-

Posts

1,285 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by reklein

-

I'm pretty sure that "carton" is the German word for card or cardboard . The a cartonis is one who builds from card. The best wine to drink while building is "Cardboardeau" Cheers.

-

I think you have your scarf joints bolted wrong. They should be pinned top to bottom and therefore not visible. Google scarf joints for ships.

- 2,697 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

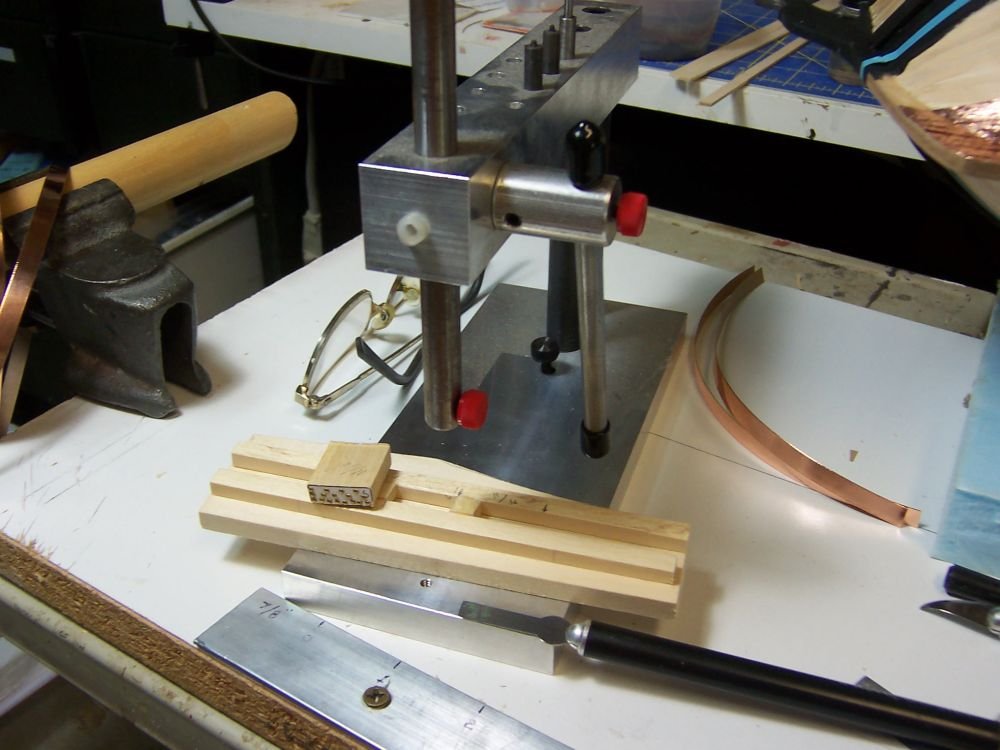

Dremel Drill pess adapter

reklein replied to Derek C's topic in Modeling tools and Workshop Equipment

He bought a dremel and is now looking for accessories. He did not buy the drill press adapter. -

Dremel Drill pess adapter

reklein replied to Derek C's topic in Modeling tools and Workshop Equipment

I have one and its pretty handy for holding the dremel sideways to use as a more precise cutoff tool with the carbide wheels. Its a little floppy though for precise milling or the like' . For drilling plastic I like the Ryobi electricians screwdriver with a special chuck for drilling plastic. It has lots of torque and turns slow enough not to melt the plastic. IThe Dremel turns too fast for that and doesn't have low speed torque. -

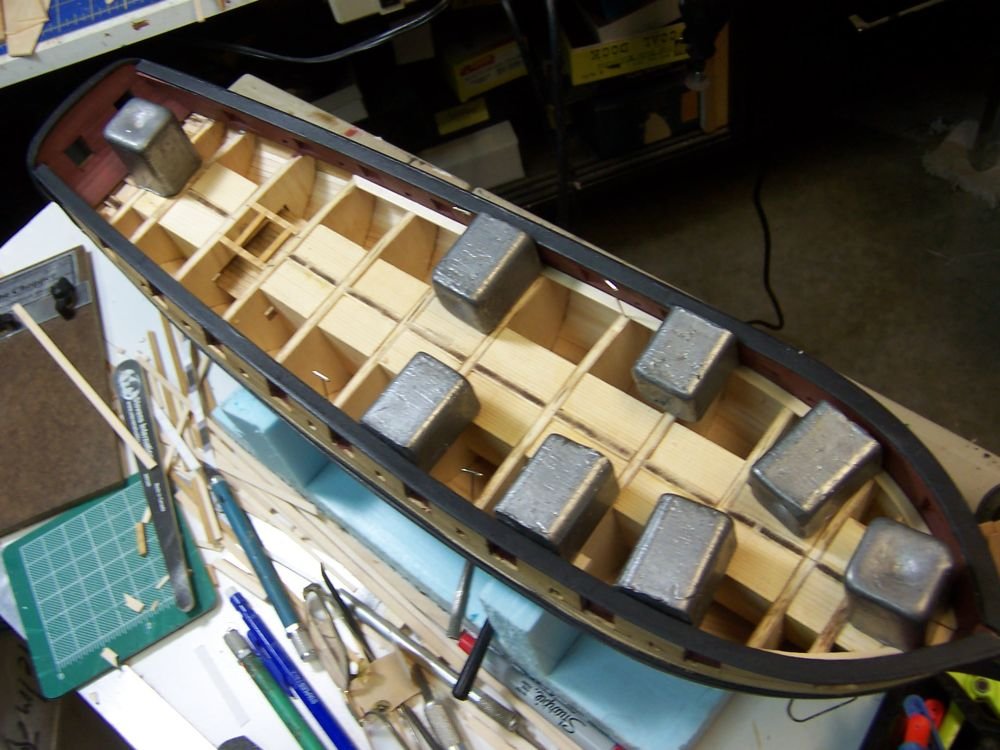

I stained all my planks before I applied them to the hull' I used min-wax golden oak. I used pencil to simulate caulking. No running, more subtle caulking. I applied the stain with a piece of old cotton T shirt. I like to lay wet stained planks out on triangular blocks to dry. The sharp edges leave little or o marks. I forgot to say I sanded them with 220 before staining.

