-

Posts

695 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RichardG

-

Miter boxes----What is the best one.

RichardG replied to roach101761's topic in Modeling tools and Workshop Equipment

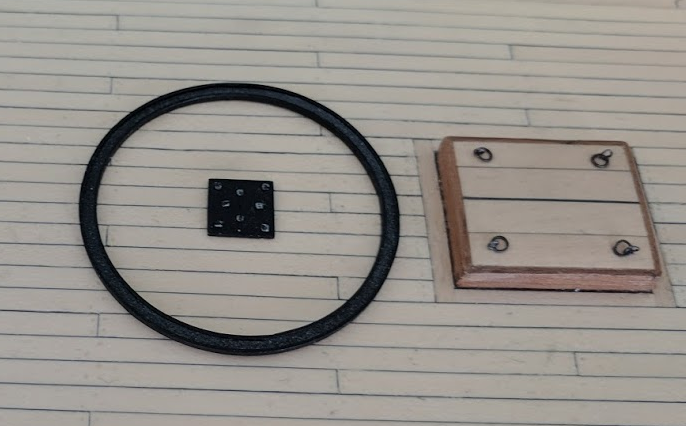

This is mine. A couple of strips of double-sided tape holds it down (you can see the extra cuts before I thought of that!). It protects the teeth of the saw as well. You do lose the various grooves but I never found those to be of much use, finger pressure to hold the wood in place is enough. Richard. -

Miter boxes----What is the best one.

RichardG replied to roach101761's topic in Modeling tools and Workshop Equipment

I use the Zona 37-240 Aluminum Thin Slot Miter Box. I like that the slots are thin so you don't get the play that I found with the X-Acto version. I stick a 1/4 thick piece of wood to the bottom with double-sided tape to avoid sawing into the metal. The miter box from UMM that Kurt mentions is on my "to buy" list. Richard. -

Wonderful!! It's always a treat to see your work. Richard.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Thank you Steve. The model will have compromises because of the lack of information and limitations in my skills. But something that I knew was wrong and was easy to fix - it would have constantly bugged me. Fortunately when she's complete (sometime in the next decade or so!), all of my mistakes and retries will be forgotten. Richard.

- 78 replies

-

- dallas

- artesania latina

-

(and 1 more)

Tagged with:

-

Making it worse so I can make it better! She's no longer the "Dallas" The primer is preparation for coppering. Richard.

- 78 replies

-

- dallas

- artesania latina

-

(and 1 more)

Tagged with:

-

Fusion 360

RichardG replied to Williamo's topic in CAD and 3D Modelling/Drafting Plans with Software

I was wondering if l should download a copy. But the thought of the time it will take me to learn stopped me. At least for a little while -

Fusion 360

RichardG replied to Williamo's topic in CAD and 3D Modelling/Drafting Plans with Software

If you take a look here: https://knowledge.autodesk.com/support/fusion-360/troubleshooting/caas/sfdcarticles/sfdcarticles/How-to-activate-start-up-or-educational-licensing-for-Fusion-360.html Richard. -

Wow nearly 2 years since I posted on my build. I am honestly ashamed. Thank goodness this is a hobby otherwise I’d have been fired . I have not however been completely idle. I’ve been doing some work, some planning, a fair bit of procrastination, and lots of scope creep. The gun carriage is almost complete along with deck reinforcement for the pivot. I've also made a base. This is a piece of walnut from my local Rockler store. It’s nicely figured to give an impression of water flowing. It has been mounted to a ceramic tile to provide a rigid and neutral colored substrate. The biggest item I’ve been working on is preparation for coppering the hull. My original planking was not great and I was not going to remove it as I did with the deck. However it took me a long time and many tries to find a way to create a nail pattern on the plate that was reasonably accurate and within my abilities. At this point it’s looking good. I’ll be posting about this separately. Other than that I spent a lot of time worrying! Mainly about the rigging. The plan that came with the kit is obviously simplified and I now know enough that I can’t use it. However I don’t know enough to create one for myself. So more work is needed there (mostly reading). Also this is not the Dallas. I’ve known that for a while. Finally I decided to just rename my log and live with it. Richard.

- 78 replies

-

- dallas

- artesania latina

-

(and 1 more)

Tagged with:

-

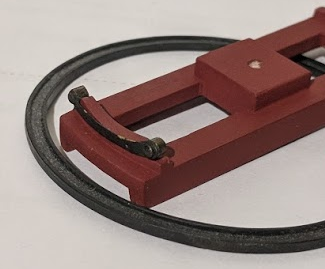

For my track on the 80-ton cutter I decided on a "u" cross-section and am using 2mm brass tube (with a toothpick filling the center) for the wheels. These are mounted on curved brackets with very small pins. The inspiration for this came from the USS Constitution As you can see the blackening of the bracket needs some work and I haven't fitted the rear bracket yet. I'm continuing to watch your builds with interest. Richard.

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

-

Model Shipway Ratline tool

RichardG replied to fnkershner's topic in Modeling tools and Workshop Equipment

Thanks so much for taking the time to review this product. Richard. -

Try the book by John Mckay in the Anatomy of the Ship series. You should be able to get a good second-hand copy for around $50. The ISBN-13 number is 9780851778945. All the best, Richard.

-

Well I definitely can't do a "Like" for this. So I'll just pass on my sincere best wishes for you to get well and that we'll see more of your Revenge soon. Richard.

- 208 replies

-

What Would It Take To Build This Interior?

RichardG replied to Julie Mo's topic in RC Kits & Scratch building

I'm not sure if any expensive tools are needed. Here's a wonderful example of a detailed interior from Doris's Royal Caroline build https://modelshipworld.com/index.php?/topic/854-royal-caroline-by-doris-card-1749-140/&do=findComment&comment=325142. (The whole build log is a treat). Richard -

Sorry to hear about the backward step. The two steps forward are really good though. It's been nice to see you back and working on this. Richard.

-

Maybe these? https://www.menards.com/main/tools-hardware/hand-tools/clamps-vises/wolfcraft-reg-micro-needle-nose-clamp/p-1444439537678.htm Richard.

-

I used a razor saw for mine with a sanding stick to finish. I also did them in pairs and slightly longer than needed so I could sand them flush after assembly. Richard

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

-

The copper tape I have does seem to be around 0.002 in. According to the USS Constitution the thickest plates would have been 28oz per sq. ft. See https://ussconstitutionmuseum.org/2015/08/12/copperbottomed/. This is then an 8lb plate. At 1/48 scale this would have been 0.00077. Well I'm working at 1/50th which is a bit better but the tape is still between 2.7 and 3.5 times too thick. Now even if I could get tape thin enough, I don't think it would be usable. Plus to be strictly accurate, I'd need 3 different thicknesses (28/26/22 oz). So basically I'm not going to worry about it . I'm not sure what to do about an overlap though. Yes, it's out of scale but to the naked eye it didn't really look that way (at least to me) when I stuck a couple of sample pieces to a plank. I will not be able to get a 100% accurate 1in overlap but if I don't overlap, can I avoid a small gap between each strip? Since I'm using strips there will be no overlap at the vertical joints (this will need to be an indent from the jig). So I'll have to experiment. I'm currently work on a nailing jig. Once that's done (and if it works), I'll create some test strips and see if I can actually apply them. I have to say, nothing in this hobby is simple. One thing that did surprise me was how thin these plates are in real life - less than a millimeter. Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.