-

Posts

2,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hubac's Historian

-

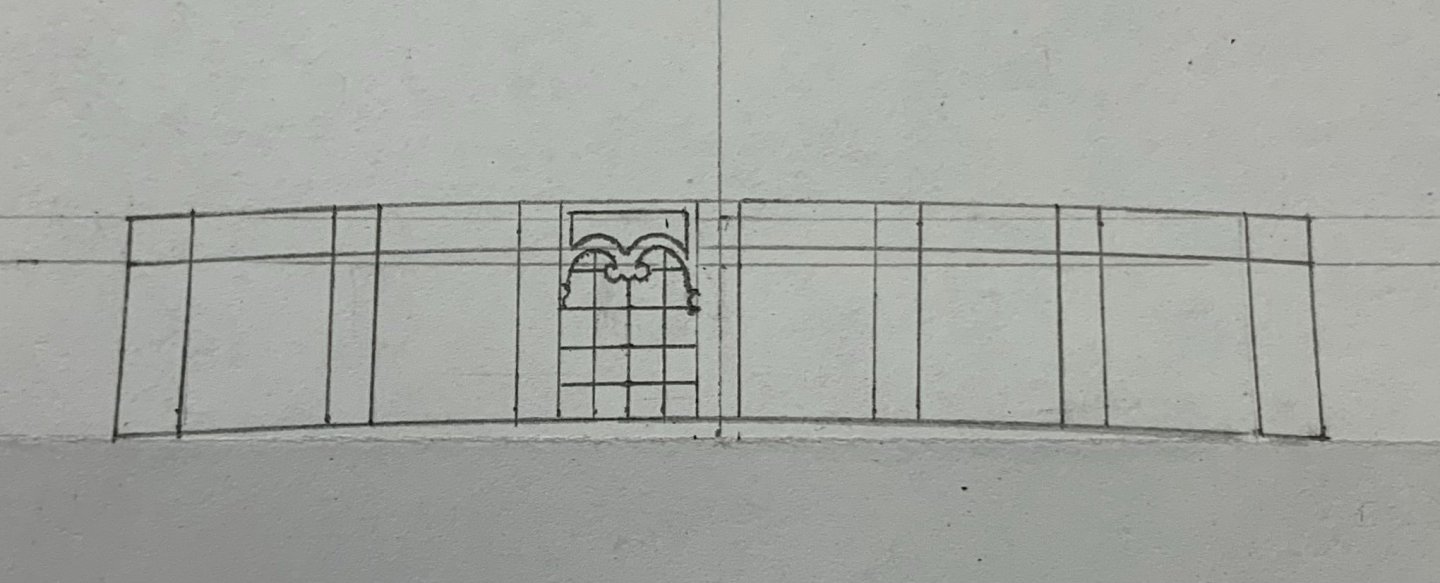

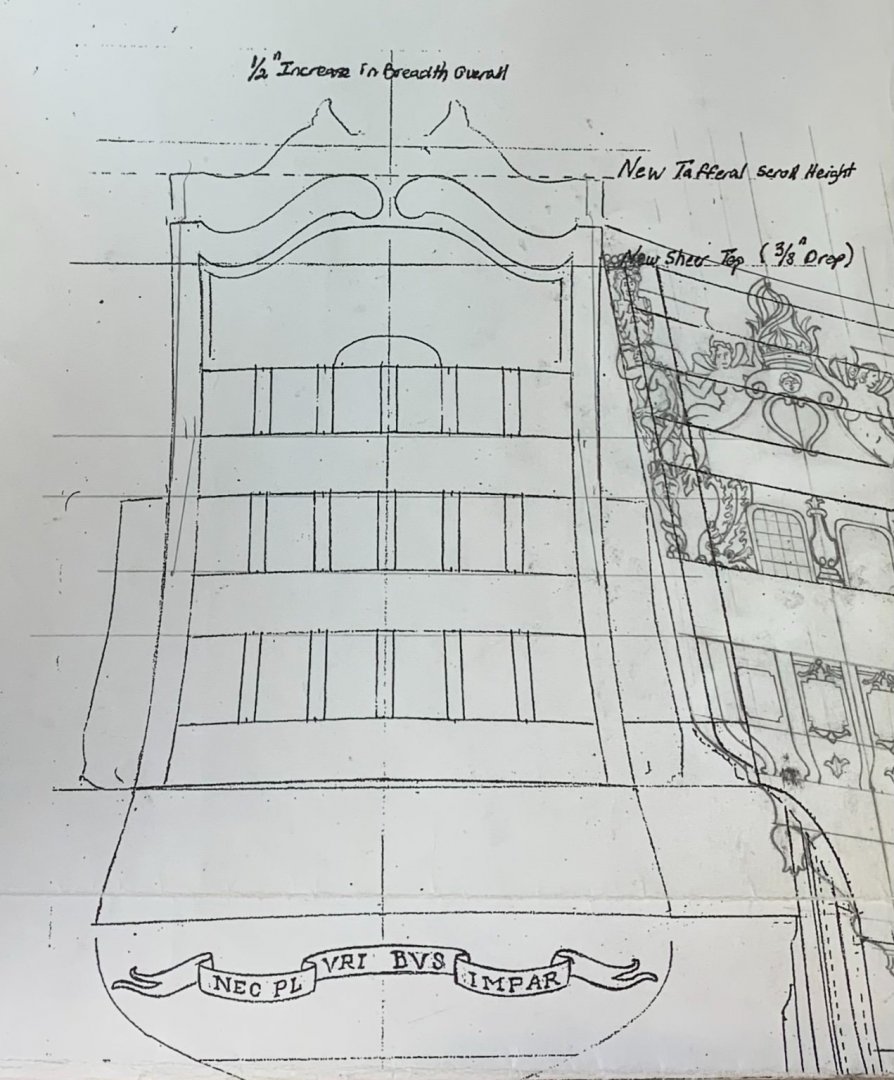

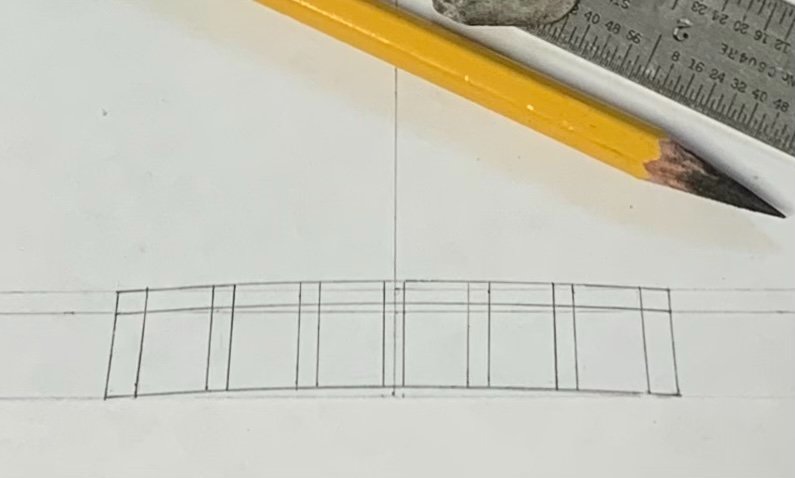

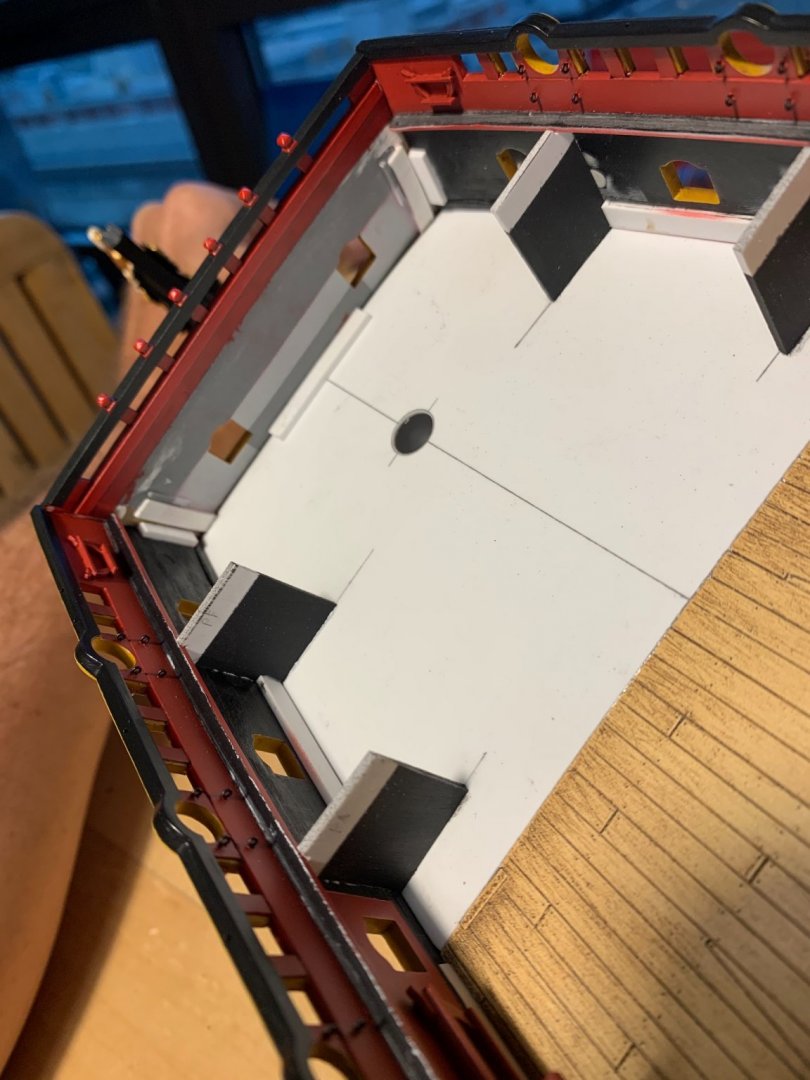

The particular challenge of erecting the aft bulwark pieces is that I don’t have the stock stern plate, in place, to guide their placement. It is helpful that the forward bulwarks are in place, as they provide an anchor point, but they do nothing to help establish the slope of tumblehome that should be present. The first step was to spend as much time as necessary fettling the lap joint to ensure that the part seated snuggly, along the upper main wale. With that much established, I could secure additional glue tabs to the inside face of the bulwark, just as I had done with the forward bulwarks. It was also necessary to fir-out, behind the upper main wale, so that these glue tabs had a firm landing spot. Whereas with the forward bulwarks, I glued the bulwarks in-place, and then secured the gusset pieces, afterwards - the process reverses for the aft bulwarks because it is the gussets that establish the slope of tumblehome by providing a positive stop to clamp against. At the very beginning of this project, I drew the transom by simply tracing the outer profile of the bulwark ends to the increased breadth of the transom; the additional 1/2” would enable me to add the missing 6th window at all three levels. This was my initial drawing: As a side note, it is funny to look back at my first attempt to draw the quarter galleries; the results were