-

Posts

1,129 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Stuntflyer

-

-

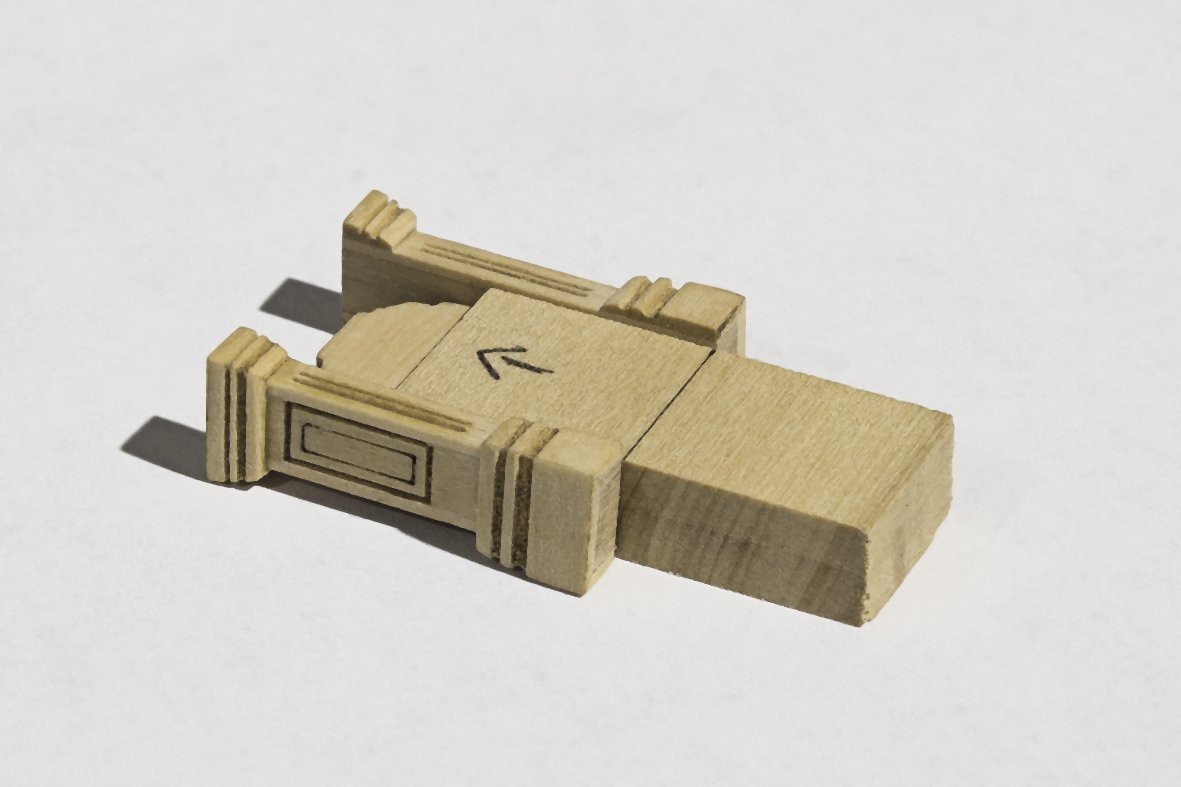

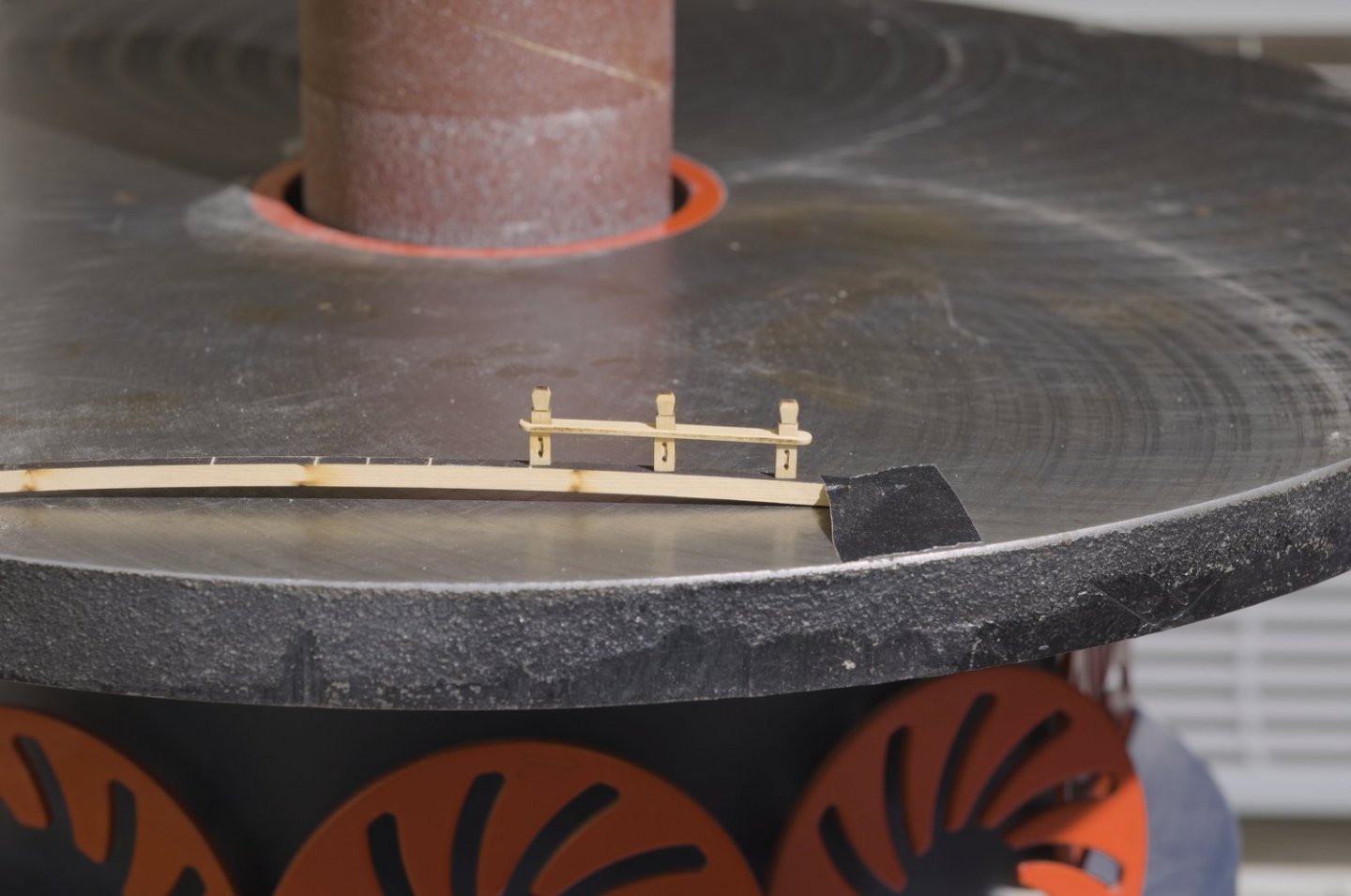

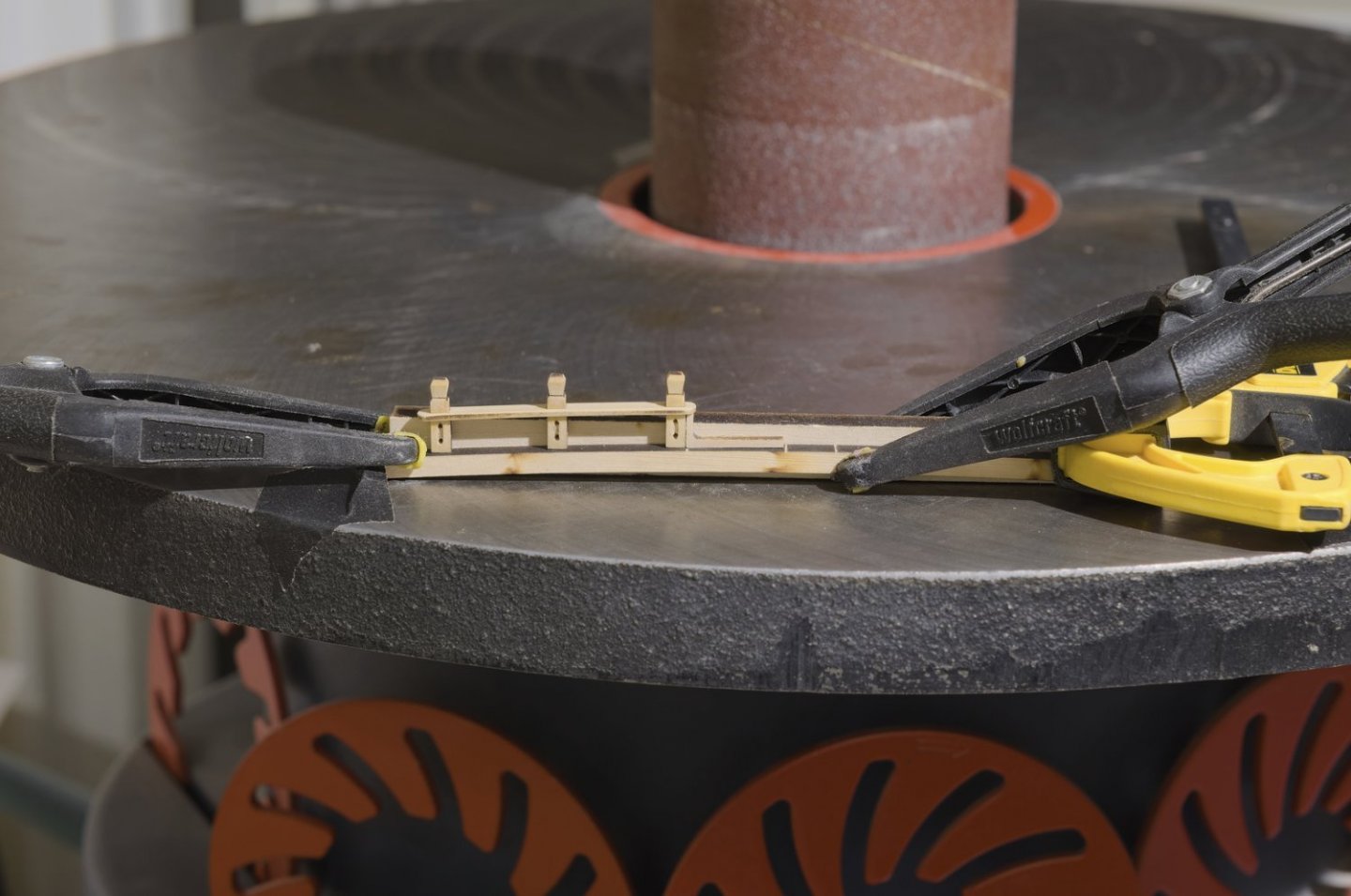

I mitered the molding that wraps around the uprights using the disc sander.

I used this method on a longer piece.

Though I used a long piece for the photo, I used this method when the length was short. Push the stick up to until the desired length is achieved.

Once the uprights where completed, I used a jig to register the holes for the headstock which sits between the uprights.

Jigs like this help to align and hold everything together during assembly.

