-

Posts

9,700 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Thats looking real good. A fine job. You are almost to the fun bits!!!!

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

No resin this time around. So far so good. I am just laser cutting them out of boxwood. Should have some pics shortly. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Greg. I have noticed that other MFGs are trying to replicate that already. But they are having a hard time. Their attempts are falling rather flat. My guess is they will do the same and try to copy this concept next. I have already made some great progress on the cheeks. The main headrail is next. If I can get over that hurdle then I will be home free. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you guys. I will be working on the cheeks next so I can add the hawse holes. I have been contemplating a new concept for making these for quite some time. The one thing that is always disappointing me with even the latest and most innovative kits are the head rails. They just look awful. Even with these so-called Chinese kits that everyone is raving about. Once you get beyond the framing on those its basically the same old stuff. So I am spending lots of time trying to engineer something that will finally make these less difficult to make while not looking kit-like or awful. Hopefully have an update soon. If I stare at these photos enough I am sure I will come up with something!! 😉 Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

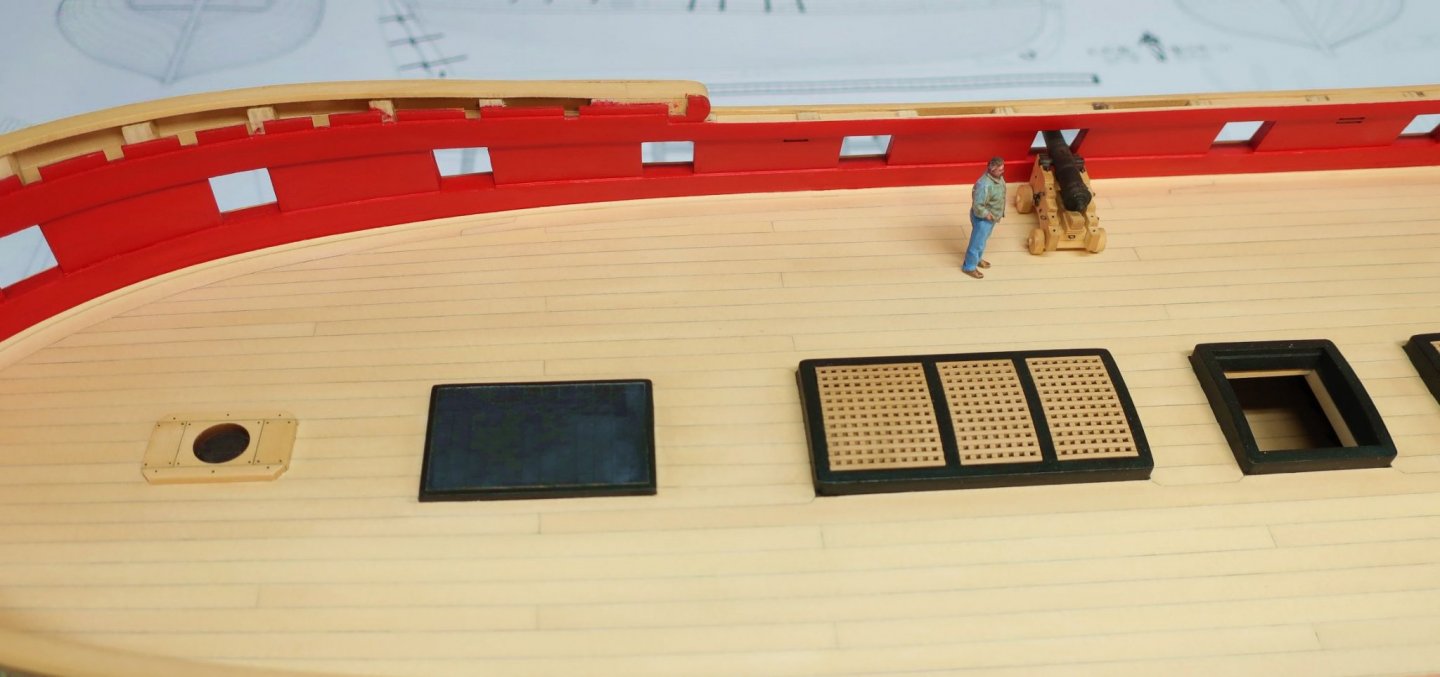

Finally finished chapter four in its entirety. The deck is finally planked. There shouldnt be much much planking for a while. Pretty straight forward from my last update. Just follow your lining out of the deck planks and take your time. Match the tapering and curve of each plank just like you did when planking the outboard hull. I will begin chapter chapter five by getting back to some outboard details. First the cheeks and hawse holes...then the rudder. Afterwards it will be back inboard to add the details to the bulwarks and the guns. Feel free to ask me any questions. Some photos...

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks fantastic. Hope you are enjoying the model. You are doing really well with it. Beautiful work.

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Its really not enough to just make tick marks. If you take the next step and use thin tape or thread along your tick marks, you can see if what you measured out is correct. Trust me as there will always be a ton of mistakes until you do this step which most omit for whatever reason. With your tape in place from bow to stern you can adjust them until it looks right when viewed from many angles. Then remark those tick marks along your tape which is probably now better positioned than your initial tick marks alone. This step should not be skipped and its probably one of the most important. Hope that helps. You wont get any dips in the the run of your planks this way. Its like a quick test before you cut a single planks from wood. Chuck

-

Really nice model. Well done. Looking forward to your Ontario. Chuck

- 37 replies

-

- Finished

- model shipways

-

(and 1 more)

Tagged with:

-

2021 NRG/MSW Calendar

Chuck replied to tlevine's topic in NAUTICAL RESEARCH GUILD - News & Information

Very Nice Job folks!!! -

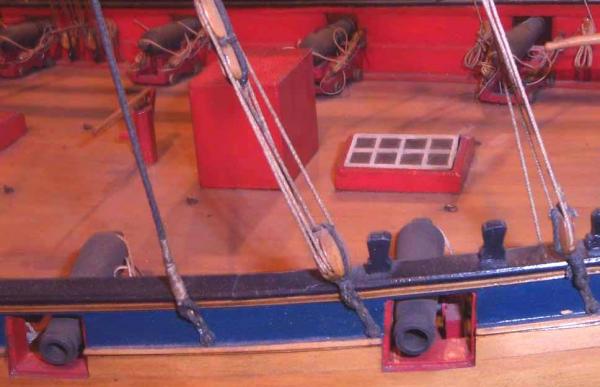

If you look at the contemporary models of cutters in the gallery you will see some fine examples. The spirketing is thicker and the top edge runs flush with the bottom of the gunports. This can be easily faked and look just like actual practice. For whatever reason this detail is always omitted on kits. Even those so called newer and innovative kits. Its easy to add this detail. Whether in one layer or two. I prefer two layers so I can adjust the run with the second layer of spirketing. Then I follow that with a rounded or concave waterway.

-

Dont forget that you will need to get 3 packages of grating strips (with camber) along with the jig. It is available in Yellow Cedar, Cherry or Boxwood. You will probably need more cedar planking sheets to mill strips for the bulwarks as well. Check out the materials list below. Materials List for Winnie fourth.pdf

-

Absolutely Beautiful Bob.... Wonderful work on those sails. Time for you to start the Winnie next...LOL!!! Chuck

- 87 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The monograph chapter is already available. I just have to finalize the 12 chapter 4 packages I have already laser cut. I am trying!!!! Aside from this I woke up this morning with 26 items out of stock!!! I am having a record breaking month of sales once again during this pandemic and its rather impossible to catch up. I am trying my best and shooting for the weekend. Have to create the part in my online store so you guys can place an order. Chuck

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.