-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Chattter usually means that the feed rate ot the tool bit are not positoned propoerly. Have you checked into this? David B

-

All comments are appreciated. As I said before not perfect. I had a feeling that the waterline might be off. However This is my second attempt at this kit. I am just getting my feet wet. I would be grateful for any help I get. I was debating a do over but then I would be wasting ink and never get anything done. I have a golden rule. If you never make a mistake you ave never attempted anything and you can learn from your mistakes. Thr first time the bow was a disaster the second time close but no cigar. I made the fold a little too sharp. Thanks for catching it and offering to coach me. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Thanks for the comment. This is indeed a different medium. This time around it looks better,but not perfect. I will keep updating the good and the bad. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Congratultations on a job well done. David B

- 89 replies

-

- scottish maid

- clipper

-

(and 2 more)

Tagged with:

-

Airbrush results in "fuzz"

dgbot replied to jmorgan11's topic in Painting, finishing and weathering products and techniques

The problem is acrylics are water based as a result they tend to raise the grain on certain woods. Basswood will always fuzz when using acrylics. You have to use a sanding sealer before you can airbrush. David B -

I admire your metal work. It is hard to believe that you do not have a small machine shop. David B

-

And you are going to put it in the water? Nice work. David B

- 366 replies

-

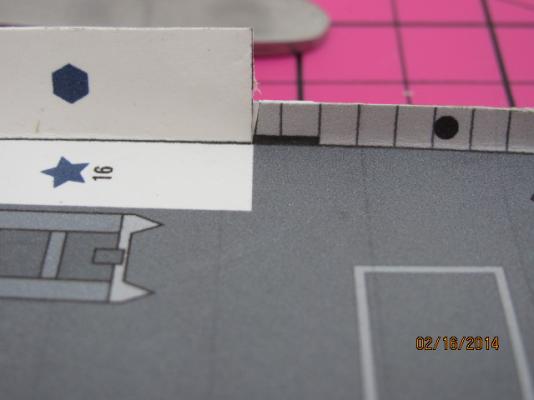

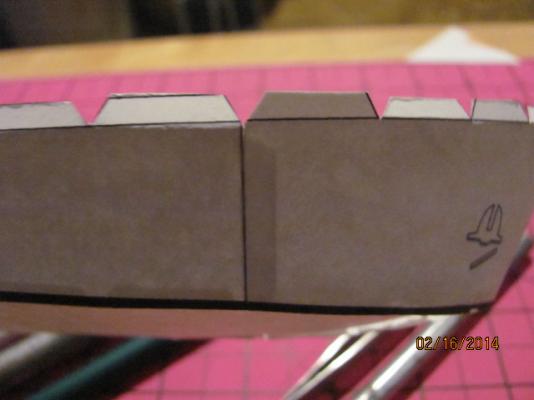

Thanks for commenting. The heavier stock makes the job much easier. Plus this time around I had a good idea of what I was getting into. The interesting areas are just starting. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Outstanding job Kevin. I can understand why you wish to leave it natural. David B

- 55 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

What you found is probably one of the ways of spiling a plank. As to three or four bands make it easy on yourself and stick with the three. That way you have a visual aid. Once the battens are laid out to your satisfaction you then proceed to fill it in. It may seem hard but in the long run it will be worth it. At one of my club meetind there is an old saying. Practice makes perfect. The biggest hurdle is getting there. David B