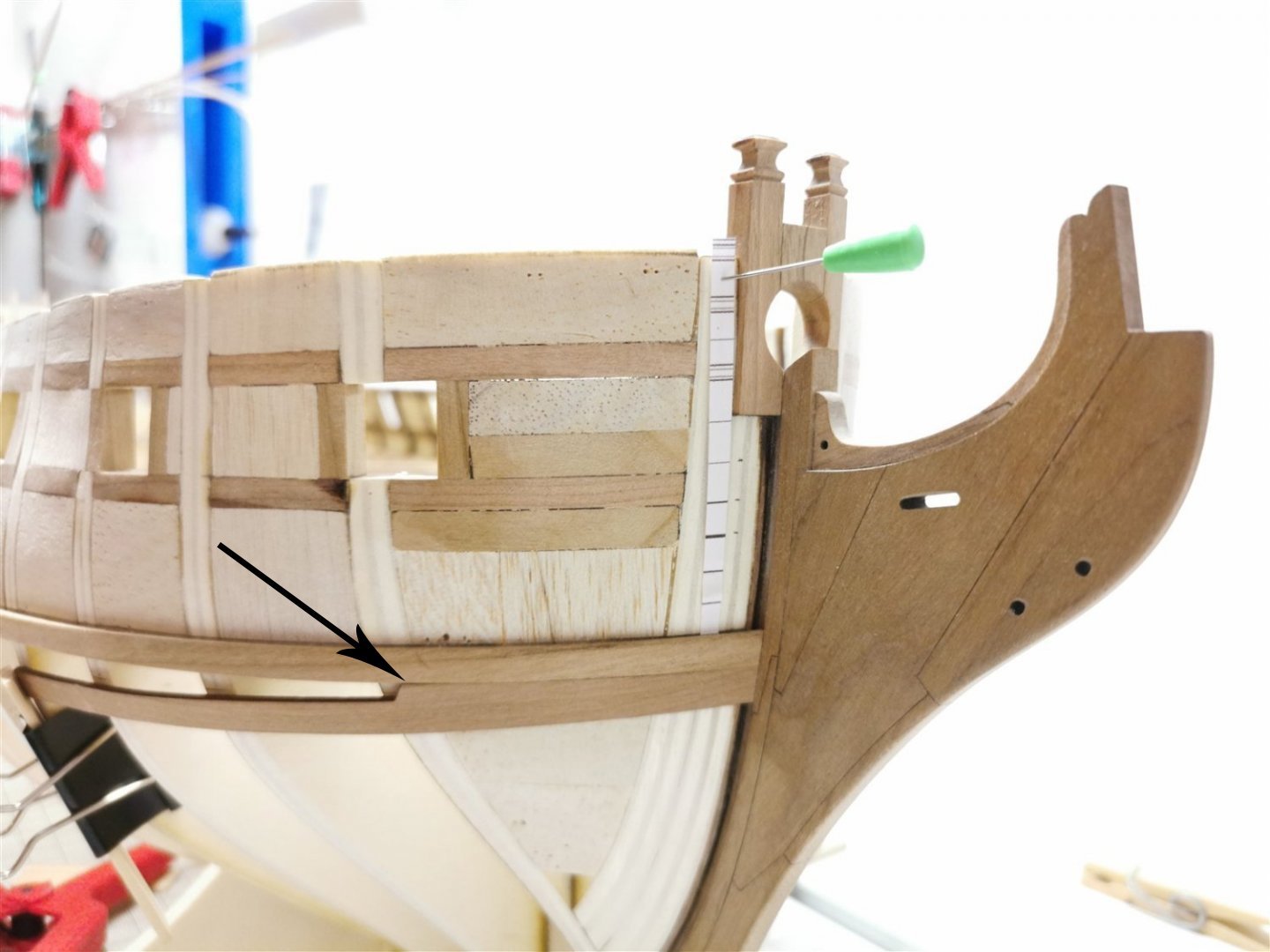

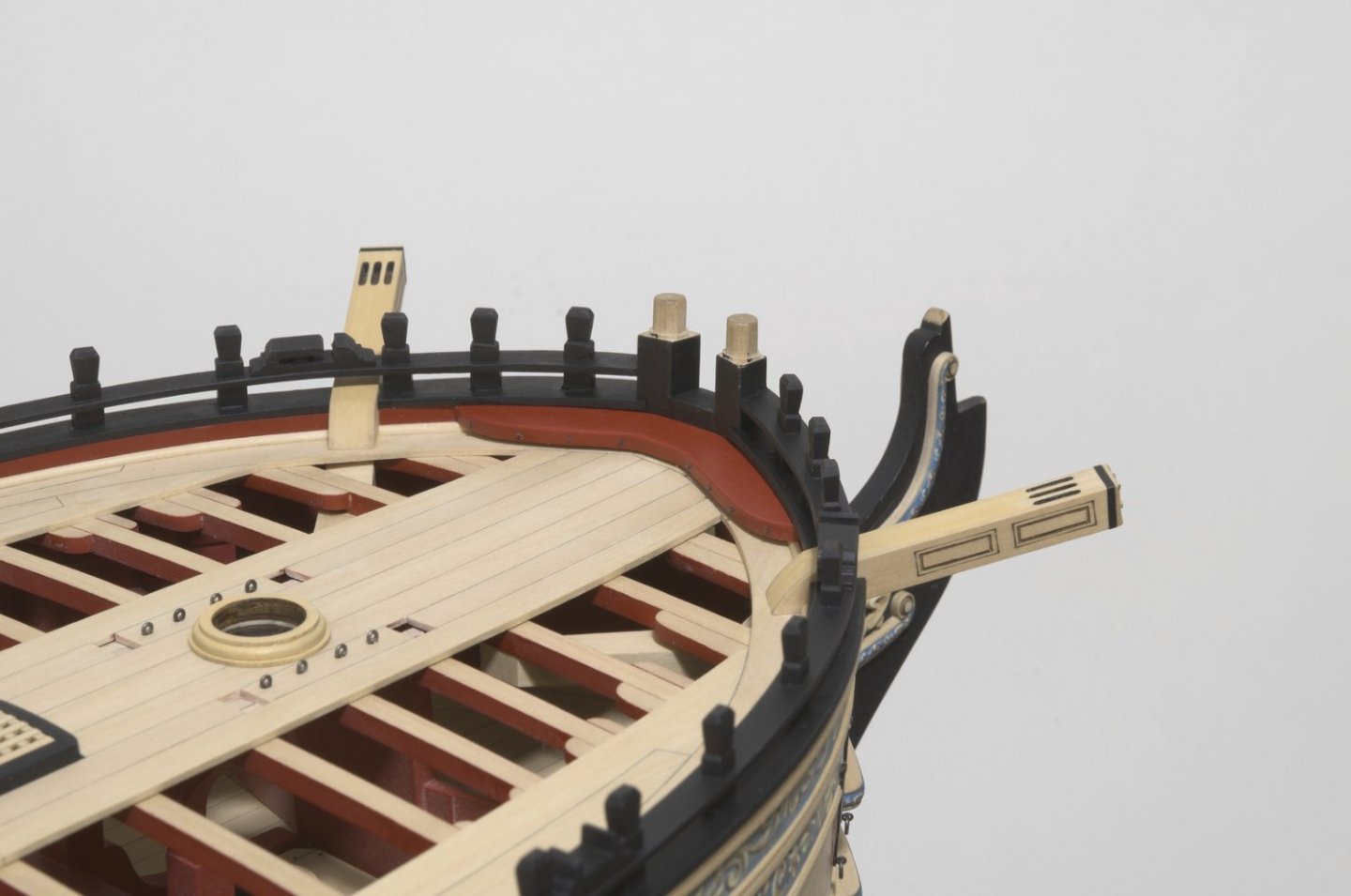

A left over beam was used simulate the actual positioning of the belfry rail as seen on the ship. This makes it easy to see if the timberheads are at the correct angle to the deck. Tweaks where needed.

