-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Greek Galiot by Robert V802 - Amati

dgbot replied to Robert V802's topic in - Kit subjects built Up to and including 1500 AD

Robert one of the rules in planking is the type or design of a hull. If you can get a copy of Monfeldt's book on ship modeling he can show you the different ways it was done depending on the area and time. Many of the mediterranean vessels were built without stealers. They were built with the hull planking first and the frame and supports were put in later. In Europe it was frame first then the planking was added. This is the reason for the straight run of planking. If my memory is correct your kit is single planked. I wish I could find the photos I took all those years ago to show what I am talking about. That is why I suggested going to look at the English Longboats. To further your research Google galleys and check out the results. The end result will be your choice and what you are happy and satisfied with. Satisfaction and enjoyment in your work is the greatest and most important rule of all. If you are having a good time that is all that counts. David B -

You took a C grade kit and turned it into an A grade model. Congrats on a great job. David B

- 85 replies

-

- yacht mary

- mamoli

-

(and 1 more)

Tagged with:

-

These sanding pads can be found at a good woodworking store or hardware store. I have seen them at our club meetings. I forget where Kurt got them. But he said they were the cats meow. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Great work Ed. Have you ever used those new sanding pads for the final polishing? This way you can stay away from the mess and clean up of steel wool. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I know little about these vessels. I think it will be fun seeing what it will look like. David B

- 20 replies

-

- finished

- bosphorus sandal

-

(and 2 more)

Tagged with:

-

casting metal parts including cannon

dgbot replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

If the finished master is made properly you will never know what it is made from by looking at the casting. David B -

