-

Posts

9,722 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

HMS Winchelsea (1764) 32 gun frigate GROUP PROJECT INFO

Chuck replied to Chuck's topic in Group Projects on Model Ship World

No sorry I cant supply those. -

That looks pretty darn good. Once you clean up the rough spots with some fine sandpaper and apply a finish it is goong to look famtastic.

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

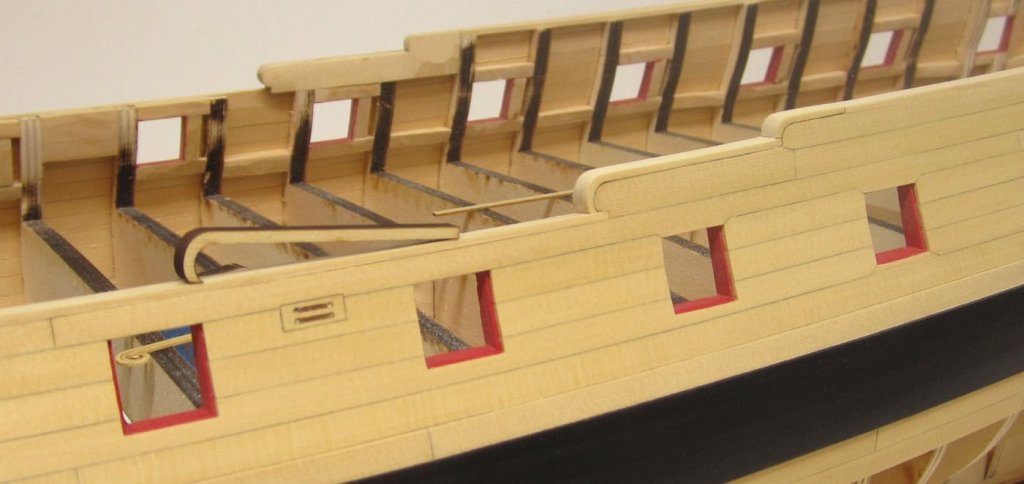

A small update after a lot of work and elbow grease. The fairing cap is completed. I am calling this the fairing cap only because it is an aid to help you fair the bulwarks inboard to a consistent thickness. It is 3/16" wide and 1/16" thick and sits atop the sheer. It really finishes off the sheer nicely. It will be completely covered up so it doesnt matter what type of wood you use. You should start in the waist and lay down a length of stripwood along the sheer first. Keep it flat and level and make sure the outside edge is flush with the exterior hull planking. Then work your way towards the bow and stern adding the laser cut hance caps if you bought them....and then finally finish it up with more 3/16" x 1/16" strip along the quarter deck and at the bow. At the bow because it is curved, you will need to cut it from a 1/16" thick sheet. I pressed this on top of the sheer and simply traced the outboard shape of the bow up to the bollard timbers. Then I drew another line to indicate the inboard edge so the piece would be 3/16" wide. Cut it out with a sharp #11 blade. Once done, you can fair the bulwarks inboard. This will take a while but its best to get it done now so all of that dust and mess falls away rather than collect inside your hull. One thing to consider while fairing....look at your gunport sills as a gauge and try to keep them consistently deep from bow to stern. I am about 95% of the way faired which is good enough for me at this point. Now I will start lining off the hull so I can plank below the wales. Notice how clean and free of laser char the bulkheads are inboard in comparison to the photo below which shows the hance fairing caps. Nice and clean. That sheet laying on deck is just scrap and helped me keep my knuckles from getting scraped up on the top of those bulkheads as I faired inboard.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The paper cutter does work but its a real pain when you want accuracy. It really doesnt work perfectly, especially with the thicker stuff. It messes up the edge of the strip too. Cutting a 3/64" wide strip is not easy. You would need a Guillotine Shear cutter that jewelry makers use. They are expensive. With the paper cutters, it will want to pull the sheet in so if you want a perfect 1/16" or a 1/32" wide strip 12" long that is not the way to go. If you can settle with less accuracy and curling then its fine. I may have to buy a good Guillotine shear in the future but when you need 100's of these strips for kits and parts, its not an efficient way to go. Much better to buy 250 strips from K & S bulk wholesale. I dont think Model Expo or Bluejacket can stand in front of a paper cutter making brass strips, LOL. They use far more than I do. I just talked to K & S on the phone....its not the tarrifs. Its just low demand. Nobody is doing the crafts and models like they used to. They are still doing the tubes and other parts. They just discontinued making these because nobody buys them. For you tool guys...This is what I will eventually have to get. But probably a bigger one. They had about 250-300 of the three sizes I use left in the warehouse so I just bought them all. That should last me a few years....Worth it for me as it would take hours to cut those.

