-

Posts

5,185 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by michael mott

-

-

Hi Nils one method I have found for creating curved U channels is to first anneal some thin wall brass tube then fill it with the appropriate diameter of styrene rod then bend it to the curve with finger’s then use a torch to burn out the styrene the file away the top slowly. And it would also work by just filing the top without the burning anyway.

Michael

- Keith Black, Canute and Mirabell61

-

3

3

-

Hi Nils just finished going through your build, wonderful creative work. I’m amazed by how fast you get the work done.

Michael- Canute, Mirabell61, Retired guy and 1 other

-

4

4

-

Great to see another one taking shape Mark.

michael

- druxey and Mark Pearse

-

2

2

-

Love the lines drawings Keith, it is so satisfying hearing a pencil slide across the paper! And congratulations on the new addition to your family keen looking lad.

Michael

- Retired guy, KeithAug, mtaylor and 1 other

-

4

4

-

-

-

-

-

-

- davyboy, PeteB, Mark Pearse and 15 others

-

18

18

-

On 6/6/2022 at 3:13 PM, Richard Dunn said:

Ha, yeah I bet

The answer is yes but its grown for the purpose of marine fitouts, many of the super yachts still use it although it's a 5mm veneer not solid so it goes further.

Anyone can correct me if I am wrong but nowadays there are products to keep teak in good order instead of washing and scrubbing, and those that have it can afford to pay someone to look after it.

The burmese teak is what they use nowadays still (Tectona Grandis).

There is an alternative wood that has been used in place of it for several decades now and that is Iroko, its horrible stuff, we used some on a boat 20 years ago and its terrible to work, it also has dust that causes your throat to close, its very course grained and splintery stuff, it shares the oily nature of teak though which is why they use it.

Mahogony depends what species, their are over 30 species of mahogany, but the one i think you are referring to is Brazilian mahogany or Swietenia Macrophylla its been the staple for guitar builders for centuries for necks and bodies.

thier is also sepelle and many others which are still grown for the purpose but solid has become harder to get as veneer is seen as a better usage and less wasteful way of extracting the wood.

In Australia we have a few identical looking timbers that are actually better, Queensland maple being the most common, its beautiful stuff and you cant tell the difference. here is a chair I made with it, as you can see it looks like Mahogony.

Anyway I don't want to hijack this post.Lovely work Richard also the cabinet in your earlier post. I am always on the lookout for salvageable wood for my model projects, it always breaks my heart to see an old house being crushed into matchsticks by huge machinery when much of the wood used could still be salvaged! The time is money myth will become apparent one day, but I digress.

I am still using some of the eastern sugar maple that I acquired in 1973 as a six foot long green log after slabbing it up into quarters after taking a three inch plank from the centre for a coffee table and air drying the rest. It is what I am using for the interior of my Bristol pilot cutter.The deck is close grained salvaged old growth clear Douglas Fir.

michael

-

Hi Rob just catching up with your work, nice mod on the bow.

The water reminds me of my immigration journey from the UK back in September 1967 we were on the Cunard ship the Sylvania during a force 10 for three days in the North Atlantic. 40 foot waves.

Michael

-

Keith , having spent the last hour and a half starting at the beginning, it looks like a marvelous project. I will most certainly be following along and gleaning tips from your ingenious problem solving skills. The comment about the breakfast counter made me laugh. It looks like you will have some fun with the bright-work and all those panels.

Good to hear you are well, and getting stuck into the prep for the start of keel laying.

Michael

- MAGIC's Craig, KeithAug, mtaylor and 2 others

-

5

5

-

-

Thank you to everyone for the positive comments and welcome back.

Michael

-

31 minutes ago, Jack12477 said:

Michael, I echo the sentiments expressed by others above! Welcome back! Glad you've recovered.

There are some photos at Olde Rhinebeck you might be interested in.

Thanks for the link Jack, I made a comment over there.

Michael

-

Hello everyone I’m just getting my mojo back in the ship modeling world. I had a heart attack in November 2022 and am now recovered from that. I had a wonderful conversation with David Anscherl earlier this week and he challenged me to do something on the cutter within the next 2 weeks. Yesterday I dug in and am happy to say that I am enjoying the work I am going to continue with the galley area which also includes the chart table on the starboard side