I backed the jig with another strip in order to add the "L" shaped piece. This keeps it inline with the timberheads.

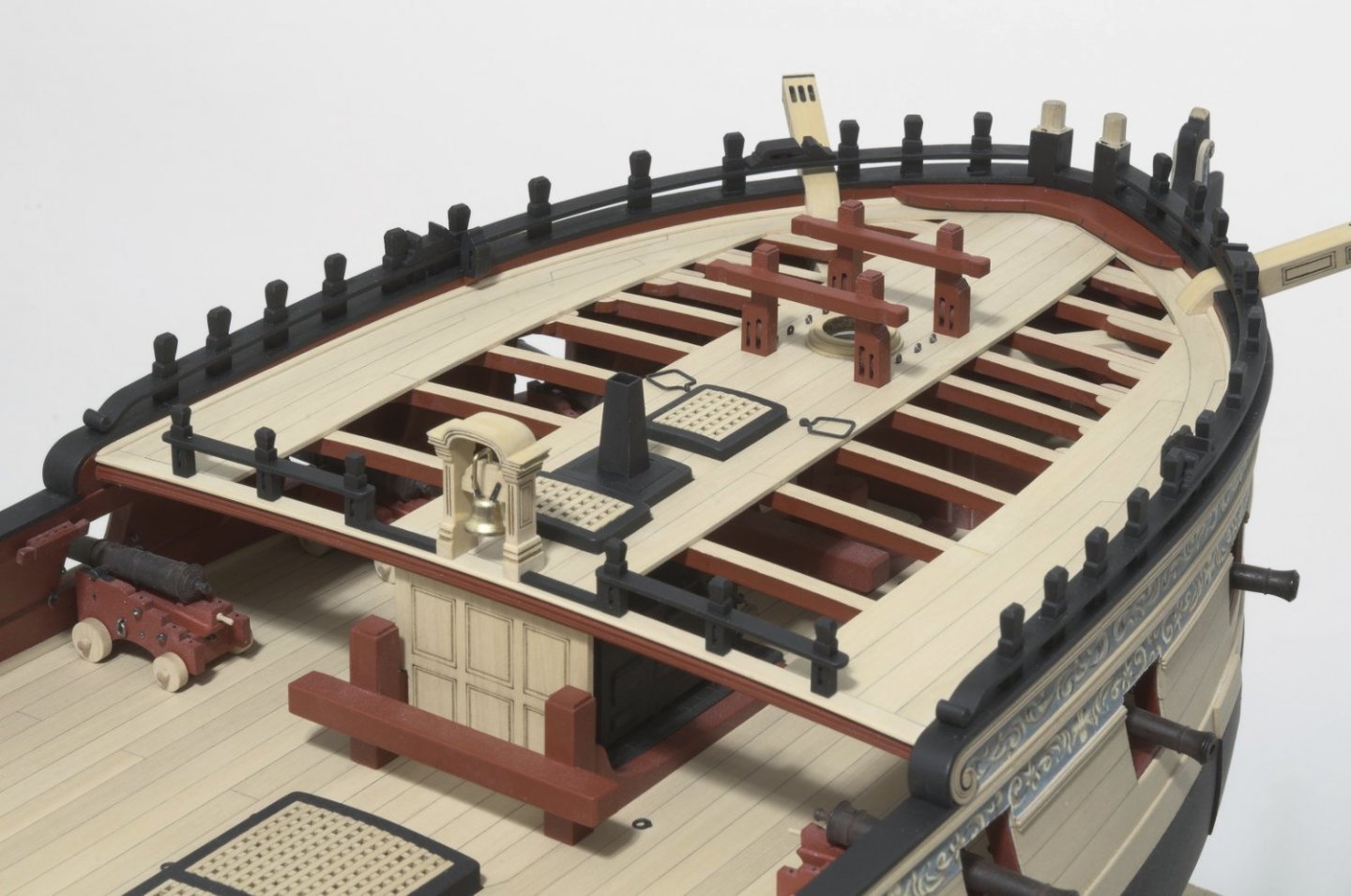

I added the cover boards for the stove stack along with other fittings to complete chapter nine.