poorly scaled and relatively crude, as I was attempting to include all five false windows along the lower tier if the QG. Anyway, at the time that I made this drawing, it was pointed out to me that the top of the bulwarks appear to flare outboard, again, at the very top. Back then, I was not too concerned about this. At this stage, though, I can see that the finished bulwark piece does not look right at all, if I allow it to flare out at the top; the whole upper structure of the ship changes in a way that is neither pleasing, nor reflective of actual practice. The only thing to do, here, was to shape my gussets in a way that would pull these bulwarks in more, thus providing a nicely sloping tumblehome. Frankly, this is more art than science. I simply manipulated the bulwark, inboard towards the centerline, until I had a pleasing profile. I then took a measurement from the bulwark rabbet to the centerline, along the bottom edge of this window tier: 1 1/2” to center, and 3” overall. This seemed like it would be adequate. So, I clamped and taped the bulwark in this attitude, so that I could make card gusset templates. I then made the gussets with all necessary beveling, and added a prop leg to make them a little stiffer for the eventual glue-up of the bulwark piece: I went to bed feeing really good about this. The part would have some minor tension, but I had increased glue surface area significantly enough to cancel out those forces. In fact, there will be a third, aft-most gusset fitted after the glue-up. Then, I woke up the next day and remembered my original layout drawing. I took some measurements