donrobinson

Members-

Posts

1,909 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by donrobinson

-

I also would like to Thank You for all your time and effort and for sharing your knowledge and techniques with us all. I will be so looking forward to your next adventure.

- 366 replies

-

- pegasus

- victory models

-

(and 2 more)

Tagged with:

-

Congratulations Hennie, she is a real beauty. Will be looking forward to your S.O.S. build.

- 214 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Looks really good, the new blocks look much better. It is looking pretty cool at the stern

- 291 replies

-

- bounty

- billing boats

-

(and 1 more)

Tagged with:

-

Looks great Bob. Was your Kingfisher built in the same manner, upside down building jig, or was it upright? I am only asking, and I know it is early in the build, what your preference would be, if they were different?

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

I forgot to ask, what is that in the top left hand corner of the third picture?

- 107 replies

-

- brazzera

- marisstella

-

(and 1 more)

Tagged with:

-

Those lights really add to her, very nice work!!

- 296 replies

-

- chaperon

- model shipways

-

(and 1 more)

Tagged with:

-

Your scupper planks look great, as does all the planking. Super work. I wish I could tell you the hard part is over

- 107 replies

-

- brazzera

- marisstella

-

(and 1 more)

Tagged with:

-

Looks good Mike, I didn't realise there were so many sailors on the ship

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

Now I can see it, dah on me, need more coffee

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

Looks good E.J. I am not sure if is just a photographic illusion, but what are those two white things by the foremast? Looks like they are attached to the stay

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

Thanks Dave, hopefully someone with more knowledge than I will see your post and have an answer for you.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Zoltan: Thanks, I'm just passing on a idea that I found here on MSW E.J.: No problem, it really is a good little jig and it also works for making hinges

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Ian, Thanks buddy. This a real good project for the new mill. Canadian Tire has the brass rod