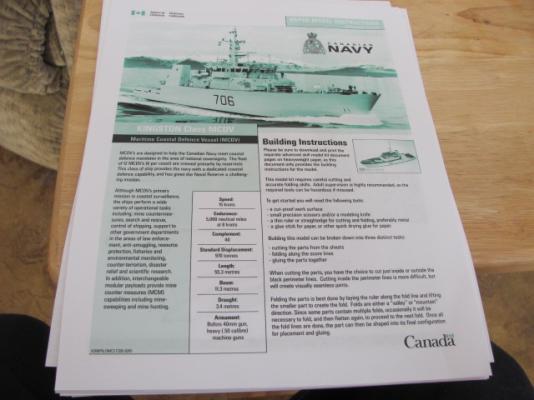

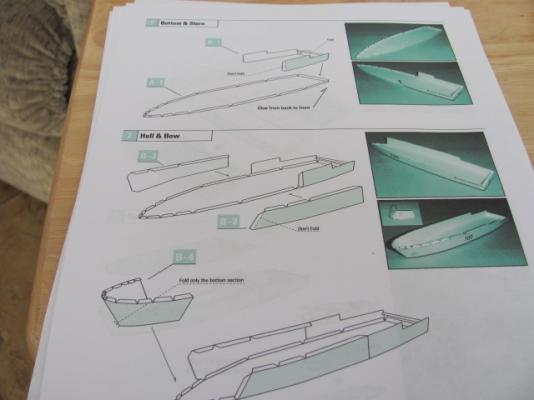

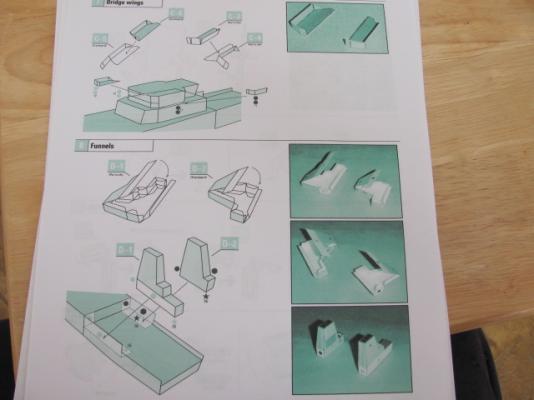

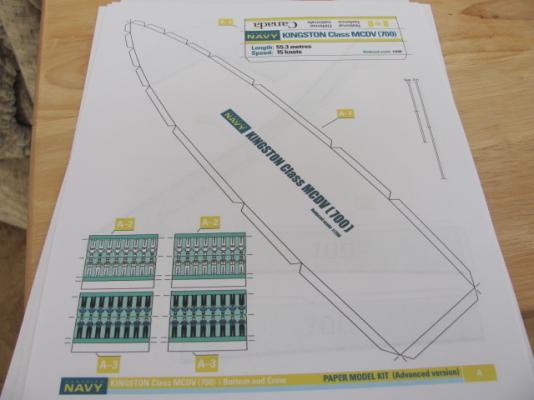

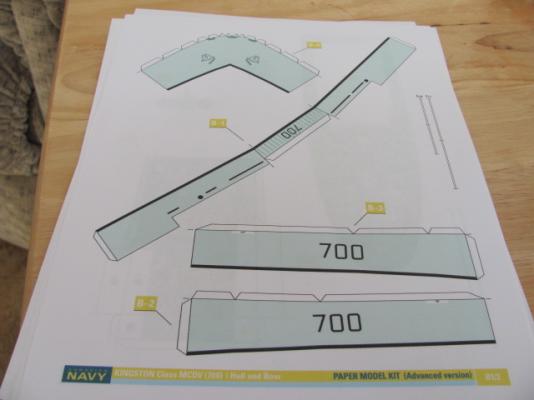

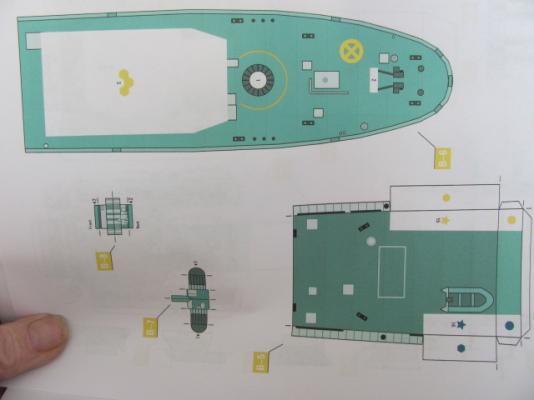

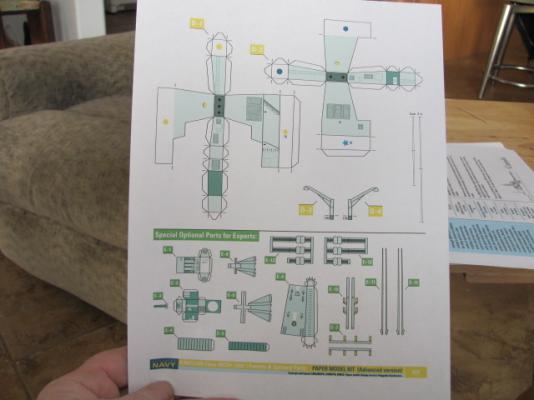

I found a card model I like. If I screw up I will be able to print out another sheet. Here are some photos. I will show the progress I make along with the booboos. David B

- 50 replies

-

- kingston class mcvd

- finished

-

(and 1 more)

Tagged with:

-

Greek Galiot by Robert V802 - Amati

dgbot replied to Robert V802's topic in - Kit subjects built Up to and including 1500 AD

This is one of the interesting parts. The planks are straight run for the top ones. What I did was literally make card templates for the rest. Since there are no stealers you will have to bend and shape every plank to fit. It will take some practice but if you like the end result you did it right. Check out the English Long Boat Logs and they will give you a good idea of what I am describing. David B. -

Looking good Dan. I wish I was there to see it up close. You are getting there. Keep up the good work. David B

- 175 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Greek Galiot by Robert V802 - Amati

dgbot replied to Robert V802's topic in - Kit subjects built Up to and including 1500 AD

There is an old saying in this hobby. The more you learn the more you do not know. David B -

Greek Galiot by Robert V802 - Amati

dgbot replied to Robert V802's topic in - Kit subjects built Up to and including 1500 AD

You picked a model that will give you some interesting moments. I built this model years ago when I still had a full head of hair. But I will be glad to give you any advise you need if my feeble memory can remember. David B -

One of the things you have to think about is lexan needs a plastic cleaner. Be careful of the type of cleaner you use. Do not use any product containing ammonia and use a cloth np paper towels. This will keep the case from clouding and getting scratched. David B.

- 152 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

What a great idea. Several years ago a modeler I know was out walking his dog and he saw his neighbor getting rid of a dinner table. His neighbor said it was getting to old and scratched and he was tired of it. My friend offered to take it off his hands. So they hauled over to his garage. He had a very large supply of aged cherry that he has been cutting down for several years now. That old furniture was made from solid wood no particle board or mdf. David B

-

casting metal parts including cannon

dgbot replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

I think that would make a great tuorial. You are a champ Joe. David B -

You are doing good Kevin. Keep up the good work. David B

- 55 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

looking you are double good amigo. I like the way you are double checking your work. When I was still working we had a rule in my dept. Triple check your dimensions before the you make the first cut. Saved me the hassel of getting yelled at by the boss. David B

- 264 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

casting metal parts including cannon

dgbot replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

If you cast with a resin you can ad extra ingredients to simulate metal. Resin casting can reproduce a stray fingerprint left on the master. It is a cheaper process and much safer. David B -

Nice work Toni, but it does look a little on the fragile side. You must have a delicate touch. I am afraid My ham fist would do to much damage. Great work. David B

- 1,449 replies

-

Airbrush vs Hand Brush

dgbot replied to Intasiabox's topic in Painting, finishing and weathering products and techniques

There are several individuals who either do not like using them to probably not having the room to. David B -

In my opinion you should do a stubbed mast model. All of the rigging would hide all the wonderful work you have put into the Vulture. David B

-

Congratulations on a great looking model. David B

- 152 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.