-

Deck Planking

reklein replied to michbyerley's topic in Planking Techniques's Click Here for Topics dedicated to planking!!!!

If you only blacken one edge remember to fasten the planks correctly so you don't have two black edges together. -

Need a tip on staining or coloring the running rigging

reklein replied to Tallsails2's topic in Masting, rigging and sails

Rit dye is not color fast. I was gonna say tea stain,but now I don't know about the acid stain. How about very dilute sepia india ink. Dilute with alcohol and water. -

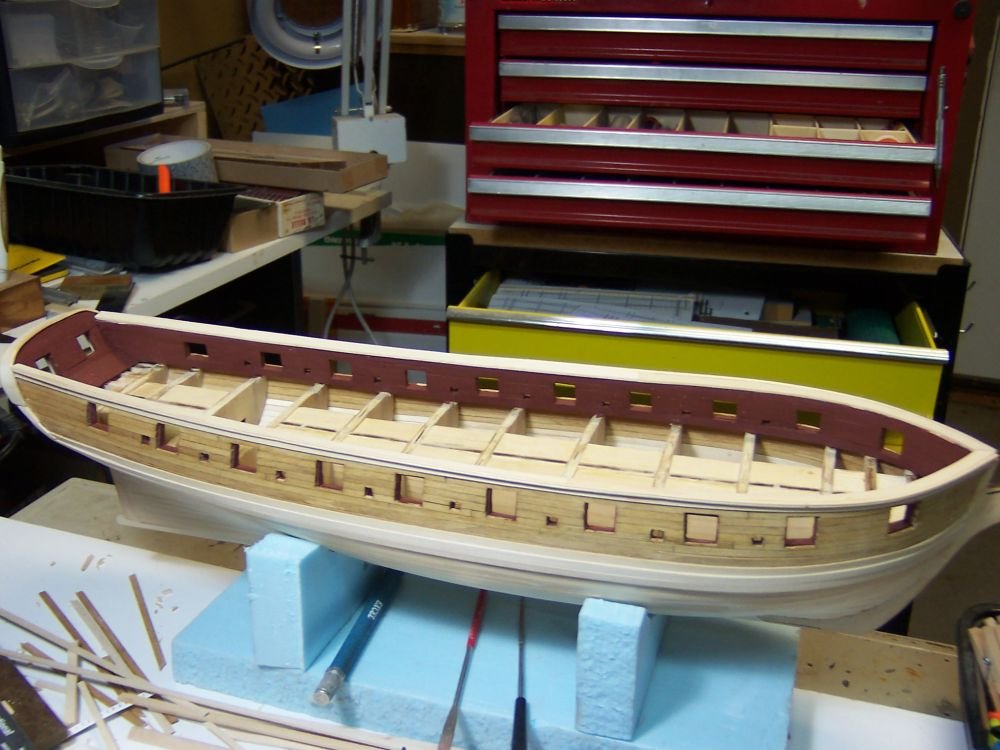

Probably would be best to test out a section off the model. I use oil base sealer and acrylic paint. Its an old trick for getting a good clean line on waterlines, model airplanes and trains. you can apply masking tape, then seal with the clear and then paint with your color. When you remove the tape there is no leakage or running under the tape. I don't think you'll get a color change but I know you'll get running in unsealed end grain.

- 99 replies

-

- essex

- cross-section

-

(and 1 more)

Tagged with:

-

Doug,If you go with painting the ends black . You can prevent any bleeding by first using a coat of clear sanding sealer. It will prevent any black from running down the grain.

- 99 replies

-

- essex

- cross-section

-

(and 1 more)

Tagged with:

-

Seems to me with a 3D rendition of that quality it would be a fairly easy step to 3D printing of such a model. That's a terrific rendition , it took a couple of looks before I realized it was just electrons on a page. I was also struck by the shape of the hull. How it looks like a balloon with too much water in it.;)

-

Planking a solid hull

reklein replied to Srodbro's topic in Building, Framing, Planking and plating a ships hull and deck

Blue Jacket ship models make very good use of the carved solid hull ,with planking on top. There Constitution model comes to mind first. -

Greg, for drilling plastic try using one of these Ryobi electricians drills. They turn slowly but still have enough torque to drive a sheetrock screw.

-

Nice work Steve. You're gonna love building and flying that cub. Friends of mine built it years ago and it was really fun to watch flying around low and slow. PS get the set of floats for it,even better.

- 291 replies

-

- bounty

- billing boats

-

(and 1 more)

Tagged with:

-

Theres probably only 3 people on the planet that know what was actually there back in 1805, but, I saw one photo in my copy of the aots book showing a wooden bar across the davits as a spreader. Also the paragraph on the quarter davits describes them as probably straight rather than curved because it was easier to find materials on board to replace them when damaged. I just wish I could model this as well as Ken is doing and unless somebody hadn't asked the question I would never have known the difference. Good work Ken.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.