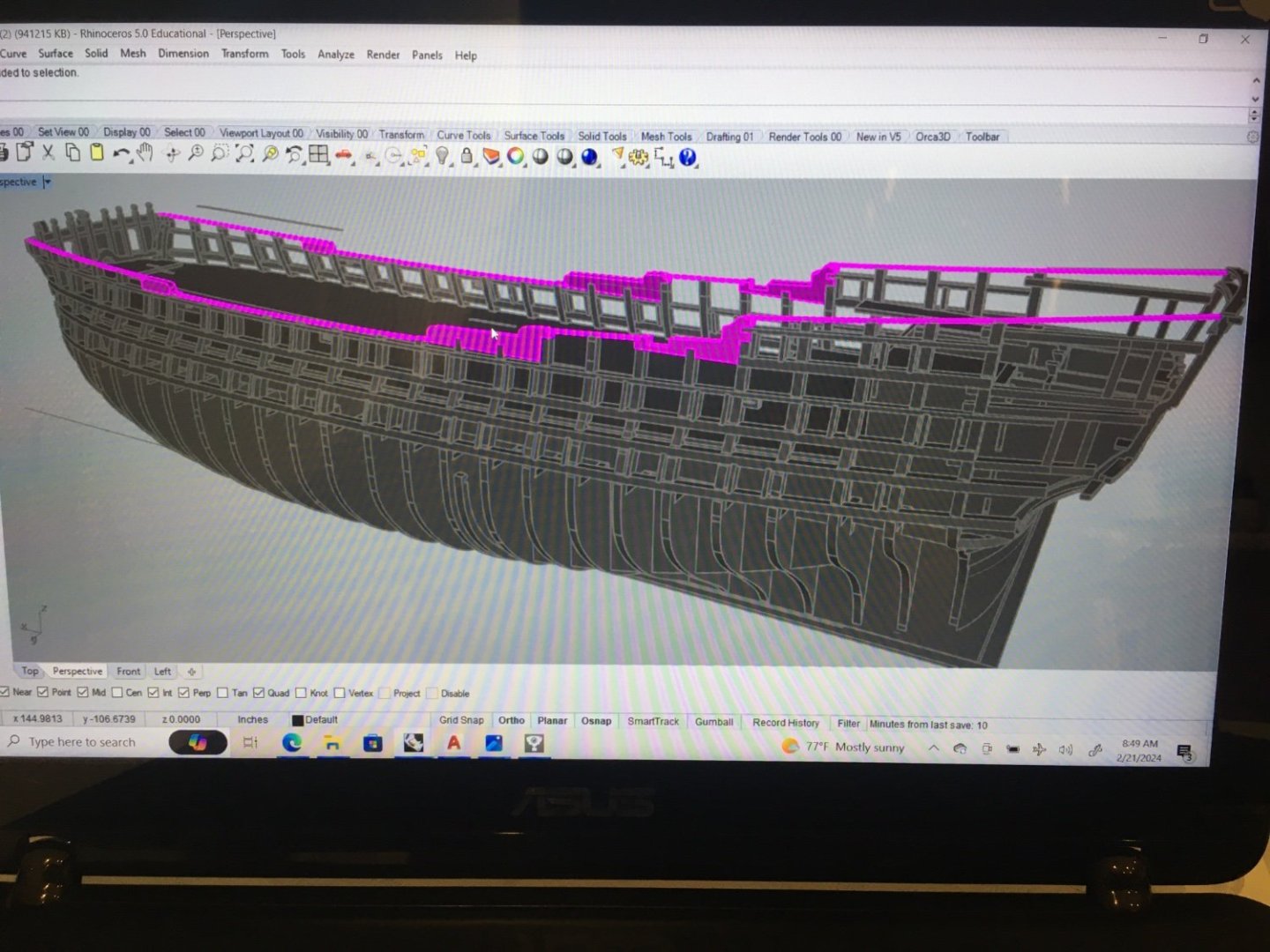

Thank you Siggi. I’ve had to build two models, one complete on the computer and one that’s at my workbench. The goal is to get them as close to exactly the same as possible!

-

This will be my first shot at painting a figure like that, so there may be a couple do overs. I do plan to remove from the base and build a thin one out of AYC. The current base puts him close to an additional 6”+ taller at scale. These figures really put the models in perspective.

