-

Posts

2,848 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by kurtvd19

-

-

I used Blacken It - started using it many years ago. Used the Birchwood Casey (BC) blackener as a trial after Blacken it disappeared and liked it so much more for brass & copper I never missed Blacken It except for ferrous metals. There are good blackeners for ferrous metals but I don't use much of them as it's easier to machine brass and then used the BC stuff.

- allanyed, Canute, Ryland Craze and 1 other

-

4

4

-

-

Great video Kevin - nicely moderated.

Kurt

- mtaylor, Kevin Kenny and Chuck Seiler

-

2

2

-

1

1

-

Bill:

There is no CD provided. The 10 sheets of 24" x 36" plans are mailed rolled to the purchaser - not folded. The monograph, lumber list and flag are PDF files that are downloaded from our store - you can download this information at any time - check it out if you are deciding if its a project for you. The monograph is meant to be printed out by the purchaser as needed. Many download and print all the pages at one time and put them in a binder. Others print the pages out as needed.

Whatever you choose to do I highly recommend you read and understand all 64 pages of the monograph BEFORE you start the construction. I also recommend that you save the monograph on your hard drive for ease of use.

Take care,

Kurt

-

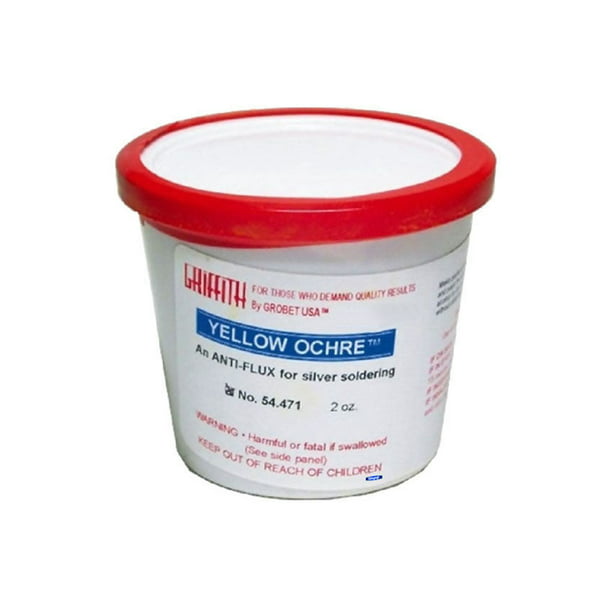

An easy way to not have visible solder at joints is to use Yellow Ochre as an anti-flux "painted" on the parts where the solder is not wanted. Yellow Ochre repells the flux and solder will not stick w/o flux. To use add alcohol to yellow ochre powder to make a paste apply with a small paint brush where you do not want solder to flow - let dry in place or burn off the alcohol with a torch. Flux the joint and solder normally.

Use a small resealable container to mix and store the wet paste. The paste can be adjusted to your preference for its fluidity so it can be applied easily just to the area you want it to stick and coat the pieces being worked with. Dried flux can be reactivated in the container by adding alcohol. I use an old modeling size paint brush or a micro-brush to apply the paste, some use tooth picks or other applicators.

I suggest one practice a bit to find your preference for the consistency of the paste and how to apply it so it is effective in controlling the flow of flux around the joint.

Yellow ochre powder is available at jewelers supply stores for about $12.00 for 2 oz. a life time supply - or split it with somebody. Tix Anti-Flux is a premixed product available at hobby suppliers. It's about $8.95 per ounce.

Kurt

- FriedClams, FlyingFish, Canute and 6 others

-

8

8

-

1

1

-

2 hours ago, Bob Cleek said:

Better yet, buy the second set pictured below which has tubes of ten bits each of the same size ranges in a nice case.

The bits in the wooden box hold up and are a good deal. However check the sizes as I found some were mislabeled as to size. Take the time to be sure the right size is in eaach tube and that all 10 match. Then when you need them you can be sure that you are using the right size - this is the voice of experience speaking...

Kurt

-

Clovehitch:

I see this is your 19th post so you are sort of new here. Please do a search about lathes - this topic has been covered many times. Once you have looked at the various replies about lathes feel free to ask any questions you may still have.