Mike

-

That looks really nice. Sounds like you had fun making it too. It's amazing how Chuck was able to make all of the parts fit together so well.

Mike

- FrankWouts and Rustyj

-

2

2

-

I second all of the comments above! Take your time and you will be rewarded.

Mike

-

Thanks guys, much appreciated!

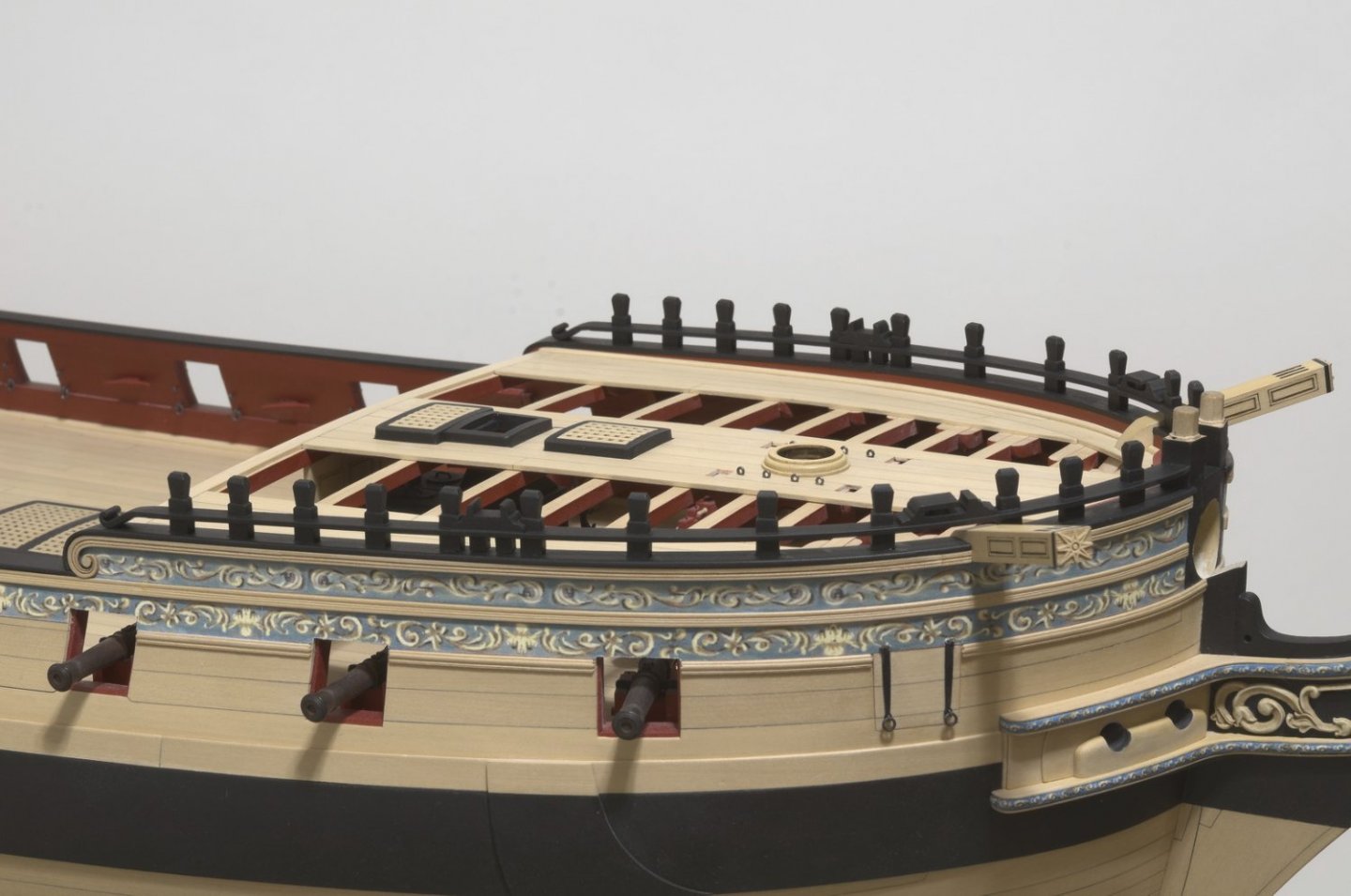

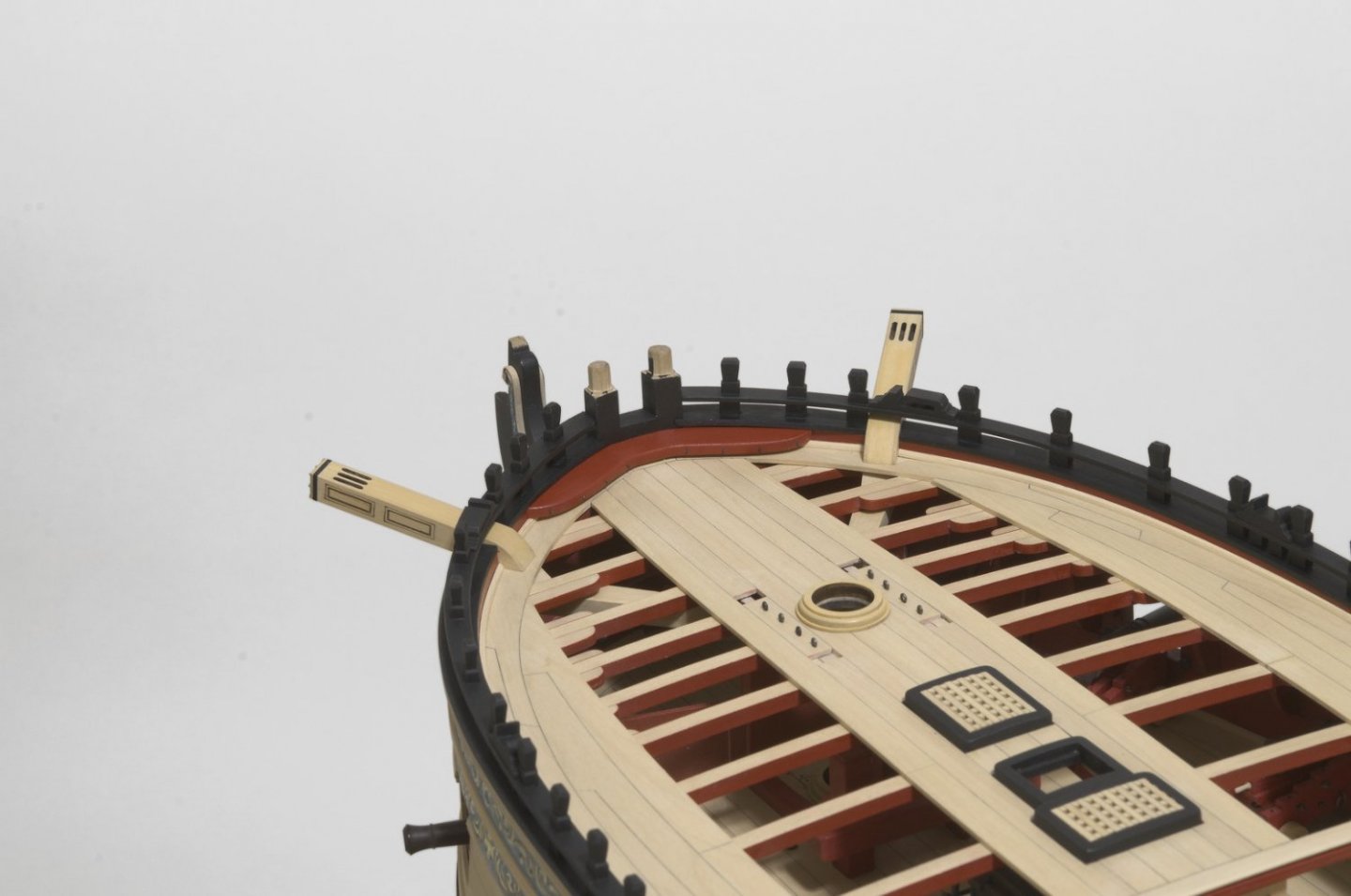

I've finally managed to get some more of the forecastle work completed. Only a few fittings left to do.