-

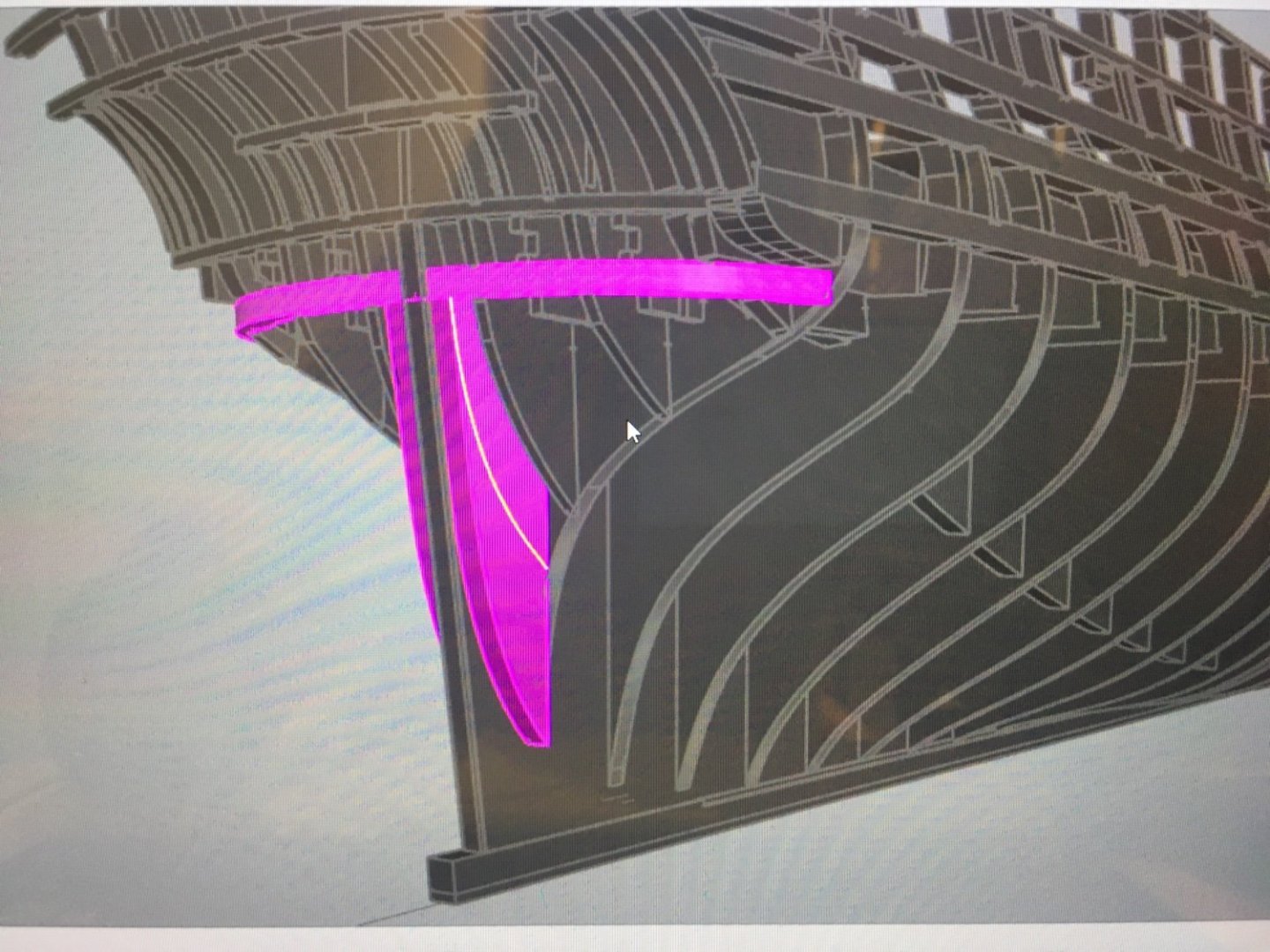

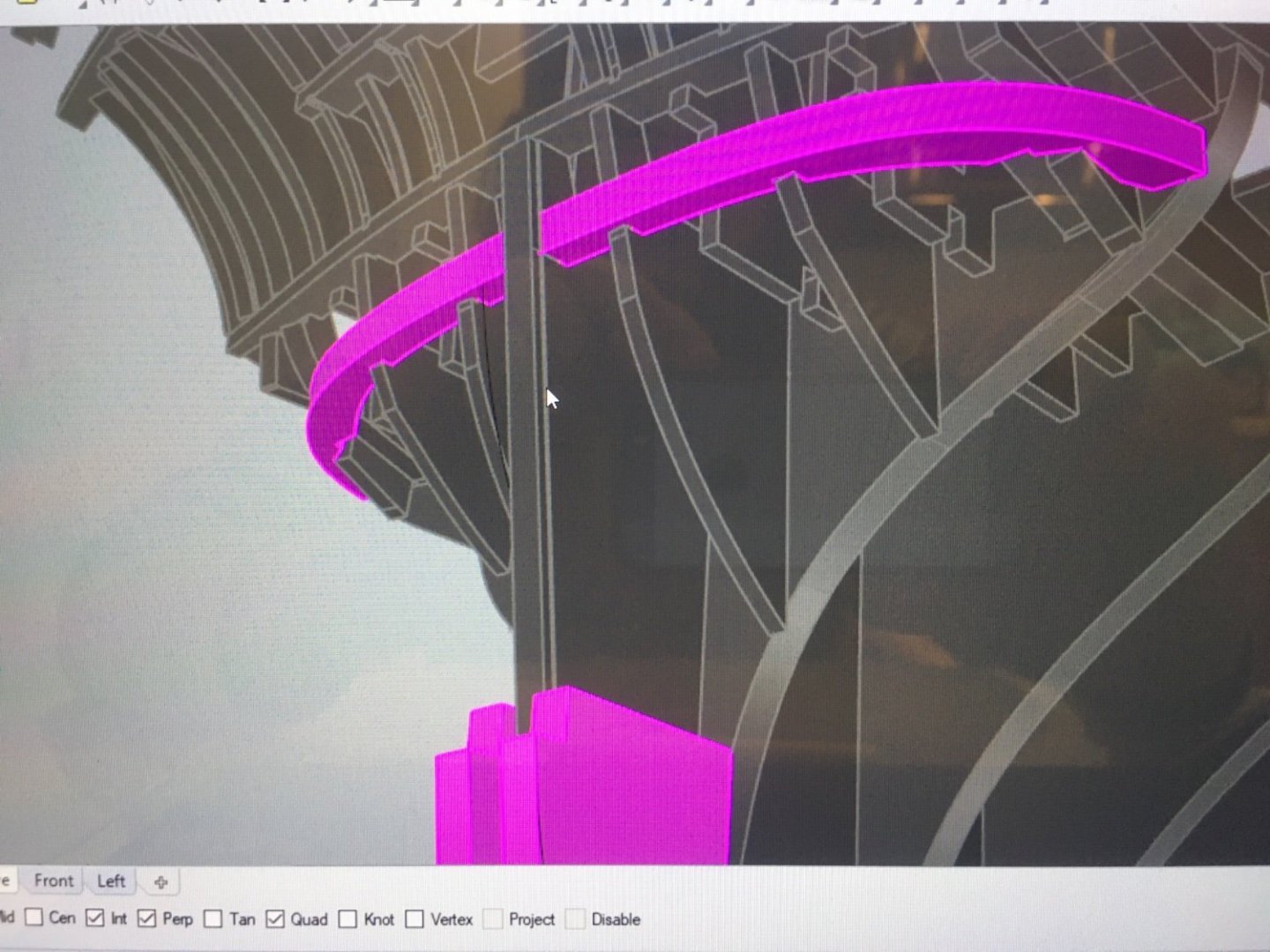

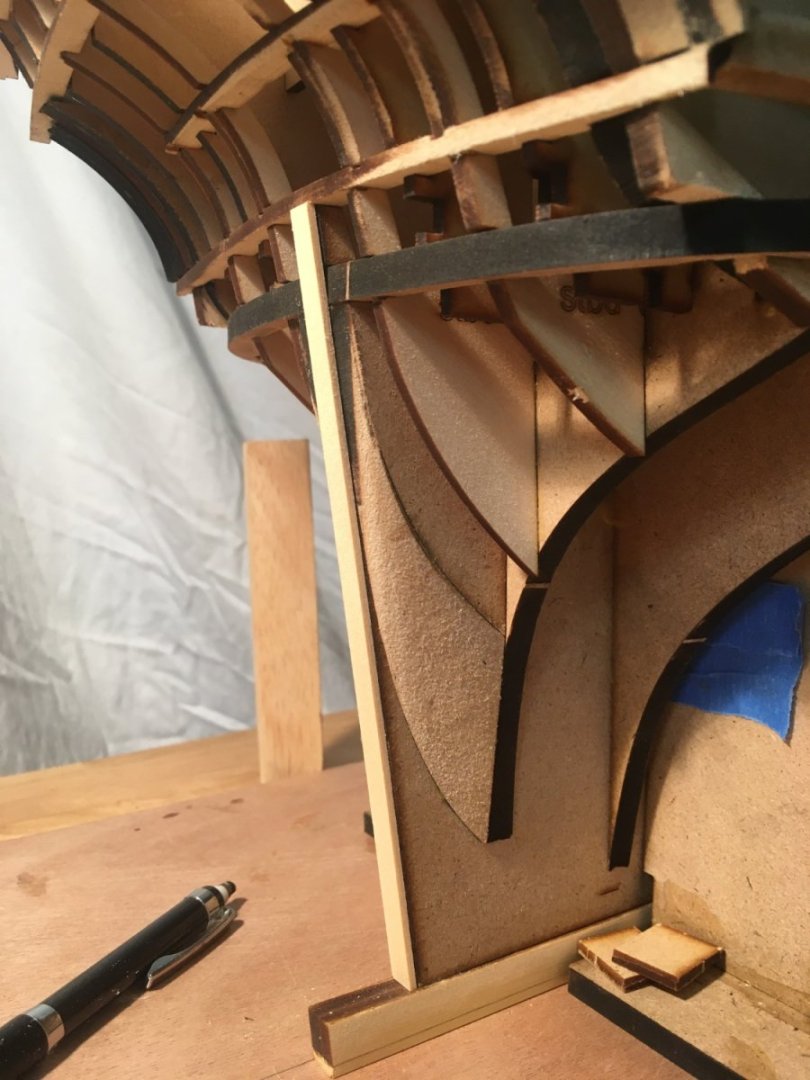

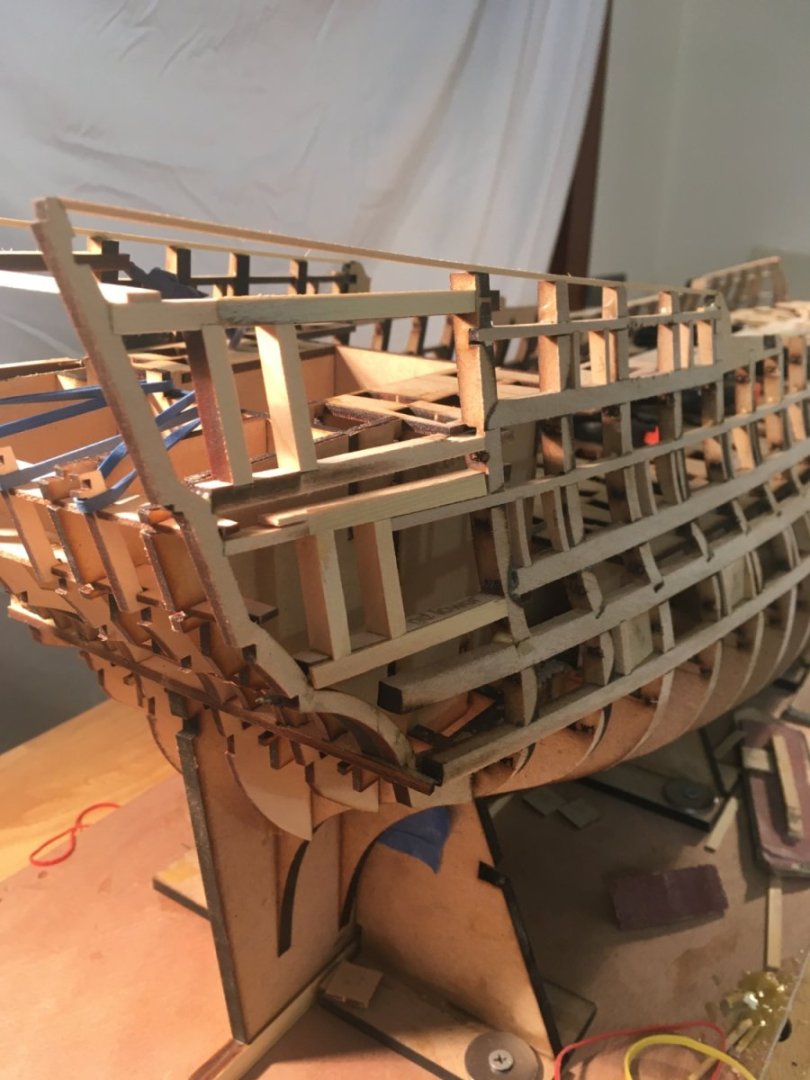

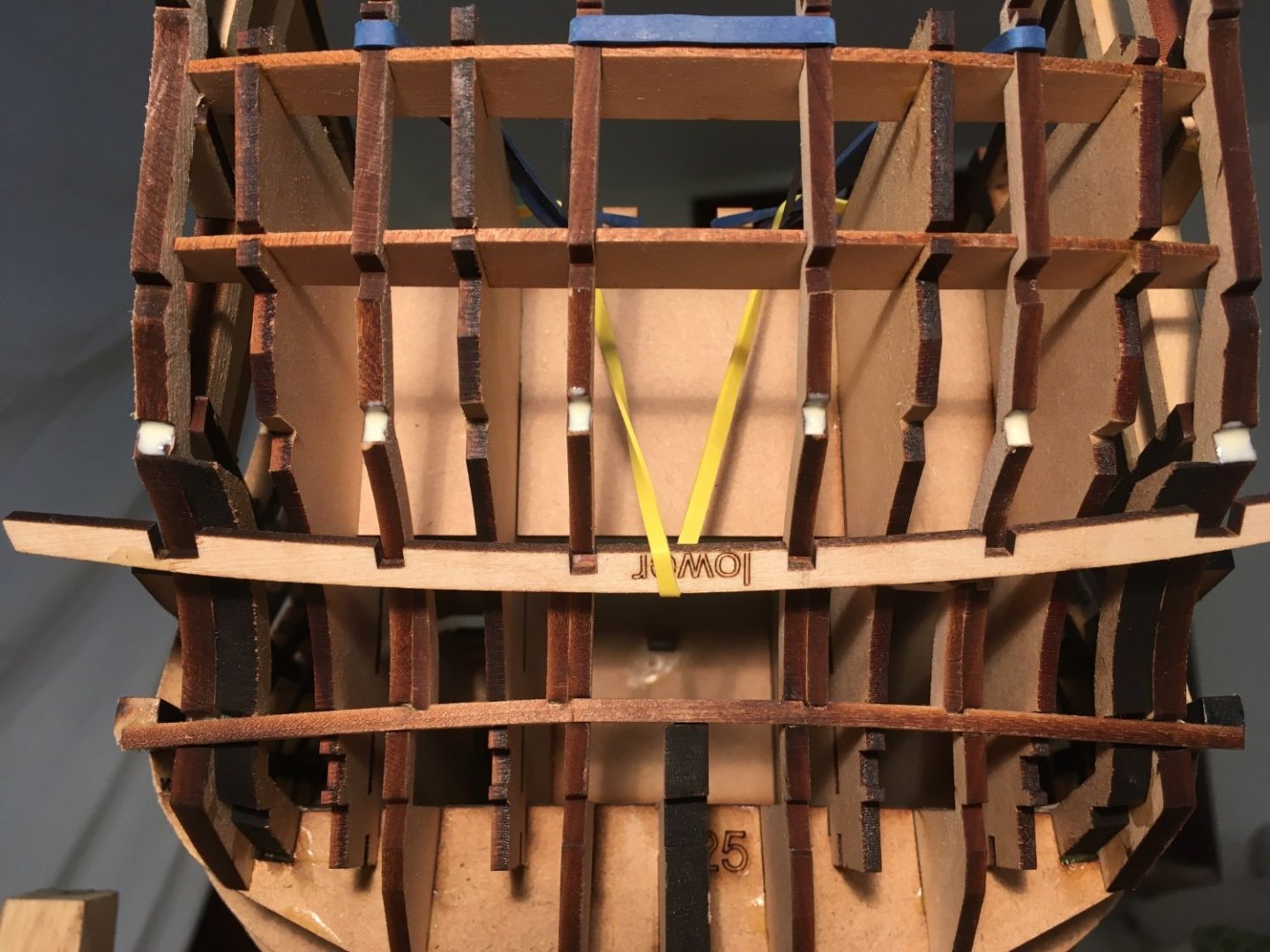

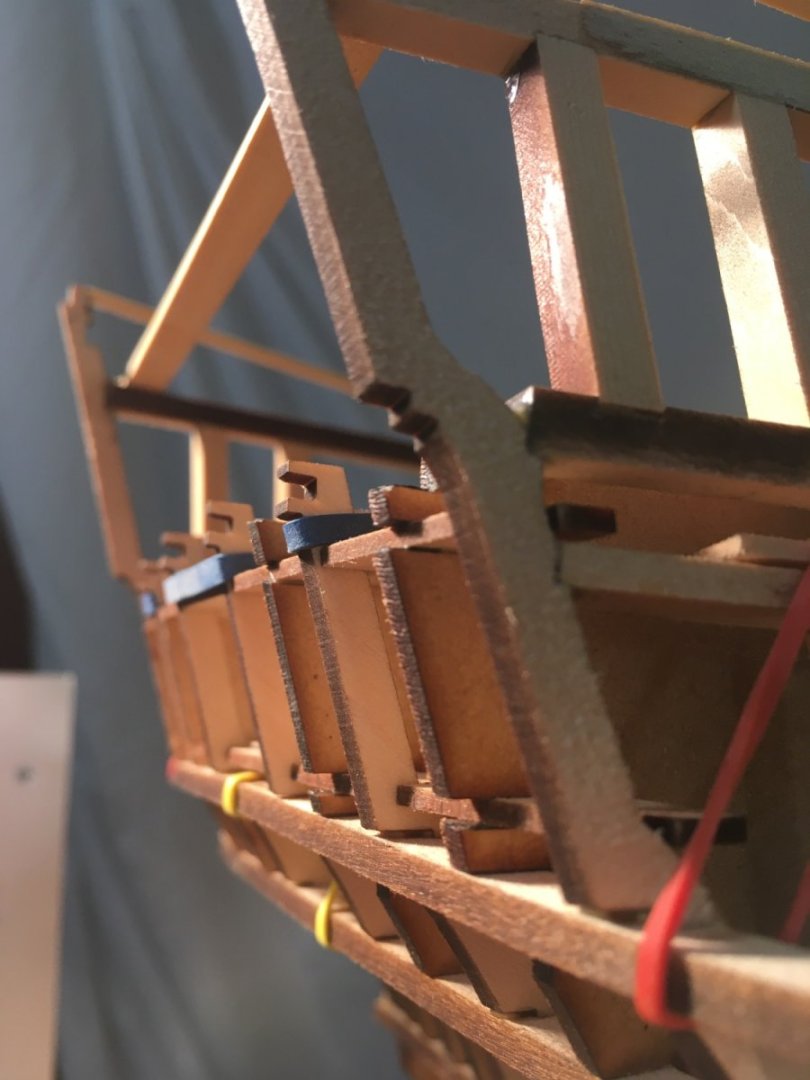

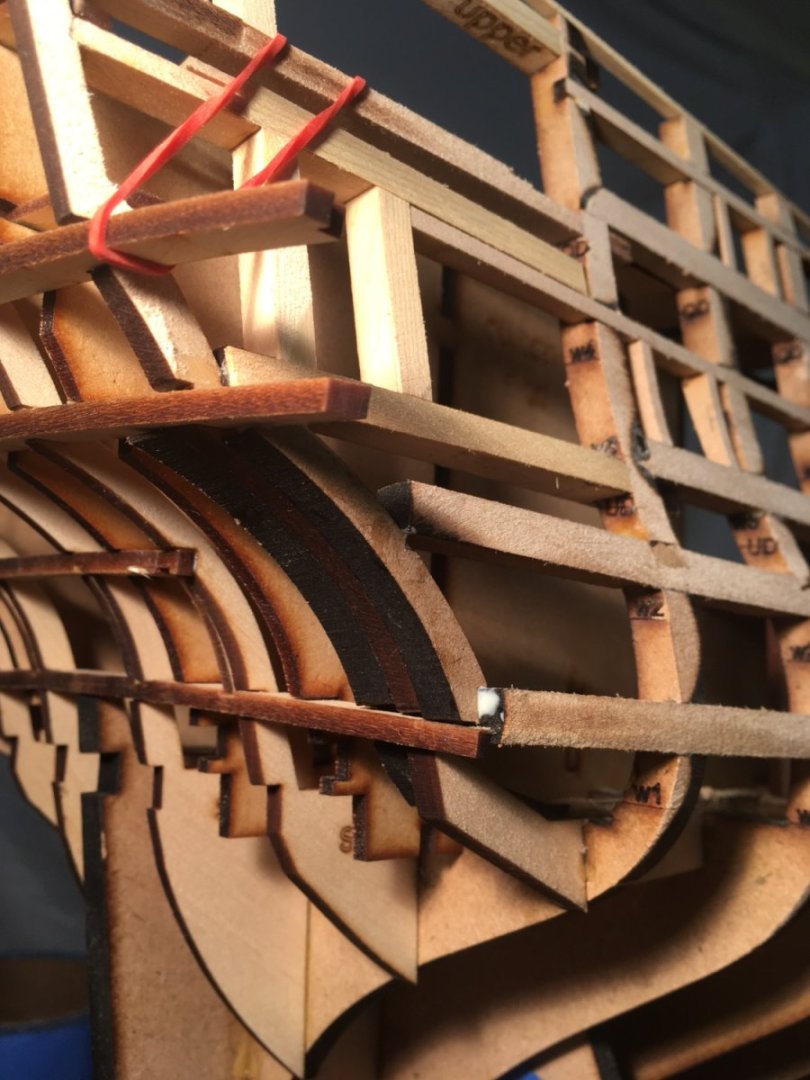

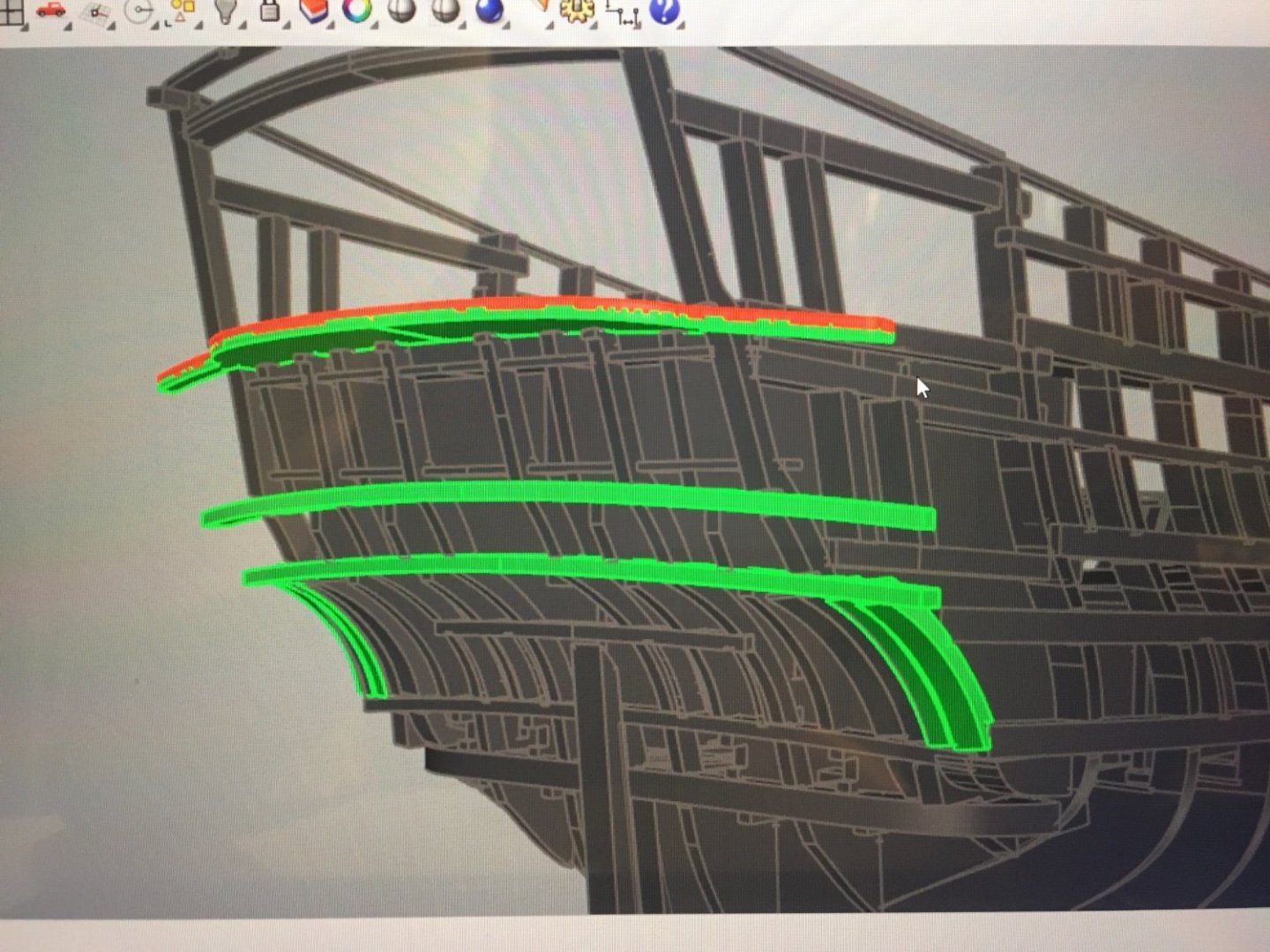

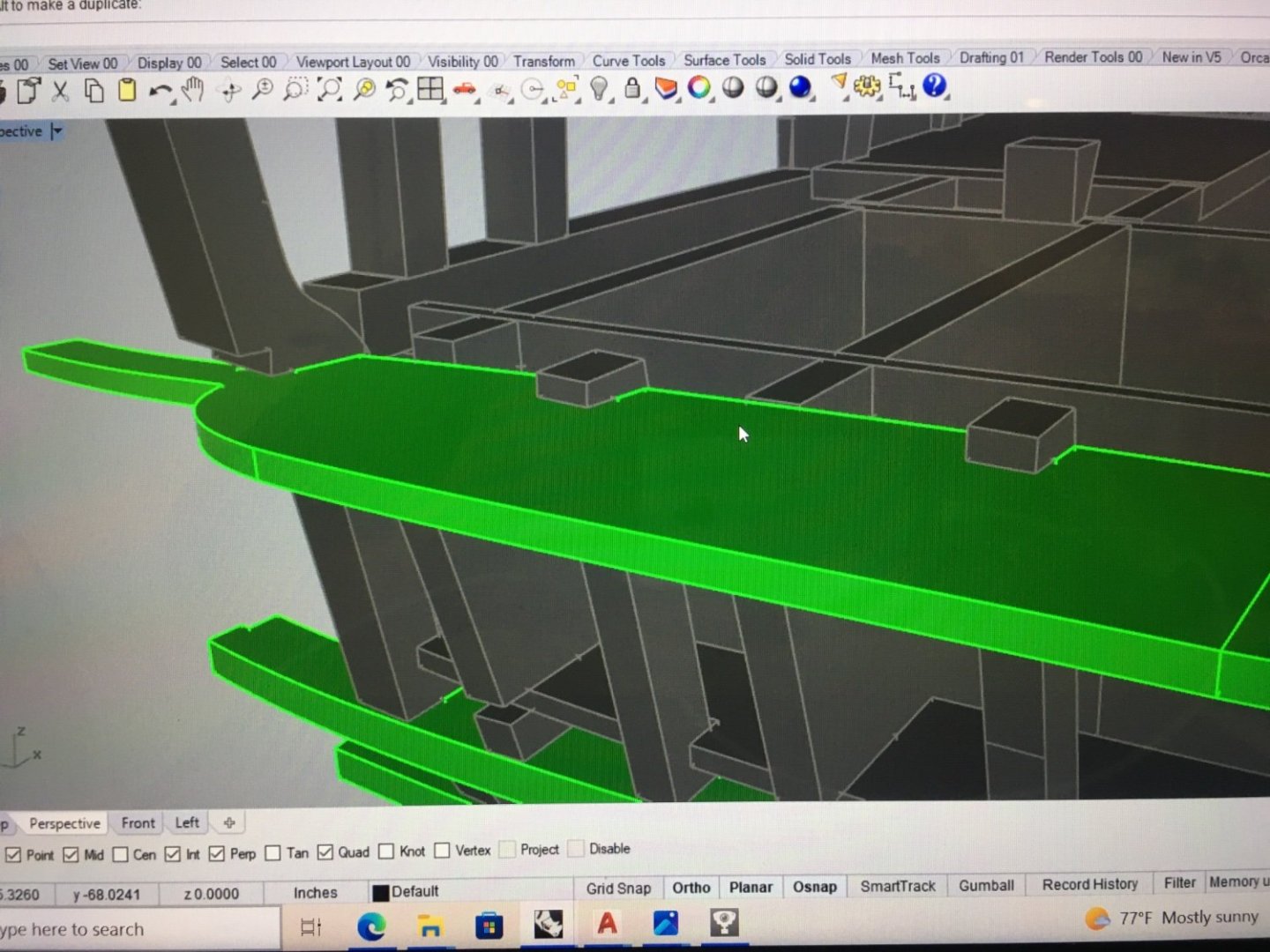

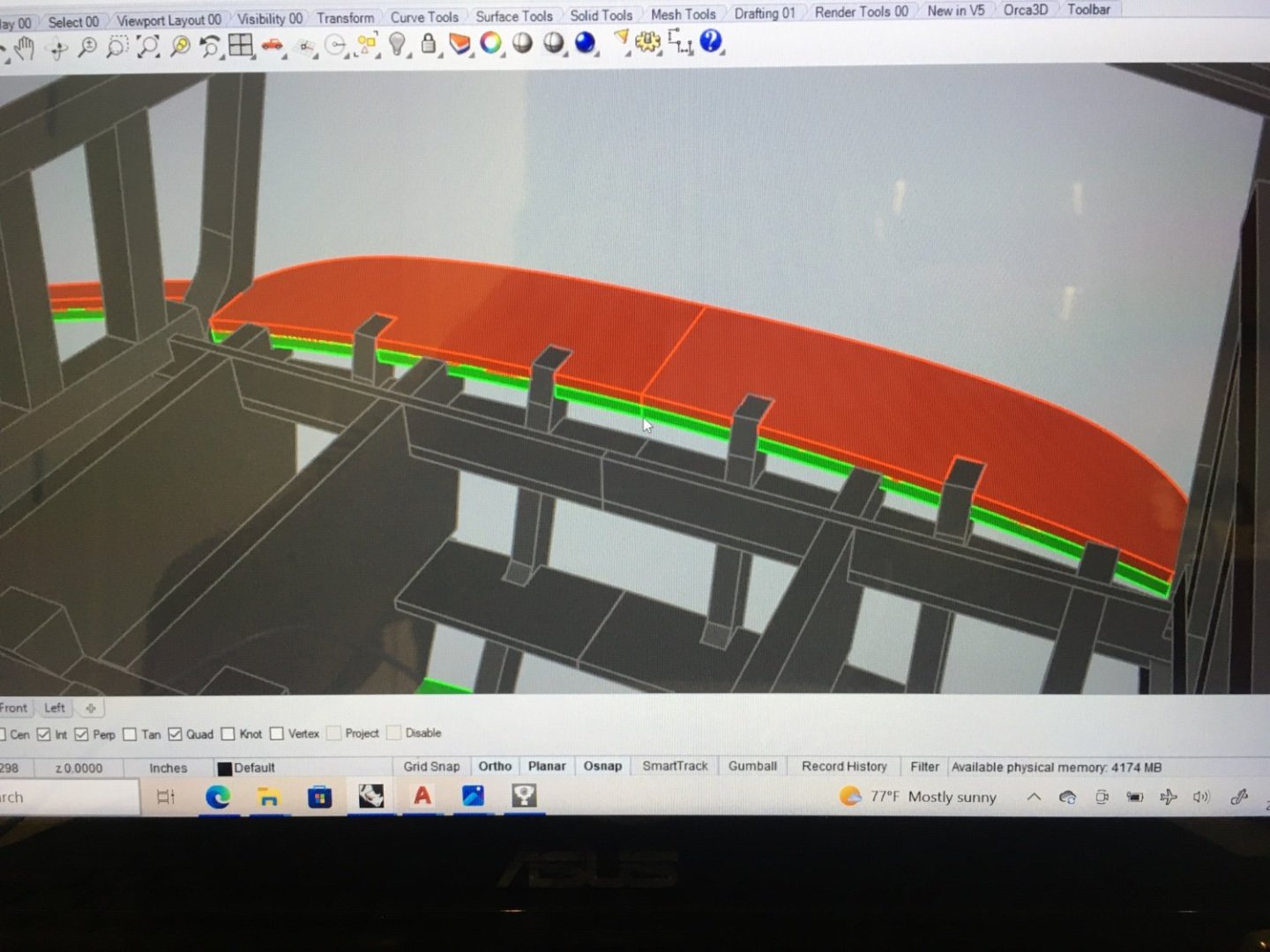

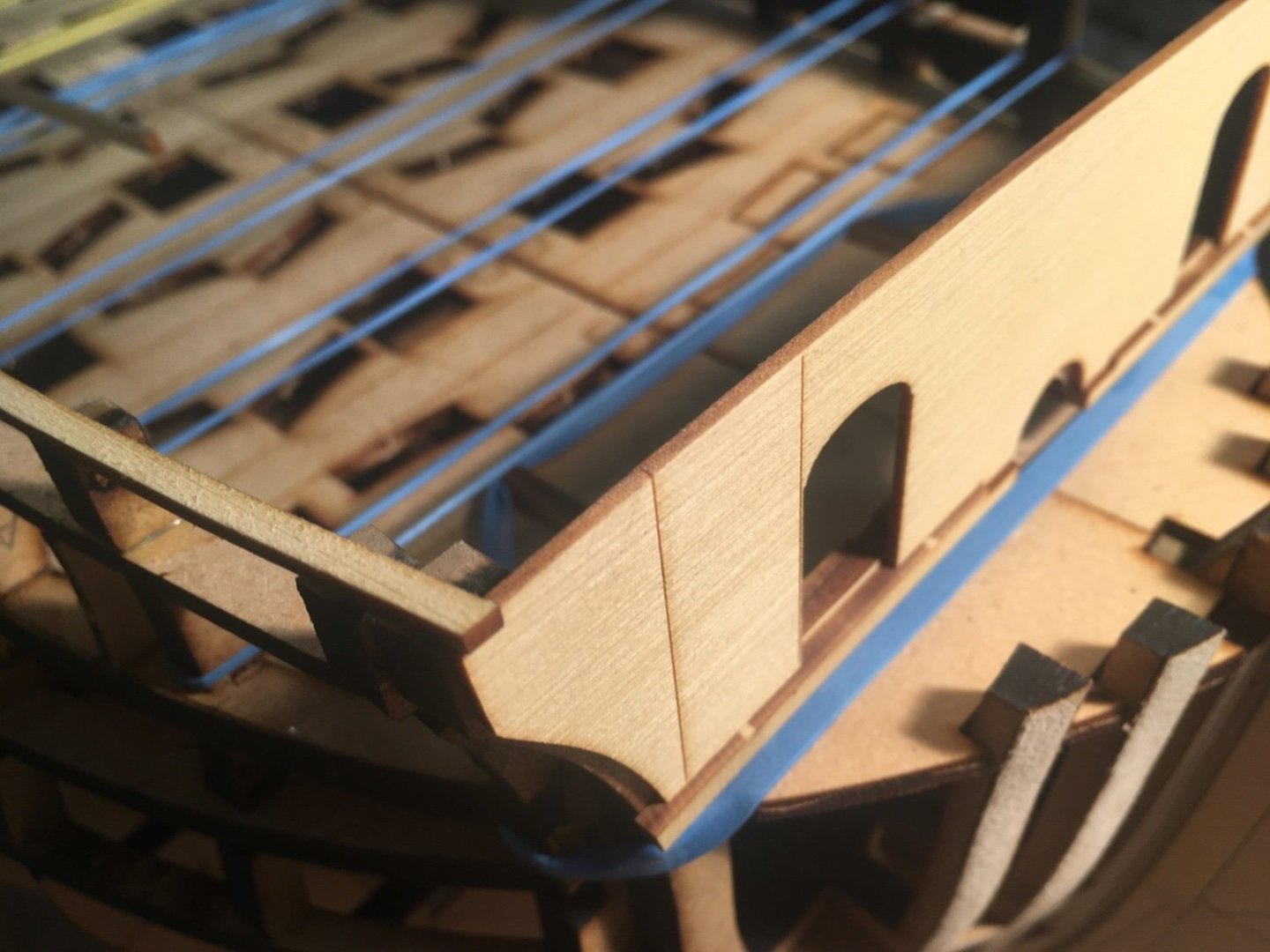

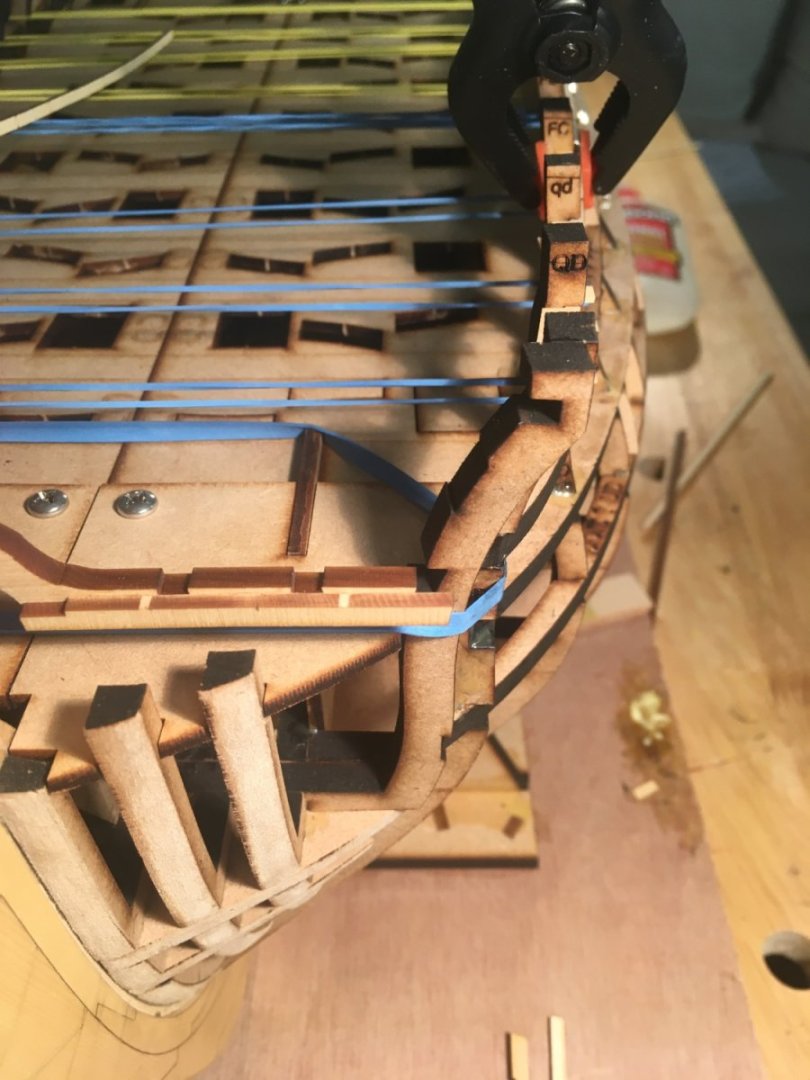

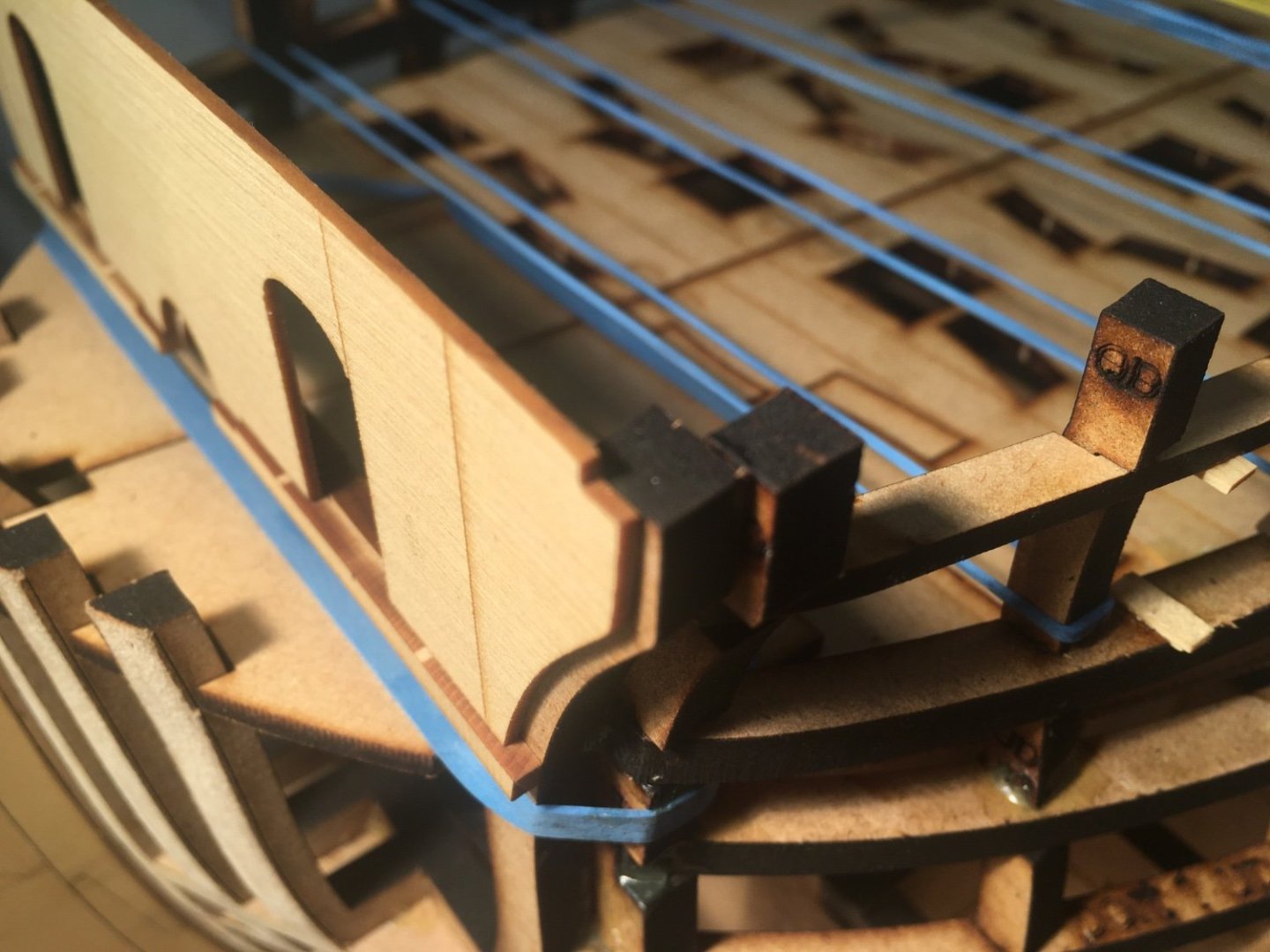

So I have been fairing the hull up the last week, I’ve mostly been working on the top sides with the model remaining upright. My plan is to fair the hull to the lower wales and start planking upwards on both sides before I move the hull from its stands