-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

The only drawback to a metal sheer is it is not a perfect cut. It will get it close enough that you can snap it off. Then you clean up the edge. Of coarse I am talking about thicker material such as aluminum and steel. I have no experience with thin copper sheet. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

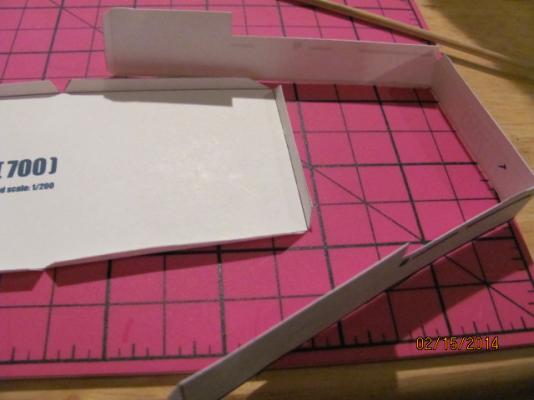

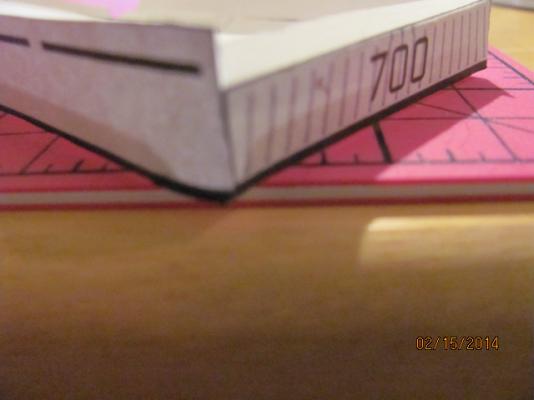

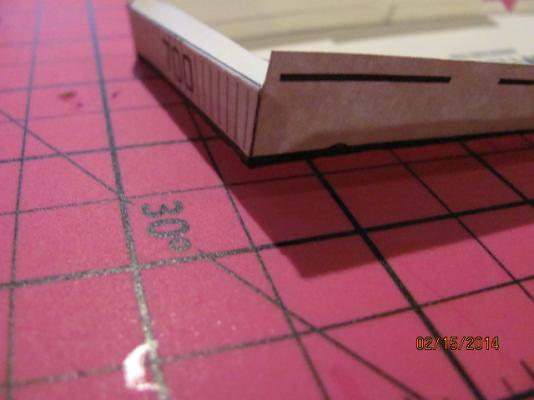

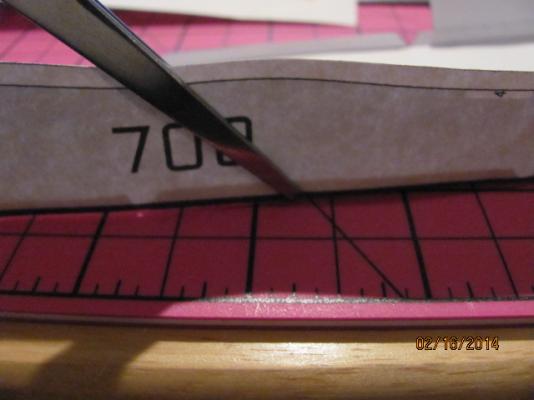

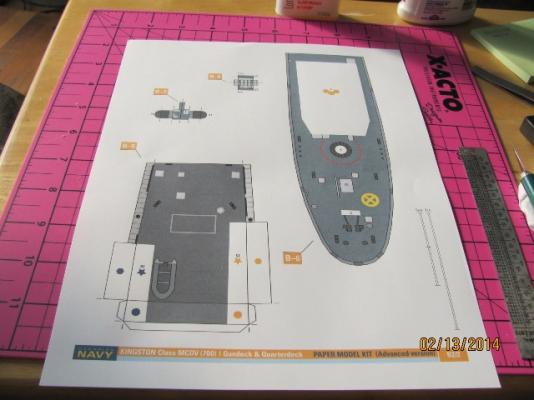

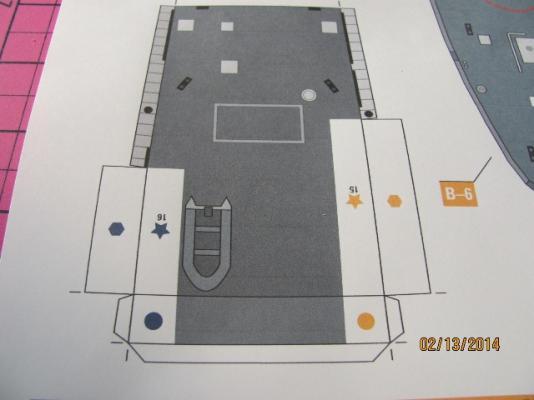

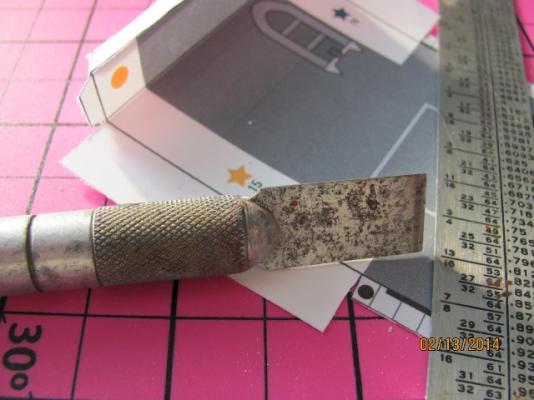

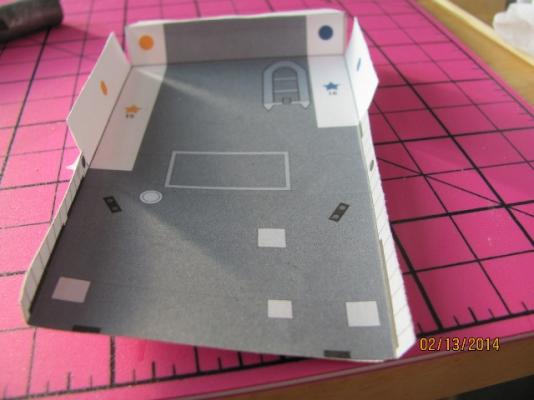

The paper I am now using is twice the thickness. I am sure some would say go thicker but I like the way it works. I will go thicker when I have to. The first thing was to run it through my HP 6000. I might be able to go thicker later. I started by putting together the hull. As I wrote before these two items made the job easier. I started in the same order as before and was able to correct the mistakes I made earlier This time I was able to make the stern area run even. So far everything came out nicely. I found that a couple of drops of Elmers glue applied with a bamboo skewere works well for apppling and spreading the glue. Also a set of twezers to hol those corners tight. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

US Brig Syren by knightyo

dgbot replied to knightyo's topic in - Build logs for subjects built 1801 - 1850

It is good to see this build again. David B -

My sister had a bundle of thicker stock lying around so I am beginning again. I will post photos as soon as I get going. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Nicely done you are doing a great job. Keep up the good work. David B

- 234 replies

-

Welcome back to the fold Slog I will be watching your build with interest. You must be getting eye strain with all that photo-etch. Will you airbrush them or leave as is, David B.

-

Before I bought my Preac table saw I would clamp my brass down to a piece of lamitated board and score it several times with a utilty knife. After I bought the Preac I would sandwich it between two thin pieces of would anc just cut it down using a slittlng blade. You can di the same thing if you have the Byrnes saw with a slittlne blade. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Looking good. Did you rub down your planks? David B

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Now to study up on different ways of planking so you can do another superb job. I would recomend Donald Dressels Planking the Built up Ship Model. David B

- 264 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

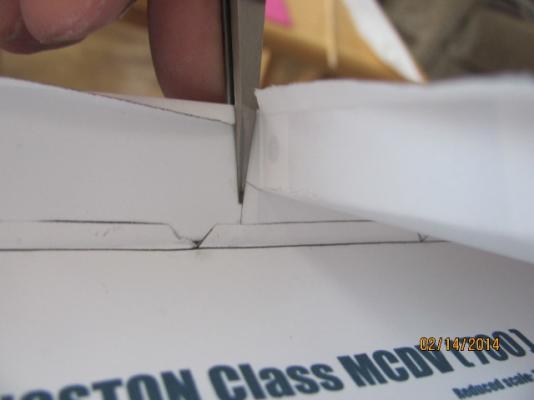