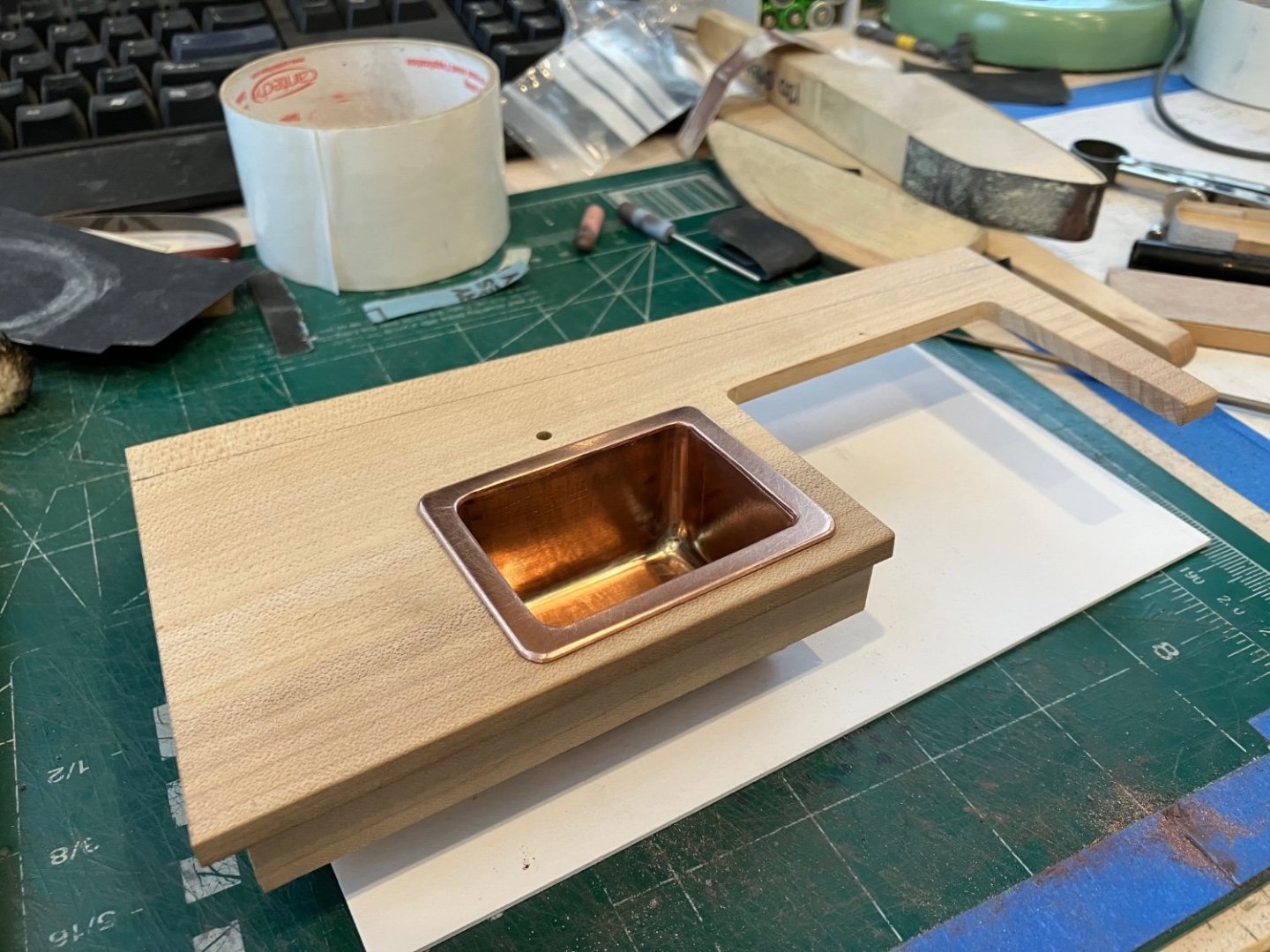

The first task was trying to remember just what I was doing, then deciding what was the next step. The galley counter needed to be drilled for the tap and then the sink needed some serious work to clean up the sloppy silver soldering. So a few custom sanding sticks are being used to tidy up the sink.

Time for some lunchMichael

- Jack12477, Wintergreen, mtaylor and 16 others

-

19

19

-

Excellent work Keith. Quite the journey on this build lots to absorb.

Michael

- mtaylor, FriedClams, Keith Black and 3 others

-

6

6

-

Rob, Thanks for taking the time and energy to keep us all appraised of the ups and downs of this wonderful build. You have done to this layman at least an outstanding bit of research, and model-building in a way that has given me a much better appreciation for the shipbuilders art.

A magnificent model of a beautiful ship.

Congratulations.