At the aft end of the Fcastle rail there is a short piece which is added on. I decided to strengthen the joint by adding a strip between the two pieces. Final sanding was completed after the glue dried overnight.

The rail was assembled and painted before installation. Due to some of the timberheads fitting snug into the cap rail below, I left the bottom of each one unpainted. I raised the rail slightly in this photo to show that.

Any bare wood showing after gluing was easily touched up.

The catheads were easy enough to make. I picked the ones that seemed to have the most consistent laser cut sheaves. I did my best to align the catheads with the short extension below deck. The breast beam had to be scratch built. It was done in such a way as to insure that it ran below the level of the cap rail its entire length.

Mike

-

Nice work, Frank!

Tip: As you move further down the hull you can bevel the front of each plank. This will allow you to get a tight fit against the stem rabbit, with no gaps showing. Hope that makes sense.

Mike

-

It looks good to my eye. Just keep a close eye on those butt joints.

- Saburo, Captain Poison, FrankWouts and 4 others

-

7

7

-

-

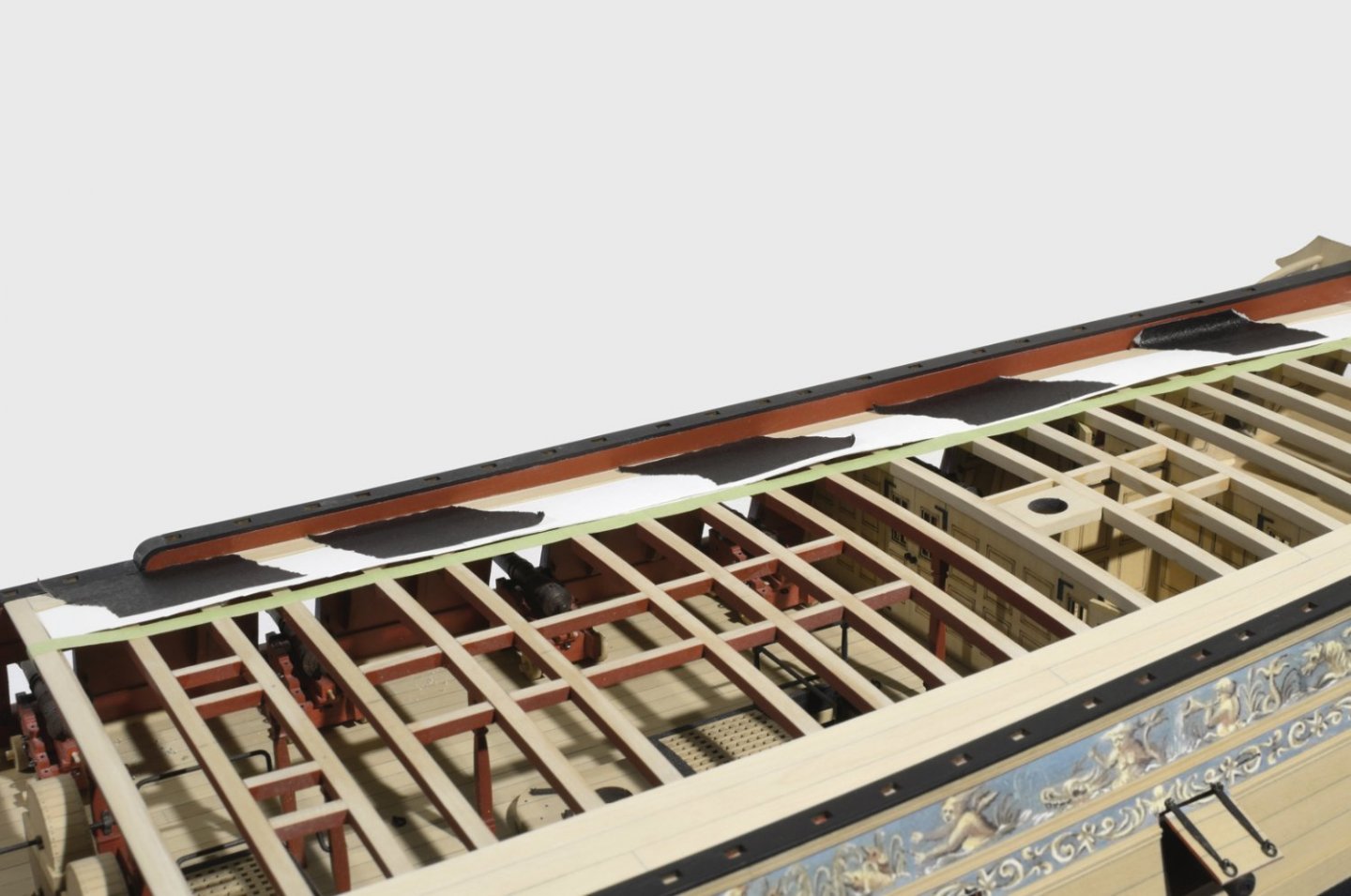

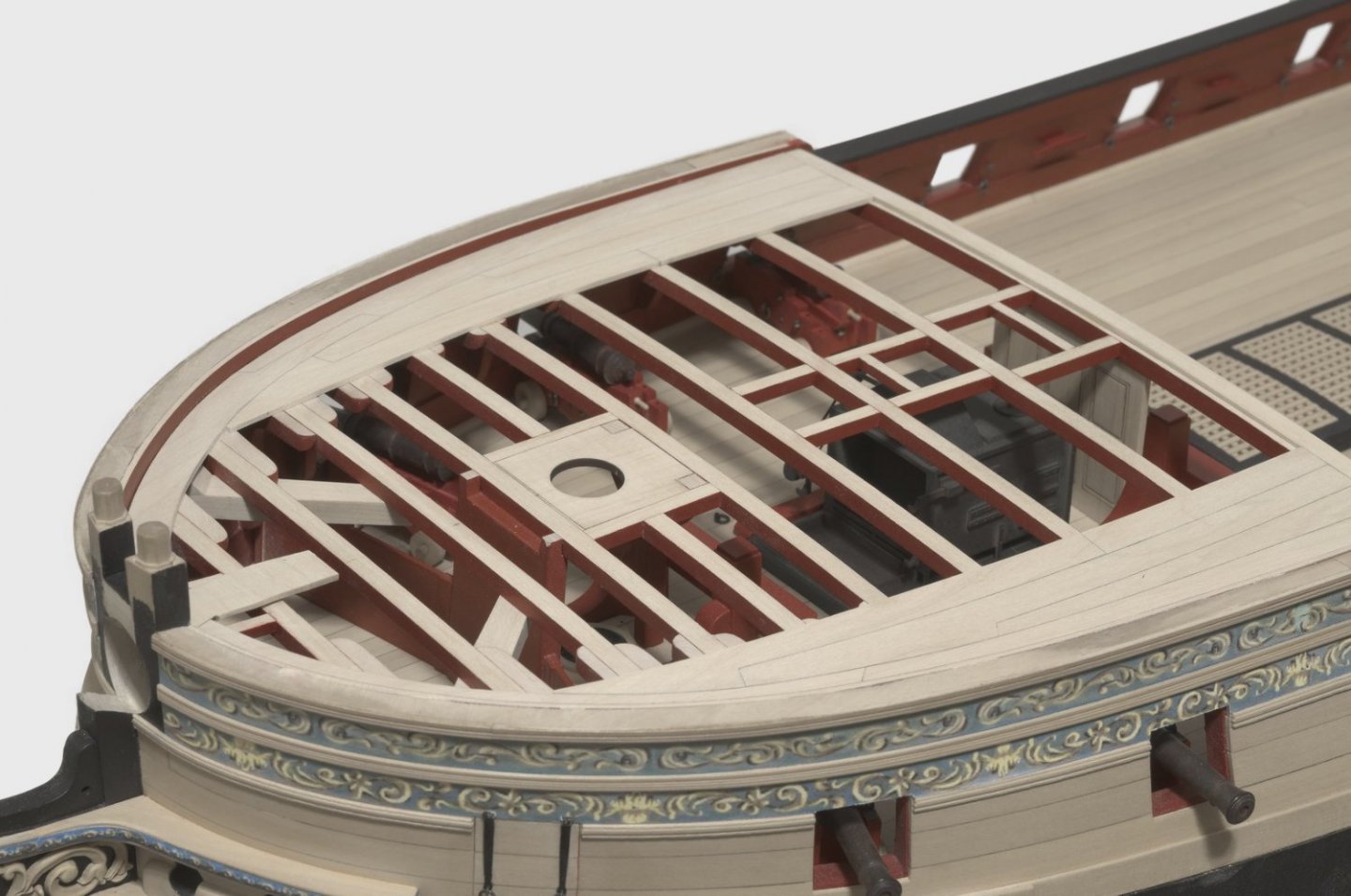

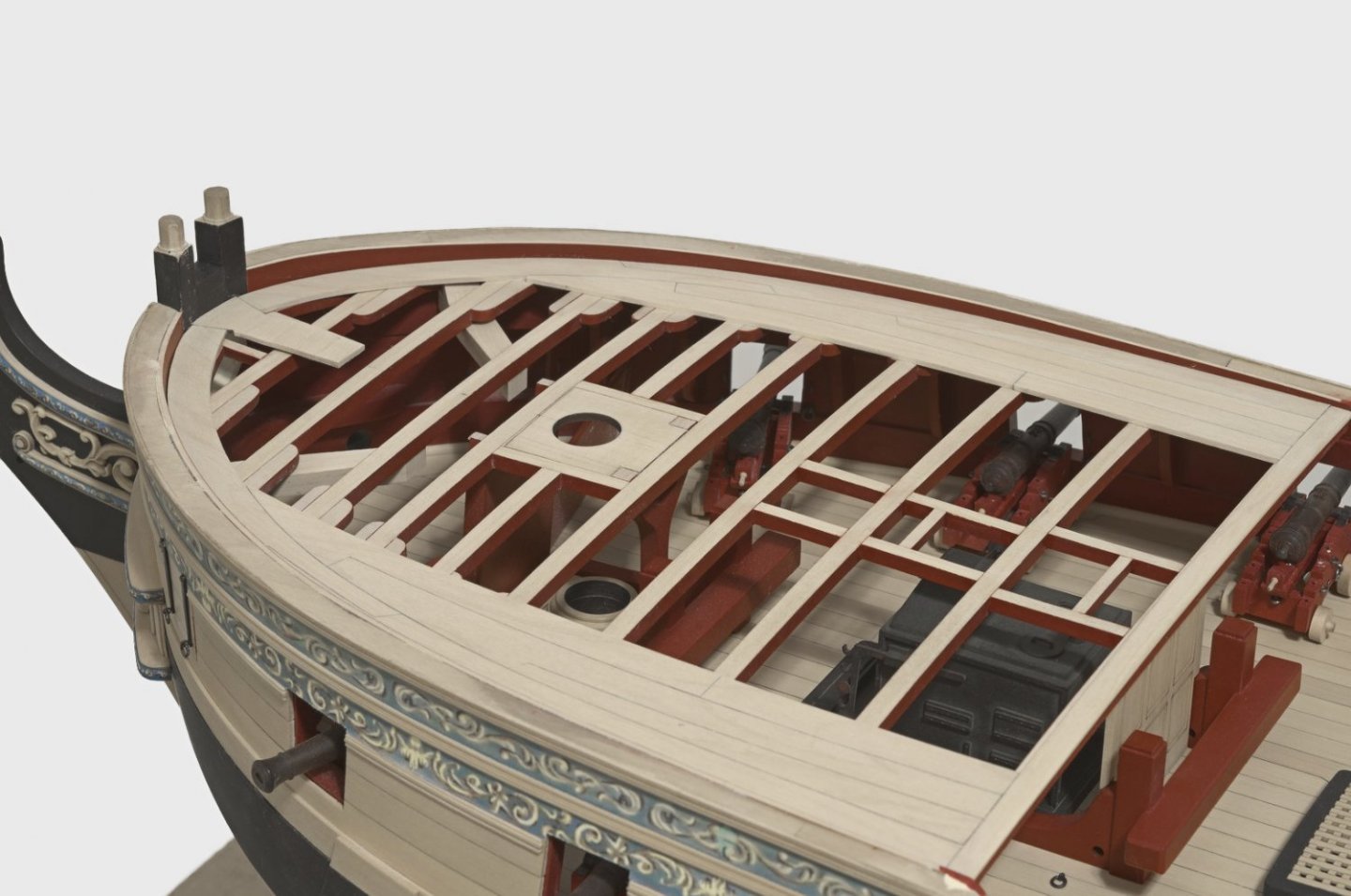