Out of sheer stubborness I decided to put on the last piece I cut out. Then I proceeded with the glue up. The difficult part of this was keeping the edges even. At this point I used a set of siccers to hold it together After I was done I was not happy with the end result. Since I now have an idea I am going to start over some some thicker stock. This card modelling is beginning to intrigue me. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

The Lobster Smack makes into a nice boat. What makes it really nice is that you can make a dozen of them from the same kit and each one can be different. You could start your own fleet. David B

- 60 replies

-

- muscongus bay lobster smack

- first build

-

(and 2 more)

Tagged with:

-

I you go to a jewelry supply store they have silver bearing solder flux that will blacken. I use Sante Fe Jewelry Supply http://www.sfjssantafe.com/ another good site is Contenti Jewelry Supply http://www.contenti.com/ I have used this material in the past and it works pretty good. Check out both websites I think you will like what you see. David B

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

dgbot replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Doris, your work is magnificent. There are a lot of modelers out there who are in awe of your craftmanship. That is a work of art and beauty worthy of a gallery or a museum. I would love to see that model at our contest in Manitowoc WI. It would take peoples choice modelers choice and best of show. David B- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Much of the wood that is used is run through a sheer while still green. They then stack it up and claamp it down until dry. Much of the wood strip are dried out with no structural integrity after a long time just sitting around in storage. I saw a video of this years ago at a club meeting. Ever since I have been leery of using it. I will either cut it myslef or go the the Hobby Mill. David B

- 206 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Druxey, I took your comment to heart and dragged out a digital caliper and measure the thicness. I should have gone upto 110 which is just under 1mm. However in order to get the paper I would have to get to the store. I will probably continue with what I have and make modifications. I am pretty sure as I can use this mistake to good use. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Thanks for the video. Nice and easy way to do the job. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

There are several book on hull contruction that talk about the use and style of coppering. Underhille. Monfeld,Gardner,etc. Most will give you a base from which to start from. One of the books I always liked was by Milton Roth titled Ship Modeling from Stem to Stern. An oldy but a goody. David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.