-

Posts

1,477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by vossiewulf

-

Yeah, that's why I haven't gotten one either. I don't want an extrusion machine as I think they're inherently limited in the scale of detail and quality of surface finish. But when you look at stereolithography machines, well if you're willing to spend $5k-$8k you can get an excellent reliable machine, but that's extremely expensive. And all of them under that price range seem to come with some gotcha or other and seem to need constant maintenance and adjustment to get what you want. In short, not really baked for hobbyist/prosumer use. And unfortunately I've seen little progress in the last couple years.

-

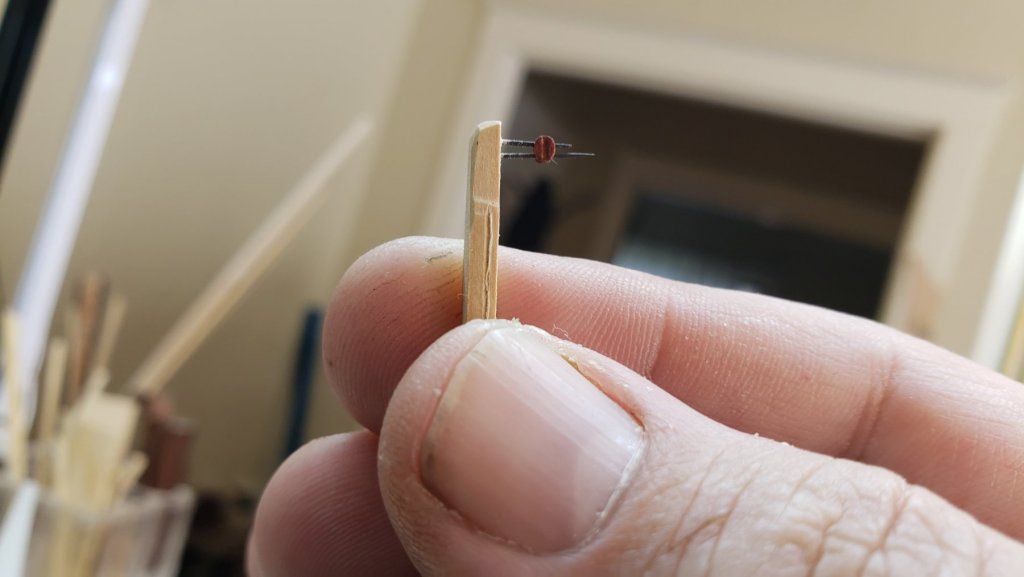

I got some 32 gauge copper wire and managed to make an eye hook roughly half the size of the previous ones, but it's still not good enough, as below. There just seems to be not enough room here, if I had known this I would have positioned the ringbolts for the train tackle inward at least one plank width. But at the same time I also have to wonder whether they really used train tackles for 3 pounders, they seem small enough that handspikes and muscle were enough. So I'm gluing in the guns finally and working on the anchors, and have made buoys. If I'm doing buoys I suppose I should put them well up in the shrouds as Chuck does for Cheerful, he says that's what they did. But it looks pretty odd, I have no idea why they would have done that other than maybe the goal was to throw the buoy as far as possible and the elevation of being up on the shrouds helped. Also I guess a line has to run from the buoy coil all the way to the anchors, will have to see how to do that. And I don't see a spot to belay the anchor-fishing line that comes from the blocks on the cathead, so I'll have to add a cleat on the cathead, or belay them to the timberheads next to the catheads, but that is where I was intending to put the stopper lines. I wish I know more about what I am doing. And I need to get back to mounting the rudder, all the parts are done. I just have been avoiding it because it will be tricky to get right and I haven't thought of a good clamping/jig arrangement to make it easier.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

I don't see how you could make common parts across different ships unless it's deck/hull fittings and yards/masts and even then you'd have to offer a series of say 32/38 gun RN frigates from the 1780s for it to make sense. What I hope for in the long run is Chris and Chuck or people like them have reasonable cost access to excellent laser and zillion axis CNC milling machines and highly accurate stereolithography 3d printers. With a (reasonably significant) amount of CAD work, you could offer multiple decorations and figureheads for ships in a class, or offer POB and POF versions of the same model. Line and some fittings and strip wood is stocked, the rest of the parts are produced when an order comes in and the person has chosen this particular ship's decorations and the POF version and selected any other options like wood or quality of fittings. That way they wouldn't have to maintain large part inventories, and the flexibility for the customer leads to more orders. But since none of us are actually doing it for a living, we just have to see whether any of it makes sense to Chris and Chuck, who are the people putting out money to produce kits.

-

Custom photo etch is not insanely expensive, I've had the linked company make me things a few times. There are others.

-

Greetings from Columbus, Indiana

vossiewulf replied to Sluicemaster's topic in New member Introductions

-

They will probably have to add new categories to the spark test for powdered metals. They are not real alloys in the sense that the component metals were never mixed while fully melted, so they can be made up of metal ratios that would never be used in traditional alloying, and that's going to lead to odd spark test results. In the case of PM-V11, it has a much more vanadium than is ever used in normal alloys, somehow that is yielding a spark test result that is similar to HSS. Also now that you are going to be fully in the knife sharpening business, I suggest you look at Shapton Glass Stones. I have a large drawer overflowing with all types of sharpening stones- water stones, ceramics, diamond, if someone has made it I've tried it. The best by far in terms of both metal removal rate and stone flatness is the Shapton Glass. Water stones work very well, but they are 1) very messy and 2) very soft, they have to be constantly flattened to avoid a curved stone surface that will never sharpen a perfectly flat bevel. I've been using my Shapton Glass stones for 6 or 7 years now and have yet to have to flatten them. They also remove metal faster than anything I've tried, including water stones. I use 1000/4000/8000 and finish with a strop, and I have a 220 grit stone for reshaping bevels.