- 264 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

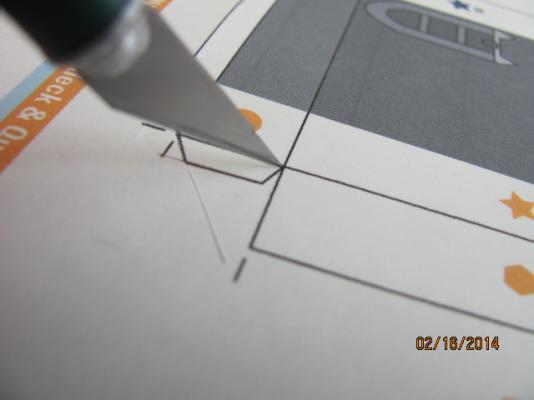

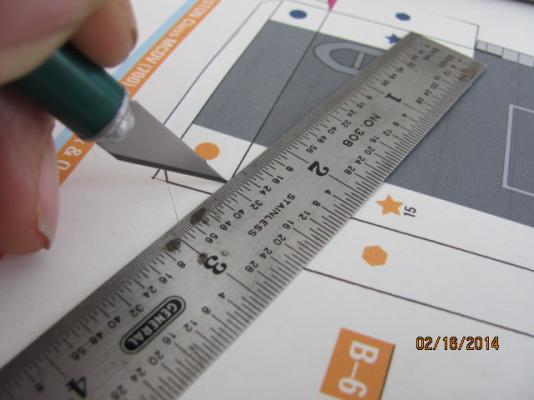

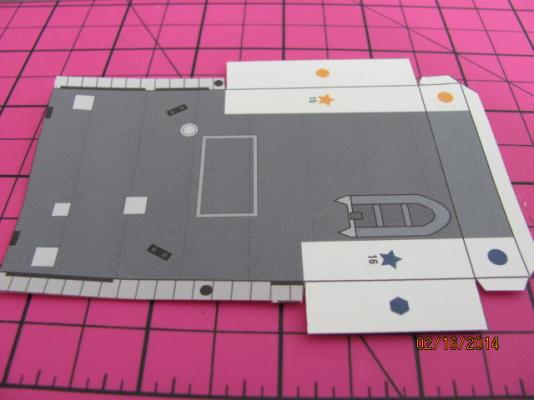

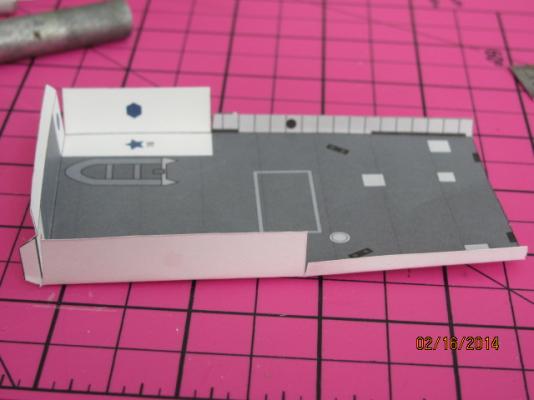

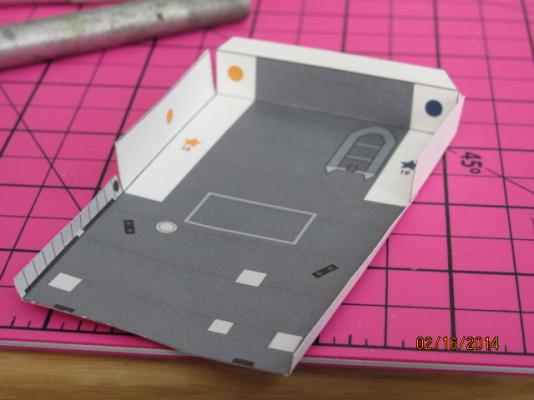

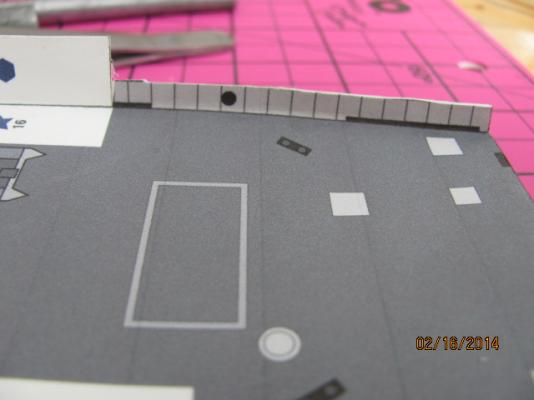

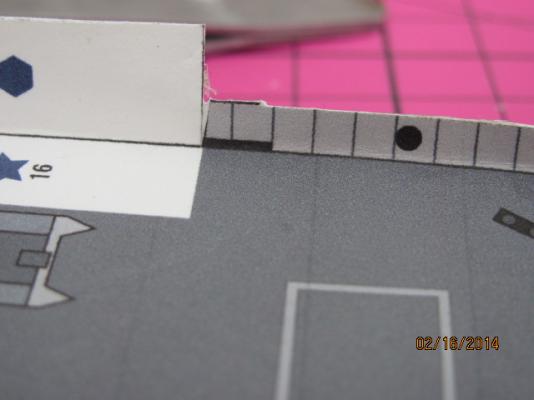

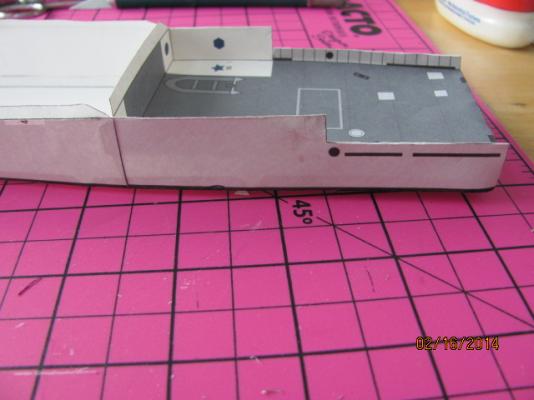

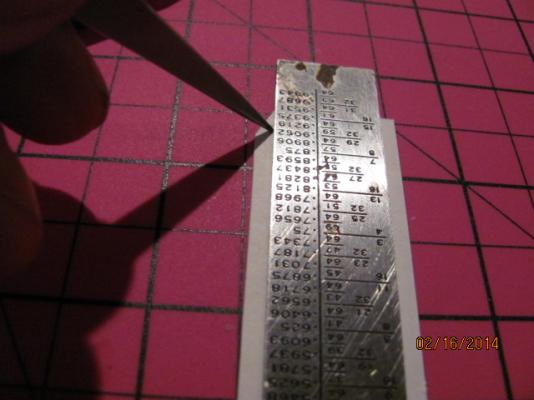

I just finished the quarter deck. I had problems aligning the edges the first time. One of the things I learned was that for those angles cut from the line outward that way you do not damage the part. After cutting it out I began the job of bending the part to shape. To help make the folds I took a dress maker pin and put it into a xacto handle and cut the tip down. This made the job alot easier. I then proceeded to fold the part into shape Then came the glue up. This time I was able to keep the edges aligned. Instead of starting at one side I tacked an edge and then worked both way using tweezers as needed. I have a pair of scissors that were perfect for cleaning those little bits that I could not get with a knife. Those selflocking tweezers came in handy in the corner. So far I am happy with the result. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Fantastic, you have more nerve than I. Probably a steadier hand as well. I am learning many things just by watching. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I never saw the need for simulating the caulking. The reason for this is that at the scale I am work at it would not be visible. David B

- 206 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Would this work as well as bees wax or better? David B

-

Coptoper tape is a thin foil. It is used in the stained glass industry all the time. It conforms to the hull nicely. Many modlers prefer it because it is easy to work with. If you wish to fully simulate indiviual plates you then score it. David B

-

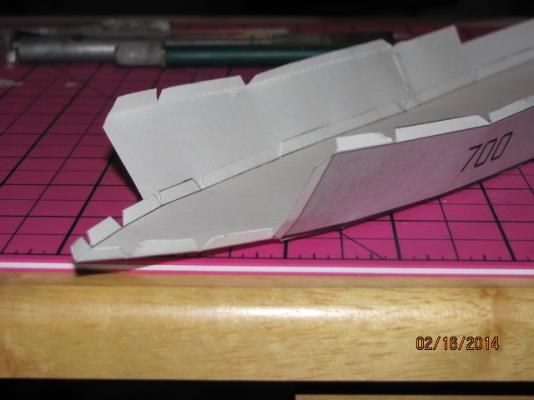