QD planking: I thought that it might be a good idea to mention an issue that I ran into recently. Using the provided template, I tried to shape each plank using a trace and sand method. After adding all three planks I noticed that the innermost plank ended up with a slight "S" curve. This meant that one or more of the planks where not shaped correctly. I suppose I could have left things as they were since the 4 guns that would be on the deck would mask most of it. Well, who was I kidding!

Although stressful to think about, I pulled all the planks off the deck including the margin plank. The margin was never glued to the bulwarks, so no damage was done to the red paint. I had to pull it since it was coated with glue and pencil marks. Trying to clean it only ended up softening the crisp edge and that would never do. So, I replaced the margin plank.

I cut away the margin plank from the planking template and placed the three plank template against the margin plank. To my surprise the template conformed nicely to the shape of the margin plank. I ran masking tape along the template edge. Lastly, I used tick marks between the tape and margin plank to get the run of the three planks.

I was determined to keep things as neat as possible. There is no trace of the original planking work. I think that the extra work was worth the effort and thankfully everything looks good now, I think! 😁

Mike

- Trussben, JpR62, CaptMorgan and 19 others

-

22

22

-

On 1/7/2022 at 1:32 PM, westwood said:

So I checked the bow shape.

More sanding was needed, so far the right side is doneBoy, I wish that I had that cap rail template when I was fairing my hull. You are avoiding what could potentially be a huge headache.

