-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

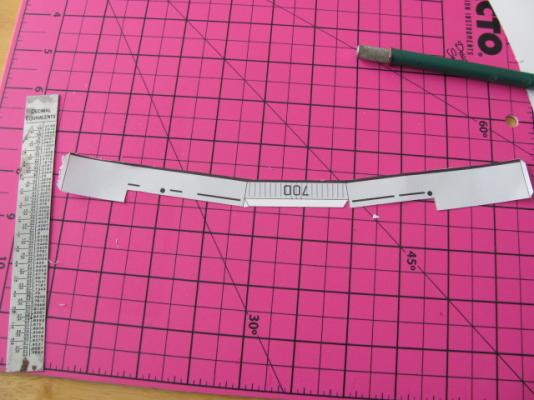

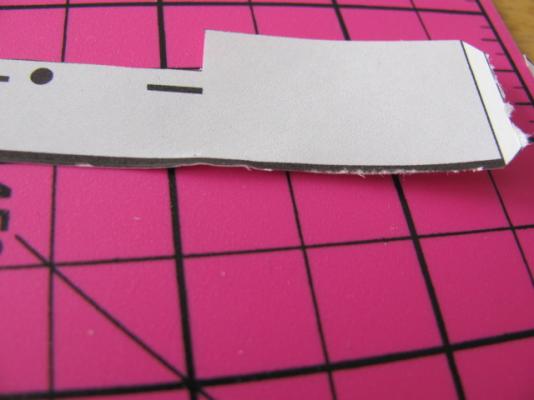

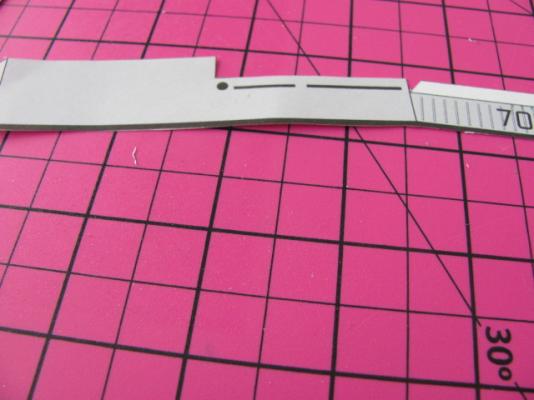

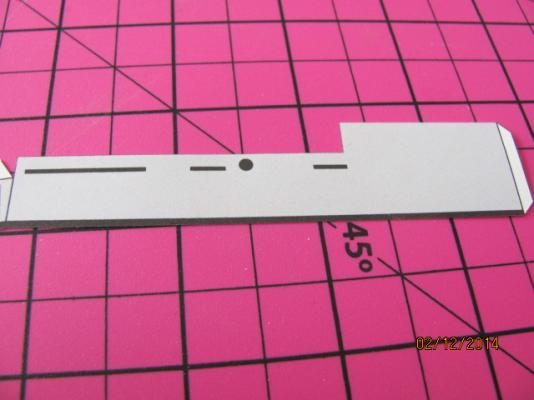

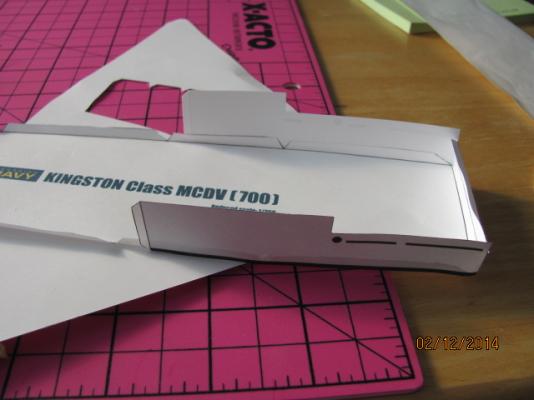

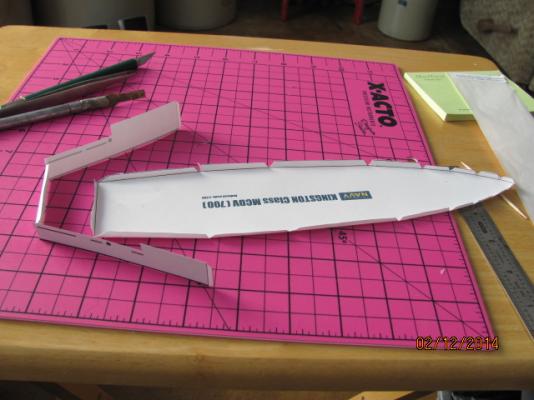

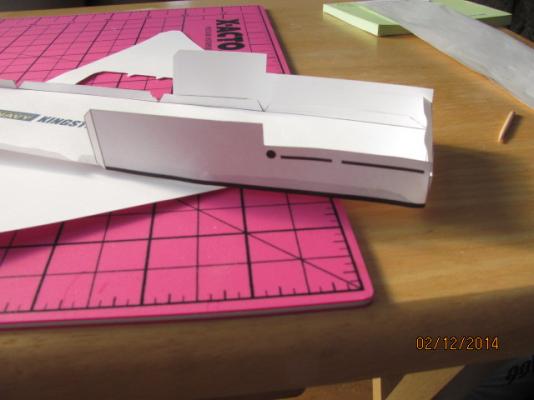

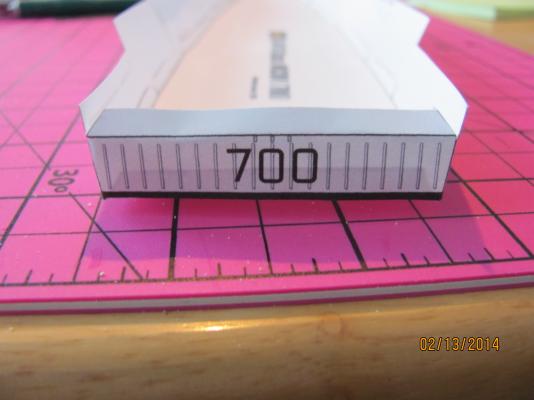

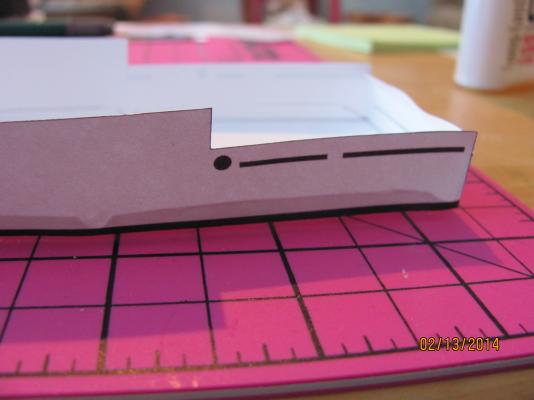

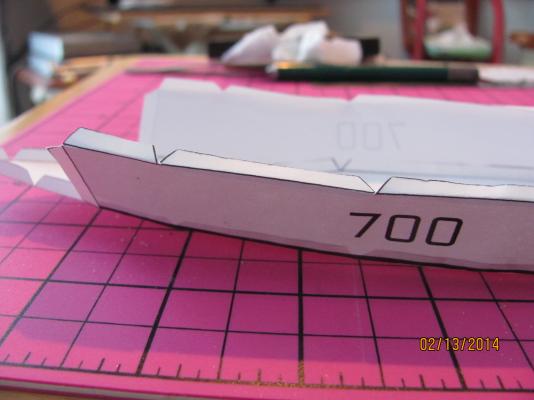

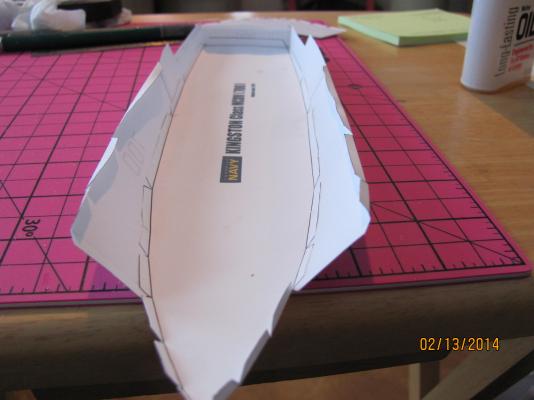

I stared cutting out the parts yesterday. Needless to say I had to print out a few extra sheets. The straight edge along with a sharp knife is crucial. This is a new medium so I have a learning curve. I found out quick that the cutting pad will dull the tip in the middle of a cut and I would have to start over. Instead of replacing a blade on every piece I am using a honing stone every now and then. Then came the glue up. Not perfect but I can always start over at this moment if I am not happy. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Mike it is good to see your Aggie again. I just found your build log and went through it. Your workmanship is as outstand as usual. I will be watching your build closely. Too bad you do not have the sufficient time to work on her all the time. PS Here in Waterloo IA and in Chicago beat you out on the cold temps for the past few weeks. David B

