-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

I would like to know that as well. As for Solder-it I have tried using it with a torch and the part i was working on dissolved on me. I wonder what I was doing wrong, David B

-

Jessie, they add that little bit exra that people will notice. David B

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Microwaving the wood?

dgbot replied to a topic in Building, Framing, Planking and plating a ships hull and deck

I rarely went to the trouble. I would wet the strip and take a bending iron to it and once it dried I would repeat the process until I got what I needed. The iron I use is one I got from Amati. I hop my sister brought with her since it was stashed in one of my parts drawers. David B -

A book that would help you tremendously would be Rigging in the Age of the spritsail topmast by R.C. Anderson. I found it a good reference for the time period you are working in. It can be bought from Amazon in the Kindle edition at a good price. David B

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Bevel 2nd planking

dgbot replied to Tompslattery's topic in Building, Framing, Planking and plating a ships hull and deck

Then I doubt it beveling would be used to get a tight close fit between planking because of the hull shape. But when the planking is .5mm it is not really needed because they will sit tight with no thickness. David B -

Bevel 2nd planking

dgbot replied to Tompslattery's topic in Building, Framing, Planking and plating a ships hull and deck

If the planks from the kit stripped veneer do not bother but anything over that my answer would be yes David B -

you are going to need filters an aircompressor a recirculating pmp extra. We had one where I worked and it was in constant use. Depending on the abrasives you added to the mix we cut everything from rubber and belting to 5/8 dieboard maple, 3 inch shock pad and 1/4 steel plate. You will need something to keep the pump cool because it would get hot. Unless you are going into production. David B.

-

At that size I would go with a plug. Easier on my nerves. Unless you are a glutton for punishment and into sadomaschism and go for building up the frames and plankng it. In reality most boats were built on a plug. And the frames were bent to the plug and planked or planked over with the frames added. David B

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

By cutting the sail in half you will be able to furl it to scale and it will look better and neater. David B

-

- 339 replies

-

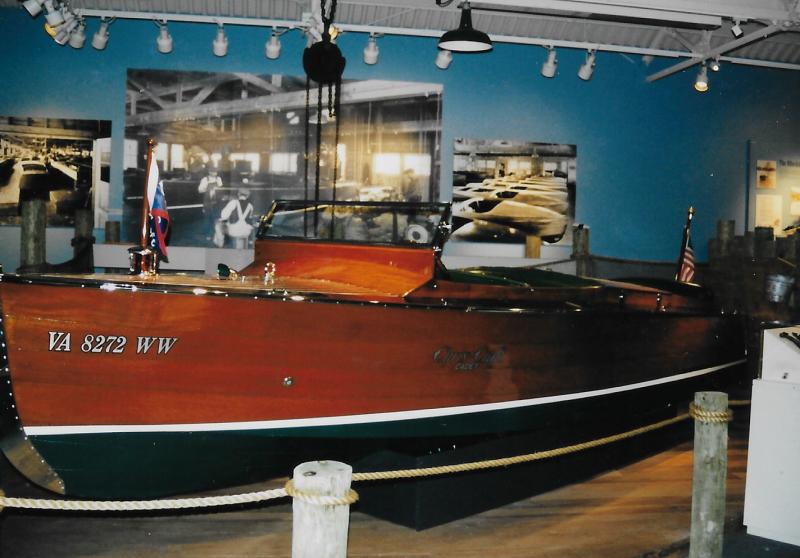

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

I do no know if there is a supplier available. ut what you can do is do a build up of th window starting out with stripsof wood that are 1/16 or 1/32 thick. I am not sure of your dimensions. make a copy of the window and glue it to a surface that will fit the contour of the stern and shape the strips to the plan. when you have the shape cut and position it and start over again. until the plan s covered. If you check out some of the other logs they will have some photos to show what I am trying to explain. David B

-

I have a problem with passwords so I have a list on my laptop and in my phone. Since my phone is my lifeline with the Drs and my sister I never go anywhere without it. It gets embarrasing when you try to log into your hospital account or bank account and cannot remember your password. Some of them are so old i doubt if I can remember my secret questions and answers David B

-

You are doing a fantastic job. It looks like you are going to really show your skills on later models. What do you have in mind for your next project ? David B

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

I am not sure if this is the spot for this but I think this information would be helpful for those members who like the yachts of old that had character and find lines. http://www.classicboat.co.uk/news/complete-lloyds-register-memory-stick/ David B

-

My nephew in Council Bluffs is an IT guy and uses either Linux or a mac. He will not use MS unless he has to. He told me that he was rebuilding a clients PC and the clients wanted something called a dual boot. XP and Linux. My nephew told him that XP will not be supported anymore and is a dead OS. His client said that for the work they are using it for it is perfect. And they will not be going on line with it. He told me that MS has been playing fast and lose with their updates and want everyone to adopt w10. But I have been happy with what I have so I will not waste the money. Kudos Julie for being able to do something I fear to try. David B

-

sharpening stones which are best for the price

dgbot replied to John Allen's topic in Modeling tools and Workshop Equipment

I can remember one of our club members giving a demonstration using a Japanese water stones that by utilizing the water you develop a slurry using the dust and filings from the blade and from the stone this helps to really put heads on the blade once you finished you would take the stone to a strap and with the green Rouge buffing compound the end result was a chisel that you could shave with. I on the other hand am a firm user of a good oil Stone which has given me good use. I picked up some of the Diamond Stones that was shown earlier I didn't take my blades to a leather strap that's been charged with the green roof the end result is something I can work with As for sharpening exacto knives I've done it with my card models and it doesn't not really work very well. David B -

Terry, Since this model will be taking a dip what are you going to use for ballast and a false keel> That model might be a litle topheavy. David B

- 97 replies

-

- macedonian

- frigate

-

(and 2 more)

Tagged with:

-

That is a wonderful model. You really out did yourself. To bad you cannot bring it to WI. I know many who would be drooling over it and the judges would probably fall in love with it. You even might be going back empty handed. David B

- 225 replies

-

- chaperon

- model shipways

-

(and 1 more)

Tagged with:

-

Awe inspiring Nils. David B

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Another thing you could do is try Bluejacket their blocks might do the trick as well

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.