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

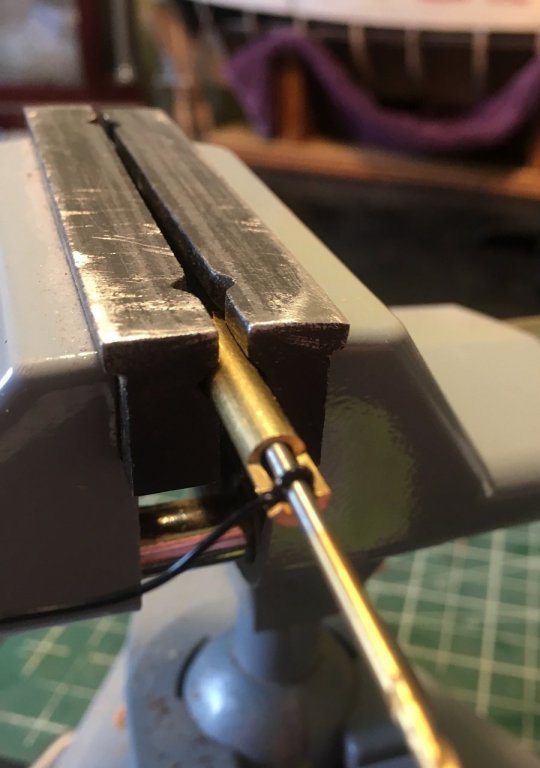

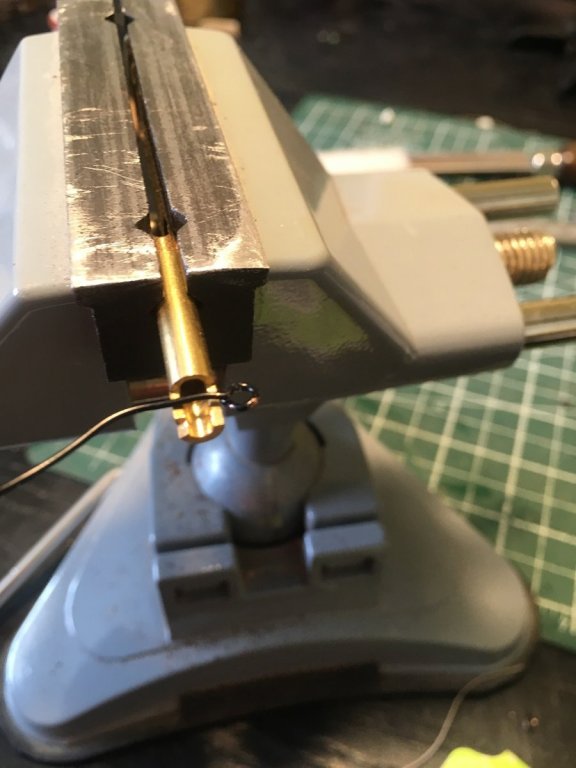

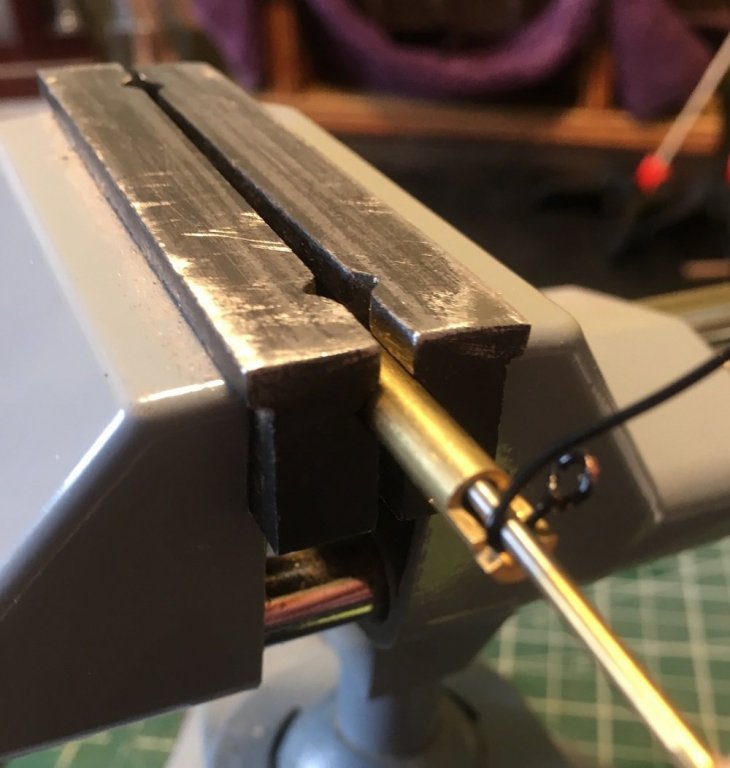

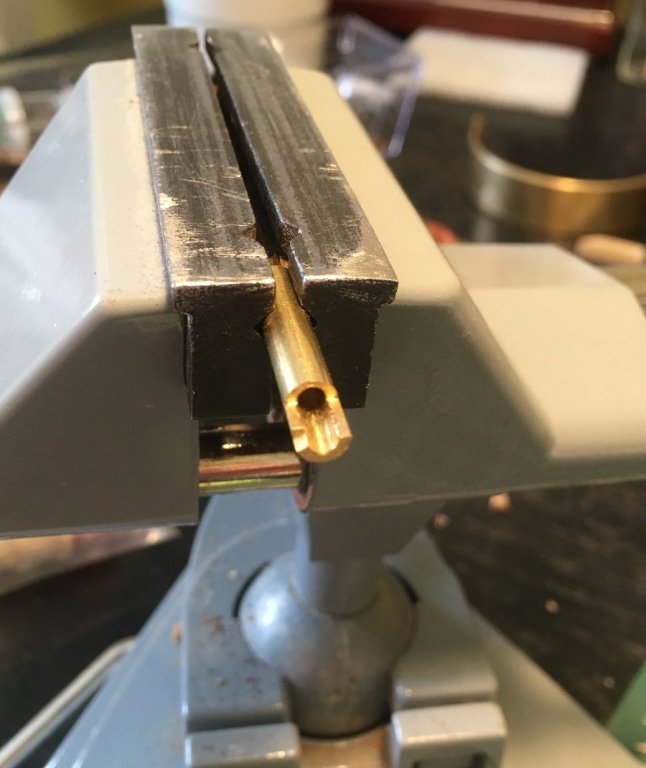

Mike : Yes, you can make very consistent ones. The brass rod I used was approx. 5mm or 3/8". To determine the size of hole required you take the size of eye you want( 1mm for example) plus twice the diameter of wire (.5 mm) so a hole of 2 mm would be required, you would then use a 1 mm bit to form the eyes. Drill hole into rod, file off approx. half the length of the hole until half of it is exposed then at the very end file a little bit of a bevel as seen in the pictures. I must admit I use this same jig almost all the time, making a jig for the exact size you want would make it even easier. On the jig shown the opposite end has a different size hole.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

