-

Posts

610 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Remcohe

-

-

It's looking very very good!

Remco

- Eddie, mtaylor and AnobiumPunctatum

-

3

3

-

I think one of the issues is I didn't use pure black Fieblings, but mixed it with Mahogany (same brand) to get a very dark brown instead of black as I liked that better. I would expect that if the tung finish (I use it not pure but thinned down with turpentine) dissolved the stain the issue would have presented it right away. But it was ok for over 6 months before it started to fade. So it must be the UV causing the issue.

Anyway I will make a few scrap pieces with and without finish with both my mixed colour and pure black to see what happens over time and use them to test if I can repair it or not.

Next to that I will try an acrylic ink

The results will follow in due time.

Remco

-

Jan, it's the stain discolouring below the oil topcoat. The shininess is just coincidence how the light fell. I have no idea how far the stain and the oil penetrated the wood. I only know I added multiple layers of stain and in the beginning it was very dark brown with no lighter patches what so ever.

Remco

-

Thanks all for your advise and especially Ed for your research. I added a pic showing the 'problem' a bit better. Under normal light conditions it's very obvious, it just doesn't show very clear on a picture unless I over expose it.

I dare not use any solvents for the risk of letting the dye getting into places I really don't want it to be or dissolve glue. I could try to carefully scrape the topcoat of the tung oil and hope the Fieblings will penetrate the wood. But this also has the risk it might get into places where it shouldn't go. Let me sleep on it for a couple of nights

Remco

-

The knees look excellent and the joinery is textbook execution style.

Remco

- Mirabell61, wyz, dgbot and 6 others

-

9

9

-

I'm going to redo the mast step, I try to avoid "I'll do that better on the next one" as much as possible. Before you know........

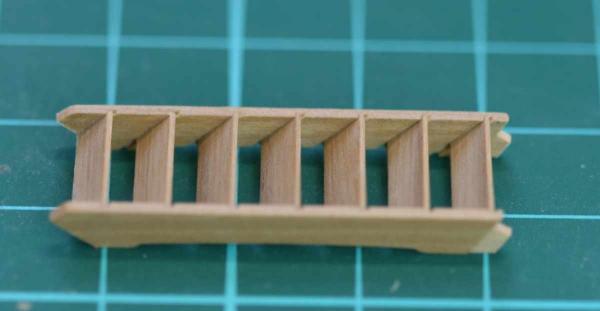

Ok but first the port stops for the gunport and sweep ports. A nice challenge to follow the contour of the hull. Well, I just used the hull to mark the contour and the rest was a matter of time and patience, fun to make.

Here you can see something that concerns me, the black strikes getting lighter and lighter over time. And also quit blotched I used Fieblings to dye pear strips of wood. Unfortunately it already received a few coats of finish (tungoil) so there is not much I can do about it.

Remco

- ggrieco, Mike Y, giampieroricci and 23 others

-

26

26

-

-

Mike, my mistake. I only use turpentine.

There is a big difference

https://en.wikipedia.org/wiki/White_spirit

https://en.wikipedia.org/wiki/Turpentine

Turpentine smells a lot better. I store a batch of the mixed stuff in a small glass jar, it keeps a long time but is does polymerise to the lid. The rest of the oil I keep in an old bottle that is vacuumed with a wine saver.

Remco

-

2 questions: what is the advantage to go 50-50 with turpentine?

does the wood could benefit from a treatment before applying Tung oil which could help to enhance the final look when completed?

Diluting has two advantages. The oil dries quicker and there is less risk of a build up of a layer of oil on top of the wood leaving a shiny finish.

I had no need to apply sanding sealer as the tung oil does not raise the grain.

Remco

-

I also did some experimenting, Tung oil, WOP, beeswax, museum wax of different brands.

I use Tung oil as a finish, 50% deleted with turpentine. Gives a nice nearly flat finish, not as flat a sanding sealer which I like better. But Tung Oil also takes care of any remaining sanding dust in joints and other very small recesses.

Remco

-

Thank you all for your very generous comments and likes. It's you folks that keep me building, without MSW I probably would have quit years ago to start an other model only to leave it unfinished later.

I moved on to the capstan step. The first version had no rebated parts, I didn't like it and made a second and a third version. The second was scrapped as I chipped a bit of that was very visible the third one is below.

I'm also considering redoing the cross blocks for the main mast step. I was not paying attention an accidentally added bolts that are way to big. Most bolts in the build are 1" but in this case I need 0,75" bolts like the ones on the capstan step. The difference is quite obvious.......

Remco

-

-

-

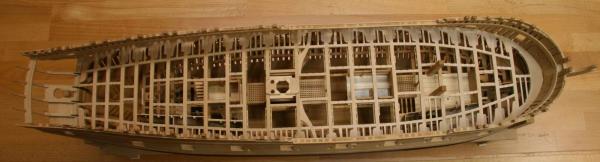

Finally after a one year, the basic structure of the upper deck is finished. I never realised I was that slow building my ship :-)

I don't plan to add more ledges between the carlings so there is a better view at the lower decks. Cutting the mortice in the wing transom was a bit tricky, especially as they had to be right the first time.

Time to add tome more bits to the deck.

Remco

- captain_hook, iosto, Dubz and 45 others

-

48

48

-

-

-

-

-

Really nice fit of the bowsprit into the deckplanking. And the rest of the deckplanking looks great too.

Remco

- giampieroricci, PeteB, WackoWolf and 1 other

-

4

4

-

Congratulations Mark, that's a serious milestone.

Regarding the duplicator, take a good look at the commercial ones and you're probably able to make one of your own. I did once a long time ago, but never really tested it, so I can't tell mine works. If al fails you may opt to procure a set of guns.

Remco

- mtaylor, avsjerome2003, Omega1234 and 2 others

-

5

5

-

Congratulations Mark, that's a serious milestone.

Regarding the duplicator, take a good look at the commercial ones and you're probably able to make one of your own. I did once a long time ago, but never really tested it, so I can't tell mine works. If al fails you may opt to procure a set of guns.

Remco

-

-

-

Anxiously awaiting the results of your paint job

Remco

- Omega1234, Piet, CaptainSteve and 2 others

-

5

5

Surabaya by Piet - 1/80 - Mid 17th-Century VOC ship

in - Build logs for subjects built 1501 - 1750

Posted

That is a nice set of anchors Piet, do you take a commission and build me a pair for the KF ;-)

Remco