-

Very nice Gaetan, it looks great, and that's a nice handle wood too. The square point is a little unusual, but if it doesn't interfere with your cuts it certainly adds more strength overall. That's interesting about the sparks, the spark stream is a standard metal composition test that is usually pretty accurate. Are the sparks less than those when you are grinding HSS?

-

Glad you had fun reading it. As far as I know Mikhail doesn't have a web site, he doesn't really need to advertise- word of mouth keeps him fully busy. He only has a few options anyway, mostly having to do with the number of tools and the handle type, he does palm or pen handle. Send me a PM and I'll dig up his email address if you don't have it. as far as I can see, what is correct is the block having a seized eye to which the eye hook is attached. If someone can show me an alternative arrangement being used I'd be happy to do that. Thanks It looks like Tony has provided some good drawings and pics, hopefully those will resolve the confusion for me. Thanks Tony, very helpful

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

I made up one set of blocks and hooks, and although the hooks are as small as I can make them without going to more extreme measures (as you will see I already filed down one tip of round-nose pliers as far as I could), I'm not going to be able to fit these tackles as there just isn't enough room- even with the guns run out, the blocks would be butting up against each other. I'll look and see if anyone has photoetched eye hooks that are small enough and maybe grab some 32 gauge wire and figure out if I can make them smaller, but otherwise this was good practice for the rigging since nothing I need to do there will be as small and fiddly as this was.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

It doesn't matter how many parts there are, assembling or mounting or whatever for each one of those parts is relatively straightforward. In this case the only parts that matter to you now are the bulkheads and the keel plate. They fit together with slots. Your first task is to assemble those bulkheads onto the keel plate and glue them so they are square to the keel plate. Worry about the next set of parts after you get that done.

-

MONTAÑES by Amalio

vossiewulf replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

Perfect seems inadequate, I'm going with "uber spiffy perfectomundo". -

Thanks Rick, yes oodles V2 using my new hyper-advanced 2mm block-stropping jig, which consists of two pieces of carbon fiber rod thinned down to .007" and stuck into a piece of basswood. Actually I guess it's semi-advanced because I know of no material other than CF that could do this, only CF has the rigidity and strength, next closest being music wire. But you'd have to have .007" on hand and it would be much more bendy. Trust me you want to have some CF rod in different sizes someplace on your workbench! Anyway, V2 looks better but still with too much glue. V3 and onward should be usable.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Model Ship Building Stands And Vices

vossiewulf replied to LEGION 12's topic in Modeling tools and Workshop Equipment

They are hard to find at a reasonable cost (they keep getting more expensive for some reason), and only work for small to medium-sized ships, but given those caveats an engraver's block (correct term) or ball vise (slang term) is really excellent for building. You can basically fix the ship in any position or twirl it around in your hand as called for. -

Thanks Rick. My question is more about how they lashed the anchor up to stow it rather than the knot on the anchor; as that thread shows, there seem to have been only three or four options for knots, largely based on the size of the anchor. I really don't know much about how lashings were done other than lots of winds around, and was the double block that runs to the cathead there all the time, or just when they were fishing the anchor? I have some drawings of stowed anchors, but they're big bowyer anchors on ships of the line and I imagine the practice in cutters was somewhat different. The evil @Chuck sent me very nice 2mm blocks, they have the same quality as the larger blocks. I can see how they're made, but I'm not sure how they're made without turning Chuck into a gibbering lunatic. I strung them on .008 line to prevent losing them one by one, this way I can lose them all in one shot Anyway, he's forced me into serving .008" line and stropping 2mm blocks because they're the perfect size for a 3 pounder gun tackle. My first effort below was marginal, need to figure out better ways to do a couple steps. This may take a while

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Thanks Rick, with all the books on rigging I thought it wouldn't be hard to find, but it seems there isn't much coverage of anchors for smaller ships.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Can anyone tell me where to find good drawings/pics of how to rig an anchor on a cutter? What little I can find on anchor rigging mostly focuses on the individual knots and if a stowed anchor is shown, it's for a big ship where the anchors were lashed to the fore channels. The best I can find is one of Tony's contemporary model pics, but I'm unclear about the double block on the cathead and it doesn't show how the buoy would have been stowed. It also have a very odd-looking knot on the anchor cable, not being an anchor clinch or anchor bend that are supposed to be used.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Yeah when I bought mine about 12 years ago I had to do some serious internal rationalization to be willing to pay $350 for it. Now they're above $600 for no apparent reason and out of the range of anyone but professional jewelers. They're hardly complex devices, they have a vise plus to the two halves are joined by a big ball bearing, and then the bottom is filled with lead, so the Chinese shouldn't have a hard time making a decent one- if I didn't have one that is what I would do, look for one at $200 or so on EBay from China. Thanks Sam, ok I will give it a try, I have waxed thread in my fly tying stuff too.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.