and flip it over. Once all the frame extensions are planked I will coat the inside with epoxy, this will make everything rigid and allow the removal of all internal jig structure, from there I will begin planking from the wales down. As mentioned earlier there are some remaining structural parts to add after initial fairing has been completed, this is all centered around the stern as you can see below. Below you can see some additional pieces that further tie the stern frames together and define the upper and lower counter. These pieces can now be added, they are quite simple. You’ll notice that one of them has decorative panels on it, this is one of the first attractive parts that needs to be added now and I’ll cover this shortly. We will begin with the two pieces etched with upper and lower, these tie the frames together and define both counters as well as where the windows will be placed on the gun deck. adding the lower piece, I did heat it a little to help it conform easier as it needs to have the proper round up on it, the frames and the jig will hold its shape but it was just easier to install with a little bend to it. Be careful NOT to glue it to the jig! You can see above that I only added glue to the frames. You can add a rubber band to it and utilize the pegs above on the jig to ensure it’s held tight. Go ahead and repeat the exact same process with the horizontal frame marked “upper”. Now we move up to the balcony area, this is made of two parts with help tie the upper structure together by also define the balcony and act as a sub deck, fancy mouldings will also attach here. You’ll notice the two little notches in the outboard stern frames as well as the notches in the middle frames, these notches line up the balcony pieces. We will begin with the lower piece that has the panels etched in. Before installing the paneled piece I finished sanded it and gave it a nice coat of WOP for protection. It will be awhile before it gets attention again. The upper and lower balcony pieces look very similar but they are not and will not interchange so pay attention. The etched panels need to face down, the panel slides into the slots in the frames, make sure it fits the frames and is angled the same as the slots. This should be easy but be sure, this also defines the angle of the upper deck. You can now install the upper piece, they will be laminated together and should line up perfectly I clamped them together carefully with some small clamps hanging off the ends to help maintain the correct round up. You can also see I put a support piece under the center clamp just to make sure the clamp weight didn’t pull the balcony down to the wrong angle below you can clearly see the deck angle on the 3D model. Once this is complete we have some filler pieces that need to be added, these will define the outside of the lower counter. Starting with the larger one and working outward this just glued to the outboard stern frame and the gun port framing structure. I only used two per side. There will be a template of the lower counter that you apply after it is all faired up. This will give you the shape of the counter that can now be shaped/sanded from the sides. You can see below I already started fairing the frames in preparation for the counter template. I will cover this next. Ive also hired Horatio Hornblower as a project manager from @chris wattonand the staffing agency at Vanguard models. Amazing detail on this resin print, now I need to attempt painting him. So far he seems pleased with the progress and I wouldn’t dare argue with an armed Captain. Thanks for looking in, JJ

-

HMS Euryalus 1803 by rlb - 1:48 scale

scrubbyj427 replied to rlb's topic in - Build logs for subjects built 1801 - 1850

Nicely done Ron! I see some sanding in your near future.- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

-

Hi Jeff, I have just saw this reply. Thank you for looking in on Portland. I will send you a PM on the project if you are interested.

