-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Drill Bit Sizes Appropriate for Ship Modeling?

dgbot replied to Mike40's topic in Modeling tools and Workshop Equipment

Pin drills is what I have almost always used. #1-#80as for their sizes in inch I had a chart that was lost during my move. II made up the chart by measuring each bit with a digital caliper. This can also convert to metric as well. David B -

Looking good Elijah. Have you thought about replacing the ships wheel? Most of the time I have found that the kit supplied ones leave much to be desired. This would be a good challenge for you and a learning experience. There are a few members of the club who can help you tremendously. David B

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Nicely done Bob. Too bad I could not pick your brains about it. David B

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Expectation of wood perfection

dgbot replied to a topic in Building, Framing, Planking and plating a ships hull and deck

You have masterly shown what I have always said about BOP Models. Better than I ever could. David B -

I have used artist color pencils with good results and have used grumbacher paints in a tube. Experiment on some scrap until you get used to the amount you need. David B

- 27 replies

-

- san salvador

- maritime museum

-

(and 1 more)

Tagged with:

-

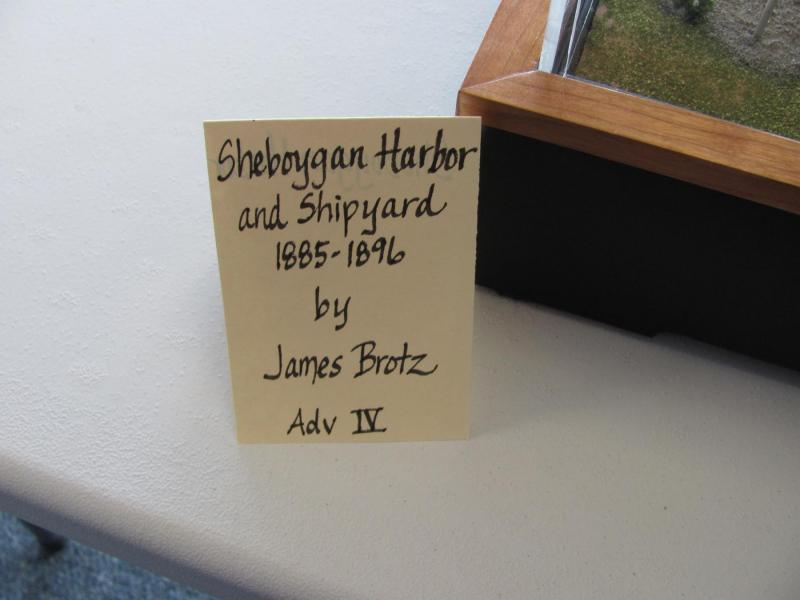

Your started a great topic Tad it gives one that actual effect of what an old shipyard was like and the manpower it took. Here is a diorama by Jim Brotz of and early shipyard in Michigan at the turn of the 20thc. I really drooled over it. He put it together from old photos and newspapers and registers. David B

-

Greg yourmodel has terrified me. I was looking to try that model but your skill just scares me to much. Marveous work. I would love to see that model at manitowoc for their show and entered in the NRG's photo contest. Chuck would be able to give you more details. David B

- 342 replies

-

- dreadnought

- zvezda

-

(and 2 more)

Tagged with:

-

They do come in handy. I remember using one when I planked Carrack for a cousin years ago. Saved me a lot of grief down the road and my cousin was thrilled. Question for you. Why didn't you plank the bow? David B

-

Sounds like a good teaching project. Is it okay for me to pull up a chair and take notes? David B

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

-

I have a question Jerry. I do not see a weighted keel so I am wondering how She will stay upright without tipping over in a light breeze. David B

- 553 replies

-

- sloop of war

- constellation

-

(and 3 more)

Tagged with:

-

How did you do your carving Mark? Marvelous workmanship. David B

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Can i live without a BYRNES TABLE SAW

dgbot replied to shihawk's topic in Modeling tools and Workshop Equipment

I am sorry to say that I do not have the PPT. But If it can be found I will try to put it up with the approval of Bob F. The way I did the jog was to clamp the blade into a vice and proceed to mark every other tooth. Then I took my Fordham and a sanding disk and put a bevel on every marked tooth. Then did the same thing on the unmarked teeth with a bevel going in the opposite angle. I do this wearing protective eyegear that is important. Sanding disc or cuttoff wheel depends on the tooth size. Once done I was able to go through 1/8 " walnut with no problems. The Preac was my go to saw at my work table instead of a razor saw. David B -

What can I say Toni but how I would love to be a fly in your workshop. I cherish the photos I was able to get and always look at them. Marvelous workmanship. The next time you are able to get to a meeting I hope Kurt can set up something so I can drool over your work. David B

- 1,449 replies

-

Can i live without a BYRNES TABLE SAW

dgbot replied to shihawk's topic in Modeling tools and Workshop Equipment

That was done by Bob Filipowski from the Midwest Modelshipwrights. I have had the pleasure of seeing his demo and talks on the subject. And I have sharpened the blades for my Preac with his method. David B -

HMS Naiad 1797 by albert - FINISHED - 1/48

dgbot replied to albert's topic in - Build logs for subjects built 1751 - 1800

I am looking at wod heaven gorgeous. David B -

I am wishing you all the best. I know about chemo and the problems it can cause. My problem is that my body rejected the medication so they had to start another medication. The dr. showed me my marker count and I almost fainted. May god keep you in his good graces. David B

- 268 replies

-

Julie, At a Shipwright meeting on of the members showed how he made life boats and other small craft using the method you were using. Once the fixture was made he would use candle wax and melt it over the form. Then he would use basswood or apple for the frames. After wetting the wood he would wrap it plastic wrap and nuke it. After that he would bend it to the bulkheads and use a small pin to hold them down. David B

-

Congrats on a nice job Elijah. Patience is everything and a little at a time will usually do the trick. Your railings came out looking great. David B

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

We had a couple at work for repairing dies. But I think it is overkill. sanding blocks and using dowels and just take your tie. You will be happy with the end result. Patience is a virtue in this hobby. David B

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.