Mike

- FrankWouts, glbarlow, Saburo and 2 others

-

5

5

-

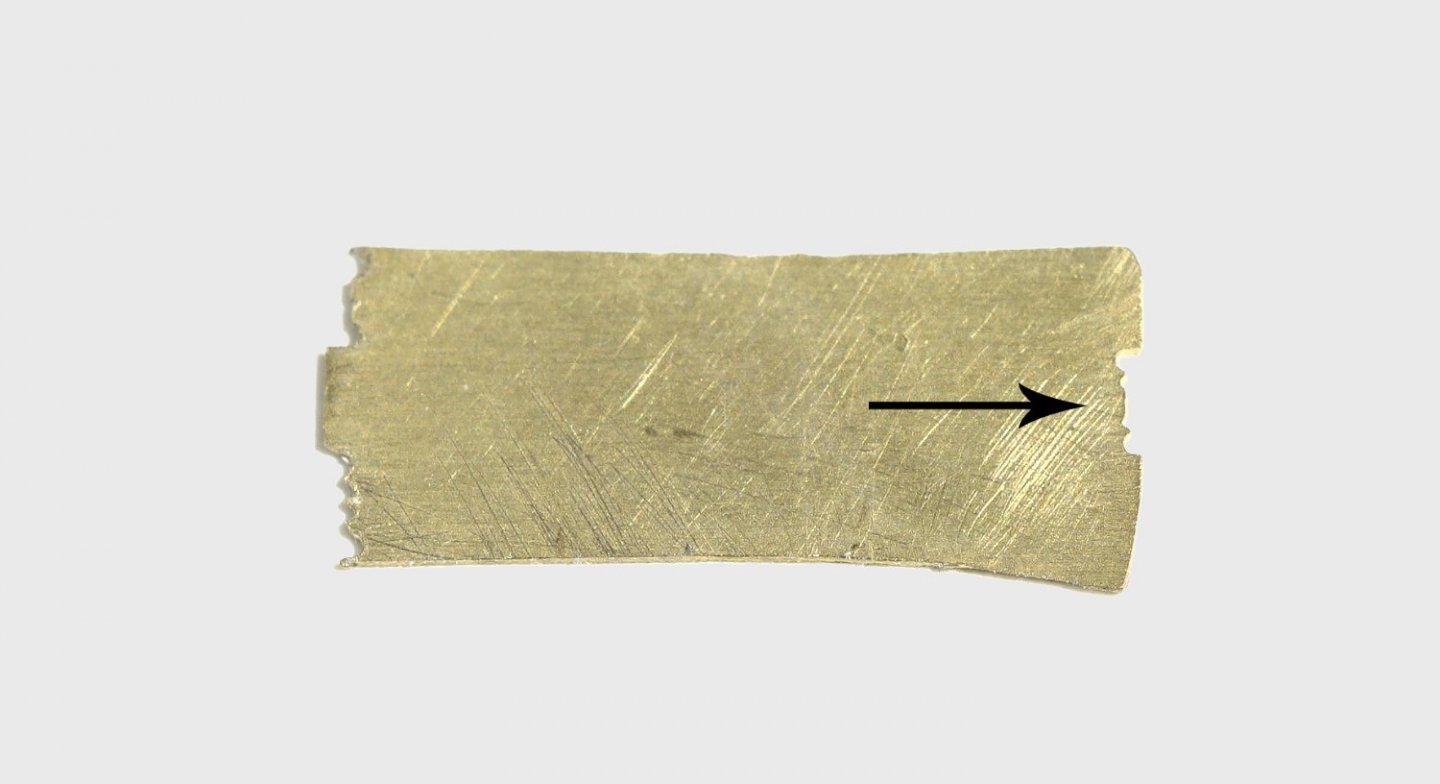

The black strake should clean up the top edge of the wales nicely. As Jim suggested, I painted the bottom edge of the wales off the ship.

The entire wale should be gradually tapered. The bottom edge was tapered to about 1/32”. The top edge thinned as well, so that it doesn't stand too proud of the black strake.

Anyway, that’s the way I did mine.

Mike

-

-

Looking really Nice!

Mike

-

Thank you all for the kind words and for all the “Likes”.

Glenn, I used more than one scraper. Can you be more specific as to which molding you are referring to?

Happy New Year! Mike

- glbarlow, Jorge Diaz O, FrankWouts and 1 other

-

4

4

-

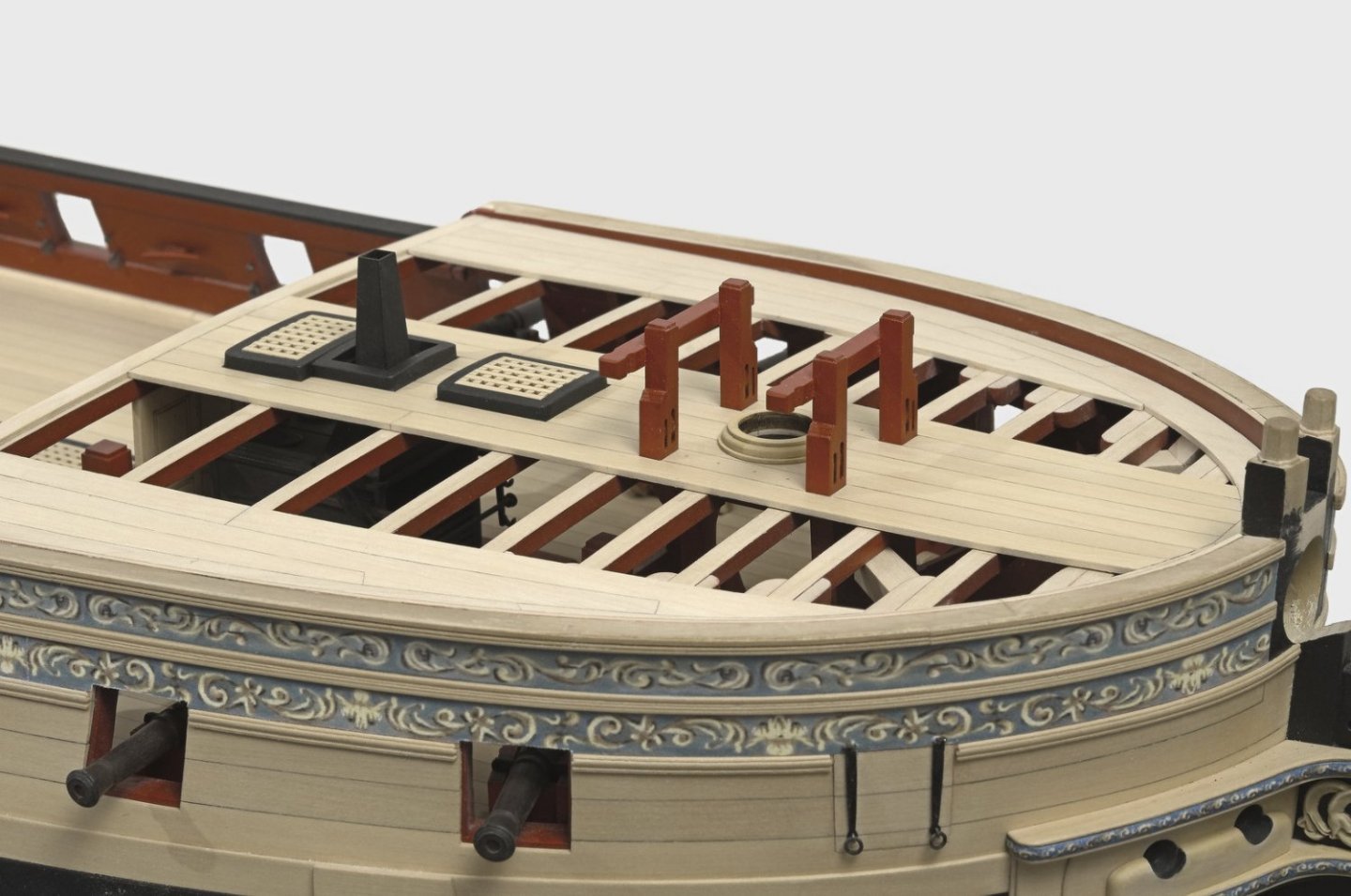

I'm feeling good about finally completing the forecastle planking. It probably doesn't seem like it, but work in the center area can be tricky. Getting those planks that sit snug around the deck fittings required some forethought and constant tweaking. The bitts and stove stack are not glued in. Next I will do the waterway, W-O-P the outer deck area and then the cap rail.