Michael

-

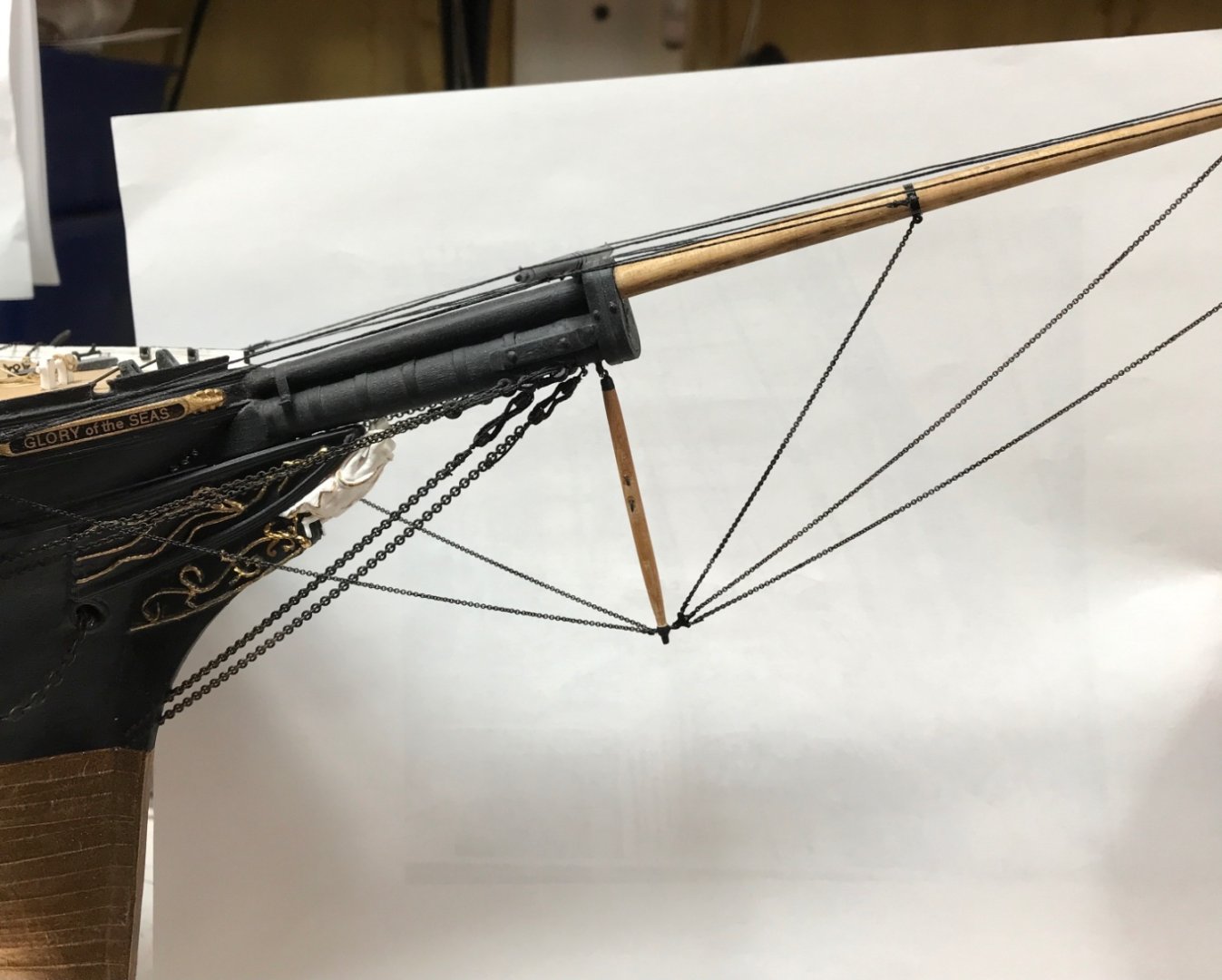

Hi Keith,

Tricky stuff rigging, you are doing a superb job, like Eberhard said not exactly friendly to the folk who are challenged, but then there are all sorts of activities that require great dexterity and visual skills, which you appear to have in spades.

Lovely work as always.

michael

- Keith Black, KeithAug, Retired guy and 1 other

-

4

4

-

Magnificent, simply Magnificent!!

Michael

- mbp521, mtaylor, Retired guy and 3 others

-

6

6

-

Lovely work Keith, I am surprised that the harnesses for the main sheet are just wire with no protection against chafing the wood boom. That wire would cut into the wood of the boom with the amount of pressure that the main would generate.

Michael

- druxey, Retired guy and mtaylor

-

3

3

-

- druxey and Keith Black

-

2

2

-

13 hours ago, Canute said:

Very intriguing build, Michael. What is the ducket 's purpose. It looks like a smaller version of the observation position on a bay window caboose/van. Excellent work.

Ken the ducket is for exactly the same purpose, the clearances and loading restrictions that were part of the early English railway standards are likely the reason for the small protuberance.

Grant thanks for coming along for the ride.

Mike, thanks. Learning and sharing of information it one of the joys I find that this site does so well with all the contributors and their various builds.

Michael

- Old Collingwood, Jack12477, druxey and 5 others

-

8

8

SS Benjamin Noble by Roger Pellett - 1:96 - Great Lakes Freighter

in - Build logs for subjects built 1901 - Present Day

Posted

These sorts of little jigs are so satisfying because as you demonstrate they are so helpful and easy to make.

Michael