So far it is coming along and I like the way it looks. And now for the bow this time I made sure that I had it positioned before gluing up. I found that a selflocking tweezer with a wide tip helps pressing the tabs and making sure of a tight fit. As far as I am concerned it is an improvement. I am doing my work right beside a large window with the sun shing most of the day. That is the reason for the light shading of the paper. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

US Brig Syren by knightyo

dgbot replied to knightyo's topic in - Build logs for subjects built 1801 - 1850

I am happy you were able to save your photos. I enjoyed your log before the crash. David B -

I then started on the port and starboard which gave me so much trouble This time I was a little more careful in cutting them out. After scribing the tabs were able to bent a little easier and closer to the line. So far so good. I like the end result so far. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

US Brig Syren by knightyo

dgbot replied to knightyo's topic in - Build logs for subjects built 1801 - 1850

Another thing that will help is to use a scraper instead of sandpaper. The sandpaper will lightly tear the small fibers and might spread the caulking. Scraping is like using a sharp razor. It shaves the fibers and as a result will not affect the caulking. it will also polish the deck David B -

Dan, you did an excellant job on that gun staion. I just hope you are staying warm. I heard on the news your area was really getting hammered. David B

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Unfortunately not at the moment. The Chicago Maritime Society would like to get a museum going but are having a hard time getting started. When Daley took over he siad that we do not need that heritage. I can put you into contact with some people who can probaly help you out. One of them is Kurt Van Dahm. If you PM him he might know who you can talk to. David B

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.