Mike

- FrankWouts, KenW, Gahm and 19 others

-

22

22

-

Beautifully done, Chuck. It’s all coming together so nicely. I can’t wait to get there.

Mike

- dvm27, Jorge Diaz O and FrankWouts

-

3

3

-

On 12/25/2021 at 7:30 AM, FrankWouts said:

Would someone please be so kind to measure the width of the lowest two counter planks for me on their model please?

Since you have already started to plank the lower counter there is a good chance that your width so far is different than anyone else’s. I would suggest that you refer to Chucks log to see how far down you should go with the planking and just use whatever widths would be necessary in order to achieve that.

Mike

- FrankWouts and Jorge Diaz O

-

2

2

-

On 12/25/2021 at 7:30 AM, FrankWouts said:

The oversanded area on the two side parts ST-C will be filled with scrap planks and chiseled and sanded in the correct shape this time, as I’m not a fan of fillers on this beautiful model.

Happy holidays, Frank!

I suppose it doesn’t matter but I’m just wondering why you didn’t correct the over sanded area on the two stern frames before adding the lower counter planking? That way the lower counter planking would cover the edge of those filler planks that you want to add.

Mike

- Jorge Diaz O and FrankWouts

-

2

2

-

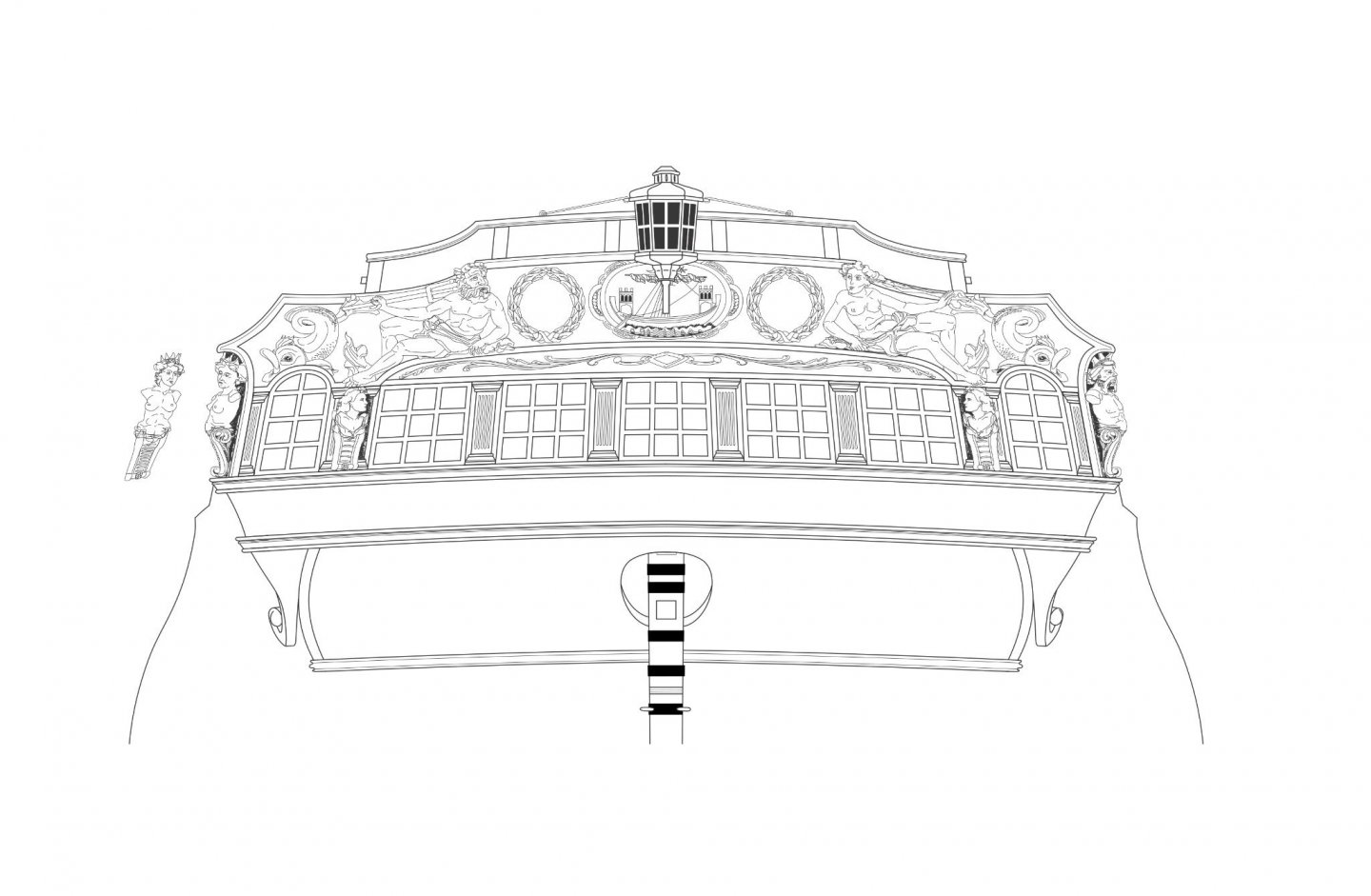

On 12/23/2021 at 5:20 PM, Chuck said:

You can also choose not to add this railing at all. Many contemporary models including the one for Winchelsea dont show such a rail. But I think it adds a nice detail.

I think it looks great! I really like the shape work on the uprights.

Mike

-

Frank,

If you take the time to fix it now it will save you a few potential headaches down the road. As Ben mentioned, the frieze will fit better. Also, it will be much easier to get the drop that sits below the Quarter Galleries to fit against the hull.

Mike

- Trussben and FrankWouts

-

2

2

-

- FrankWouts and Trussben

-

2

2

-

Work continues on chapter nine with some of the forecastle planking completed. W-O-P has not been applied which makes it harder to see the butt joints. Hopefully you will see enough to get the idea. That center piece behind the bollards was made that way which makes it easier to hold. The grain runs port and starboard. This makes it easier to slice off that long tab after the glue dries.

Mike

-

Ben, I agree with you. 1:48 is the way to go.

Mike

-

I'm in on the POF build as soon as the Winnie is completed. I would probably go with boxwood. Don't want to burn up the laser which means I would have to scratch the framing. I'm looking forward to that. Exciting stuff ahead!

Mike

- VTHokiEE and FrankWouts

-

2

2

-

Just my older Nikon D5100 with a 60mm f/2.8 macro lens. A tripod of course.

Mike

- FrankWouts, WalrusGuy, glbarlow and 1 other

-

4

4

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

in Member Build logs for the HMS Winchelsea

Posted

Thanks, Chuck! Weather permitting I could bring it to the February meeting.