Take care,

Kurt

- NavyShooter, tlevine, mtaylor and 2 others

-

5

5

-

-

I suggest that you check the diameter of the column and see what a piece of longer stock costs from a supply house near you. That's what a good friend of mine did. The excess height is not an issue when doing individual parts and it can allow one to raise the chuck a long way from the base. It wasn't much to purchase.

Kurt

-

Harry:

I one buys a brand name there isn't a need to find a source of parts.

Kurt

- Canute, thibaultron, Ryland Craze and 3 others

-

6

6

-

Joe:

I have a bunch - all Badger. My 360 is my #1 gun. I use several others regularly but the little old 350 is my hull painting brush.

Take care,

Kurt

- Ryland Craze, rshousha, Canute and 2 others

-

5

5

-

-

That's it. Thanks I think this is much clearer.

- Canute, Cathead, Keith Black and 2 others

-

5

5

-

The data below is from a report by the Maritime Administration of the US Dept. of Transportation titled "Environmental Advantages of Inland Barge Transportation".

As staggering as the fuel costs are, barges are the least expensive method of transportation. I can't locate the pictorial chart the IL DOT uses to show the amount of the average barge loads of a common tow vs how many RR cars and semi-truck loads. One barge can carry 1,500 Tons, while a single Railroad Hopper car can carry 100 Tons and a single Semi trailer can carry 25 Tons. Or the average 1,500-ton barge carries the equivalent of fifteen 100 ton Rail cars or sixty 25 ton semi trucks.

Or the average load of a 15 barge tow has a capacity of 22,500 tons and will stretch for 1/4 of a mile.

To match this capacity takes 225 rail cars = to 2 3/4 miles or 900 Twenty-five ton semis stretching 36 miles - assuming 150 feet between trucks. The fuel used to move a ton of product is 59 miles by truck, 202 miles by rail car and 514 miles by barge.

Comparison on a ton-mile per gallon basis shows that a semi-trailer on the hwy carries a bit less than 300 pounds per HP. A 175 car trainload of iron ore carries about 4,500 pounds per HP. A 3,600 HP towboat propels some 30,000 tons of cargo which is = to 10,700 pound per HP.

Of course water of suitable depth must be usable from point A to B to use these comparisons.

-

I use Badger's STYNYLREZ primers before the finish paint but often just use the STYNYLREZ as both primer and finish coat. These primers come in 18 colors.

Prep of metal parts is a dip in heated Sparex (I use a small crock pot as it will not boil liquids and it is IMPORTANT to not boil Sparex) for several minutes with a thorough rinse of plain water and then I air dry the parts without touching the parts with bare hands. I use exam gloves w/o powder. When thoroughly dry I prime the parts with STYNYLREZ and let them dry thoroughly.

The STYNYLREZ name is to show it is usable on Polystyrene, nylon and resin. But it also works great on metals and wood. If thinned use distilled water. Also, Badger recommends STYNYLREZ a point .05 needle (or larger).

- thibaultron, DaveBaxt, Canute and 2 others

-

5

5

-

I am attaching a link to Badger's website. Click on it and then download their ULTIMATE AIRBRUSH 101. It is a great guide to almost everything one needs to get started in airbrushing. On Page 5 of 13 the part about how to pick an airbrush starts. This tells you the brush or brushes they recommend for doing particular jobs. There is no one best airbrush for every job, but there is one best brush for a specific job. The trick is deciding what's most important for your particular job. And there are great brushes from all of the name brands.

Badger Website CLICK HERE

-

2 hours ago, Roger Pellett said:

Note to all: I am NOT suggesting that Badger is involved in this sort of practice.

Right you are Roger. Every piece of every brush is made in the USA.