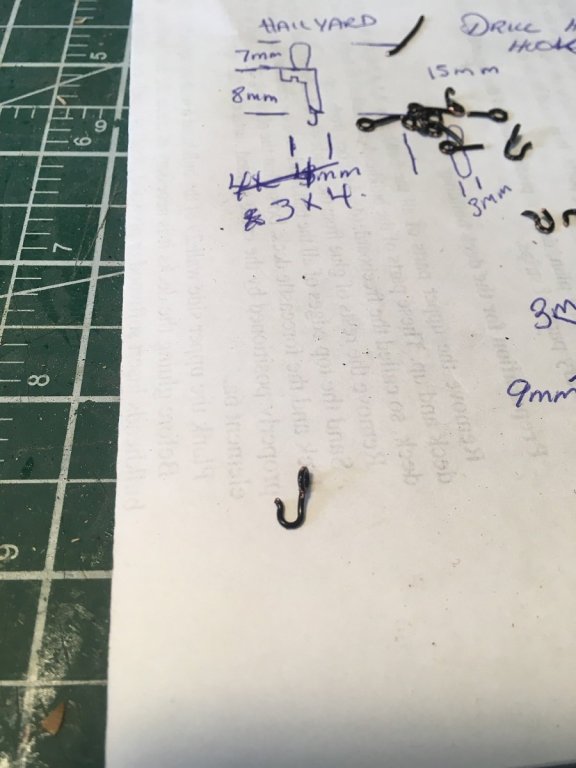

Here is the process for making eyebolts and hooks, please remember this not my idea but one I found here and I don't remember the gentleman's name: Lay wire on jig insert drill bit and pull down on the bit Keep bending and turning the wire over the bit leaving a slight overlap move the wire around and bend it down on the bevelled edge, this lines the eye up with the shaft of the bolt sorry for blurry picture, my left hand was a little shaky today. This a finished eyebolt to make a hook lay the eyebolt flat on the jig insert bit and bend the wire up turn bolt back around to bevelled edge of jig and make a slight bend cut the excess wire off and you have a eyebolt. This picture shows the hook we just made(on the left) and some other sizes I've made. The bronze hooks and eyebolts are for the gun carriages on my Pegasus a clearer picture of the jig, easy to make and easy to use Hope this is useful Mike: I forgot to answer your question about the rigging rope The rope does not compare to Syren, nothing does,but the rope supplied is quite adequate and I won't be exchanging it out. I used the Syren rope for the anchor as it was a little bigger, which I thought looked better.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

len: Thanks, hope it helps someone Mike : Thanks. The tool is clamped in a vise then using an appropriate sized drill bit you bend the wire around it. I can post some pictures if you want

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Hey everyone, I hope you are all enjoying the weekend. Thanks to all for stopping, for your likes and comments. Today's update is showing the catheads and anchors. I realise it is a bit early for the anchors but I couldn't resist the urge to see how they would look, they can be easily removed if required. This is a practice cathead, just to get the fit, angles and dimensions right. This is just 6 x 6 mm basswood, the final product is made from 6 x 6 mm rosewood. The holes and simulated sheaves were made on the mill using a 1 mm end mill cutter. I am just showing for those who haven't done this before how I install the anchors. A line is put through the eye on the cathead pulled through, doubled over itself forming a loop, wrapped around itself(three times in this case) and then fed through the loop Pull both ends to tighten seizing Then move seizing up into place There is a hook stropped to the double block. The line is then fed through block and sheave in cathead and finally belayed to a cleat. The rope around the anchor shaft has a thimble seized in it. Rope is wrapped around the shaft and belayed to the kinighthead. I didn't care for how loose the line through the cathead and block was so I painted the line with diluted pva glue and added the tweezers for weight This is the final result. The anchor rope is from Syren that has been dyed from tan to brown. All other rope used is kit supplied, The hook on the block needs some touching up...as does some of the other some of the other paint by looking at these close ups And a shot from inboard Finally a picture of the tool I use to make hooks with. I found this here on MSW some time ago and I can't remember the fellow's name but I surely thank him as it works great.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Everything looks great. Good clean work

- 165 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.