- 150 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Fair-a-frame

dgbot replied to Don Quixote's topic in Building, Framing, Planking and plating a ships hull and deck

Every year at our clubs we would have a round table on tools that are not needed or are a waste of money. The fair a frame is always the first item listed. David B -

Marvelous you must really enjoy working and building with metal. I think I might chicken out and go to resin casting. David B

-

In my dept at my job we use 3 measurements. Metric, decimal. and standard. It depends on who the customer is. There are only 2 people there who can work with that confusion all the time. As a result we have three rulers and we just convert otherwise. I wish it was just one of them. David B

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

dgbot replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

I truly admire your work. You are an insperation to me. By going through your log I have learned a lot. Thank you. David B- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Nice work. Have you experimented with stains like Minwax? David B

- 755 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

I think the reason for this is you have total control over the build and you can make sure the measuremnet oare correct and to your standards. David B

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

The firstt three to for top planks are always full . The reason is the are providing support from the wales on up. From the wale down to the garboard is when they start changning in width. The wales or rubbing strake was usually double planked for reinforcment. You are doing a fine job. Top down to the rubbing strake then the garboard then any way you feel comfortable. David B

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Ollie, Do you know the thickness of the copper you are using. If it too thick you can buy copper tape form a stain glass supply. David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

I would have to agree with themadchemest. You put alot of work and effort into your first build. I admire your tenacity. A link to your old build would help many others learn. Now for the cheer. GO! GO! GO! MARK! David B

-

Help with king plank

dgbot replied to captainbob's topic in Building, Framing, Planking and plating a ships hull and deck

I believe the king plank served the purpose of strengthening and reinforcing the main deck. The upper deck did not need this and did not have one. David B -

That is what we are here for. David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

They have those also. What these are is a piece of sponge sandwiched inbetween two micromesh sanding pads. Unfortunately when I moved I forgot to bring them with me so I could show you what they look like. To my knowledge several woodworking stores will carry them. Rockler, Woodcraft etc. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Druxey go to woodcraft.com. Navigate to shop essentials and click on sanding in the list you will find sanding pads. I have seen them and think they are pretty good. No left over metal dust and when the get dirty just rinse them and let dry. The grits are coarse to fine polishing. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Many ships had drag. This means that the keel is not parallel with the water line. Look at the plans. They should show you the water line. The draw a line parallel to the line underneath the keel keeping track of the distance 1 to 3 inches your judgement. Then measure the keel from the base line if the keel runs parallel it is then easy. On your building prepare a holding station that will hold the keel at a even distance from the board and 90 degrees on the sides. On this site there are pictures of a waterline markers. Trace it around the hull. If there is drag do the same thing with the keel holder but make it even from the waterline. I hope this helps. David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

HMS Druid by Krug - FINISHED - 1:48 - Hahn

dgbot replied to kruginmi's topic in - Build logs for subjects built 1751 - 1800

Inquiring minds would like to know. As a TV detective once said "Very Interesting." I am now showing my age. David B. -

Steve, The garboard strake usually started out as the widest plank used. It was shaped to help the hull planking run smooth and keep the use of stealers down to a minimum. Donald Dressel wrote a book titled Planking Techniques for The Model Ship Builder. This book will give you a detailed explanation on the entire subject. I consider it a must in any library. It is still available at very reasonable prices. David B

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I read the instructions on the meds I am taking with my chemo therapy. One of them is a special order to the manufacturer by the doctor where they will confirm the exact dosage inform me then tell everything I cannot do by law. The side effects are fatal. The reason for the enforcement. This drug will cause either birth defects or kill the fetus. David B

-

I like the way you are double checking your work. You are progessing well. Your work shop would be a candy store. I would try going with a full strake for as long as possible to establish a good run as you go. Then add stealers. Have you thought about how you are going to do the garboard strake? David B

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.