- rshousha, thibaultron, Canute and 2 others

-

5

5

-

-

On 1/27/2023 at 10:07 PM, Oldsalt1950 said:

If you are just starting out, this combo can't be beat: Airbrush Kit

Edited Friday at 10:12 PM by Oldsalt1950 (see edit history)

Oldsallt1950:

Your signature line of "I stand firmly against piracy!" is misplaced with this post as at a minimum one of the 3 brushes is pirated from Binks. The bottom black airbrush is a direct copy of the Badger 350 - who took over the design from Binks - their neighbor across the street when Binks stopped making airbrushes. I have both the original Binks "Wren" I got for Xmas and two of the 350's from Badger. I think this is the most copied airbrush on the market. And there is a reason, ass it is a very good airbrush for it's intended use.

I am willing to bet that all 3 are pirated, but I know the black one is a knockoff of the 350. I consult with Badger, so I know of what I speak. Why do I have two of the 350's? I teach airbrushing for Badger using Badger brushes. I have many Badger brushes (two were custom made for me) and they are all great. They fit my large hands perfectly with the exception of their Crescendo 175 model. I use the Badger Modelflex Marine Colors for all my models and teaching. I developed these colors for Badger a bunch of years ago. They are acrylics. I was using the Badger 360 and Modelflex paints long before I had a relationship with Badger.

http://www.badgerairbrush.com/library/175.jpgIt is too fat for me to hold comfortably which was why I sold my Paasche brush and bought my Badger 360. I know what you are asking? I thought he had big hands? I do but the fat brushes just don't fit my hand.

I love my Badgers, but they are only one make. All of the legitimate name airbrushes are great brushes - IF they fit your hand and you use the right brush for the job. In my local IPMS club that I attend there is another modeler who does essentially what I do with Badger except he goes to more trade show for Iwata. When somebody asks a general question about airbrushes we are both given equal time to answer the question unless it's specific with one brand or another. Many times all that the other will have to say is "I agree completely" because the name brands produce near identical results with comparable models.

But, please purchase name brand brushes - you will benefit in the end. And try getting somebody from the Pirates to answer questions or come to your club meeting to show the latest brushes, paints or let you spray with one.

Take care,

Kurt

-

Did you set the fence up to be perfectly parallel or did you st it so it is parallel only up to the blade? Byrnes builds in a slight taper for more clearance beyond the blade. It is something like 0.003" to 0.005" to provide relief for the expansion of the cut off. I don't remember where the taper starts but it would be equal to the centerline of the blade or before the center line of the blade - not beyond the center line. I know I have the information somewhere and I am looking for it but I bet it's available right here where Jim described the method of adjusting the alignment.

Kurt

-

-

The Cameron is overkill if you are building wooden ships/boats. The Proxon or Microlux drill presses are more than accurate enough. Wood will expand and contract due to atmospheric changes more than one drill presses accuracy over another. Personally I don't consider the various adaptions of a Dremel or other brand press - they are known for the inability to hold settings as they age - some right out of the box.

I have the top of the line Microlux press - variable speed with digital depth measure readout - with a good XY table & vise attachment the accuracy is more than adequate - at least for me.

-

That's a nice tight joint!

- Greg Davis, druxey, Keith Black and 3 others

-

6

6

-

Correct Ron. I always wipe the needle with Regdab - it is simply a needle lube and each mfg has their own - when I reinsert the needle after cleaning. I put a drop of it on a clean rag and drag the needle through it and then lightly wipe the needle before inserting it into the brush. Always wipe towards the tip - you don't want to stick yourself with the extremely sharp point - and you might bend the point too.

- DaveBaxt, Ryland Craze, thibaultron and 2 others

-

5

5

The Shipyard at Foss' Landing (Diorama) by gjdale (Grant) - FINISHED - SierraWest - Scale 1:87 (HO)

in Non-ship/categorised builds

Posted

As you found out painting the parts with the Badger STYNYLREZ works wonders on the appearance when you add the final colors. Good of the designer sharing that tip with you.

STYNYLREZ is a great primer, but many are also using it as a final color with the line of colors now at 18.

I like to vary the primer color depending on what the final color will be. An example is using Stynylrez Black as the primer and Under hull Oxide Red as the final color - a much better final result, in my opinion, of the lower hull below the waterline, than using a gray primer. Paints appear differently when applied of different colors of primer - lighter final color, apply over a light primer.