-

Byrnes thickness sander

scrubbyj427 replied to GeneR's topic in Modeling tools and Workshop Equipment

Wish I knew where I could find one of those -

USS Constitution by mtbediz - 1:76

scrubbyj427 replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Your gun deck is shaping up really nice. Well done on the gun tackle too, those are not easy to do, especially at that size. -

HMS Euryalus 1803 by rlb - 1:48 scale

scrubbyj427 replied to rlb's topic in - Build logs for subjects built 1801 - 1850

Looks good Ron, very crisp.- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

-

Thank you Glenn. Doing the dreaded hull fairing now. Apologies in advance to all who may attempt building this thing.😂

-

Thank you Kenny, I’m hoping that it will finish into a nice model. Lots of work! Yes, neighbors are dirtbags. I think Vahur was even more upset to hear.

-

Thanks for looking in Guy. Yes I do plan to fully plank this hull. The design is in place for a framed version and I have some parts here to test it. Long story but I was going to partially frame this one until I couldn’t come up with enough AYC to cut remaining frames I needed, so I then ordered pearwood from Vahur and it was stolen by my lovely neighbors. So I just cut the remaining bulkheads and decided to build this version planked. I will eventually show how the framed version will work with a test mid section. JJ

-

Hi Allan, thank you for the compliments. This thing has the bar set high. I intend to park it right next to my Winchelsea when they are both complete. So I can’t afford to leave out any details. As for a kit, yes I do intend to offer it, just not quite yet, I’ve got to get quite far advanced in the build before I can release it. I’m hoping in a years time I’ll be able to offer the first two chapters.

-

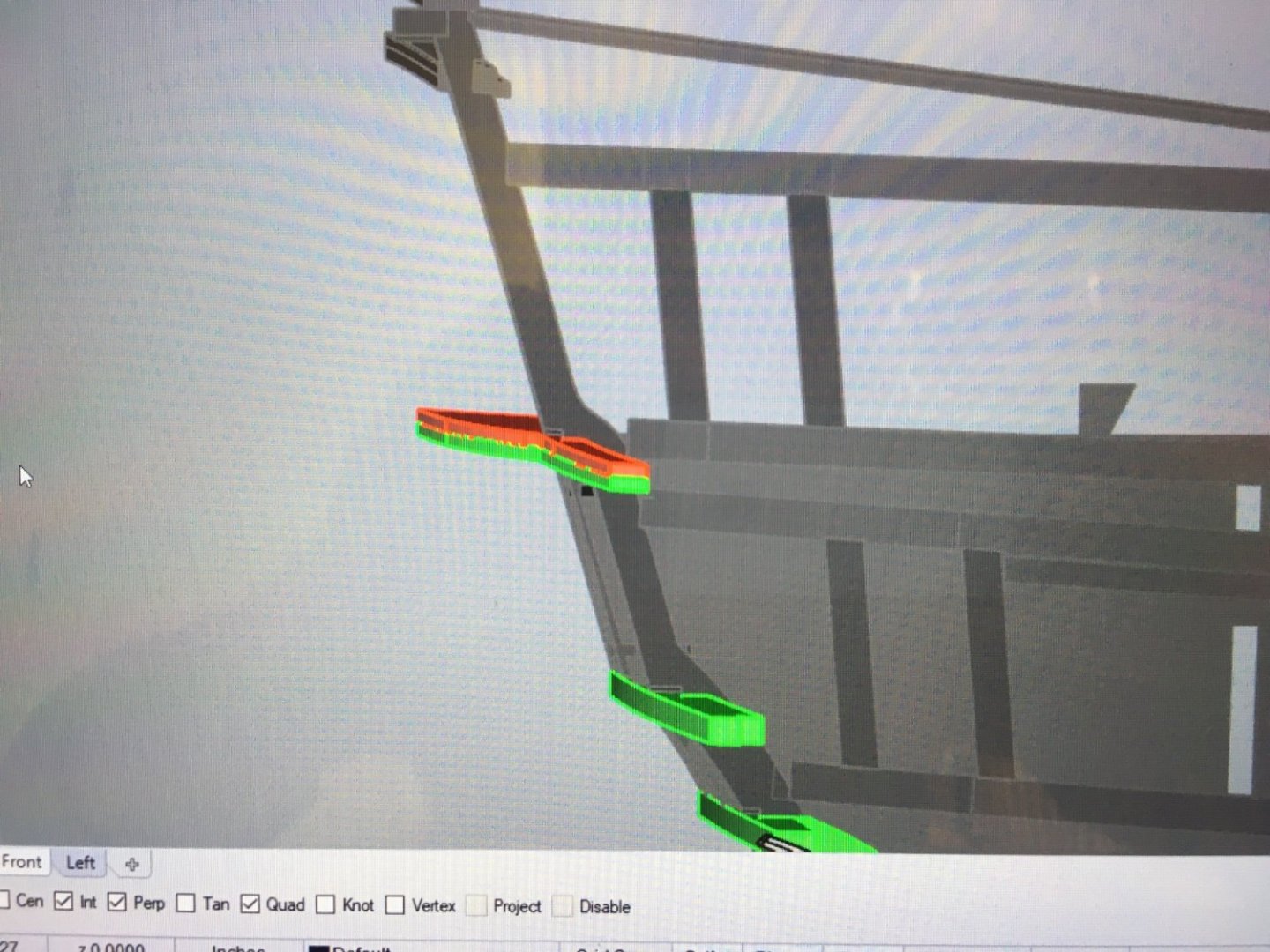

Once the gun port frames are complete we can move on to some final structural elements of the hull, there are a series of hance pieces and fairing caps that need to be added. these are quite simple and really just need to be checked for fit and adjusted if needed. Some of the frames are cut short and or at an angle for the hance pieces to rest on, for example the one seen below, aft of the waist. Both of these sit at an angle to minimize shaping. After all the hance pieces are installed then we can move onto all the fairing caps. The two forward caps are laser cut and before they get glued down, the forward bulkhead needs to be temporarily installed to make sure everything is aligned. There are a series of laser cut pieces that make up the beak head bulkhead assembly, begin with the lower beam that will support the bulkhead carefully glue the lower pieces on as seen in the photo above, the lower pieces will hang off about 1/4”, they act as a stop against the frame as well as a landing for the sundeck and later on, the grating assembly. once this is together it can be placed on the forward most frame, there are slots there to receive the beam once the beam is in place then go ahead and slide the top one in, it’s orientation isn’t important now but the slots for the timber heads faces aft, if the forward hance pieces were placed correctly then the upper forcastle fairing cap will fit perfectly into the notches in the beak head bulkhead and protrude about 1/32. Do not glue the beak head assembly together yet, it all needs to come out so we can fair in inside of the hull first. The sub deck assembly can be tested too, it should drop right in. you can see the beak head bulkhead has a larger cut for the bowsprit than the beam behind it, this is basically establishing a fairing line to clear the bowsprit. Will detail further as we approach that part of the build. The hull is now ready for some fairing, the MDF Sands down pretty easy. I got about 1/4 of the stbd side completed last night. Now there are some more structural parts that make up the stern, that need to added after the sides are faired up, I will cover those soon….after a few more days of sanding. Thanks for looking in, JJ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.