-

So I shipped out about 30 sets of the first installment of laser cut cedar parts over the last two weeks. Many of you have probably received them by now. Has anyone started to assemble those stem parts yet? I would love to start seeing some build activity in those build logs. Anyone start yet? I used Titebond to glue the stem pieces together. I am eager to see some progress from the group. Shipped out 30 sets but only half of those have started a build log. I would also love to see some more of those lurkers start a log as well. Nudge ....nudge.... Just doing a little prodding!!!! Chuck

-

Most of these guys all get K & S stuff and they are all out of stock. I need to buy 40- 50 packages. Nobody has them any more. Its more of an FYI for you guys so you can buy a few packages if you need them. The prices on the remaining stock is also going sky high so I noticed that they did have a few left of some sizes you guys should by them.... Otherwise K & S will still make the wider strips like 1/2" wide by 1/64" but you would need to cut your narrower strips from those which isnt easy unless you have a press break.

-

Just an FYI K & S has discontinued making many sizes of strip brass and other items. These are staples for us model builders. For example... They are no longer making 1/64" x 1/32" brass strips 1/64" x 1/16" strips 1/64" x 3/32" strips 1/64" x 1/8" strips ect.... Does anyone know of another source for brass strips? I just bought all of their remaining inventory of these strips in bulk....but there wasnt much left. If you know you will need them, find a hobby shop that still has them on the shelf and buy them now while you can. Chuck

-

I actually have no idea. I never used it before so I couldnt say. Try not to over think it Lou. I realize there are a lot of choices but if you deliberate every tiny tiny detail you will probablu never make any sawdust. Just go buy some and give it a try. You will know pretty quick if its not gonna work.

-

You guys are so lazy....LOL. Just cut the pieces on a scroll saw. Those pieces were cut so poorly on that laser cutter I think a blind guy could do a better job on a scroll saw than that. It would be a huge mistake to try and use my templates on a harder wood (Pear or Box) as well and have them laser cut. The parts wont fit and you will waste a lot of money and wood. Lou....the scroll saw is waiting for you!!!! Those templates and plans are made for my tight tolerances. I have never seen a laser cutter come close to replicating it. So trust me when I tell you ....you will just end up wasting your money and wood. Either use my laser cut parts or cut them with a scroll saw. Chuck

-

Indeed that is what happened. So your print outs are just fine. I mistakenly shrunk the scale bar when reducing the size of the plan sheet info or logo above it. I have fixed that up so all sheets printed will have correct sized scale bars. But your plan sheets are just fine otherwise. Sorry about that. So dont worry about reprinting them. Chuck

-

I think you guys will be just fine. If you got any laser cut parts, just place them on top of the parts on the plan and see if they match up. Or as you said....if your 8 1/2 " x 11 sheets also match the plans then you are good to go. Its the exact file i used to laser cut the parts. It could just be that i stretched the scale bar by accident as i moved them and made room for the NRG logo. I had to shrink that text above it in some cases when I decided to do this as a group build and add the Nrg logo. Then i copied it to the other sheets. I may have grouped the scale bar in with it when I did that. I will check my original file and let you know. But I am pretty sure that is what hapenned.

-

The Cherry version of Installment 1 is now available and in stock. In addition, laser cut basswood brackets to hold your false keel straight and keep it from twisting are also in stock. You get 3 pairs of basswood brackets, but the screws and washers are not included. You will have to get those on your own.

-

Queen Anne Barge by Beckmann - 1/24

Chuck replied to Beckmann's topic in - Kit build logs for subjects built from 1501 - 1750

Simply beautiful presentation. You make my kits look so good!!! Best marketing any business could hope for. I did contemplate making some figures. But I dont want to overwhelm my casting guy. He is going nuts right now working on the castings for Winnie. Chuck -

Your moving right along Chris.....time to start that build log!!! You are hooked on the project now. There are no special jigs or techniques for most of this stuff. The final fitting as all done by hand. Its a matter of going slow and testing and tweaking and testing and tweaking, repeat.... until you are satisfied. The issue becomes when some folks for whatever reason.....skip a few testing and tweaking steps and then settle before they become satisfied. They do this for various reasons. Its not a race, take your time and throw away your missteps, and try again. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I dont think I can at this point. There isnt anything magical to show anyway. I just measured the length by holding a strip in position and marked both ends. I cut it with a sharp blade slightly longer and sanded both sides with a sanding stick. I tested the fit....sanded some more.....retested......sanded some more.....etc. If I messed it up, I tossed it and started over. Its just a one at a time slow process. Nothing special other than making I sure I tossed the bad ones and only kept the good ones.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.