and found that I had effectively reduced the available space for this top tier of six windows by 1/4”. In fact, my new stern, at this top-most level, won’t be much broader than the stock kit stern-plate, which only has five windows. I began to feel a bit of panic creeping in. Before glueing-in the bulwark piece, I thought it might be prudent to take some really good measurements, and do a little drafting to see what a revised window layout might look like. One quarter inch doesn’t sound like much, but it is quite significant across this short span. If I found that the reduced breadth resulted in a cramped window layout, I would be forced to buy back at least an 1/8”, in breadth, thus compromising my ideal tumblehome. This would require very fiddly firring of the gusset pieces I had just glued-in, so my fingers were crossed tight. Here is the new layout that I arrived at this morning: And here, I’ve detailed one pane to get a better sense of the proportions.: The original by Berain: Mine isn’t the best drawing, but it’s good enough to get a sense of proportion. I’ll do a much better vellum drawing, when the time comes for it. I found that I only had to reduce each window pane by 1/32”, and each pilaster by a heavy 1/64” to get back the heavy 1/4” I had lost. And so, I will go ahead and glue-in the upper bulwark, in the next few days. I’ve been busily filling the skid joins, touching up the bulwarks, and establishing the location of the mizzen chanels. A whole lot still has to happen in the next two weeks, but I am confident that I will be on-track for the show. Thank you for stopping by!

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Just venturing a guess, here: because the gap is so consistent, I am wondering whether your problem resides at the very ends - the vertical timbers; perhaps the whole assembly is just fractionally over-long. I also may not be understanding whether you have glued-in the keelson, in which case, you are really looking for in-fill advice.

-

As for deck furniture, Bill, I’ll make a forward capstan for the forecastle deck, deck railings at each upper deck break, numerous cleats for tying off, ladder access to the poop and poop royal decks, and spare topmasts and main yards for the waist. I am glad that the color scheme is pleasing to you. Thank you for the links, Chapman; those are the clearest images I have seen of these DR drawings. The quarter view is particularly instructive for the stern architecture of an early First Marine vessel. ‘Much appreciated!

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Hi Bill - thank you! See above, from an earlier post, where I discuss the rationale behind the paint scheme.

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Kevin, if you ever plan to Visit New York - let me know, and we will mKe it happen. I am very accessible by train.

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Thank you all for the likes and kind comments! Rob - honestly, I think I’m only scratching the surface of what the reality of the ship may have been. I am sure she was a spectacle in every way. In fact, I suspect there was a significantly broader color palate, in use, but I feel that I would really only be guessing, beyond what I’ve laid out so far.

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Hey Dan, These were photo-etch pieces. I’ll show you what I mean at our ZOOM meeting on Tuesday. Leading into Labor Day Weekend, I realized that I would need to cram-in a ton of hours, if I had any hope of getting where I wanted before the Joint Clubs meeting. And so, my wife and kids went off to CT to stay poolside, with family, and I got to work. The primary objective of the weekend was to erect the forward bulwarks. I gave the lapping joint of each bulwark piece a third going-over to ensure absolutely the best fit possible. Unfortunately, it cannot be avoided that the part will always be under tension, as it must bend significantly to conform to the run of the hull. Anticipating this, I had affixed a styrene tab at the point where tension is greatest. My glue plan was to cement a welded bond along the rabbet with liquid styrene cement, but also to apply CA to the additional tab for a contact bond that would assist the tweezer spring-clamps that I bought for this purpose. Where the bulwark joins the beakhead bulkhead, I similarly used styrene cement below the forecastle deck ledge, and a spot of CA above the ledge. There was simply no good way to clamp this corner, owing to its extreme tumblehome, so I used a tape clamp to assist during drying. First, I put some blue tape down to protect the deck from any errant glue drops: I also applied two layers of blue tape to the clamp jaws, as these particular spring clamps apply a really strong bite onto the material; I was hoping not to mar my paint. For better leverage with the smaller clamps, I made up small styrene clamping cauls that hooked beneath the wales to which they were taped in-place. As with any significant glue-up, a dry-run really helps steer you away from potential pit-falls; before making the cauls, I found that the small clamps only had a tenuous grip on what is really a very shallow lap-joint. With only a few small gaps that touch-up paint will fill, I ended up with really tight-fitting joints and enough small squeeze-out to convince me that there is a strong welded bond along the part’s entire length: The relative mass of the model is becoming apparent now: I will say that while the skid segments lined up near perfectly, I will still have to fill a few gaps, here and there, with sanded shims of styrene strip. This is not a big deal, and I prefer to use plastic, rather than putty, wherever possible. Also, the squeeze-out is not a major chore to clean away. I have a purpose-ground #11 blade that works like a semi-sharp glue chisel to scrape away the excess. Now that the bulwarks were up, I could install the gusset pieces that serve a dual purpose: they re-enforce the lap-joint by increasing glue surface area between the deck and the bulwarks. Also, they will eventually serve as mounting points for my deck beams. After scribing-in and glueing, the bulwarks became notably stiffer: Unlike the lower decks, this time I thought to black-out these gusset pieces, as more light will penetrate below these upper decks. Next, I wanted to final fit the open sheaves I made for the top corners of the beakhead bulkhead rail. I also wanted to make knees for these corners. While the sheaves are a contrivance, on my part, to cover for the height discrepancy between the bulwark top rails, these knees were an actual feature of real practice. Just as they do on a real ship, the knees I made increase surface area and do quite a lot to strengthen the area. Frankly, I just don’t trust CA to do the hevy lifting of holding these corners together, over time: Although it is not readily apparent in the picture above, I simulated the bolt heads that hold these knees in place. Also, above, I am holding in-place the forward beam ledge for the forecastle deck. So, finally, I’m approaching the finish-line for painting of the aft port bulwark piece. There is still some gold work to do on the siren figures, as well as the quarter piece, but now the full color scheme comes into clear focus: My objective with the paintwork, because I have chosen such a vivid scheme, is to identify areas where I can replicate the same colors and techniques, in order to create a sense of continuity. All throughout the ship, anything with a fishtail gets painted first with a grey enamel under-wash, and then top-coated with the ver-de-gris wash. I also really liked the use of silver metallic beneath a more natural green wash, that I used for the female Four Seasons figures, on the stern. The siren on the aft end of the amortisement received this particular treatment for her dress, and the wash-coat really highlights the sculpted folds of the dress very nicely. For the face and neck of the quarter piece, I decided to use the same enamel grey wash and wipe-away technique that I applied to the horse-head of the figurehead. It’s subtle, but it really brings out the small facial features of these sculptures. The four Continental figures will also receive this treatment. I think it lends these statues a sense of aged neo-classicism. So, soon I will make and fit the gusset pieces for the aft bulwark piece, and hopefully get the whole assembly glued-up and touched-up in time for the show. Thank you all for the likes, comments and for looking in!

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Consider me a "like" for every post! I really appreciate your methodical approach and precise workmanship. I will follow with great interest.

-

Super crispy! This is the standard of work that I would like to read more about in the Nautical Research Journal.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Fair enough. Pictures often don’t do justice, so I will definitely give you the benefit of the doubt.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

The model is first-rate, but that plastic base is lacking, IMHO. The manufacturer should consider upgrading this, even just a little.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Not having built the kit myself, yet, it’s a little difficult to say with certainty, but I believe the lower extension of these round houses is deliberate, so that the waste pipes have a means of ejecting through the headrails.

-

Chuck, this is all as good, or better than the original.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I’m not sure how this one escaped my attention, but this model is truly extraordinary. What a beautiful piece of work!

-

Thank you very much, Dan! Yes, I’m really looking forward to New London. While I have you on the line, so to speak, what company produced the PE gun tackles you gave me a while back? And yes - to the stars and beyond, hopefully!

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

I managed to get the red sprayed before leaving for the Cape. We had a wonderful week in Hampton Bays with lot’s of family fun, good dinners, and plenty of medicinal scotch. I also managed to have a productive week laying down all of the primary colors: Unfortunately, in my haste, I forgot to mask off the monogramed escutcheons between the main deck guns. The centers, which will be painted ultra-marine really require a white undercoat for the color to come out right. This now necessitated hand-priming of these little ovals. I deliberated, from the start of this whole project, whether the red should extend up into the amortisement. Ultimately, I decided that it made more sense to follow a continuous, banded approach to each of the three primary colors, with the yellow ocher serving as a unifier. The impression of the amortisement is a bit skewed, at the moment, because I have yet to pick out the supporting dolphins in gold and silver. I took great care to hand-paint subtle edge borders, in yellow ocher, around the triangular panels of the upper section. From here, it is the long, steady march of careful cutting-in, followed by rounds of re-touching: Perhaps, above, it is more apparent how my idea to use ultra-marine along the lower band of fleurs, accentuates the scalloped design of the frieze. This is probably more ultra-marine than would have actually been applied, owing to the expense, nonetheless it is an artistic choice that highlights the effort of making the whole thing. Slowly and surely, we are getting there! As ever, thank you for looking in.

- 2,444 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

The beauty of our hobby is that it rewards us for our resourcefulness - for simply finding a way that works for us, individually. The beauty of your ship is that it is remarkably beautiful, and a testament to your skill and craftsmanship. It can be difficult to filter out the “noise,” but try not to pay any mind to blowhards like that. Your presence, here, has been missed very much YankeeD. Welcome back!

-

I can believe it, yes! I remember buying my first pair of titanium eyeglass frames, which were wonderful in every way, but EXPENSIVE for the times. At least I got about six years out of that pair. I would certainly agree that that experience has been beneficial for you. Disciplined best practices, taught from the outset, instill a rigorous approach. My woodworking apprenticeship was administered by a man who insisted I mill material to the nearest thousandth of an inch, as I did the final planing on a KUNDIG sanding machine. His point was not that those tolerances were critical to the work we were doing, but that paying attention to the process was. David was forever reminding me to think things through, in order to avoid “negative pre-determinants.”

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.